TERSO TS087 User manual

1TS087 User Manual

RFID DIRECTIONAL

READ POINT - TS087

USER MANUAL

2TS087 User Manual

THIS PAGE INTENTIONALLY BLANK

3TS087 User Manual

Terso RFID Directional Read Point

Terso Solutions, Inc.

5540 Research Park Drive

Madison, WI 53711

U.S.A.

Terso Solutions GmbH

Schildkrötstr. 15

68199 Mannheim

Germany

US: +1 888.376-0257

EU: +49.621.8501.233

4TS087 User Manual

THIS PAGE INTENTIONALLY BLANK

5TS087 User Manual

Terso RFID Directional Read Point

User Manual

6TS087 User Manual

Manual Revision Record

DATE REVISION DESCRIPTION

04 September 2019 1.00 Initial Release

7TS087 User Manual

TABLE OF CONTENTS

Aboutthismanual...................................................................................................................... 08

Getting Started.......................................................................................................................... 08

Getting Help.............................................................................................................................. 12

Optional Ceiling Tile Mount...................................................................................................... 12

Appendix A: Product Specifications......................................................................................... 13

Appendix B: RFID Tags and Tagging........................................................................................ 13

Appendix C: Mounting Guidelines............................................................................................ 14

8TS087 User Manual

ABOUT THIS MANUAL

The Terso RFID Directional Read Point (TS087) allows you to automatically track RFID-

tagged inventory traveling in and out of a specic area such as an operating room, point of

manufacture, stockroom, etc. This manual provides information on setting up and using the

Terso RFID Directional Read Point and its accessories.

Note: An on-site survey will need to be conducted before any install occurs as special

mounting, congurations, or other hardware may be needed.

Introduction

Notational Conventions

This document uses the following conventions:

• Bullets (•) indicate:

- Action items

- Lists of alternatives

- Lists of required steps that are not necessarily sequential

• Sequential lists (e.g., those that describe step-by-step procedures) appear as

numbered lists

• Note: indicates something of special interest or importance to the reader. Failure to read

the note will not result in physical harm to the reader, equipment, or data.

CAUTION This symbol indicates that if this information is ignored, the possibility of

data or material damage may occur.

