Safety Precautions

Form 824262 Page Number - 3

WARNING!

MV5545E must be operated by qualified service technicians.

If personal injury or material damage occurs as a result of inappro-

priate operation, e.g. if safety instructions are ignored, or resulting

from incorrect use, no claims or legal actions may be taken against

Lincoln.

The use of this service tool requires the exposure of highly

flammable gasoline. To prevent fires, explosions and/or severe

injury, always apply extra precautions when diagnosing or

working on fuel systems.

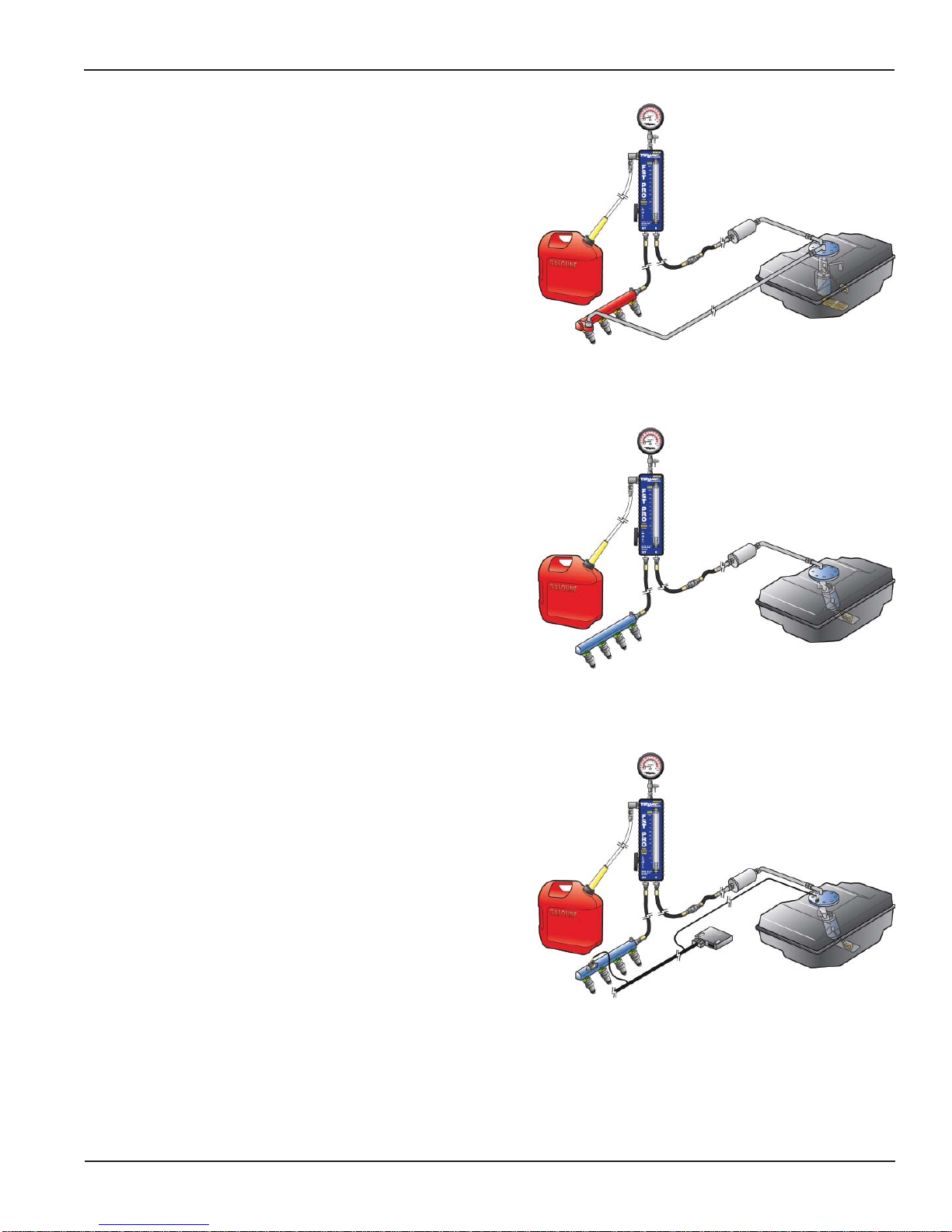

The FST Pro is designed for servicing a variety of vehicles in a

safe, convenient manner. However, fuel delivery systems vary

widely between makes and models of vehicles, potentially requir-

ing additional steps or equipment to perform a proper service job.

