Greenlee / A Textron Company 24455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

Swivels

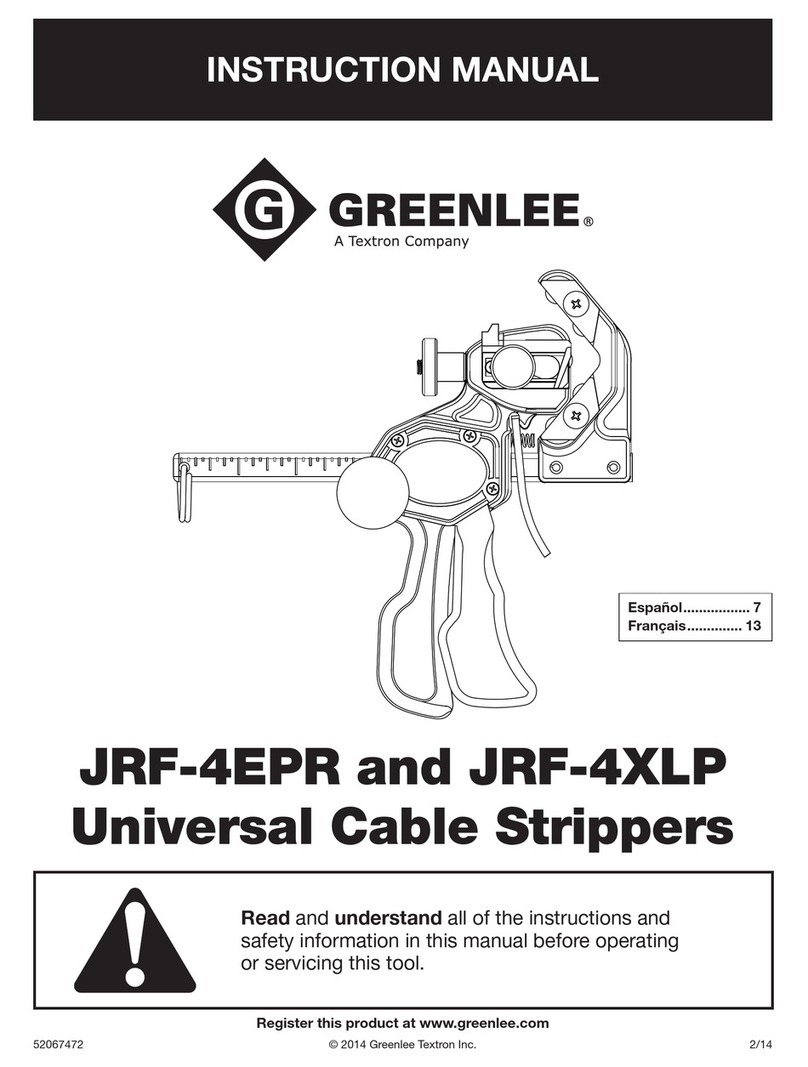

Read and understand all of the instruc-

tions and safety information in this

manual before operating or servicing

this tool.

Failure to observe this warning could

result in severe injury or death.