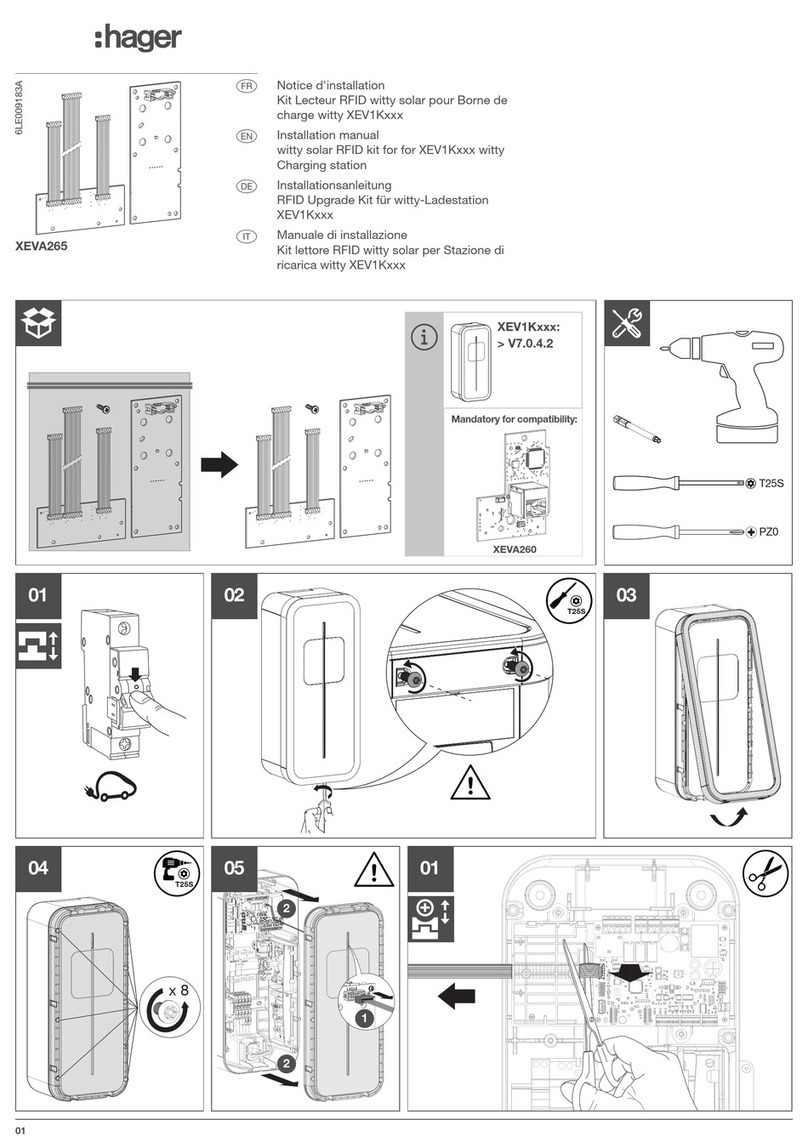

1. Terso RFID Directional Read Point (TS087), Jetstream Enabled Directional Portal

2. Power Supply

3. AC Cord

4. Ethernet Cable

5. Security screw and security screw tool (TORX)

6. VESA Mount & Associated Hardware

7. Terso RFID Directional Read Point (TS087) Setup Guide

1. Remove all items from the shipping boxes and place near location to be installed

2. Verify all components are included by referencing the “COMPONENTS” section above

3. If any components are missing, please call Terso’ Product Development Team for

assistance at (608) 298-4100.

1. Placement considerations

a. Where (near door, above door, ceiling height, etc.)

b. Only one path to read the entire scanning area

Locating the Device

Unpacking the Terso RFID Directional Read Point

Components

GETTING STARTED

9TS087 User Manual

c. Path of RFID tagged item through the read point path

d. Installing the read point path into a coered ceiling can reduce tag read

performance. The deeper the read point path is mounted into the coered ceiling,

the more imact there is on tag reads.

2. Install the Device at or below the level of HVAC equipment, pipes, and especially

lighting. Not only will such equipment block the Device beams, but orescent lighting

will also create RF noise interference if in the eld of view. This rule applies only when

the HVAC or lighting is below the Device, in the area where tags are to be read.

For example, if the Device were 10 feet away from the other equipment, this rule would not

apply since the equipment is outside of the read area.

Mounting a read point path under any of the following conditions should be

avoided:

Proximity to uorescent lights: Ideally place the Device greater than a foot away from any

uorescent lighting xture. The reason for this is that the ballasts can oscillate in the data

bands causing RF interference.

A scenario where there is a metal impediment between the tagged item and the Device.

Given that metal blocks the RFID signals, a tagged item’s readability will be greatly reduced if

it is blocked by metal.

Placement directly under or next to a re suppression nozzle (sprinkler): Devices are not

water-resistant.

The recommended mounting for the Terso RFID Directional Read Point (TS087) is

by suspended ceiling mounting. The Device comes complete with a VESA mount for

customizable mounting.

1. Location

a. Ceiling height to be between 8 ft. and 15 ft

b. Ceiling located between 2 ft. and 4 ft. of the door opening

2. Position

a. In / Out Direction must be considered

b. Position as close to the door opening as possible to achieve accurate tag reads

CAUTION Mounting the RFID Directional Read Point (TS087) under any of the

following conditions should be avoided:

i. Proximity to uorescent lights: Ideally place Devices greater than a foot away to

prevent RF interference

ii. A scenario where there is a metal impediment between the tagged item and the

Device. Given that metal blocks the RFID signals, a tagged item’s readability will

be greatly reduced if it is blocked by metal

iii. Placement directly under or next to a re suppression nozzle (sprinkler): these

Devices are not water-resistant

3. Cabling

a. There is a dedicated trough for positioning the cables from the Device to/through

the ceiling mount. Always make sure you route the cables through this path.

