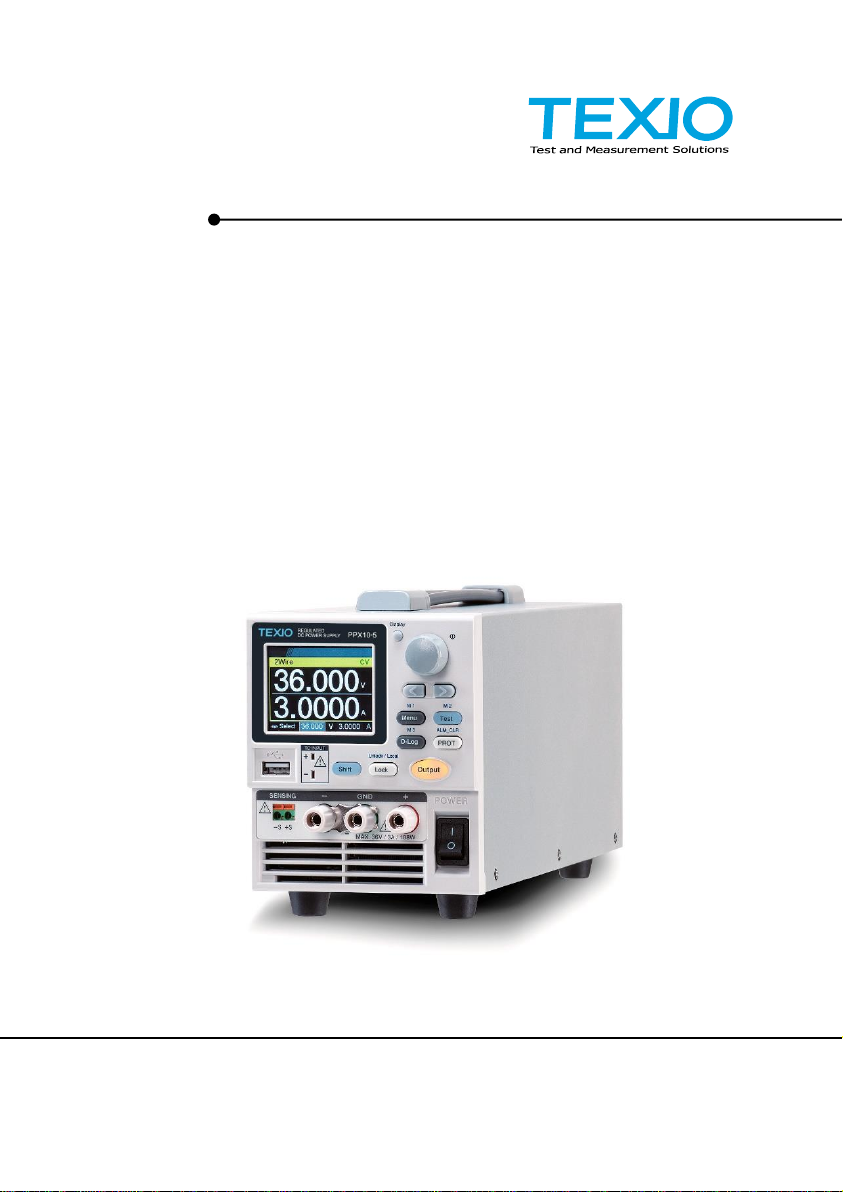

TEXIO PPX Series Owner's manual

Other TEXIO Power Supply manuals

TEXIO

TEXIO PW8-3AQP User manual

TEXIO

TEXIO PAR-A Series User manual

TEXIO

TEXIO PSF-400H User manual

TEXIO

TEXIO PBW Series User manual

TEXIO

TEXIO PDS20-10A User manual

TEXIO

TEXIO PSF-1200L User manual

TEXIO

TEXIO PA10-5B User manual

TEXIO

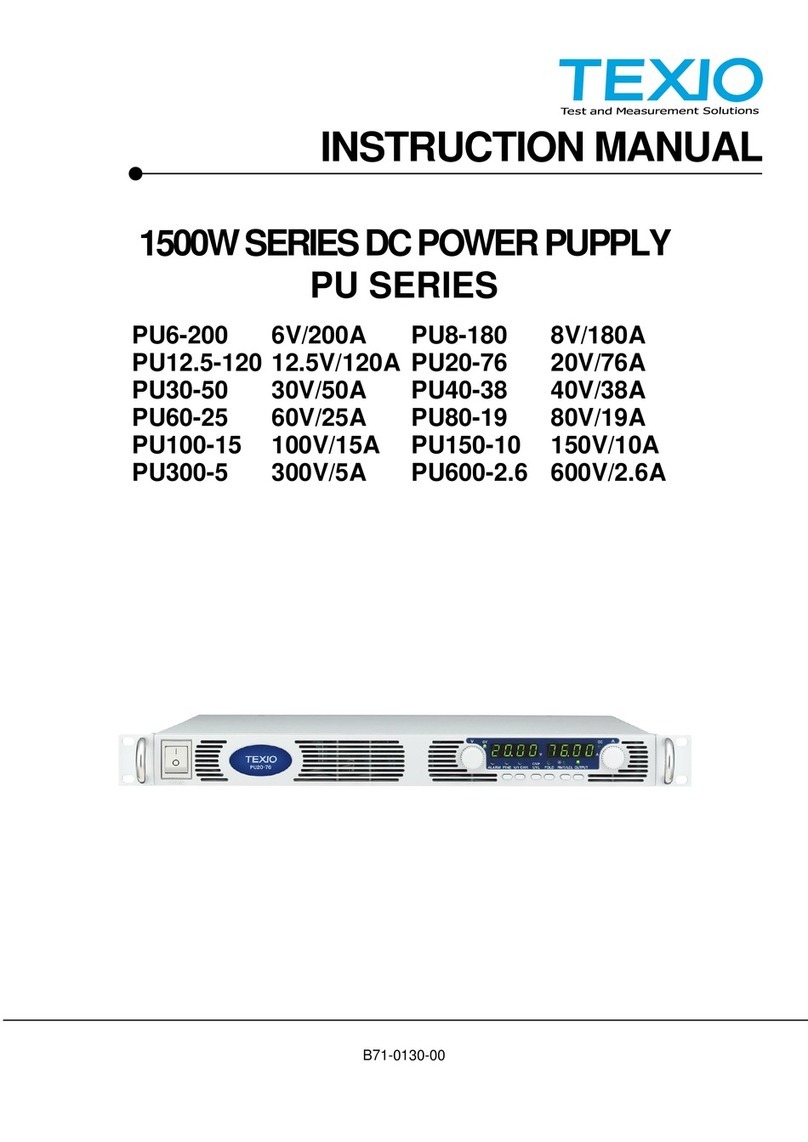

TEXIO PU6-200 User manual

TEXIO

TEXIO PU Series User manual

TEXIO

TEXIO PU6-100 User manual

Popular Power Supply manuals by other brands

Videx

Videx 520MR Installation instruction

Poppstar

Poppstar 1008821 Instructions for use

TDK-Lambda

TDK-Lambda LZS-A1000-3 Installation, operation and maintenance manual

TDK-Lambda

TDK-Lambda 500A instruction manual

Calira

Calira EVS 17/07-DS/IU operating instructions

Monacor

Monacor PS-12CCD instruction manual