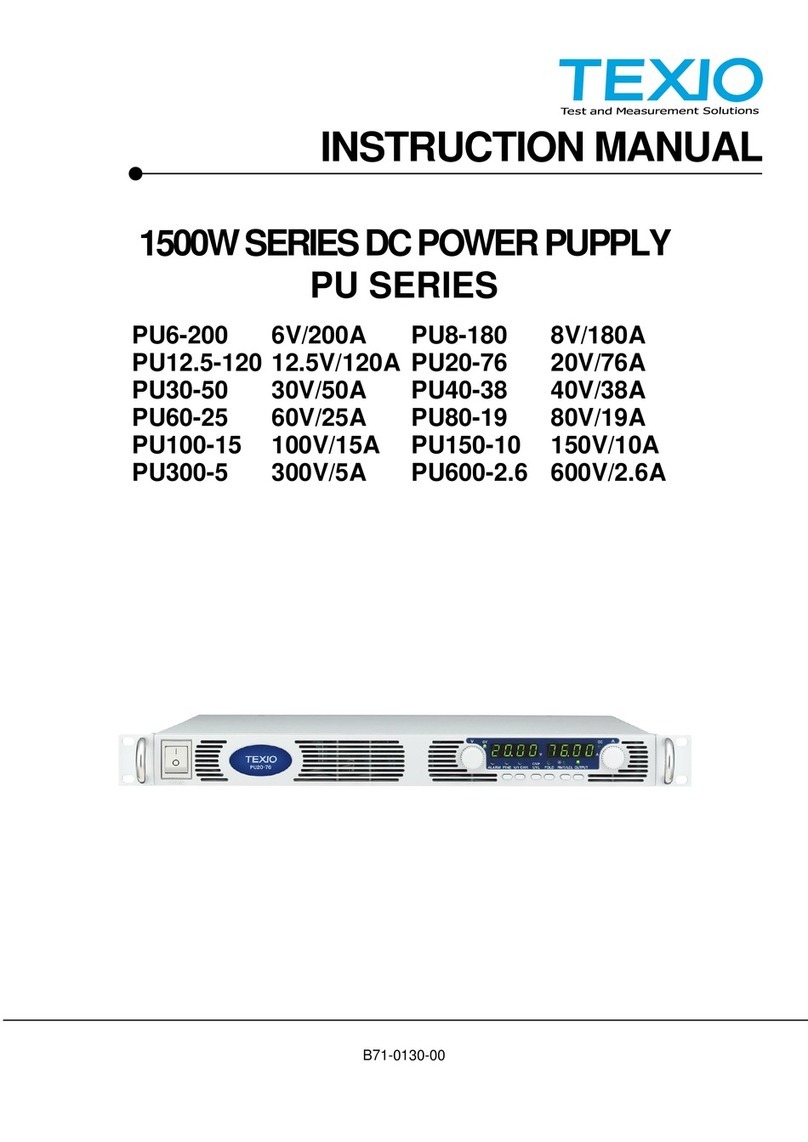

TEXIO PSW Series User manual

B71-0441-11

INSTRUCTION MANUAL

MULTI RANGE DC POWER SUPPLY

PSW SERIES

PSW-360L30

PSW-720L30

PSW-1080L30

PSW-360L80

PSW-720L80

PSW-1080L80

PSW-360M160

PSW-360M250

PSW-360H800

PSW-720M160

PSW-720M250

PSW-720H800

PSW-1080M160

PSW-1080M250

PSW-1080H800

■About Brands and Trademarks

“TEXIO” is the product brand name of our industrial electronic devices.

All company names and product names mentioned in this manual are the

trademark or the registered trademark of each company or group in each

country and region.

■About the Instruction Manual

Permission from the copyright holder is needed to reprint the contents of this

manual, in whole or in part. Be aware that the product specifications and the

contents of this manual are subject to change for the purpose of improvement.

■ About firmware version

This programming manual is required firmware version 2.25 or higher.