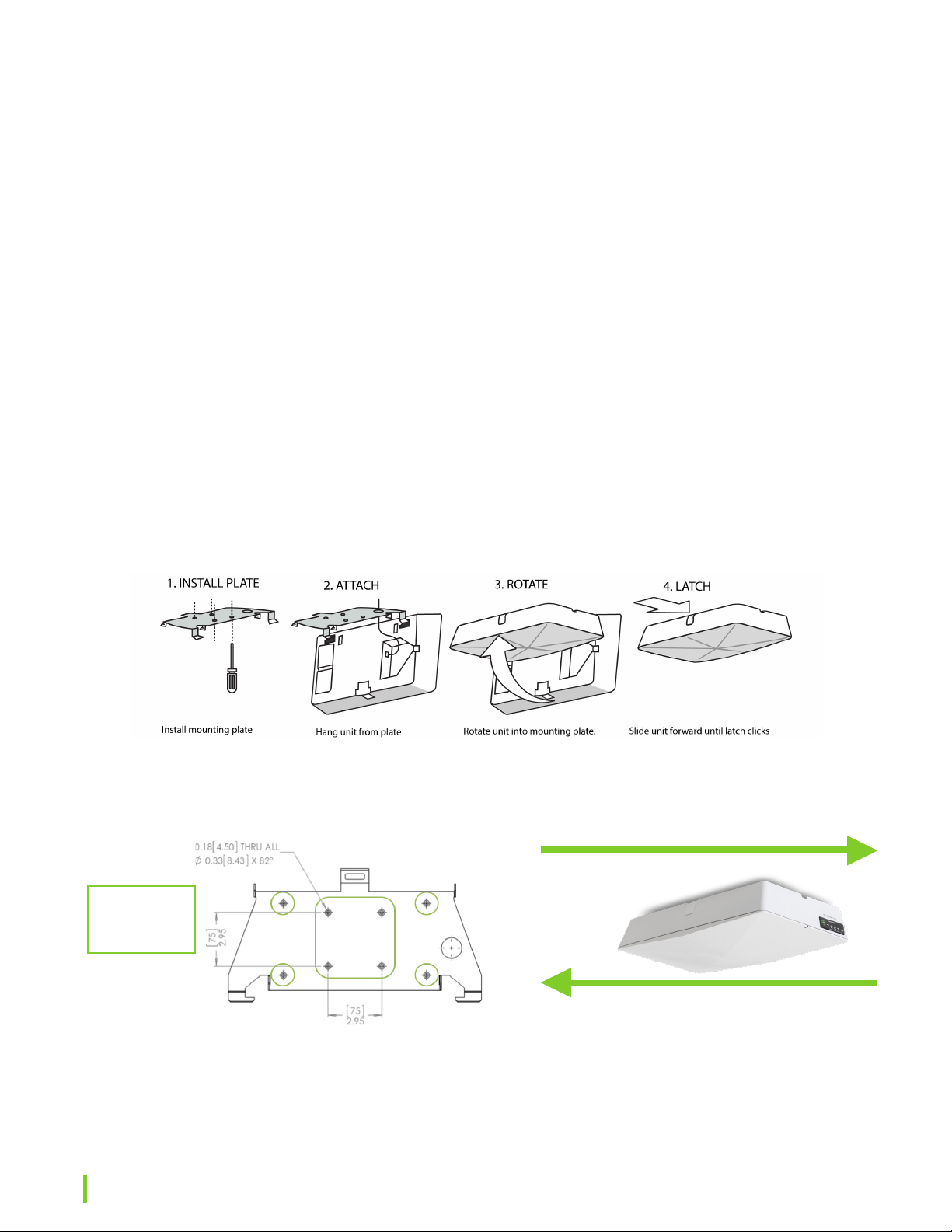

4. Physical Mounting

Mounting the Device

10 TS087 User Manual

a. Hang the Device from the mounting plate from a securely installed ceiling mount, but

do not latch. See Figure 1.

b. If using the DC Power Supply, Route the power supply cable from the Power Supply

to the recessed space on the back of the Device using the cable slot or the hole in

the mounting plate. Connect the power supply cable to the 24 VDC locking connector

on the Device. See “Connecting the Device” for specic instructions.

c. If using PoE for power, route the Ethernet network cable from a LAN outlet to the

recessed space on the back of the Device using the cable slot or the hole in the

mounting plate. Connect the Ethernet cable to the PoE Ethernet port.

d. Once the power and Ethernet cables are connected, lift the Device against the

mounting plate and securely lock it into position using the latch and security screw.

