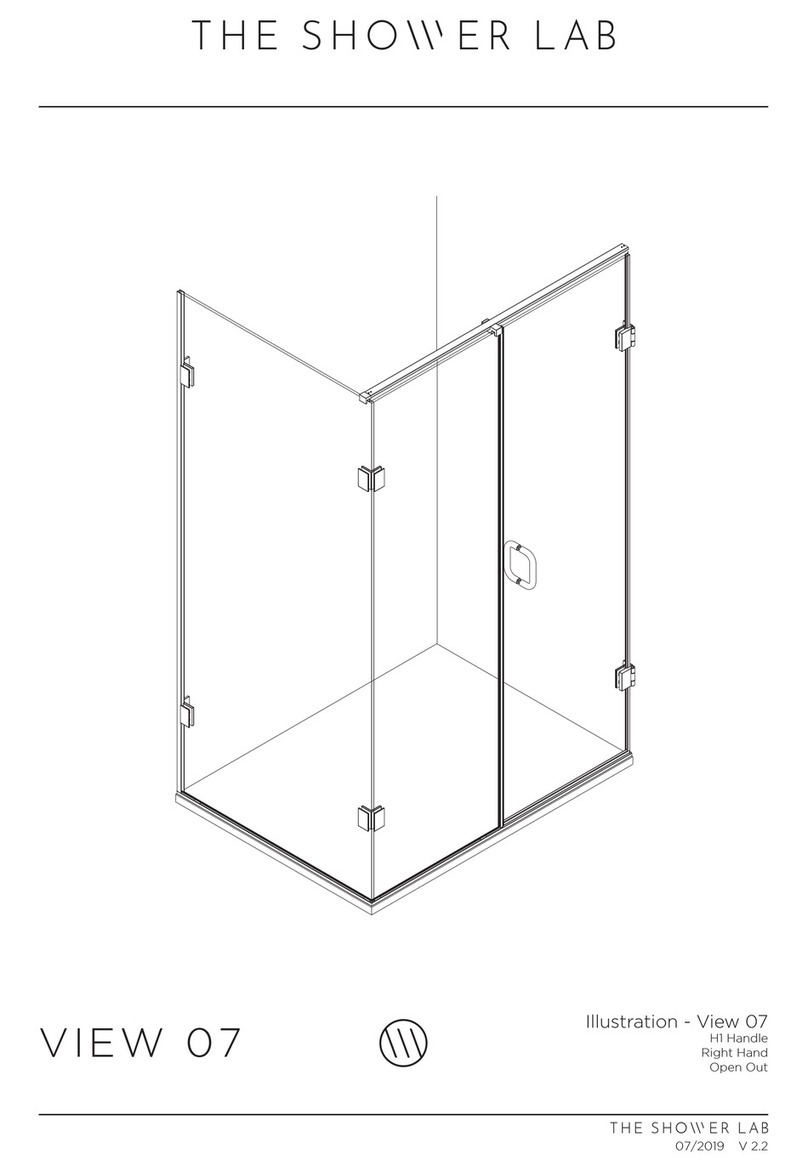

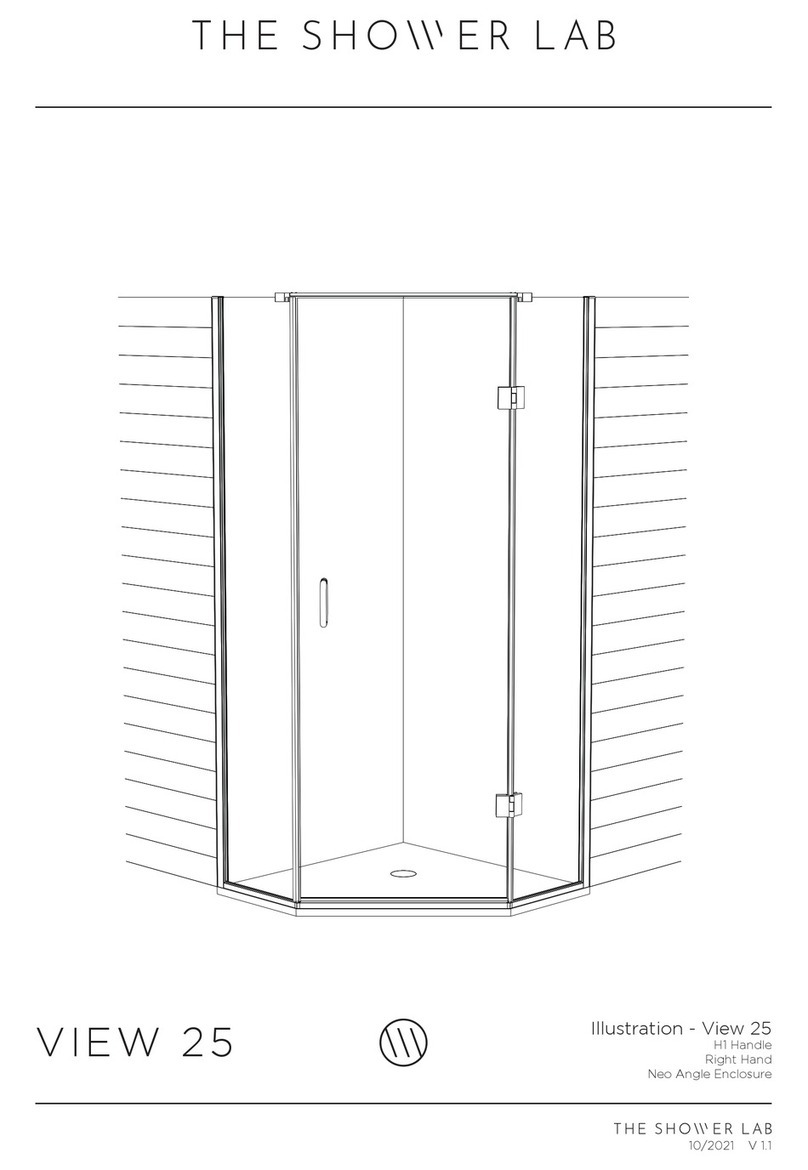

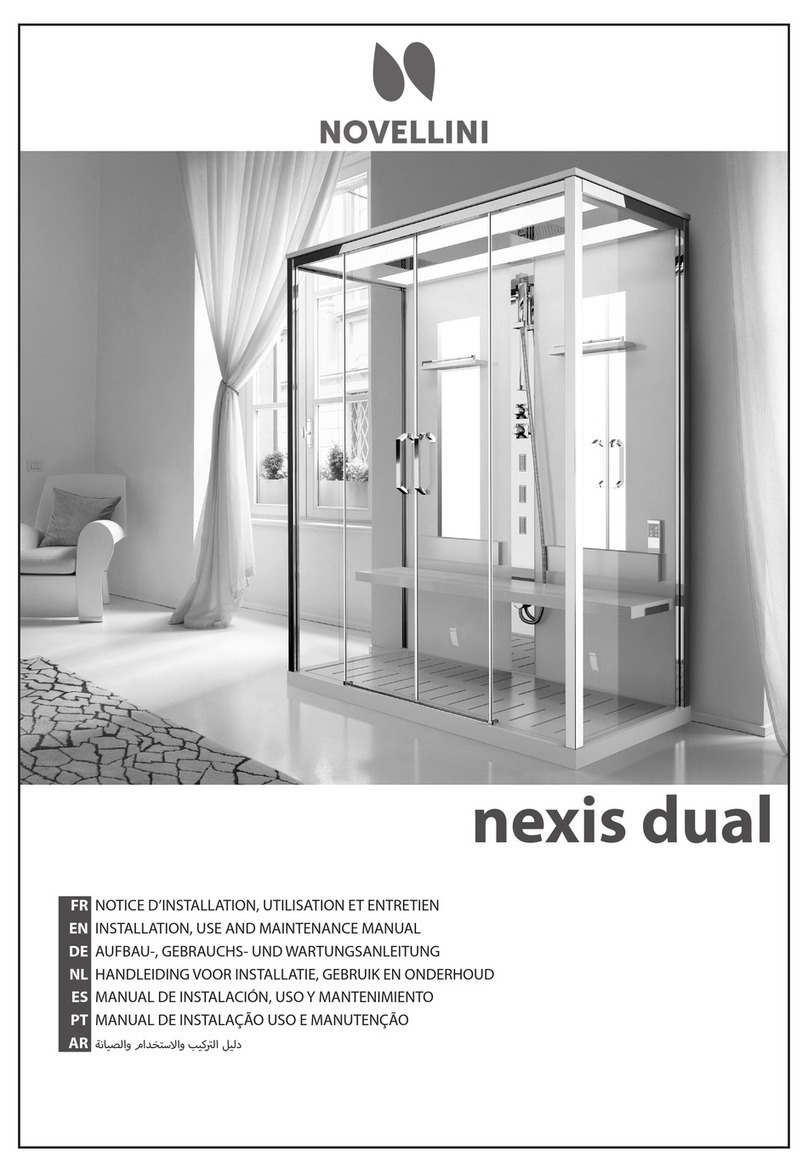

THE SHOWER LAB VIEW 04 User manual

03/2021 V 1.0

VIEW 04 Illustration - View 04

H1 Handle

Right Hand

04/2021 V 1.0

VIEW 04

IMPORTANT

•This shower screen / enclosure must be installed by suitably qualified individuals. We

recommend a minimum of two people for safe assembly of certain sections of this screen.

•Ensure all appropriate safety equipment, especially protective footwear, safety glasses

and gloves are used.

•When drilling holes in ceramic tiles, use masking tape to prevent the drill from slipping:

DO NOT use hammer action as this will crack the tiles. Use a high quality drill bit to ensure

a clean, precise hole.

Tighten hinges and brackets to the recommended 15.6N.

•

•

Please leave these instructions with the customer following installation.

PRIOR TO INSTALLATION

•Before disposing of the packaging and prior to commencing assembly, please check all