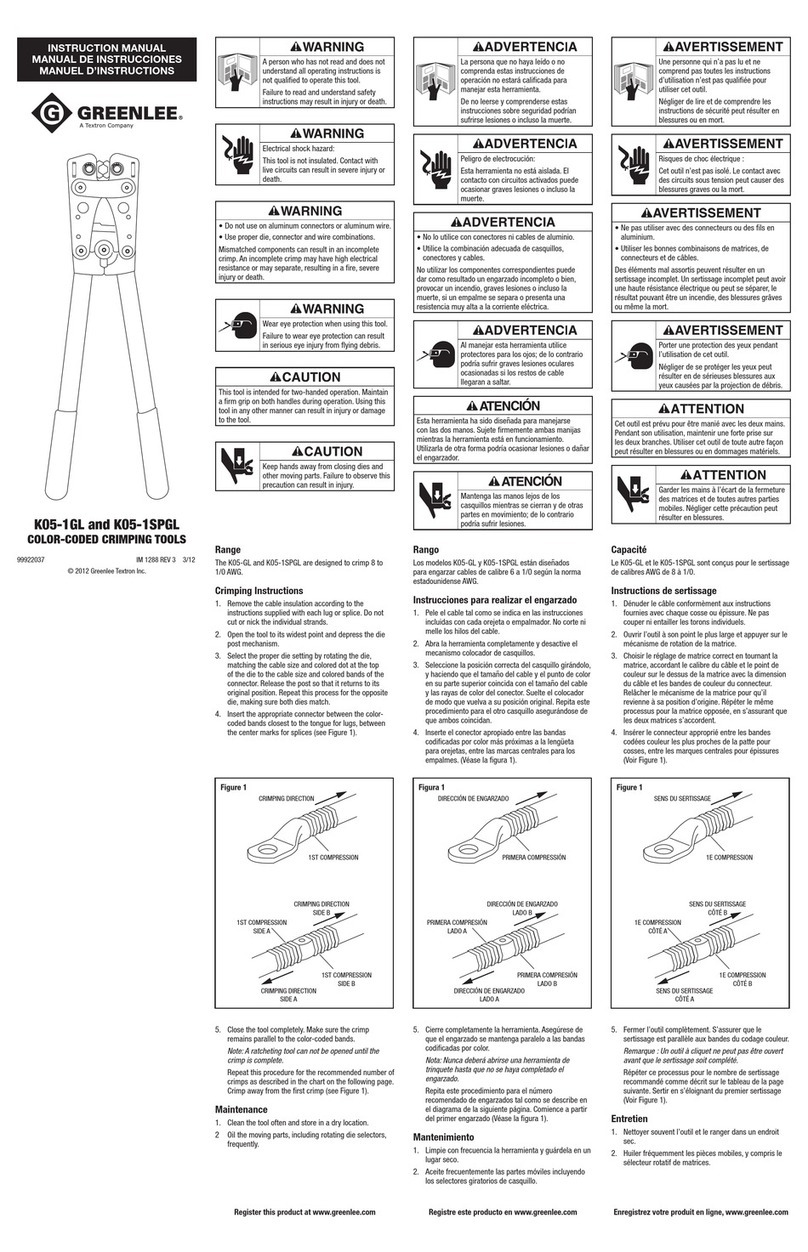

This symbol is used to call your attention to hazards

or unsafe practices which could result in an injury

or property damage. The signal word, defined below,

indicates the severity of the hazard. The message after

the signal word provides information for preventing or

avoiding the hazard.

Hazards or unsafe practices which, if not avoided, MAY

result in injury or property damage.

Hazards which, if not avoided, COULD result in

severe injury or death.

Immediate hazards which, if not avoided, WILL

result in severe injury or death.

SAFETY

ALERT

SYMBOL

IMPORTANT SAFETY INFORMATION

Excessive load hazard:

Do not exceed safe working limit (see Operating

Specifications).

• Operating swivel at loads in excess of its safe

working limit could cause permanent bearing

damage (even though separation due to failure will

not occur until the specified ultimate load is reached).

• Operating swivel at loads in excess of its safe

working limit will void warranty.

Failure to observe this warning could result in severe

injury or death.

Use recommended safe working limit:

• For underground use, and use in conduit, the

recommended safe working limit is 3:1, based on the

ultimate load.

• For overhead use, the required safe working limit is

5:1, based on the ultimate load, due to the higher risk

of severe personal injury or property damage.

Failure to observe this warning could result in severe

injury or death.

•

Never use a worn, defective or incomplete component.

• Ensure that all components of the pulling system are

able to withstand the maximum pulling loads. Compo-

nents not rated for the pull force could break and

release the stored energy of the pull.

Failure to observe this warning could result in severe

injury or death.

Do not modify or dismantle the line swivel.

The swivel was assembled, inspected and shipped in its

“covered warranty” form. Any attempt to dismantle or

modify the swivel will void the warranty and could result

in property damage, severe injury or death.

Be prepared for the unexpected.

Use recognized safety practices, and wear recognized

safety equipment.

Failure to observe this warning could result in severe

injury or death.

Swivels are not designed to be pulled over sheaves,

capstans, bull wheels or bends in conduit, since a bending

load acts to increase the tension in the line swivel and

may cause damage. If this situation cannot be avoided,

select a swivel with a safe working limit that is 20%

greater than the anticipated straight tension load.

Failure to observe this warning could result in severe

injury or death.