Once the security screw is installed, the Device cannot be removed from the

mounting plate.

e. Alternate mounting – The Device mounting plate allows the Device to be bolted to any

structure. There are clearance holes in the plate that accommodate an M4 (metric) or

a #8 (SAE) bolt / screw. See Figure 2.

f. Direction: See gure 3 for directional specic mounting.

6. Mounting recommendation

a. The recommended mounting for the Terso RFID Directional Read Point (TS087) is by

suspended ceiling. The Device comes complete with a VESA mount for customizable

mounting of the Device. If you would like information and pricing for the optional 2’ x 2’

Ceiling Tile mounting Device, please contact Terso Customer Service.

VESA Mounting Plate. Green squares on indicate VESA

mounting holes. Circles indicate structure mounting holes.

FIGURE 2

ENTER or aggregate* ADD

EXIT or aggregate REMOVE

FIGURE 3

Default setting. The direction for ADD/REMOVE can

be changed in the Device parameters. Should the

workow dictate a need to change this, please con-

tact Terso Solutions for

instructions.

FIGURE 1

Attaching the RFID Directional Portal to the mounting plate.

LED

Location

11TS087 User Manual

Connecting the Device

1. Power

a. The Terso RFID Directional Read Point (TS087) is designed to be a Power over

Ethernet (PoE) Device. However, should PoE not be available, you may use the

external power supply included in the packaging.

b. There are two methods for powering the Device:

i. IEEE 802.3af (Power over Ethernet) compliant source

ii. Power supply, included, with 24Vdc output, rated minimum 2.1A

c. The Device operates at the Class 3 limit for PoE power (for a standard 100 meter

length cable).

Important: Terso does not reccomend connecting both a PoE and the external power supply to

the Device.