the components to ensure that they have been supplied correctly and are undamaged.

Subsequent claims for missing or damaged pieces will not be accepted once the

packaging has been disposed of and installation commenced.

•In the event of any queries please contact your supplier quoting the relevant model

information.

•The Tray / Tiled floor on which this screen is to be installed must be level on all sides.

•It may be necessary to use alternate fixings to those supplied, depending on the properties

of the walls to be fixed to.

•Use the protective corners supplied at all times until the glass is moved to its final position.

•Ensure that the glass is installed correctly, taking care to avoid installing the glass upside

down. On certain panels an easy clean coating is applied to one side only, this is clearly

marked with a sticker on the non-coated side. The coated surface is to be fitted inwards

towards the inside (wet side) of the screen.

•Ensure that all surfaces to be sealed are clean and dry prior to applying the silicone

sealant. Use a high grade fungal resistant sealant.

•Allow a minimum of 24 hours after application of the silicone sealant prior to using the

screen.

TOOLS & MATERIALS REQUIRED

Junior Hacksaw

Straight Edge (Steel

Rule)

Fine Tooth File

Set or Roofing

Square

Masking Tape

Modelling Knife

Spirit Level

Pencil

Silicone Gun

Power Drill

Ø6mm Masonry Drill Bit

2x Suction Glass Lifters

High Quality Silicone Sealant

Tape Measure

Pozi-drive

Screwdrivers, PZ1&2

Safety Glasses and

Gloves

CARE AND MAINTENANCE

(please ensure that these instructions are left with the installed unit)

•We recommend routine cleaning of your screen / enclosure with hot water using a soft

cloth, then drying with a dry soft cloth or chamois leather.

Ritec Aftercare for Shower Glass is recomended for best results.

•All glass has been treated with EASY CLEAN glass finish and care must be taken to avoid

any abrasive cleaning products that may damage the special surface protection.

•DO NOT use acidic based de-scaler products or products containing bleaches or solvents.