CONTENTS

USING THE PRODUCT SAFELY·········································· Ⅰ-Ⅳ

1 GETTING STARTED ............................................................. 1

1-1. PSW Series Overview ............................................................ 1

1-1-1. Series lineup.......................................................................................1

1-1-2. Main Features.....................................................................................2

1-1-3. Accessories........................................................................................2

1-2. Appearance ........................................................................... 4

1-2-1. PSW Front Panel ................................................................................4

1-2-2. Rear Panel...........................................................................................6

1-3. Theory of Operation .............................................................. 9

1-3-1. Operating Area Description...............................................................9

1-3-2. CC and CV Mode ..............................................................................11

1-3-3. Slew Rate..........................................................................................12

1-3-4. Bleeder Control................................................................................13

1-3-5. Internal Resistance ..........................................................................14

1-3-6. Alarms...............................................................................................14

1-3-7. Considerations.................................................................................15

1-3-8. Grounding......................................................................................... 17

2 OPERATION ....................................................................... 18

2-1. Set Up.................................................................................. 18

2-1-1. Line Voltage Connection –Type III Models....................................18

2-1-2. Filter Installation ..............................................................................19

2-1-3. Power Up...........................................................................................19

2-1-4. Wire Gauge Considerations............................................................20

2-1-5. Output Terminals(30V,80V,160V)....................................................20

2-1-6. Using the Output Terminal Cover(30V,80V,160V)..........................22

2-1-7. Output Terminals(250V,800V) .........................................................22

2-1-8. Using the Output Terminal Cover(250V,800V)...............................25

2-1-9. Using the Rack Mount Kit................................................................25

2-1-10. How to Use the Instrument............................................................26

2-1-11. Reset to Factory Default Settings.................................................26

2-1-12. View System Version and Build Date...........................................27

2-2. Basic Operation................................................................... 29

2-2-1. Setting OVP/OCP Levels..................................................................29

2-2-2. Set to C.V. Mode...............................................................................30

2-2-3. Set to C.C. Mode...............................................................................33

2-2-4. Display Modes..................................................................................35

2-2-5. Panel Lock........................................................................................35

2-2-6. Remote Sense ..................................................................................36

2-3. Parallel / Series Operation................................................... 38

2-3-1. Master-Slave Parallel Overview ......................................................39

2-3-2. Master-Slave Parallel Connection................................................... 40

2-3-3. Master-Slave Parallel Operation .....................................................42

2-3-4. Master-Slave Series Overview ........................................................43

2-3-5. Master-Slave Series Connection.....................................................45

2-3-6. Master-Slave Series Operation .......................................................46

2-4. Test Script ........................................................................... 47

2-4-1. Filename of TestScript.....................................................................47

2-4-2. Test Script Settings .........................................................................47

2-4-3. Setting the Test Script.....................................................................48

2-4-4. Load Test Script from USB drive....................................................49

2-4-5. Run Test Script.................................................................................49

2-4-6. Run Test Script (At Startup)............................................................50

2-4-7. Export Test Script to USB ...............................................................50

2-4-8. Remove Test Script..........................................................................51

2-4-9. Test Memory.....................................................................................51

2-4-10. Data structure of the test Script....................................................52

2-4-11. Setting values of the test Script....................................................53

3 CONFIGURATION............................................................... 54

3-1. Configuration Table ............................................................. 54

3-2. Normal Function Settings.................................................... 57

3-3. USB/GP-IB/RS-232C Settings............................................... 60

3-4. LAN Settings ....................................................................... 60

3-5. System Settings .................................................................. 61

3-6. Power On Configuration Settings ........................................ 62

3-7. Calibration........................................................................... 63

3-8. Setting Normal Function Settings ....................................... 63

3-9. Setting Power On Configuration Settings............................ 64

4 ANALOG CONTROL ........................................................... 65

4-1. Analog Remote Control Overview........................................ 65

4-1-1. Analog Control Connector Overview .............................................65

4-1-2. External Voltage Control of Voltage Output ..................................67

4-1-3. External Voltage Control of Current Output ..................................68

4-1-4. External Resistance Control of Voltage Output ............................70

4-1-5. External Resistance Control of Current Output ............................71

4-1-6. External Control of Output.............................................................. 73

4-1-7. External control of Shutdown .........................................................74