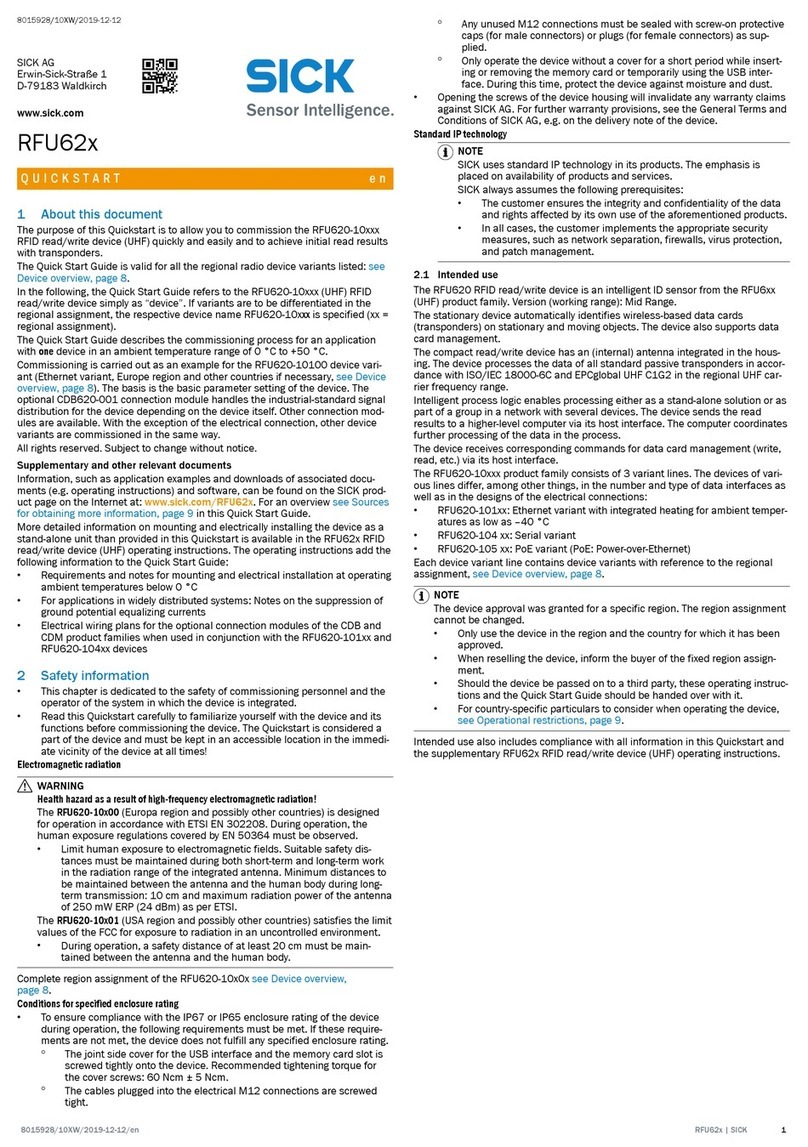

2. Connection (See Figure 4)

a. Before plugging in the Device to the optional DC power supply, plug the Ethernet

cable from the source into the Device. If the LED turns RED, this means PoE is

available and no DC power supply is necessary.

b. If PoE is unavailable, plug the DC power supply into the Portal in the ‘Power’ port.

c. Plug the AC cord into the Power supply

d. Plug the AC cord into a 115V source

e. Verify LED status is in the “Powered’ or RED state when it is rst plugged into an AC

outlet.

f. See the CONNECTIONS section following this step for the physical location and types

of connections available.

FIGURE 4

1. Power (24V, 1A)

2. PoE / Ethernet

3. USB Device (Not Needed)

4. USB Host (Not Needed)

5.Console connection for Terso

Setup and Programming

3. Boot Sequence

a. Boot sequence begins when power is supplied to the Device. This sequence typically

completes within 60 to 120 seconds.

b. After the Device is powered, and connected to a network, verify the exterior LED is

ashing BLUE throughout the connection sequence.

c. Once the Device is connected, the LED will turn a solid BLUE. The Device is now

ready to provide data to Jetstream

4. LED Status Indicator

LED STATE PORTAL STATE

O O (No power supplied)

RED- Solid Powered

YELLOW - Solid Ready

BLUE- Solid Connected

RED- Blinking Fault condition occurred

Blue- Blinking Connecting

12 TS087 User Manual

Support

Terso’s RFID Directional Read Point (TS087) has many RF Performance settings that can

be changed to improve RFID tag reads such as RFID Power, read sensitivity, tag population,

and others. If you are having issues achieving consistent tag reads, please contact

Terso’s Product Management team at (608) 298-4100. You may also contact the Product

Management team if you are experiencing problems with your Device, such as connectivity

issues or power-up issues.

Please make sure you have the Device Digital Serial Number (DSN) ready for reference.

This DSN is on a label on the exterior of the Device near the “Powered by Terso” label.

Sta are available during Terso’s standard business hours: M-F, 8AM-5PM CT. Response

times are typically a few business hours.

GETTING HELP

5. Jetstream Aggregates

a. A Jetstream Aggregate is an event that represents a transaction/change to the

Devices tags.

b. These are events that captures what RFID tags were added and/or removed from

the Device, along with the pass RFID (if applicable) that was provided to access

the Device.

Raw Aggregate example:

{ “PassRd”: “0123456789”,

“Removes”: [

“AD4424044149F1765B0000CF”,

“AD4424044149FB7B5C0000D0”],

“Device”: “MyDeviceName”,

“ReceivedTime”: “2018-05-19T13:23:44Z”,

“Type”: “AggregateEvent”,

“EventId”: “a85745f7-a348-4454-8a97-8eee2aeef853”,

“EventTime”: “2018-05-19T13:23:36Z”,

“Version”:2 }

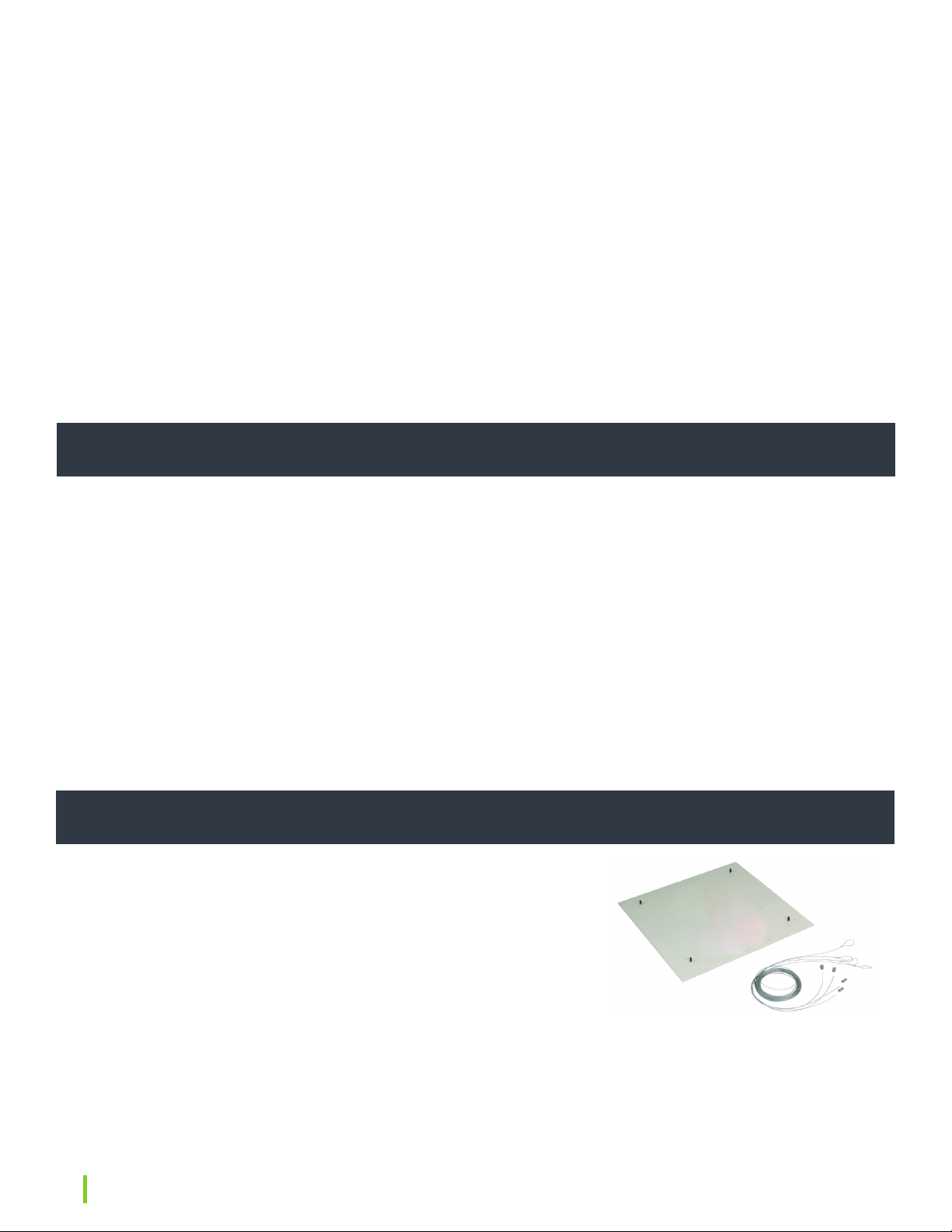

OPTIONAL CEILING TILE MOUNT

The recommended mounting for the Terso RFID Directional

Read Point (TS087) is by suspended ceiling mounting. The

Device comes complete with a VESA mount for customizable

mounting in a 2 ft x 2 ft suspended ceiling tile system.

Please contact Terso Solutions for information and pricing of

the Ceiling Tile Mount.

13TS087 User Manual

APPENDIX A: PRODUCT SPECIFICATIONS

DESCRIPTION SPECIFICATION

Environment

Power (PoE) IEEE 802.3af power over Ethernet

Power DC 24Vdc output, rated minimum 2.1A

Power Consumption 7 W idle, 13.8 W typical

Operating Temperature -20 to 50 C (-4 to 122 F)

Operating Humidity 5-95% non-condensing

RoHS RoHS 2011/65/ EU compliant

FCC Class B digital Device, pursuant to Part 15 of the FCC rules

Physical

Dimensions (LxWxH) 18.75 in x 8.66 in x 3.45 in

Ceiling Mount (optional) Typical 2ft x 2ft ceiling tile

Weight (Device only) 5.97 pounds, 7.56 pounds with VESA plate

Coverage area 1000ft² per unit with Monza r6 based RFID tags

(rectangular)