Digital Torque Wrench

03/2021 V 1.0

VIEW 04

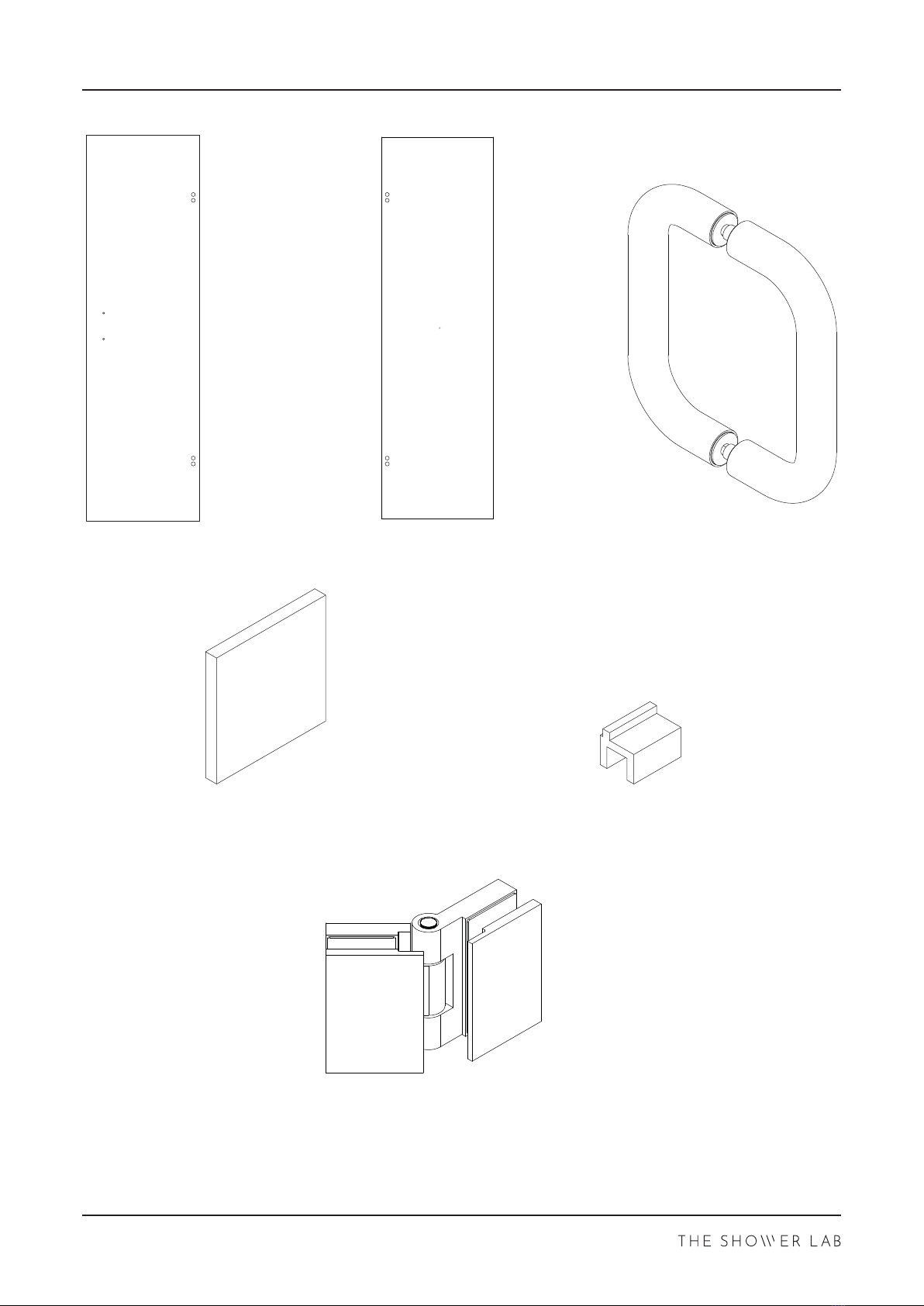

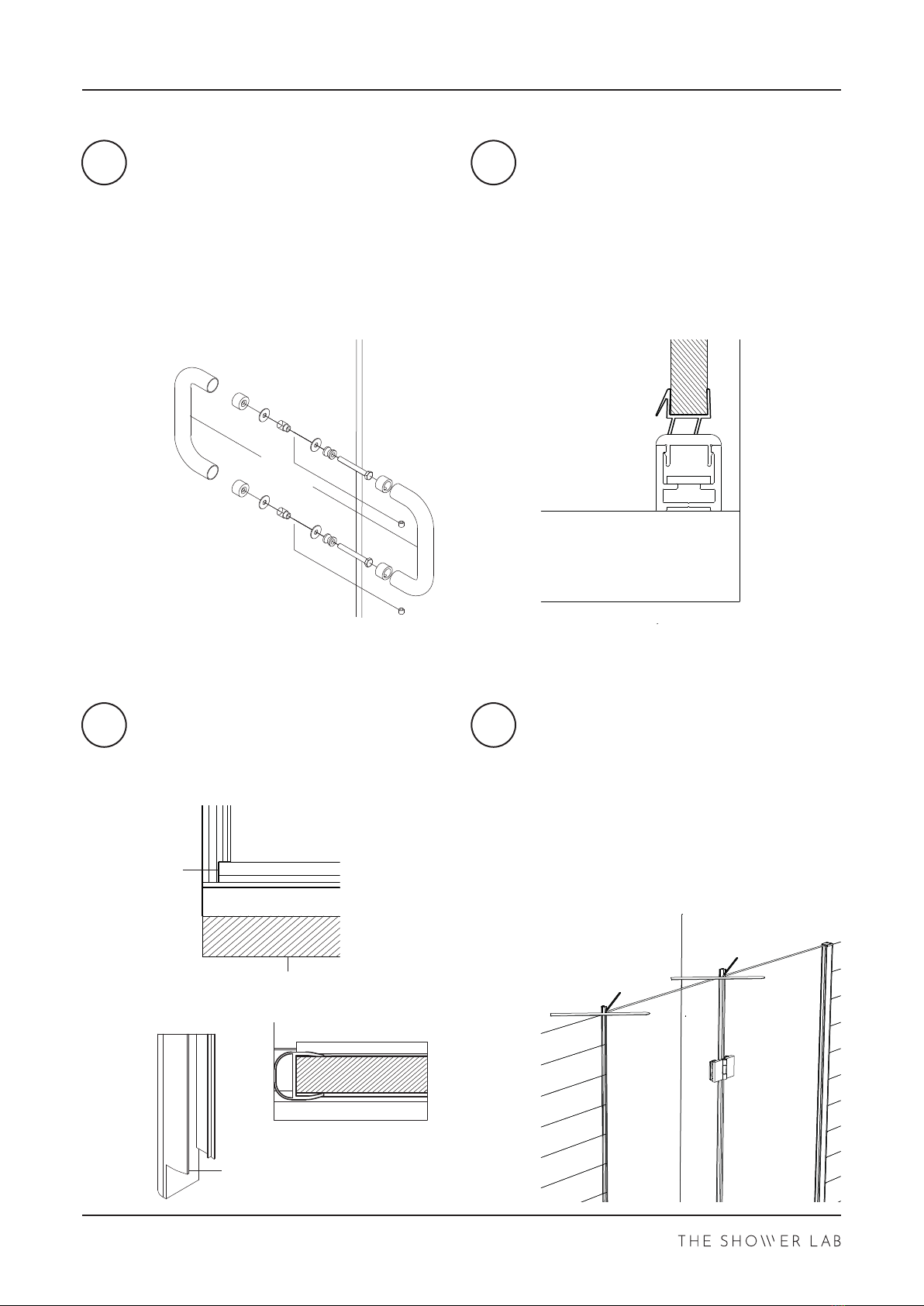

Supplied Parts

Inline Fixed Panel

x1

Glass to Glass Hinge

x2

Door Handle

(Option dependant)

