TEXIO PR-A Series User manual

INSTRUCTION MANUAL

REGULATED DC POWER SUPPLY

PR-A SERIES

PR18-1.2A

PR18-3A

PR18-5A

PR36-3A

B71-0040-01

■About Brands and Trademarks

“TEXIO”is the product brand name of our industrial electronic devices.

All company names and product names mentioned in this manual are the

trademark or the registered trademark of each company or group in each country

and region.

■About the Instruction Manual

Permission from the copyright holder is needed to reprint the contents of this

manual, in whole or in part. Be aware that the product specifications and the

contents of this manual are subject to change for the purpose of improvement.

CONTENTS

SAFETY ································································· Ⅰ-Ⅳ

1. OUTLINE ....................................................................................1

2. FEATURES .................................................................................1

3. SPECIFICATION.........................................................................2

4. PERCAUTION FOR USE............................................................ 4

5. EXPLANATION OF PANELS......................................................5

5-1. Front panel....................................................................................................6

5-2. Rear panel.....................................................................................................7

6. OPERATION PROCEDURES .....................................................8

6-1. Stand-alone operation...................................................................................8

6-2. Serial connection...........................................................................................8

6-3. Parallel operation (master-slave control).......................................................9

7. TROUBLESHOOTING...............................................................11

Note.

This instruction manual is described for four models.

(PR18-1.2A,PR18-3A,PR18-5A,PR36-A)

Refer to item applied to your product.

I

USING THE PRODUCT SAFELY

■Preface

To use the product safely, read instruction manual to the end. Before using this

product, understand how to correctly use it. If you read the manuals but you do

not understand how to use it, ask us or your local dealer. After you read the

manuals, save it so that you can read it anytime as required.

■Pictorial indication

The manuals and product show the warning and caution items required to safely

use the product. The following pictorial indication is provided.

Pictorial

indication

Some part of this product or the manuals may show this

pictorial indication. In this case, if the product is

incorrectly used in that part, a serious danger may be

brought about on the user's body or the product. To use

the part with this pictorial indication, be sure to refer to the

manuals.

WARNING

!

If you use the product, ignoring this indication, you may get

killed or seriously injured. This indication shows that the

warning item to avoid the danger is provided.

CAUTION

!

If you incorrectly use the product, ignoring this indication,

you may get slightly injured or the product may be

damaged. This indication shows that the caution item to

avoid the danger is provided.

Please be informed that we are not responsible for any damages to the user or to

the third person, arising from malfunctions or other failures due to wrong use of

the product or incorrect operation, except such responsibility for damages as

required by law.

II

USING THE PRODUCT SAFELY

WARNING

!

CAUTION

!

■Do not remove the product's covers and panels

Never remove the product's covers and panels for any purpose.

Otherwise, the user's electric shock or fire may be incurred.

■Warning on using the product

Warning items given below are to avoid danger to user's body and life and avoid

the damage or deterioration of the product. Use the product, observing the

following warning and caution items.

■Warning items on power supply

●Power supply voltage

The rated power supply voltages of the product are 100, 120, 220 and 240VAC.

The rated power supply voltage for each product should be confirmed by

reading the label attached on the back of the product or by the “rated”column

shown in the instruction manual. The specification of power cord attached to

the products is rated to 125VAC for all products which are designed to be used

in the areas where commercial power supply voltage is not higher than

125VAC. Accordingly, you must change the power cord if you want to use the

product at the power supply voltage higher than 125VAC. If you use the

product without changing power cord to 250VAC rated one, electric shock or

fire may be caused. When you used the product equipped with power supply

voltage switching system, please refer to the corresponding chapter in the

instruction manuals of each product.

●Power cord

(IMPORTANT) The attached power cord set can be used for this

device only.

If the attached power cord is damaged, stop using the product and call us or

your local dealer. If the power cord is used without the damage being

removed, an electric shock or fire may be caused.

●Protective fuse

If an input protective fuse is blown, the product does not operate. For a

product with external fuse holder, the fuse may be replaced. As for how to

replace the fuse, refer to the corresponding chapter in the instruction manual.

If no fuse replacement procedures are indicated, the user is not permitted to

replace it. In such case, keep the case closed and consult us or your local

dealer. If the fuse is incorrectly replaced, a fire may occur.

III

USING THE PRODUCT SAFELY

■Warning item on Grounding

If the product has the GND terminal on the front or rear panel surface, be sure to

ground the product to safely use it.