The procedures outlined in this manual are to serve as guidelines

for the use of this equipment. In addition to these guidelines,

always follow the manufacturer’s recommended

procedures when servicing each unique vehicle. Use common

sense in the application of this tester and do not attempt to force

a test on a fuel system for which this equipment is not designed to

perform.

This tester is designed for use on gasoline/petrol or diesel engines

only. It is safe for use with gasoline and most gasoline additives,

including alternative/flex fuels that contain high levels of ethanol.

• Always read carefully and understand instructions prior to us-

ing this equipment

• Wear safety glasses at all times

• Operate the vehicle only in a well ventilated area, and away

from potential sources of flame or ignition.

• Prior to starting an engine, make sure all components of the

tester, body parts, and personal clothing are clear of rotating

engine components

• Avoid burns by remaining cautious of engine parts that may

become hot when the engine is running

• Never leave a vehicle unattended while testing

• Check and secure all fuel system connections before

starting the vehicle or activating the fuel pump

• Wear gloves and protective clothing to avoid the contact of

fuel on skin. If contact occurs, immediately wash the area and

perform necessary first aid

• Always keep a fire extinguisher on hand when performing fuel

related diagnostics. Make sure the extinguisher is rated for fuel,

electrical and chemical fires

• Avoid spilling fuel on hot engine parts. Clean-up any fuel spills

immediately after they occur

CAUTION

Specifications

Maximum Flow Capacity:

3.8 liters/min. (1 gal./minute) gasoline/petrol (.73 specific gravity)

225 liters/hour (60 gal./hour) gasoline/petrol (.73 specific gravity)

3.5 liters/min. (0.9 gal./minute) diesel (.85 specific gravity)

205 liters/hour (55 gal./hour) diesel (.85 specific gravity)

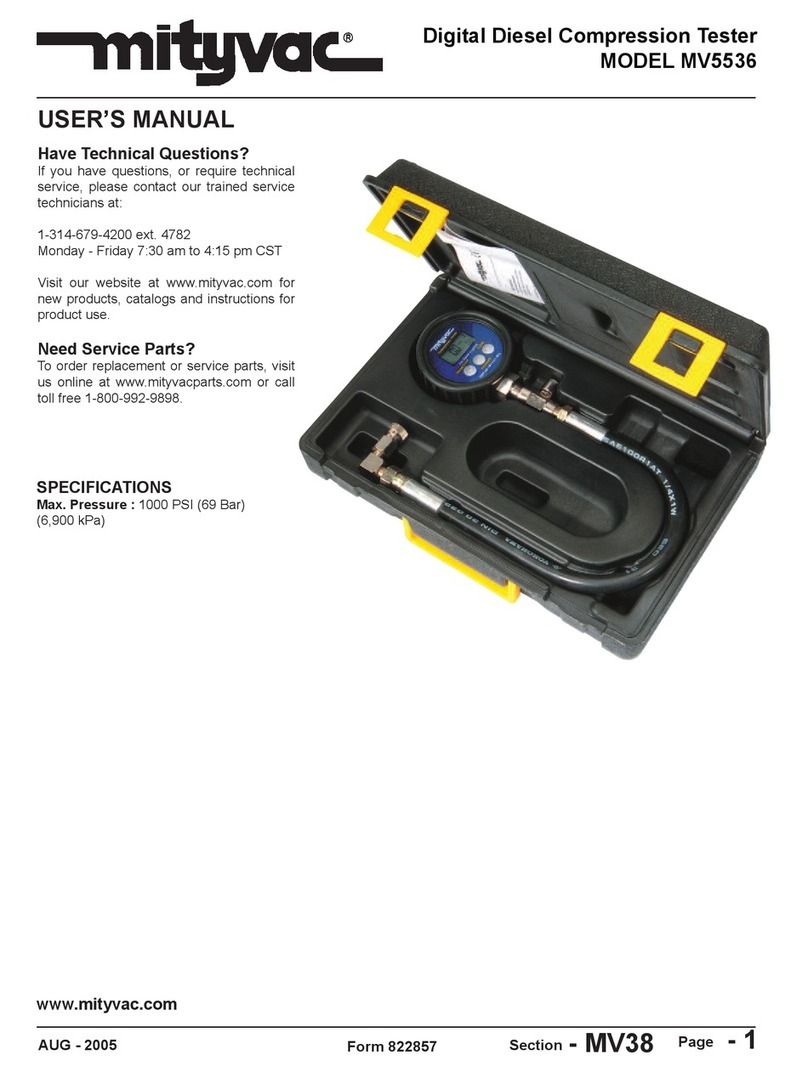

Maximum Rated Pressure: 8 bar (120 PSI) (800 kPa)