4-2. Remote Monitoring .............................................................. 76

4-2-1. External Voltage and Current Monitoring ......................................76

4-2-2. External Operation and Status Monitoring ....................................77

5 Digital Control ................................................................... 79

5-1. Interface Configuration ....................................................... 79

5-1-1. USB Remote Interface .....................................................................79

5-1-2. Configure GP-IB Interface ...............................................................79

5-1-3. Configure RS-232C Interface...........................................................80

5-1-4. Configure Ethernet Connection......................................................80

5-1-5. Web Server Configuration...............................................................81

5-1-6. Sockets Server Configuration.........................................................81

5-1-7. USB Remote Control Function Check............................................82

5-1-8. Web Server Remote Control Function Check................................82

5-1-9. Socket Server Function Check .......................................................83

6 MAINTENANCE .................................................................. 87

6-1. Replacing the Dust Filter..................................................... 87

7 FAQ.................................................................................... 88

8 APPENDIX.......................................................................... 89

8-1. PSW Default Settings .......................................................... 89

8-2. Error Messages & Messages ............................................... 91

8-3. LCD Display Format............................................................. 91

9 Specifications.................................................................... 92

9-1. PSW 360W Type I ................................................................. 92

9-2. PSW 720W Type II ................................................................ 95

9-3. PSW 1080W Type III ............................................................. 98

9-4. Common ............................................................................ 101

9-5. PSW Dimensions ............................................................... 102

I

USING THE PRODUCT SAFELY

■Preface

To use the product safely, read instruction manual to the end. Before using

this product, understand how to correctly use it. If you read the manuals but

you do not understand how to use it, ask us or your local dealer. After you

read the manuals, save it so that you can read it anytime as required.

■Pictorial indication

The manuals and product show the warning and caution items required to

safely use the product. The following pictorial indication is provided.

Pictorial

indication

Some part of this product or the manuals may show this

pictorial indication. In this case, if the product is

incorrectly used in that part, a serious danger may be

brought about on the user's body or the product. To use

the part with this pictorial indication, be sure to refer to the

manuals.

WARNING

!

If you use the product, ignoring this indication, you may get

killed or seriously injured. This indication shows that the

warning item to avoid the danger is provided.

CAUTION

!

If you incorrectly use the product, ignoring this indication,

you may get slightly injured or the product may be

damaged. This indication shows that the caution item to

avoid the danger is provided.

Please be informed that we are not responsible for any damages to the user or

to the third person, arising from malfunctions or other failures due to wrong use

of the product or incorrect operation, except such responsibility for damages as

required by law.

II

USING THE PRODUCT SAFELY

WARNING

!

CAUTION

!

■Do not remove the product's covers and panels

Never remove the product's covers and panels for any purpose.

Otherwise, the user's electric shock or fire may be incurred.

■Warning on using the product

Warning items given below are to avoid danger to user's body and life and

avoid the damage or deterioration of the product. Use the product, observing

the following warning and caution items.

■Warning items on power supply

●Power supply voltage

The rated power supply voltages of the product are 100VAC. The rated power

supply voltage for each product should be confirmed by reading the label

attached on the back of the product or by the “rated” column shown in the

instruction manual. The specification of power cord attached to the products

is rated to 125VAC for all products which are designed to be used in the

areas where commercial power supply voltage is not higher than 125VAC.

Accordingly, you must change the power cord if you want to use the product

at the power supply voltage higher than 125VAC. If you use the product

without changing power cord to 250VAC rated one, electric shock or fire may

be caused. When you used the product equipped with power supply voltage

switching system, please refer to the corresponding chapter in the instruction

manuals of each product.

●Power cord

(IMPORTANT) The attached power cord set can be used for

this device only.

If the attached power cord is damaged, stop using the product and call us or

your local dealer. If the power cord is used without the damage being

removed, an electric shock or fire may be caused.

●Protective fuse

If an input protective fuse is blown, the product does not operate. For a

product with external fuse holder, the fuse may be replaced. As for how to

replace the fuse, refer to the corresponding chapter in the instruction

manual. If no fuse replacement procedures are indicated, the user is not

permitted to replace it. In such case, keep the case closed and consult us

or your local dealer. If the fuse is incorrectly replaced, a fire may occur.