■Warnings on Installation environment

●Operating temperature and humidity

Use the product within the operating temperature indicated in the “rating”

temperature column. If the product is used with the vents of the product

blocked or in high ambient temperatures, a fire may occur. Use the product

within the operating humidity indicated in the “rating” humidity column. Watch

out for condensation by a sharp humidity change such as transfer to a room

with a different humidity. Also, do not operate the product with wet hands.

Otherwise, an electric shock or fire may occur.

●Use in gas

Use in and around a place where an inflammable or explosive gas or steam is

generated or stored may result in an explosion and fire. Do not operate the

product in such an environment. Also, use in and around a place where a

corrosive gas is generated or spreading causes a serious damage to the

product. Do not operate the product in such an environment.

●Installation place

Do not insert metal and inflammable materials into the product from its vent

and spill water on it. Otherwise, electric shock or fire may occur.

■Do not let foreign matter in

Do not insert metal and inflammable materials into the product from its vent and

spill water on it. Otherwise, electric shock or fire may occur.

■Warning item on abnormality while in use

If smoke or fire is generated from the product while in use, stop using the

product, turn off the switch, and remove the power cord plug from the outlet.

After confirming that no other devices catch fire, ask us or your local dealer.

IV

USING THE PRODUCT SAFELY

■Input / Output terminals

Maximum input to terminal is specified to prevent the product from being

damaged. Do not supply input, exceeding the specifications that are indicated

in the "Rating" column in the instruction manual of the product. Also, do not

supply power to the output terminals from the outside. Otherwise, a product

failure is caused.

■Calibration

Although the performance and specifications of the product are checked under

strict quality control during shipment from the factory, they may be deviated more

or less by deterioration of parts due to their aging or others.

It is recommended to periodically calibrate the product so that it is used with its

performance and specifications stable. For consultation about the product

calibration, ask us or your local dealer.

■Daily Maintenance

When you clean off the dirt of the product covers, panels, and knobs, avoid

solvents such as thinner and benzene. Otherwise, the paint may peel off or

resin surface may be affected. To wipe off the covers, panels, and knobs, use a

soft cloth with neutral detergent in it.

During cleaning, be careful that water, detergents, or other foreign matters do not

get into the product.

If a liquid or metal gets into the product, an electric shock and fire are caused.

During cleaning, remove the power cord plug from the outlet.

Use the product correctly and safely, observing the above warning and caution items.

Because the instruction manual indicates caution items even in individual items,

observe those caution items to correctly use the product.

If you have questions or comments about the manuals, ask us or E-Mail us.

1

1. OUTLINE

The PR-A Series is a serial control type regulated DC power supply. It is a constant

voltage/current power supply whose output can be varied from 0 up to the rated

values.

It is a compact unit which, provided with both voltage and current calibrated meters,

allows both voltage and current to be monitored simultaneously. In terms of

operability, the unit enables high precision, continues variability via coarse and fine

adjust knobs.

We are confident that the unit’s design conceived with the user’s convenience in

mind to enable advantages such as arrangement in easy-to-use configurations and

its reliability will satisfy your needs very well.

With the PR-A Series, multiple units of the same model can be connected in parallel

to set up a “one- control”master/slave configuration having increased current output.

2. FEATURES

○The PR-A Series is a constant voltage/current supply which features extremely

low voltage and load fluctuation and ripple noise.

○Controls the output on and off by using output switch.

○The unit features separate voltage and current meters so that both voltage and

current can be monitored simultaneously.

○Output voltage and current can be adjusted continuously to any desired values.

Furthermore, the voltage can be preset easily and precisely using coarse and

fine adjust knobs.

○The constant current circuit operators to protect against overload and output

shorting. The limiting current can be preset from 0 up to the rated current, and

the unit can also be used as a constant current supply.

○The units enables “one-control”operation via connection in series, or via parallel

connection in a master/slave configuration.

○Using an optional rack-mounting adapter (RK-604), the PR Series can be

installed on a EIA or JIS rack.

