www.ti.com

Special Notes

5

SPRUIR3A–September 2019–Revised March 2020

Submit Documentation Feedback Copyright © 2019–2020, Texas Instruments Incorporated

F280025 controlCARD Information Guide

5 Special Notes

5.1 XDS100v2 Emulator and SCI (UART) Connectivity

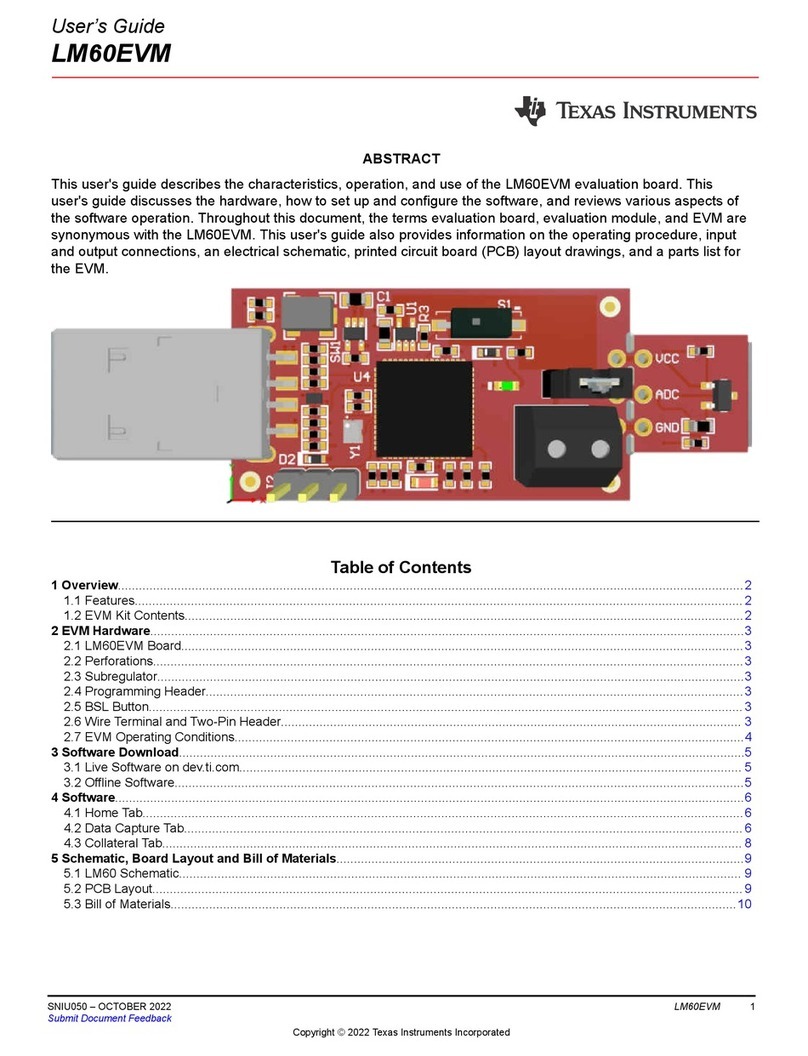

The F280025 controlCARD provides emulation and USB-to-UART adapter functionality on the

controlCARD. This allows for a convenient method to debug and demonstrate the F28002x MCU.

Note that the FTDI chip, its support circuitry, and associated isolation components are placed in Macro A

(the left section of the controlCARD). Each of these components contains an additional “:A” within the

component reference designator (that is, R2:A for resistor 2 in Macro A) (see Figure 4).

The configuration of the switches on S1:A determine if the on-board emulator is active, if an external

emulator can be used, or if the device will boot from FLASH/peripherals (see Table 1 ).

5.2 Clocking Methodology

This controlCARD is required to support a broad range of TI's baseboards. Several designs rely on

GPIO18 and GPIO 19 for SPIA , while others require these GPIO to be utilized as a precision clock input

source. To accommodate both of these systems a switch (S3) has been added to the design. This

methodology should not be used in a final system as it increases EMI emissions and creates robustness

susceptibilities. It is up to the system designer to choose the best way to implement the clocking circuity

for a given system.

5.3 Evaluation of the Analog to Digital Converters(ADCs)

When using the F280025 on-chip ADCs there are some useful guideline to follow to realize the

performance numbers listed in the data sheet. This is especially true for the AC parameters such as: SNR,

THD, and SINAD. Furthermore, it can also be shown that there is a direct correlation between the SNR of

the ADC result and the spread of ADC codes seen for a DC input; as such these tips will improve the

range and standard deviation of a DC input as well. Finally, while topics addressed will be with respect to

the controlCARD, they are applicable to other implementations using the F280025 MCU as well.

On-board resistors and capacitors: By default all inline resistors to the ADC pins are a simple 0-Ωshunt

and all capacitors to the ground plane are not populated. While this circuit can be used to supply the ADC

inputs with a voltage, likely both the resistor(R) and capacitor(C) will need to be populated based on the

voltage source's characteristics. Referring to the ADC Input Model, the ADC input has its own RC network

made up of the internal sample and hold capacitor, switch resistance, and parasitic capacitance. By

changing the inline resistance and parallel capacitor we can optimize the input circuit to assist with settling

time and/or filtering the input signal. Finally, it is recommended in general to use either NPO(Negative-

Positive 0 PPM/°C) or COG(Ceramic On Glass) as these have better stability over temperature and

across input frequencies than other types of capacitors.

Voltage source and drive circuitry: While the on-chip ADCs are 12-bit architecture (4096 distinct output

codes when converting an analog signal to the digital domain); the translation will only be as precise as

the input provided to the ADC. The typical rule of thumb when defining the source resolution to realize the

full specification of an ADC is to have a 1-bit better source than the converter. In this case that would

mean that ideally the analog input should be accurate to 13-bits.

Typically voltage supplies or regulators are not designed to be precise, but rather accommodate a wide

range of current loads within a certain tolerance and for this reason are not ideal to show the performance

of a higher bit ADC, like the one on the F280025. This does also not take into account that many times the

supply in question is providing the main voltage to power the MCU itself; which also introduces noise and

other artifacts into the signal.

In addition to the quality of the input signal there is also the aspect of the load presented to the ADC when

it samples the input. Ideally an input to an ADC would have zero impedance so as not to impact the

internal R/C network when the sampling event takes place. In many applications, however, the voltages

that are sampled by the ADC are derived from a series of resistor networks, often large in value to

decrease the active current consumption of the system. A solution to isolate the source impedance from

the ADC sampling network is to place an operational amplifier in the signal path. Not only does this isolate

the impedance of the signal from the ADC, it also shields the source itself from any effects the sampling

network may have on the system.