III

USING THE PRODUCT SAFELY

■Warning item on Grounding

If the product has the GND terminal on the front or rear panel surface, be sure

to ground the product to safely use it.

■Warnings on Installation environment

●Operating temperature and humidity

Use the product within the operating temperature indicated in the “rating”

temperature column. If the product is used with the vents of the product

blocked or in high ambient temperatures, a fire may occur. Use the product

within the operating humidity indicated in the “rating” humidity column.

Watch out for condensation by a sharp humidity change such as transfer to a

room with a different humidity. Also, do not operate the product with wet

hands. Otherwise, an electric shock or fire may occur.

●Use in gas

Use in and around a place where an inflammable or explosive gas or steam is

generated or stored may result in an explosion and fire. Do not operate the

product in such an environment. Also, use in and around a place where a

corrosive gas is generated or spreading causes a serious damage to the

product. Do not operate the product in such an environment.

●Installation place

Do not insert metal and inflammable materials into the product from its vent

and spill water on it. Otherwise, electric shock or fire may occur.

■Do not let foreign matter in

Do not insert metal and inflammable materials into the product from its vent

and spill water on it. Otherwise, electric shock or fire may occur.

■Warning item on abnormality while in use

If smoke or fire is generated from the product while in use, stop using the

product, turn off the switch, and remove the power cord plug from the outlet.

After confirming that no other devices catch fire, ask us or your local dealer.

IV

USING THE PRODUCT SAFELY

■Input / Output terminals

Maximum input to terminal is specified to prevent the product from being

damaged. Do not supply input, exceeding the specifications that are indicated

in the "Rating" column in the instruction manual of the product. Also, do not

supply power to the output terminals from the outside. Otherwise, a product

failure is caused.

■Calibration

Although the performance and specifications of the product are checked under

strict quality control during shipment from the factory, they may be deviated

more or less by deterioration of parts due to their aging or others.

It is recommended to periodically calibrate the product so that it is used with its

performance and specifications stable. For consultation about the product

calibration, ask us or your local dealer.

■Daily Maintenance

When you clean off the dirt of the product covers, panels, and knobs, avoid

solvents such as thinner and benzene. Otherwise, the paint may peel off or

resin surface may be affected. To wipe off the covers, panels, and knobs, use

a soft cloth with neutral detergent in it.

During cleaning, be careful that water, detergents, or other foreign matters do

not get into the product.

If a liquid or metal gets into the product, an electric shock and fire are caused.

During cleaning, remove the power cord plug from the outlet.

Use the product correctly and safely, observing the above warning and caution

items. Because the instruction manual indicates caution items even in individual

items, observe those caution items to correctly use the product.

If you have questions or comments about the manuals, ask us or E-Mail us.

1

1 GETTING STARTED

This chapter describes the power supply in a nutshell, including its main

features and front / rear panel introduction. After going through the

overview, please read the theory of operation to become familiar with the

operating modes, protection modes and other safety considerations.

1-1. PSW Series Overview

1-1-1. Series lineup

The PSW series consists of 9 models, divided into 3 different model

types covering 3 power capacities: Type I(360W), Type II(720W) and Type

III(1080 W).

Model name

Type

Voltage Rating

Current Rating

Power

PSW-360L30

Type I

0~30V

0~36A

360W

PSW-360L80

Type I

0~80V

0~13.5A

360W

PSW-360M160

Type I

0~160V

0~7.2A

360W

PSW-360M250

Type I

0~250V

0~4.5A

360W

PSW-360H800

Type I

0~800V

0~1.44A

360W

PSW-720L30

Type II

0~30V

0~72A

720W

PSW-720L80

Type II

0~80V

0~27A

720W

PSW-720M160

Type II

0~160V

0~14.4A

720W

PSW-720M250

Type II

0~250V

0~9.0A

720W

PSW-720H800

Type II

0~800V

0~2.88A

720W

PSW-1080L30

Type III

0~30V

0~108A

1080W

PSW-1080L80

Type III

0~80V

0~40.5A

1080W

PSW-1080M160

Type III

0~160V

0~21.6A

1080W

PSW-1080M250

Type III

0~250V

0~13.5A

1080W

PSW-1080H800

Type III

0~800V

0~4.32A

1080W

Apart from the differences in output, each unit differs in size.