2

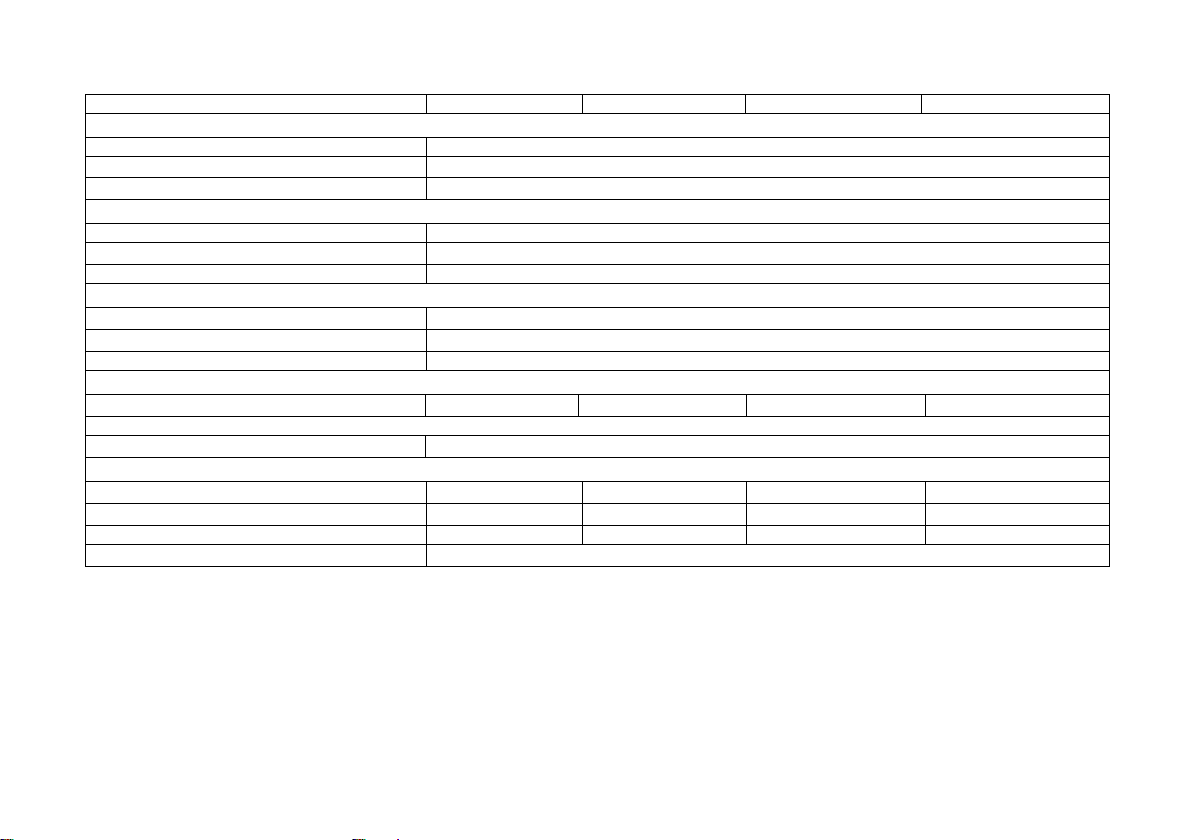

3. SPECIFICATION

Item

PR18-1.2A

PR18-3A

PR18-5A

PR36-3A

Output Voltage

(continuously variable、coarse and fine adjusts)

0V to 18V

0V to 36V

Output current(continuously variable)

0A to 1.2A

0A to 3A

0A to 5A

0A to 3A

Constant voltage characteristics

Input fluctuation ( for surge of AC±100%)

0.01%+2mV(3.8mV)

0.01%+2mV(5.6mV)

Load fluctuation(for surge of 0% to 100%)

0.01%+2mV(3.8mV)

0.01%+3mV(4.8mV)

0.01%+2mV(5.6mV)

Ripple noise、rms(10Hz to 1MHz)※1

0.5mV rms

Ripple peak(peak-to-peak)※1

2mVp-p

Transient response

(Output current 5% to 100%)

100μs Typical

Temperature coefficient

150ppm/℃Typical

Constant current characteristics

Input fluctuation (for surge of AC±100%)

2mA

Load fluctuation(for surge of 0% to 100%)

15mA

Ripple noise、rms(10Hz to 1MHz)※1

2.4mArms

6.0mArms

10mArms

6.0mArms

Ripple peak(peak-to-peak)※1

3.6mAp-p

12mAp-p

15mAp-p

12mAp-p

Temperature coefficient

500ppm/℃Typical

Instrumentation

Voltmeter(2.5-level-F.S.)

18V

36V

Ammeter(2.5-level-F.S.)

1.2A

3A

5A

3A

Constant-voltage operation indicator

Green CV LED goes on

Constant-current operation indicator

Red CC LED goes on

3

Item

PR18-1.2A

PR18-3A

PR18-5A

PR36-3A

Function

OUTPUT ON / OFF switching

Turn the output on and off.

