Texmate, Inc. Tel. (760) 598-9899 • www.texmate.comPage 10 DL-40PSF-DCA _ DL-40PSF-DCV manual (d0083)

Ordering Information

BASIC MODEL #

DISPLAY POWER SUPPLY INPUT MODULES ANALOG OUTPUT RELAY OUTPUT OPTIONS / ACCESSORIES

OA____

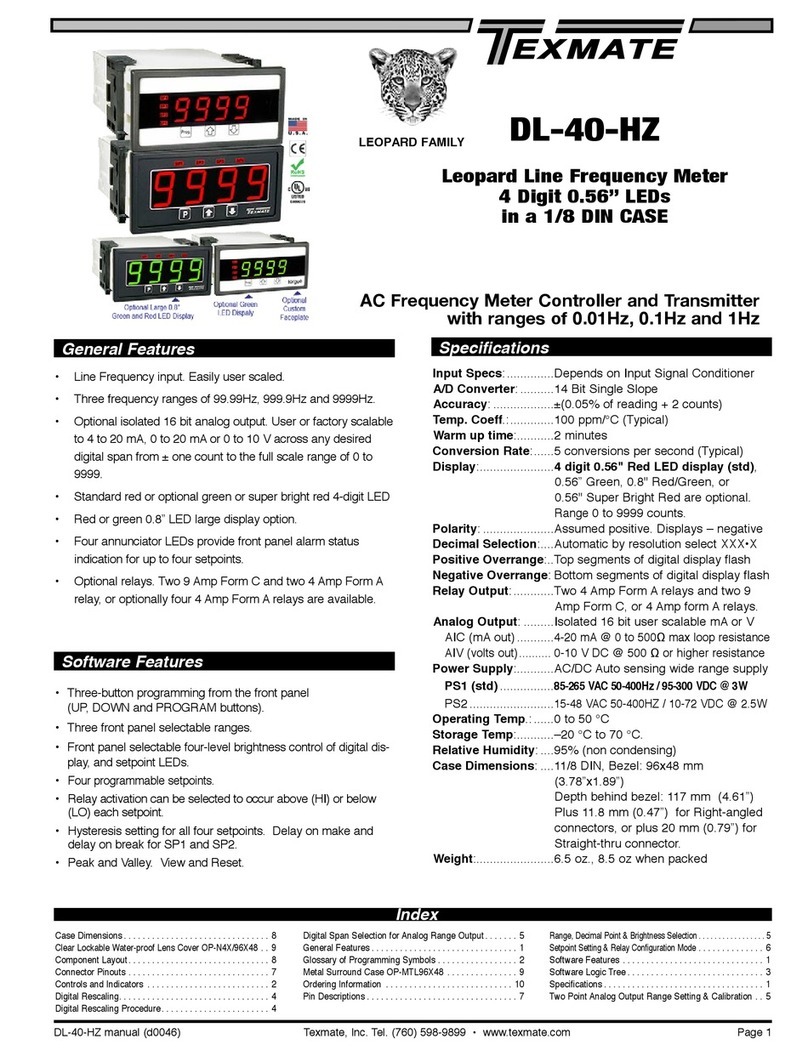

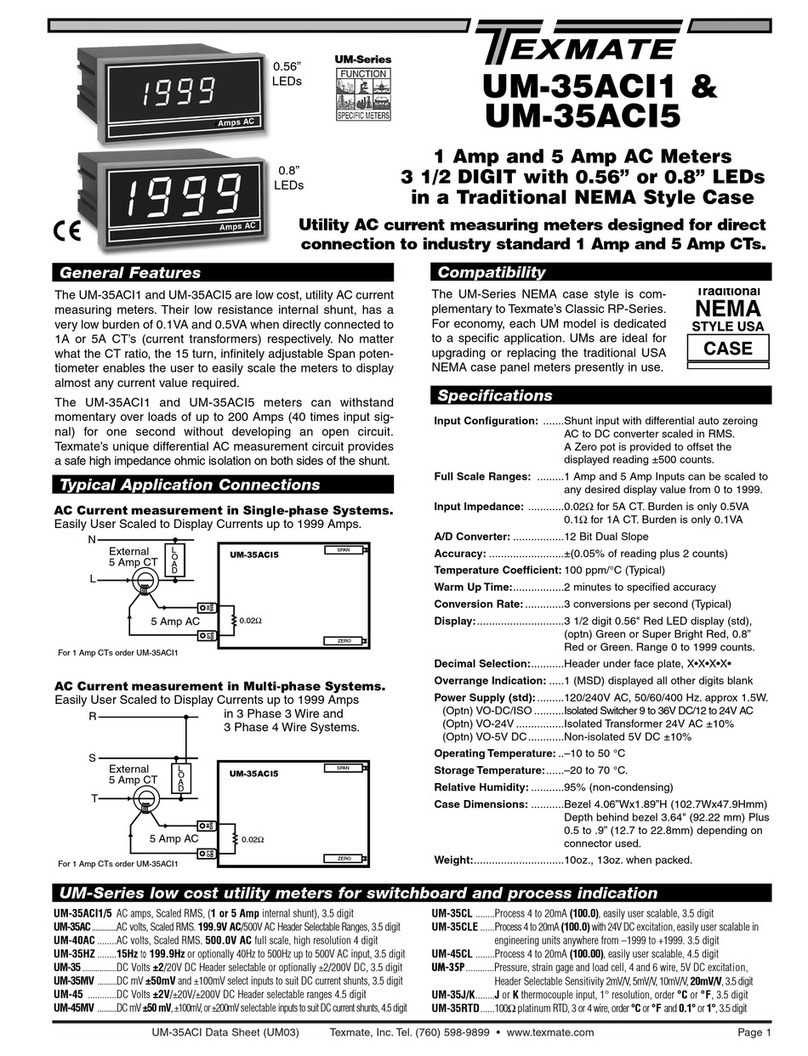

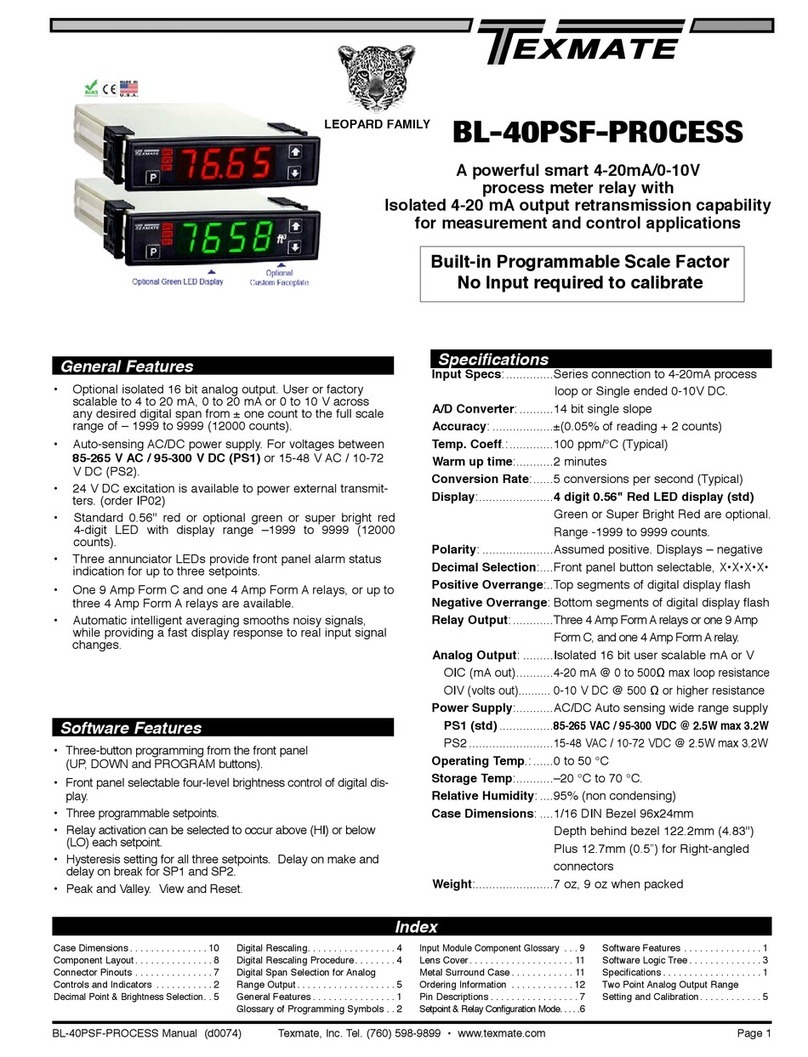

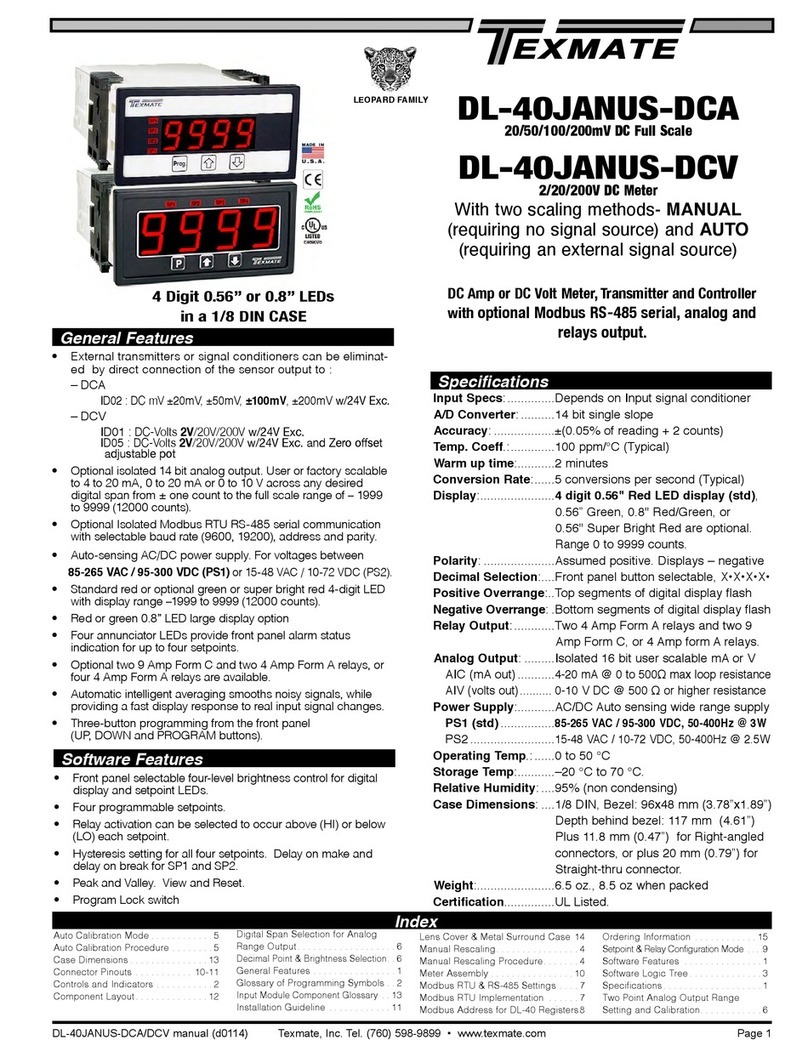

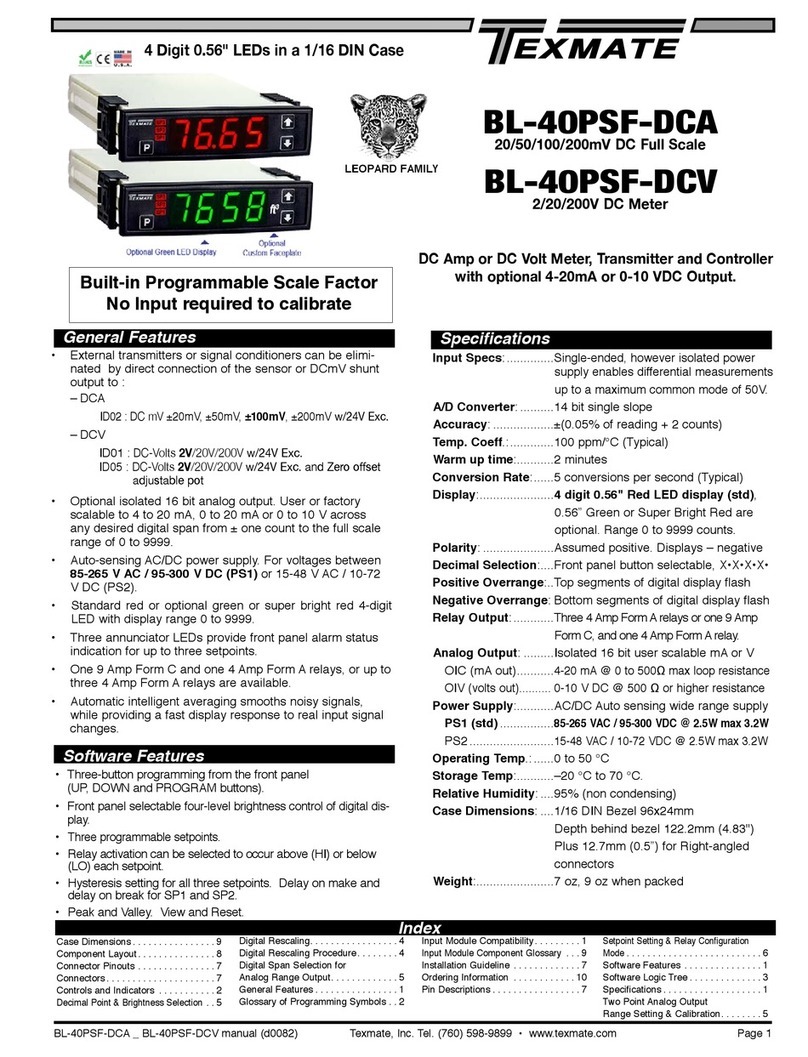

DL-40PSF-DCA

Add to the basic model number the order code suffix for each standard option required. The last suffix is to

indicate how many different special options and or accessories that you may require to be included with this product.

Ordering Example: DL-40PSF-DCA-DR-PS1-ID01-0IC-R1-OA2, the 2 OA’s are, ZR and a OP-MTL96X8

BASIC MODEL NUMBER

DL-40PSF-DCA

96x48mm, Leopard, 4 Digit, DC Amps

.............. $110

DL-40PSF-DCV