The 720 and 1080 watt models are larger than the 360 watt

models to accommodate the increase in power.

360 W model

Type I

720 W model

Type II

1080 W model

Type III

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set Output

PWR DSPLLock/LocalTest

PSW 3 0-3 6 360W

Multi-Range DC Power Supply Voltage

Current

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set Output

PWR DSPLLock/LocalTest

PSW 3 0-7 2 720W

Voltage

Current

Multi-Range DC Power Supply

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set Output

PWR DSPLLock/LocalTest

PSW 3 0-1 08 1080W

Voltage

Current

Multi-Range DC Power Supply

2

1-1-2. Main Features

Performance

・High performance/power.

・Power efficient switching type power supply.

・Low impact on load devices.

・Fast transient recovery time of 1ms.

・Fast output response time.

Features

・OVP, OCP and OTP/OHP protection.

・Adjustable voltage and current slew rates.

・User adjustable bleeder control to quickly dissipate the

power after shutdown to safe levels.

・Extensive remote monitoring and control options.

・Support for serial*and parallel connections.

*(30, 80, 160 volt models only)

・Power on configuration settings.

・Supports test scripts.

・Web server monitoring and control.

Interface

・Ethernet port (Socket/Web)

・Analog connector for analog voltage and current

monitoring

・USB host port and device port

・Option:GP-IB,RS-232C

1-1-3. Accessories

Standard

Accessories

Part number

Description

CD ROM

User manual, Programming manual,

USB Driver, Test Script Data

Power cord

Depends on Regional and Type.

PSW-009

Output terminal cover(30,80,160 volt models)

PSW-011

Output terminal cover(250,800 volt models)

PSW-012

High voltage output terminal

(250,800 volt models)

GTL-123

Test leads:1x red,1x black

(30,80,160 volt models)

GTL-240

USB Cable

PSW-004

Basic Accessory Kit(30,80,160 volt models)

M4 terminal screw and washers x2

M8 terminal bolts,nuts and washers x 2

Air filter x 1

Analog control protection dummy x 1

Analogcontrol lock level x 1

3

PSW-008

Basic Accessory Kit: (250,800 volt models)

Air filter x1

Analog control protection dummy x1

Analog control lock level x1

Option

Part number

Description

GET-001

Extended terminal(30,80,160 volt models)

GET-002

Extended terminal(250,800 volt models)

PSW-001

Accessory Kit:

Pin contact x 10、Socket x 1

Protection cover x 1

(Compatible with OMRON XG5M-2635-N)

PSW-005

Series operation cable for 2 units

(30,80,160 volt models)

PSW-006

Parallel operation cable for 2 units

PSW-007

Parallel operation cable for 3 units

GRA-410-J

Rack mount adapter (JIS)

GRA-410-E

Rack mount adapter (EIA)

GUG-001

GUR-001

GUR-001A

GP-IB to USB adapter

RS-232C to USB adapter

RS-232C to USB adapter

GTL-240

USB cable

GTL-130

Test leads: 1x red, 1x black

(250,800 volt models)

PSW-010

Air filter (Type II/III)

Driver

Name

Description

texio_cdc*.inf

USB driver

4

1-2. Appearance

1-2-1. PSW Front Panel

PSW-720**** (720W:TypeII)

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/ OCP Set Output

PWR DSPLLock/ LocalTest

720W

Voltage

Current

Multi- Range DC Power Supply

Current

knob

Output

key

Power

switch

USB A

port

Display

Cover

panel

Function

keys

Voltage

knob

PSW-1080**** (1080W:TypeIII)

PSW-360****(360W:TypeI)

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set Output

PWR DSPLLock/LocalTest

1080W

Voltage

Current

Multi-Range DC Power Supply

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set Output

PWR DSPLLock/LocalTest

360W

Multi-Range DC Power Supply Voltage

Current

Function keys

The Function keys along with the Output key will light up when a

key is active.

