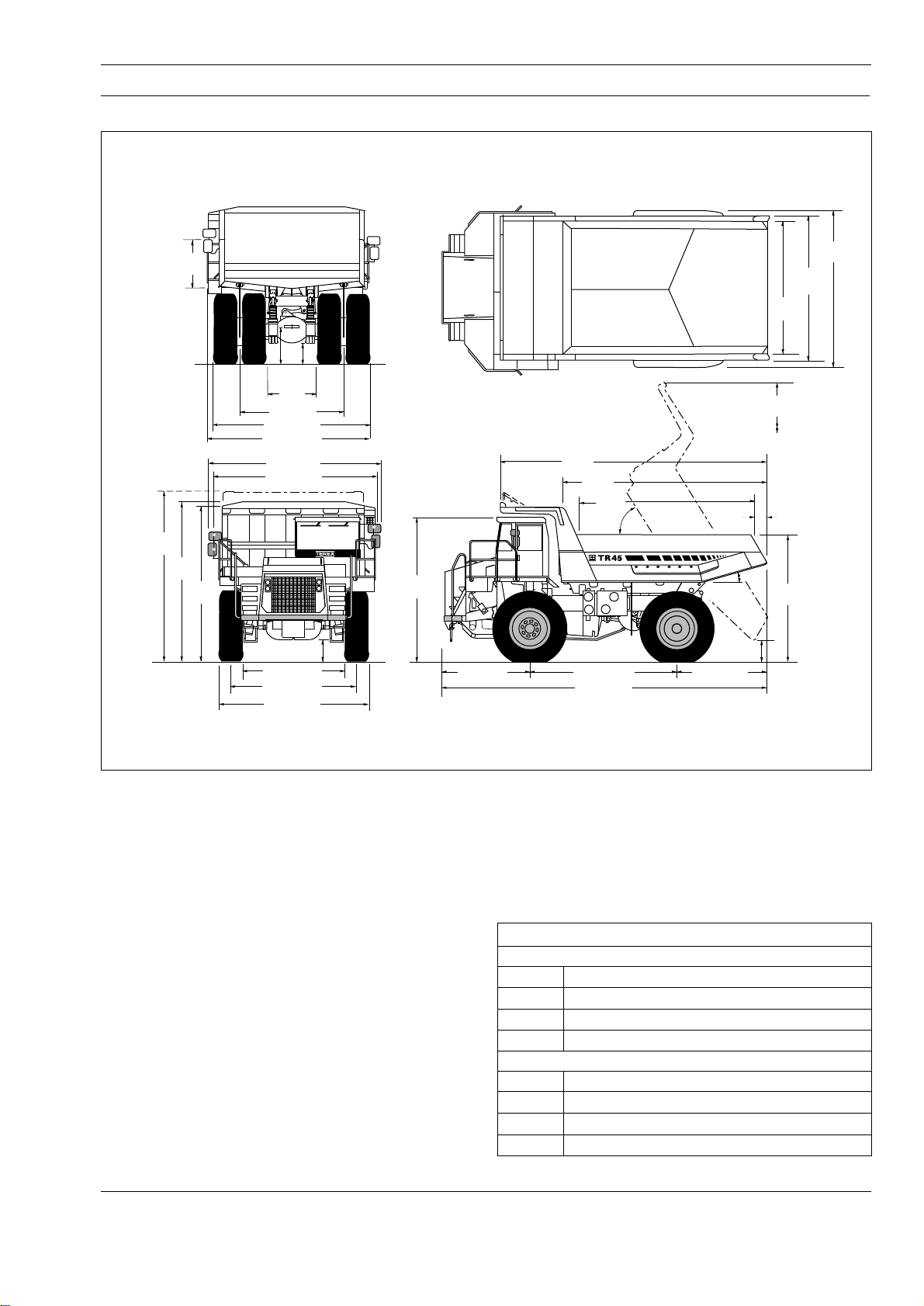

Section 000-0000

General Information - TR45 Off-Highway Truck

SM160812-982

DRIVE AXLE

Heavy duty axle with single reduction spiral bevel gear

differential, full floating axle shafts, and planetary reduction

at each wheel.