96x48mm, Leopard, 4 Digit, DC Volts

............... $110

Standard Options for this Model Number

Order Code Suffix Description List

DISPLAY

DR......Red LED, 0.56 inch high .........................................N/C

DB���� Super–bright Red LED, 0.56 inch high�����������������������$25

DG ��� Green LED, 0.56 inch high��������������������������������$10

LG���� Large Green LED, 0.8 inch high����������������������������$45

LR���� Large Red LED, 0.8 inch high �����������������������������$35

POWER SUPPLY

PS1 ....85 - 265VAC / 95 - 300VDC ..................................... N/C

PS2 ...18 - 48VAC / 10 - 72VDC ...............................$35

INPUT MODULES (Partial List. See www.texmate.com)

Unless otherwise specified Texmate will ship all modules precalibrated

with factory preselected ranges and/or scalings as shown in BOLD type.

For DL-40PSF-DCA

ID02 ..

DC mV ±20mV, ±50mV, ±100mV, ±200mV

w/24V Exc.

....... $40

For DL-40PSF-DCV

ID01 ..

DC Volts, 2V/20V/200V w/24V Exc.

....................... $35

ID05 ..

DC Volts, 2V/20V/200V w/24V Exc. w/zero offset adjustable pot

. $55

ANALOG OUTPUT

AIC � � � Isolated 16 Bit Current Output, 0-20mA and 4-20mA, pls� specify �$35

AIV ��� Isolated 16 Bit Voltage Output, 0-10VDC ��������������������$35

RELAY OUTPUT

Note: R1 and R2 are located on the main board, and are generally used when

only two Form A Relays or less are required and an Analogy Output is not

required�

R1���� Single 4A Form A Relay ����������������������������������$30

R2���� Dual 4A Form A Relays ����������������������������������$55

RELAY OUTPUT MODULES

Note: If a meter is ordered with a Relay Output Module, but without Analog

Output, an Output Module Carrier Board should be automatically added to the

order�

OR11 ��One 9 Amp Form C Relay, Isolated �������������������������$30

OR15 ��One 9 Amp Form C and Two 4 Amps Form A Relays �����������$75

OR16 ��One 9 Amp Form C and One 4 Amp Form A Relays������������$55

OR12 ��Two 9 Amp Form C Relays, Isolated ������������������������$60

OR14 ��Two 9 Amp Form C and Two 4 Amps Form A Relays �����������$105

OR23 ��Two 9 Amp Form C and One 4 Amp Form A Relay, Isolated �����$85

OR31 ��One 4 Amp Form A Relay, Isolated �������������������������$25

OR32 ��Two 4 Amp Form A Relays, Isolated ������������������������$50

OR33 ��Three 4 Amp Form A Relays, Isolated �����������������������$70

OR34 ��Four 4 Amp Form A Relays, Isolated ������������������������$90

Solid State Relay (SSR) Output Modules DC Only

OR54 ��Four 400V DC Solid State Relays (SSR) 210mA ��������������$90

Special Options and Accessories (OA’s)