Function

Function

The Function key is used to configure the

power supply.

OVP/OCP

OVP/OCP

Set the over current or over voltage

protection levels.

(Long push)Used to release protection

functions that have been activated.

5

Set

Set

Sets the current and voltage limits.

Test

Test

Used to run customized scripts for testing.

Lock/Local

Lock/Local

Locks or unlocks the panel keys to prevent

accidentally changing panel settings.

PWR DSPL

PWR DSPL

Toggles the display from viewing

V/A →V/W→V/A

Press the Current knob to switch the

display from V/W to W/A.

Display indicators

VSR

Voltage Slew Rate

C V

Constant Voltage Mode

RMT

Remote Control Mode

ALM

Alarm on

DLY

Delay Output

C C

Constant Current Mode

ISR

Current Slew Rate

20

40

60

80

100

% W

Power bar

Indicates the current power output as a

percentage.

Voltage knob

Voltage

Sets the voltage.

Setting can be settled when push the knob.

Current knob

Current

Sets the current.

Setting can be settled when push the knob.

Output

Output

Press to turn on the output. The Output key

will light up when the output is active.

USB

USB A port for data transfer, loading test

scripts etc.

Power Switch

Used to turn the power on/off.

6

1-2-2. Rear Panel

PSW-720M160, PSW-720L80, PSW-720L30 (720W)

Output

terminal(+)

Fan

Output

terminal(-)

LAN AC Input

Sense-

terminal

LAN 100 240V

1000VA MAX.

AC

47 63Hz

SER.NO. LABEL

Analog control

connector

Sense+

terminal

USB B

Port

PSW-1080M160, PSW-1080L80, PSW-1080L30

(1080W)

PSW-360M160,

PSW-360L80,

PSW-360L30 (360W)

100 240VAC 1500VA MAX.

47 63Hz

LAN LN

SER.NO. LABEL

AC Input

LAN

100 240V

47 63Hz 500VA MAX.

AC

7

PSW-720H800, PSW-720M250 (720W)

LAN 100 240V

1000VA MAX.

AC

47 63Hz

SER.NO. LABEL

V SN.C. S V

Output

terminals +V

Fan

Chassis

ground

USB B

port

LAN

AC Input

Sense-

terminal

Analog control

connector

Sense+

terminal

Output

terminals -V

PSW-1080H800, PSW-1080H250,(1080W)

PSW-360H800

PSW-360M250

(360W)

LAN LN

SER.NO. LABEL

47 63Hz 1500VA MAX.

AC 100 240V

V VSN.C. S

AC Input

LAN

100 240V

47 63Hz 500VA MAX.

AC

V S N.C. S V

8

Analog Control

Connector

Standard 26 pin MIL connector

(OMRON XG4C Plug).

The analog control connector is used to

monitor current and voltage output,

machine status (OVP, OCP, OTP/OHP

etc.), and for analog control of the current

and voltage output.

Use an OMRON XG5M socket as the

mating socket.

Output Terminals

(30V,80V,160V)

Positive (+) and negative (-) output terminals.

Chassis ground

Sense (-) and Sense (+) terminals.

Output

Terminals

(250V, 800V)

The 250 and 800 volt models use a 9 pin connector and

a plug for the output and sense terminal connections.

The plug is a MC420-38109Z plug by DECA SwitchLab

Inc. This plug is also available separately

V SN.C. S V

Positive (V+) and negative (V-)

output terminals (3 of each).

V SN.C. S V

Chassis ground

V SN.C. S V

Sense (-S) and Sense (+S)

terminals.

USB B port

The USB B port is used for remote control.

Fans

Temperature controlled fans

Ethernet port

LAN

The ethernet port is used for remote control

and digital monitoring from a PC.

