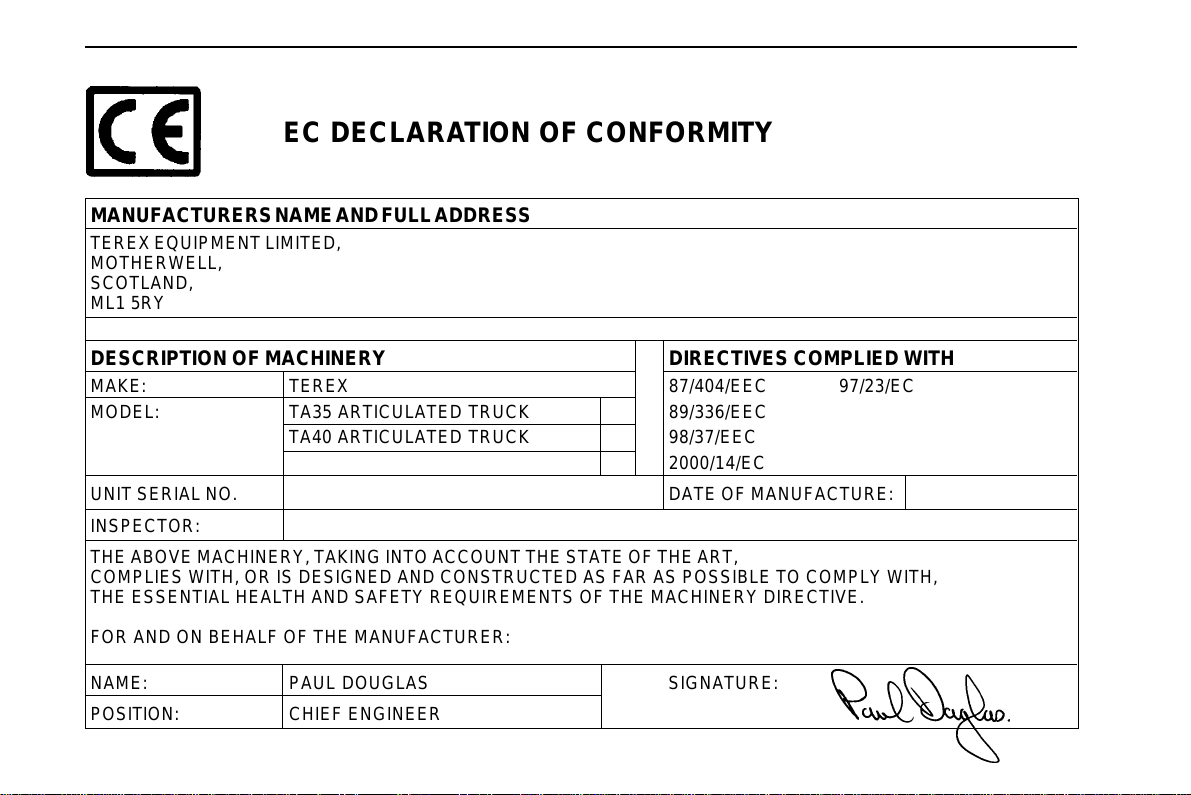

MANUFACTURERSNAMEANDFULLADDRESS

TEREXEQUIPMENT LIMITED,

MOTHERWELL,

SCOTLAND,

ML1 5RY

DESCRIPTION OF MACHINERY DIRECTIVES COMPLIED WITH

MAKE: TEREX 87/404/EEC 97/23/EC

MODEL: TA35 ARTICULATED TRUCK 89/336/EEC

TA40 ARTICULATED TRUCK 98/37/EEC

2000/14/EC

UNIT SERIAL NO. DATE OF MANUFACTURE:

INSPECTOR:

THE ABOVE MACHINERY, TAKING INTO ACCOUNT THE STATE OF THE ART,

COMPLIES WITH, OR IS DESIGNED AND CONSTRUCTED AS FAR AS POSSIBLE TO COMPLY WITH,

THE ESSENTIAL HEALTH AND SAFETY REQUIREMENTS OF THE MACHINERY DIRECTIVE.

FOR AND ON BEHALF OF THE MANUFACTURER:

NAME: PAUL DOUGLAS SIGNATURE:

POSITION: CHIEF ENGINEER

EC DECLARATION OF CONFORMITY

Courtesy of Machine.Market