Serial connection (independent control mode)

Can be connected in series (within limits of ground proof voltage.)

Parallel operation (master-slave mode)

Can be operated in “one‐control” parallel configuration (only with other machines of same model)

OUTPUT

Polarity

Positive or negative ground possible

Output terminal (color)

+(red)、-(white)、GND(black)

Ground proof voltage

±250VDC

Operating conditions

Operating Temperature/Humidity Range

0 ℃to 40 ℃、10% to 85%R.H.

Storage Temperature/Humidity Range

-20 ℃to 60 ℃、10% to 85%R.H.

Cooling mechanism

Natural convection

Power consumption

VA / W (For rated load of AC 100V)

Approx. 60VA/45W

Approx.125VA/100W

Approx. 200VA/165W

Approx. 225VA/170W

Input Voltage

Voltage、Frequency

AC100V/120V/200V/220V/240V ±10%、50Hz/60Hz

Dimensions and weight

Dimensions mm (hight×width×depth)

147×104×180

147×104×215

147×138×230

147×138×230

Max. Dimensions mm (hight×width×depth)

161×108×200

167×108×265

167×142×290

167×142×290

Weight

Approx. 3.8kg

Approx. 5.7kg

Approx. 8.1kg

Approx. 8.6kg

Accessory items

CD-ROM(Instruction manual)

※1 Measured with positive or negative grounded

Circuit and ratings subject to change without notice due to development in technology.

4

4. PERCAUTION FOR USE

WARNING

!

1) Confirming the supply voltage

*Use this unit within the specified range. The unit’s rated voltage is single-phase

100/120/200/220/240VAC ±10% at 50/60Hz.

*The rated voltage is indicated on the specification and name plate located

beside the input connector on the rear panel.

2) Do not remove cover or panel

The user never open the case panel whatever may happen.

If the user needs to open case for replacing the fuse, changing the source voltage

or repairing the internal circuit or parts, please contact your dealer or our

distributor.

CAUTION

!

1) Precautions for connection of output terminals.

*This units is a floating type power supply. For ordinary use, be sure that the

MASTER/SLAVE switch on the rear panel is set to MASTER, and that either the

(+) output terminal or the (-) output terminal is connected to the GND terminal

(case GND) via the shorting bar.

2) Output current value setting

*To set the constant current value, short-circuit output terminal (+) and (-) and

deliver the output current

3) Set-up environment

*Be sure to use this unit within the specified ambient temperature range of 0 to

40 ℃.

*Because the unit is cooled by natural convection, do not place objects on top,

place the unit on or near any heat-emitting device, or use multiple units in any

stacked configuration. Also use the unit in an environment that is as well

cross-ventilated as possible.