Line Voltage Input

(Type I/TypeII)

Type I: PSW-360L30/L80/M160/M250/H800

Type II: PSW-720L30/L80/M160/M250/H800

・Voltage Input: 100~240 VAC

・Line frequency: 50Hz/60Hz

(automatically switchable)

9

Line Voltage

Input

(Type III)

LN

Type III:PSW-1080L30/L80/M160/M250/H800

・Voltage Input: 100~240 VAC

・Line frequency: 50Hz/60Hz

(automatically switchable)

1-3. Theory of Operation

The theory of operation chapter describes the basic principles of operation,

protection modes and important considerations that must be taken into account

before use.

1-3-1. Operating Area Description

Background

The PSW power supplies are regulated DC power supplies

with a high voltage and current output. These operate in CC or

CV mode within a wide operating range limited only by the

output power.

The operating area of each power supply is determined by the

rated output power as well as the voltage and current rating.

For example the operating area and rated power output for the

PSW-360L30 is shown below.

Voltage

Current

30

360W Rated power

10

12 36

PSW-360L30 Operationg Area

When the power supply is configured so that the total output

(current x voltage output) is less than the rated power output,

the power supply functions as a typical constant current,

constant voltage power supply. If however, the power

supply is configured such that the total output (current x

voltage output) exceeds the rated power output, the effective

output is actually limited to the power limit of the unit. In this

case the output current and voltage then depend purely on the

load value.

10

PSW 30V Series Operating Area

0

5

10

15

20

25

30

020406080100

Volt…

Cur…

Po…

0

5

30

Current(A)

Voltage(V)

10

15

20

25

0 20 40 60 80 100

10

12 24 36

30

35

120

Type III

Type II

Type I

72 108

PSW 80V Series Operating Area

0

5

10

15

20

25

30

020406080100

Volt…

Cur…

Po…

Current(A)

Voltage(V)

26.6

4.5 9.0 13.5

80

Type III

Type II

Type I

30 45

40205 10 15 25

035

0

20

40

60

80

90 27 40.5

PSW 160V Series Operating Area

0

5

10

15

20

25

30

020406080100

Volt…

Cur…

Po…

0

20

160

Current(A)

Voltage(V)

40

60

80

140

0510 15 20

180

25

Type III

Type II

Type I

100

120

2.25 4.5 6.75

160

50

14.4 21.67.2

11

PSW 250V Series Operating Area

0

5

10

15

20

25

30

020406080100

Volt…

Cur…

Po…

Current (A)

Voltage (V)

036912 15

Type III

Type II

Type I

1.44 2.88 4.32

250

80

9 13.54.5

250

200

150

100

50

0

PSW 800V Series Operating Area

0

5

10

15

20

25

30

020406080100

Volt…

Cur…

Po…

0

100

800

Current (A)

Voltage (V)

200

300

400

700

01234

900

5

Type III

Type II

Type I

500

600

0.45 0.9 1.35

800

250

2.88 4.321.44

1-3-2. CC and CV Mode

CC and CV mode

Description

When the power supply is operating in constant current

mode (CC) a constant current will be supplied to the load.

When in constant current mode the voltage output can

vary, whilst the current remains constant. When the load

resistance increases to the point where the current limit

(ISET) can no longer be sustained the power supply

switches to CV mode. The point where the power supply

switches modes is the crossover point.

When the power supply is operating in CV mode, a

constant voltage will be supplied to the load, whilst the

current will vary as the load varies. At the point that the

load resistance is too low to maintain a constant voltage,

the power supply will switch to CC mode and maintain the

set current limit.

The conditions that determine whether the power supply

operates in CC or CV mode depends on the set current

(ISET), the set voltage(VSET), the load resistance (RL) and

Other manuals for PSW Series

1

This manual suits for next models

15

Table of contents

Other TEXIO Power Supply manuals

TEXIO

TEXIO PU6-200 User manual

TEXIO

TEXIO PR-A Series User manual

TEXIO

TEXIO PFR-100 SERIES Owner's manual

TEXIO

TEXIO PA10-5B User manual

TEXIO

TEXIO PFR-100M250 Manual

TEXIO

TEXIO PBW Series User manual

TEXIO

TEXIO PW8-3AQP User manual

TEXIO

TEXIO PSF-1200L User manual

TEXIO

TEXIO PDS20-10A User manual

TEXIO

TEXIO PPX Series Owner's manual