1

SPRUIK1–June 2018

Submit Documentation Feedback Copyright © 2018, Texas Instruments Incorporated

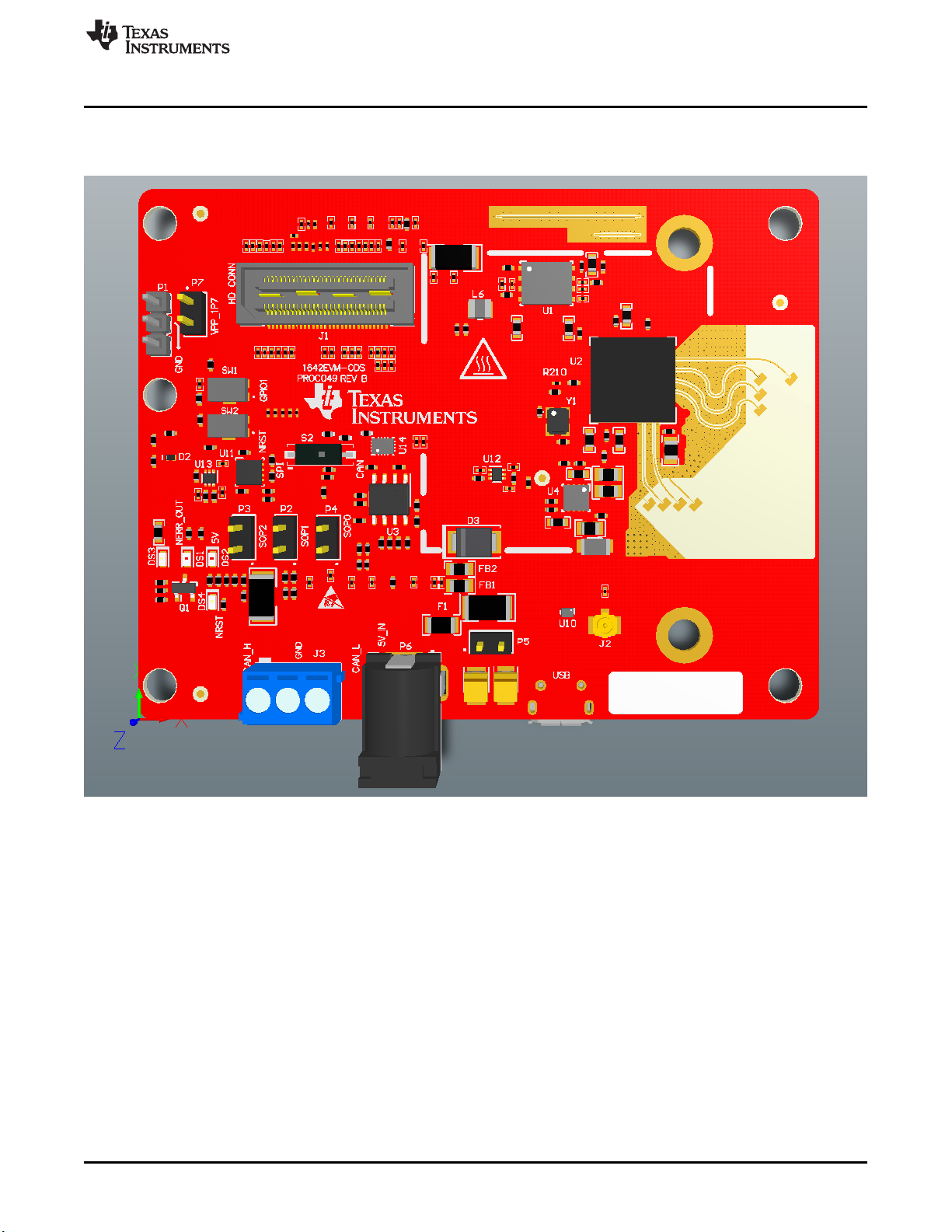

AWR1642 Obstacle Detection Sensor (AWR1642BOOST-ODS) Single-Chip

mmWave Sensing Solution

User's Guide

SPRUIK1–June 2018

AWR1642 Obstacle Detection Sensor

(AWR1642BOOST-ODS)

Single-Chip mmWave Sensing Solution

The AWR1642 Obstacle Detection Sensor from Texas Instruments is an easy-to-use evaluation board for

the AWR1642 mmWave sensing device, with direct connectivity to the microcontroller (MCU)

LaunchPad™ Development Kit. The Obstacle Detection Sensor contains everything required to start

developing software for on-chip C67x DSP core and low-power ARM®R4F controllers, including onboard

emulation for programming and debugging as well as onboard buttons and LEDs for quick integration of a

simple user interface.