5

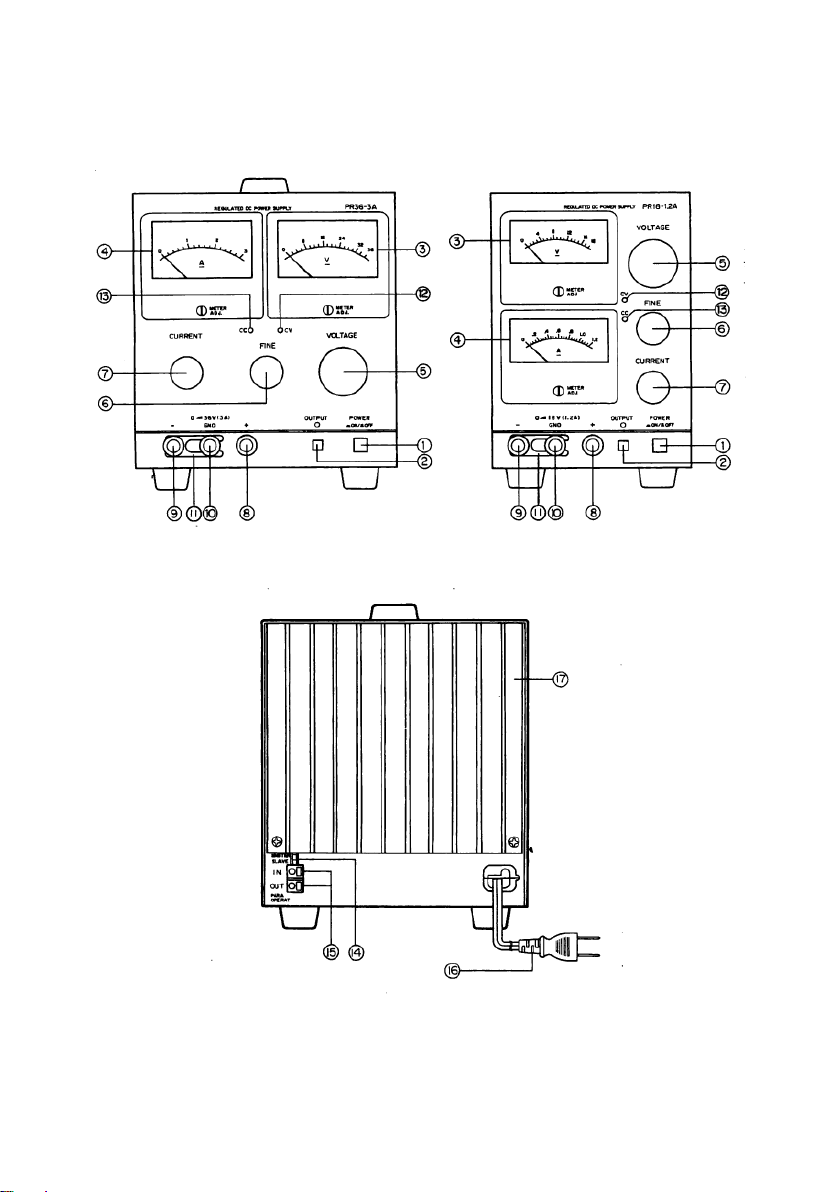

5. EXPLANATION OF PANELS

Figure1.

Figure2.

6

5-1. Front panel

①POWER ON/OFF

The power switch. The power supply should be on and operating when this switch

is depressed.

②OUTPUT switch

Turns the output on and off.

When the output is turned on, the OUTPUT LED goes on.

③Voltmeter

ADC voltmeter that indicates the output voltage.

④Ammeter

ADC ammeter that indicates the output current.

⑤VOLTAGE COARSE

Coarse adjust knob for the output voltage.

⑥VOLTAGE FINE

Fine adjust knob for the output voltage.

⑦CURRENT

Knob for setting the current value in the constant current mode. It can be used to

set limiting value for the output current.

⑧Output terminal (+)

Terminal for tapping of (+) output voltages.

⑨Output terminal (-)

Terminal for tapping of (-) output voltage.

⑩GND terminal

The ground terminal, it is connected to the main chassis. Normally, this terminal

for connected to either the (+) or (-) terminal with short bar.

⑪Short bar

Normal use, this bar connects between GND and output(+) or output (-) terminal.

⑫CV LED(Green)

The LED keeps lighting in process of constant- voltage operation.

⑬CC LED(Red)

The LED keeps lighting in process of constant-current operation.

7

5-2. Rear panel

⑭MASTER/SLAVE switch

Used during “one-control”parallel operation in the master/slave configuration.

During normal operation, the switch should be set to MASTER. (For details, see

section 6-3;“Parallel Operation”)

⑮IN/OUT terminals for parallel operation

Control terminals for use in the “one-control”parallel operation mode.

⑯Power cable

Approx. 2 meter-long power cable, equipped with standard wall plug.

⑰Heat sink

A heat dissipater for the transistors, be careful as this area can became quite hot

during operation.

8

6. OPERATION PROCEDURES

6-1. Stand-alone operation

*When using the power supply in stand-alone, simply operate by manipulation of

the panel switches as needed. However , be sure that the MASTER/SLAVE switch

is set to MASTER.

6-2. Serial connection

*Two or more units of the power supply can be hooked up in series to achieve in

increase in output voltage. The final output will be the sum of the outputs of the

individual units. In this situation, however, care must be taken that the voltage of

neither of the terminals with respect to the chassis GND exceeds the ground proof

voltage.

*In the case of serial operation of two units (both same model);

a. For connection as in Fig. 4, the output voltage, but output current will be limited

to within the value specified for a single unit.

b. For connection as in Fig. 5, where an intermediate point is hooked up to ground,

the configuration can be used as a plus/minus power supply.

GND

+

-

E1

GND

+

-

E2

+

-

E0

E0E1

=+E2

Connection of GND

For positive ground(dotted line)

For Negative ground(solid line)

LOAD

GND

+

-

E1

GND

+

-

E2

+

-

+E 1

-E 2

Intermediate point is

hooked up to ground.

LOADLOAD

Figure3. Figure4.