Part Number Description List

SPECIAL OPTIONS (Specify Inputs or Outputs & Req. Reading)

Output Module Carrier Board

*One carrier board must be ordered with any meter that includes any one or

more of the following options: Analog Output and/or Relay Output Modules�

SA-DL/OM-CB ���Output Module Carrier Board, DL series ������������� $7

ZR ����������

Range Change from Standard Range shown in BOLD type

$7

ZS ���������� Custom display scaling within standard ranges ���$12

ZS-AO ������� Custom scaling of analog output ���������������������� $15

ACCESSORIES

75-DBBZ9648F����Black Bezel for 96x48mm Case������������������� $2

75-DMTCLIPF ����Side Slide Brackets (2 pc) - extra set, extra strength �� $2

75-DTP2X9624����Panel cutout metal trim plate 96x48mm ������������ $10

76-DL40G-N4 �����"Touch" Green LED Faceplate, NEMA 4, Factory install $8

76-DL40LG-N4 ����"Touch" Large Green LED Faceplate, NEMA 4, Factory install $8

76-DL40LR-N4 ����

"Touch" Large Red LED Faceplate, NEMA 4, Factory install

$8

76-DL40R-N4 �����"Touch" Red LED Faceplate, NEMA 4, Factory install�� $8

ART-FS-S/D ������NRC for artwork & set-up Faceplate/Desc����������� $35

ART-FS-001 ������Install Custom Faceplate per meter - 1 color��������� $10

OP-MTLCLIP �����Screw Mounting Clips (2 pc) - to screw tighten slide brackets $6

OP-MTL96X48 � � � �Metal Surround Case, includes screw mounting clips �� $16

OP-N4X/96X48����96x48mm clear lockable front cover–NEMA 4X, splash proof $20

OP-PMA/SWBD ���Switch Board Panel Mounting Adapter ������������� $35

Prices subject to change without notice.

Many other options and accessories are available. See full price list for more details.

Prices subject to change without notice.

WARRANTY

Texmate warrants that its products are free from defects in material and workmanship under

normal use and service for a period of one year from date of shipment. Texmate’s obligations

under this warranty are limited to replacement or repair, at its option, at its factory, of any of

the products which shall, within the applicable period after shipment, be returned to Texmate’s

facility, transportation charges pre-paid, and which are, after examination, disclosed to the sat-

isfaction of Texmate to be thus defective� The warranty shall not apply to any equipment which

shall have been repaired or altered, except by Texmate, or which shall have been subjected

to misuse, negligence, or accident. In no case shall Texmate’s liability exceed the original pur-

chase price� The aforementioned provisions do not extend the original warranty period of any

product which has been either repaired or replaced by Texmate�

USER’S RESPONSIBILITY

We are pleased to offer suggestions on the use of our various products either by way of printed

matter or through direct contact with our sales/application engineering staff� However, since

we have no control over the use of our products once they are shipped, NO WARRANTY

WHETHER OF MERCHANTABILITY, FITNESS FOR PURPOSE, OR OTHERWISE is made

beyond the repair, replacement, or refund of purchase price at the sole discretion of Texmate�

Users shall determine the suitability of the proDXct for the intended application before using,

and the users assume all risk and liability whatsoever in connection therewith, regardless

of any of our suggestions or statements as to application or construction� In no event shall

Texmate’s liability, in law or otherwise, be in excess of the purchase price of the product.

Texmate cannot assume responsibility for any circuitry described� No circuit patent or software

licenses are implied� Texmate reserves the right to change circuitry, operating software, speci-

fications, and prices without notice at any time�

DL-40PSF-DCA_DL-40PSF-DCV Technical Manual Copyright © 2019 Texmate

Inc. All rights reserved. Published by: Texmate Inc. USA. Information in this

Technical Manual is subject to change without notice due to correction or en-

hancement. The information described in this manual is proprietary to Texmate,

Inc. and may not be copied, reproduced or transmitted, in whole or in part, in

connection with the design, manufacture, or sale of apparatus, device or private

label product without the express written consent of Texmate, Inc.

1934 Kellogg Ave�, Carlsbad, CA 92008

Tel: 1-760-598-9899 • 1-800-TEXMATE