Contents

1 Getting Started............................................................................................................... 2

1.1 Introduction .......................................................................................................... 2

1.2 Key Features ....................................................................................................... 2

1.3 Kit Contents.......................................................................................................... 2

2 Hardware...................................................................................................................... 3

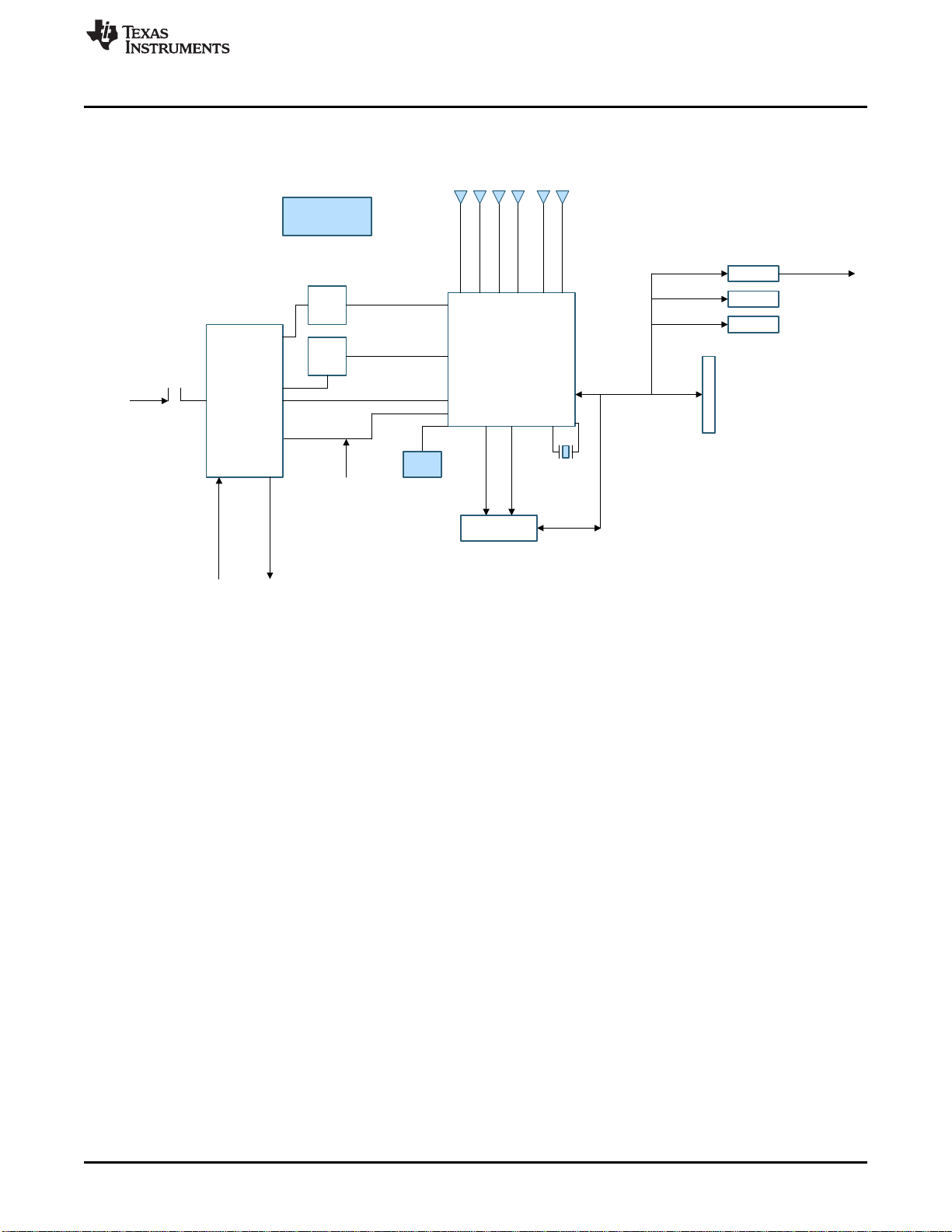

2.1 Block Diagram....................................................................................................... 5

2.2 Power Connections................................................................................................. 6

2.3 Connectors .......................................................................................................... 6

2.4 PC Connection..................................................................................................... 10

2.5 Connecting the Obstacle Detection Sensor to the LaunchPad or the MMWAVE-DEVPACK........... 11

2.6 Antenna............................................................................................................. 11

2.7 Jumpers, Switches, and LEDs................................................................................... 13

3 Design Files and Software Tools......................................................................................... 17

3.1 Hardware........................................................................................................... 17

3.2 Software, Development Tools, and Example Code........................................................... 17

4 Design Revision History .................................................................................................. 17

5 Mechanical Mounting of PCB............................................................................................. 18

6 PCB Storage and Handling Recommendations........................................................................ 18

7 Troubleshooting ............................................................................................................ 18

Trademarks

LaunchPad, Code Composer Studio are trademarks of Texas Instruments.

ARM is a registered trademark of ARM Limited.

Windows is a registered trademark of Microsoft Corporation.

All other trademarks are the property of their respective owners.