Ratios: Standard Optional

Differential ............................................. 3.15:1 3.73:1

Planetary ............................................... 5.66:1 5.66:1

TotalReduction.................................... 17.83:1 21.11:1

SUSPENSION

Front:Kingpinstrut typeindependentfront wheelsuspension

byself-contained,variablerate,nitrogen/oilcylinders.

Rear:Variableratenitrogen/oilcylinderswithA-framelinkage

andlateralstabilizerbar.

MaximumStrutStroke

Front........................................................... 251 mm(9.9 in)

Rear ........................................................... 182mm (7.2in)

MaximumRearAxleOscillation ....................... ± 6.5 Degrees

WHEELS AND TYRES

Wheel Rim Width .......................................................... 13 in

Wheel Rim Width (Optional) ......................................... 15 in

Standard Tyres (Front & Rear) ..............18.00 R33 ** Radial

Optional Tyres (Front & Rear) ...............21.00 R35 ** Radial

Note: It is recommended that for tyres both listed and

unlisted, the user should consult the tyre manufacturer and

evaluate all job conditions in order to make the proper

selection.

BRAKES

Service

All hydraulic brake system. Transmission mounted pressure

compensatingpump provideshydraulic pressurefor brakes

andsteering.Independent circuitsfront andrear. Eachcircuit

incorporatesanitrogen/hydraulicaccumulatorwhichstores

energyto provideconsistentbraking response.

Front Brake Circuit Pressure ................ 159 bar(2 300lbf/in²)

Rear Brake Circuit Pressure ....................52 bar (750 lbf/in²)

Accumulators:

NitrogenPrecharge Pressure ................. 55bar(800lbf/in²)

Front:

Type............................... Dry Disc with 1 calliper per wheel

DiscDiameter .......................................... 660mm(25.5in)

PadArea,Total ..................................... 1 395 cm²(216 in²)

Rear:

Type..................Oilcooled,multiple frictiondiscs(14 total),

completelysealedfromdirtandwater.

Braking Surface, Total ....................38 310 cm² (5 938 in²)

Cooling Flow, Max. .......... 553 litres/min (146 US gal/min)

Parking

Application of rear brakes by springs in brake disc pack.

Hydraulically released.

Hold-off Pressure ..................................83 bar (1 200 lbf/in²)

Retardation

Modulated lever control of rear disc pack.

Retarder Actuation Pressure ......... up to 33 bar (480 lbf/in²)

Emergency

Push button solenoid control applies service and parking

brakes.Automaticallyapplies whenengine isswitchedoff.

Parking brake applies should system pressure fall below a

predeterminedlevel.

Brakes conform to ISO 3450, SAE J1473 OCT 90.

STEERING SYSTEM

Independenthydrostaticsteeringwithclosed-centresteering

valve,accumulatorandpressurecompensatingpistonpump.

Accumulatorprovidesuniformsteeringregardlessofengine

speed. In the event of loss of engine power it provides

steering of approximately two lock-to-lock turns. A low

pressure indicator light warns of system pressure below

83 bar (1 200 lbf/in²). Steering meets ISO 5010, SAE J53.

System Pressure................................ 159 bar (2 300 lbf/in²)

Relief Pressure ...................................207 bar (3 000 lbf/in²)

Steering Cylinders ................... Double Acting, Single Stage

Accumulator:

Oil Capacity .................................. 14.0 litres (3.70US gal)

NitrogenPrecharge Pressure .................55bar (800lbf/in²)

SteeringAngle(LeftandRight) .........................................39°

Pump:

Type......................................................................... Piston

Capacity at 2 100 rev/min ..........1.4 litres/s (22 US gal/min)

BODY HYDRAULICS

Twobody hoistcylinders aremounted betweenthe frame

rails. Cylinders are two-stage with power down in the

second stage.

System Relief Pressure ..................... 190 bar (2 750 lbf/in²)

Pump:

Type........................................................................... Gear

Capacity at 2 100 rev/min.............................227 litres/min

(60 US gal/min)

Control Valve ...................... Servo Controlled, Open Centre

Body Raise Time................................................ 13 Seconds

Body Lower Time ................................................. 9 Seconds

Find manuals at http://best-manuals.com/search?&s=TEREX-SM1606