9

6-3. Parallel operation (master-slave control)

*Two or more units of the same machine can be hooked up in parallel to give an

increase in output current. The total output current will be the sum of the output

currents of the individual machines.

*In parallel operation, one machine will act as the master and all others will act

slaves. The output voltages and output currents are all set from the master

machine.

*When hooking the machines up in parallel, be sure that all the power ON/OFF

switches are OFF.

HOOK-UP PROCEDURE;

1)Turn the power switches of the master unit and slave unit(s) all to “OFF”.

2)Turn the MASTER/SLAVE switch (located on the back panel) on all the slave units

from “MASTER” to “SLAVE”.

3)Hook up the parallel operation-use terminals (IN/OUT, located on the rear panel) of

the master and slave(s) as shown in Figure 5.

4)For connecting the output terminals of each of the machines to the load, use all

cords of the same length.

5)For (+) and (-) grounding to the GND terminal, hook up the master and slave

machines via the terminals on the panels.

Figure 7 shows the output connection scheme for (-) grounding.

6)Set the voltage and current knobs of all the slave unit(s) it the maximum setting.

7)Turn the power switches of the master unit and slave unit(s) all to “ON”. Control

the output voltage and current as desired via the voltage and current knobs on

master unit.

*When the output goes to 0 amperes in the parallel operation mode, output voltage

can no longer be controlled by the master machine. Be sure to keep a current

flowing that is several % of the rated current.

Hook-up of rear panel terminals in the parallel operation mode

MASTER

MASTER

SLAVE

IN

OUT

SLAVE(1)

MASTER

SLAVE

IN

OUT

SLAVE(2)

MASTER

SLAVE

IN

OUT

Figure5.

10

Hook-up front panel terminals in the parallel operation modes.

- +

G

- +

G- +

G

I2

I3

I1

+

-

I0

MASTER SLAVE(1) SLAVE(2)

LOAD

Note ; I0= I1+ I2+ I3

The voltage presets on all the slave machines are set to maximum. The master

operates in constant voltage mode and the slaves operate in constant current

mode. Figure 6.

For instruction on how to achieve parallel operation of multiple machines of different

models, please contact your dealer or our distributer.

*Connection of Terminal on Rear Panel

While pressing on the slit portion of the terminal with an ordinary (-) screwdriver,

insert the connecting cable into the round jack. When insertion is complete,

remove the screwdriver.

The cable will remain locked into the terminal even after the screwdriver is

removed.

Insert the

connecting cable

Push with (-) screwdriver

10mm

φ0.4~1.0 (AWG26~18), 0.3~0.75m ㎡

Figure7.

Note : When using stranded (twisted) cable, the connector should be attached by

soldering.

11

7. TROUBLESHOOTING

Problem

Indicators orAreas to check

Cause

Power supply will

not go on.

Power ON lamp does not light

up.

*Poor connection of

power cord, or broken

wire.

*Bad power switch.

*Fuse meltdown.

No output voltage.

Voltmeter does not move.

*Circuit malfunction.

No output current.

Ammeter does not move.

*Circuit malfunction.

Excessively large

output.

Output voltmeter and ammeter

readings do not decrease.

*Bad power transistor or

control mechanism.

*Circuit malfunction.

Unstable output.

Input voltage is wrong.

Machine is vibrating.

Strong magnetic or electrical

field nearby.

*Operating outside the

rated voltage range.

*Oscillations due to

special load type.

*Remove from source of

oscillations.

WARNING

!

The user never open the case panel whatever may happen.

If the user needs to open the case for replacing the fuse, changing the source

voltage or repairing the internal circuit or parts, please contact your dealer or our

distributor.

7F Towa Fudosan Shin Yokohama Bldg.

2-18-13, Shin Yokohama, Kohoku-ku,Yokohama, Kanagawa, 222-0033 Japan

http://www.texio.co.jp/

This manual suits for next models

4

Table of contents

Other TEXIO Power Supply manuals

TEXIO

TEXIO PDS20-10A User manual

TEXIO

TEXIO PS-A Series User manual

TEXIO

TEXIO PFR-100M250 Manual

TEXIO

TEXIO PSW Series User manual

TEXIO

TEXIO PU6-100 User manual

TEXIO

TEXIO PAR-A Series User manual

TEXIO

TEXIO PU Series User manual

TEXIO

TEXIO PU6-200 User manual

TEXIO

TEXIO PD18-10AD User manual

TEXIO

TEXIO PU6-200 User manual