RFID

Frequency 902- 928 MHz

Standard

RAIN RFID: EPCglobal

UHF RFID Class 1 Gen2v2

ISO 18000-63

Modes

Read Point

The Device takes an inventory by reading RFID tags within its eld of view (FOV). An

Aggregate Event add is when the RFID tag is read in the read eld of view. An Aggregate

Event Remove is when an RFID tag exits the read eld of view.

Direction The Device detects the direction of a tag as it transitions across the Device’s eld of view

(FOV). One direction of travel will provide an Aggregate Event Remove.

APPENDIX B: RFID TAGS AND TAGGING

RFID Tags & Tagging

RAIN RFID tag choice and tag placement is critical to a successful deployment. Terso will work

closely with all parties to assist in providing the strongest recommendation for a successful

tagging strategy.

Tags vary from application to application. On-metal, read range, tag orientation, and tag chipset

all can have eects on read performance. Terso recommends an RFID tag using the Monza® R6

UHF RFID tag chip or newer.

Please contact Terso for additional guidelines and suggestions on the proper tag(s) to use for

your specic application.

Variables to Consider When Tagging

Product/packaging material

Metals, liquids, foil, active electrical Devices - These materials will aect the tag performance

14 TS087 User Manual

DO DON’T

DO check if the application surface is clean and dry DO NOT ever bend or crease the tag

DO ensure there are no wrinkles in the tag after

application DO NOT place tag directly on a container with liquid

DO try to keep all tags aligned in the same

orientation

DO NOT apply tags to a curved surface with a diameter smaller

than 3”

DO try to keep all tags aligned in the same

orientation

DO NOT place tag on or near any metal surface or any packaging

containing metal unless it is an ‘On-Metal’ tag

DO prevent tags from contacting each other when

stocked 5-95% non-condensing

DO allow for some separation between tag - ideally

> 1” DO NOT remove and reuse a tag once applied

Dimension of items

Tags should be placed on a product that allows the entire tag and adhesive to be adhered to the

product. Do not allow the tag to overhang over an edge.

Available space is available on the product for applying a tag on a at surface

Stocking orientation requirements may be necessary. Consider the direction in which the tag will

be read.

APPENDIX C: MOUNTING GUIDELINES

Mounting and Deployment Success Factors

A successful Device deployment requires users to understand a range of external factors

that can constrain the use case details and success criteria requirements, including but not

limited to: the physical environment, RFID tag constraints, RFID tag read sensitivity, Device

mounting variations, and conguration settings.

Generally, most deployments require some detailed testing of use cases to ensure the

required outcome is possible within the customer’s typical RF environment.

Terso’s preferred mounting location is on a ceiling near the opening of the entrance or exit to

a specic area.

At a minimum, the following should be considered:

• Verify the model is correct model for the geographical region - US, ETSI (Europe), etc.

• Identify the RFID tag type and performance to ensure the item being tagged can be

read by the Device. (i.e. On-metal tag, tag orientation, tag size, tag sensitivity, item

material)

• Tags with Impinj Monza R6 chips using inlays of at least 70mm long is recommended.

The Monza R6 chip has the best and most consistent read ranges

• Consider the likely area coverage for planning where to install your Device for success

• The Device is designed for installation at heights ranging from 8ft to 15ft. However,

lower ceilings may be used. A typical 8 foot ceiling will have a smaller read area and

may require specic positioning based on the location.

• When deciding on the placement the Device, don’t base placement decisions on the

furniture, racks, cabinets, or other large objects below especially if the positions are

subject to change.

• Install the Device at or below the level of HVAC equipment, pipes, and especially

uorescent lighting.

15TS087 User Manual

• Installing the Device into a coered ceiling can reduce RFID tag read performance.

The deeper the Device is mounted into the coered ceiling, the more impact there is

on tag reads.

Hallway & Ceiling Mounting Guidelines

16 TS087 User Manual

Table of contents

Other TERSO RFID System manuals