x1

Door

x1

Nylon Block

x1

Glass Support

x2

03/2021 V 1.0

VIEW 04

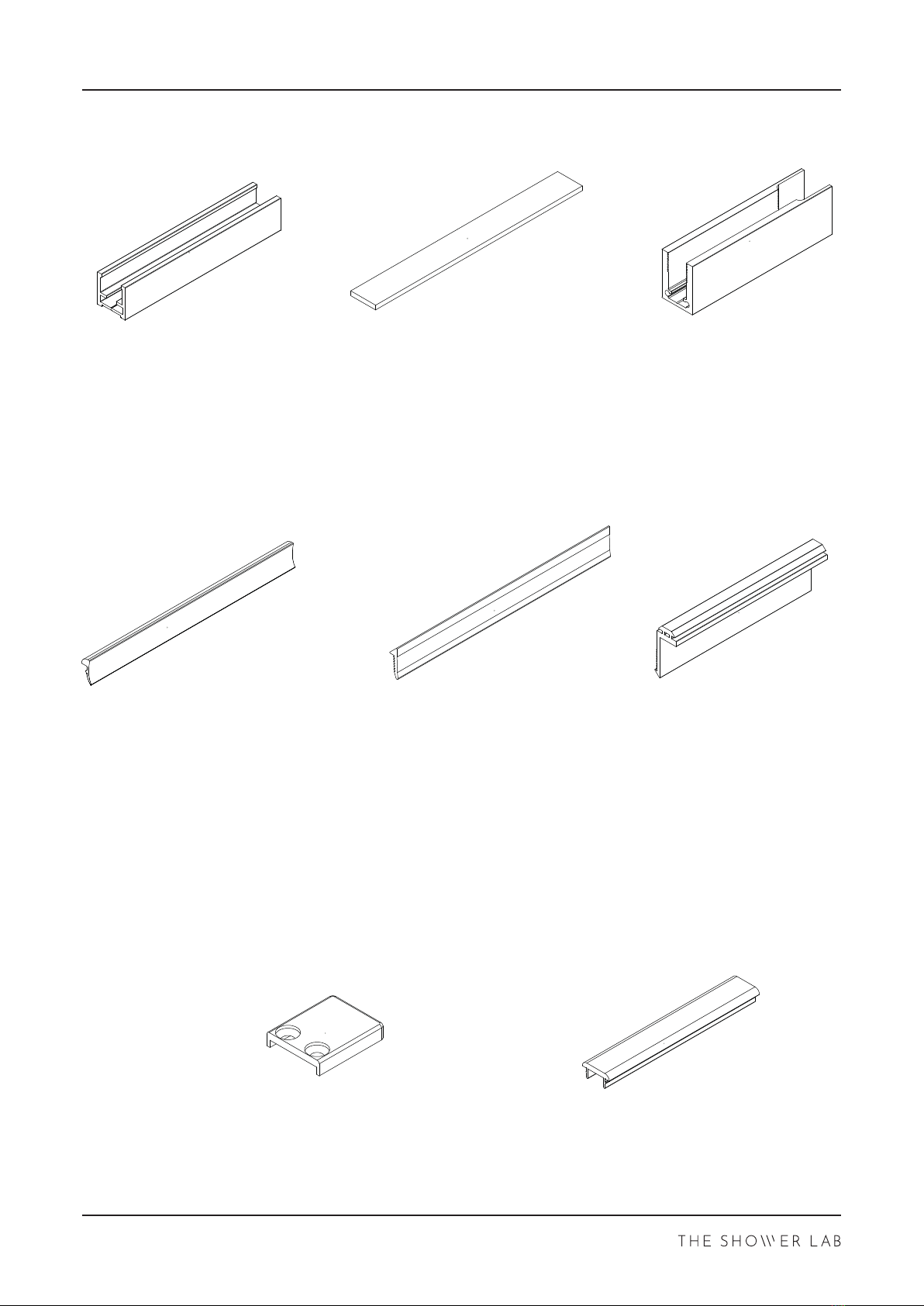

Supplied Parts

Underframe Wedge Gasket

x2

Underframe

x1

Underframe Gasket

x1

Wall Prole

x1

Wall Prole Soft Seal

x1

Wall Prole Rigid Seal

x1

Wall Prole End Cap

x1

Underframe Top

x1

03/2021 V 1.0

VIEW 04

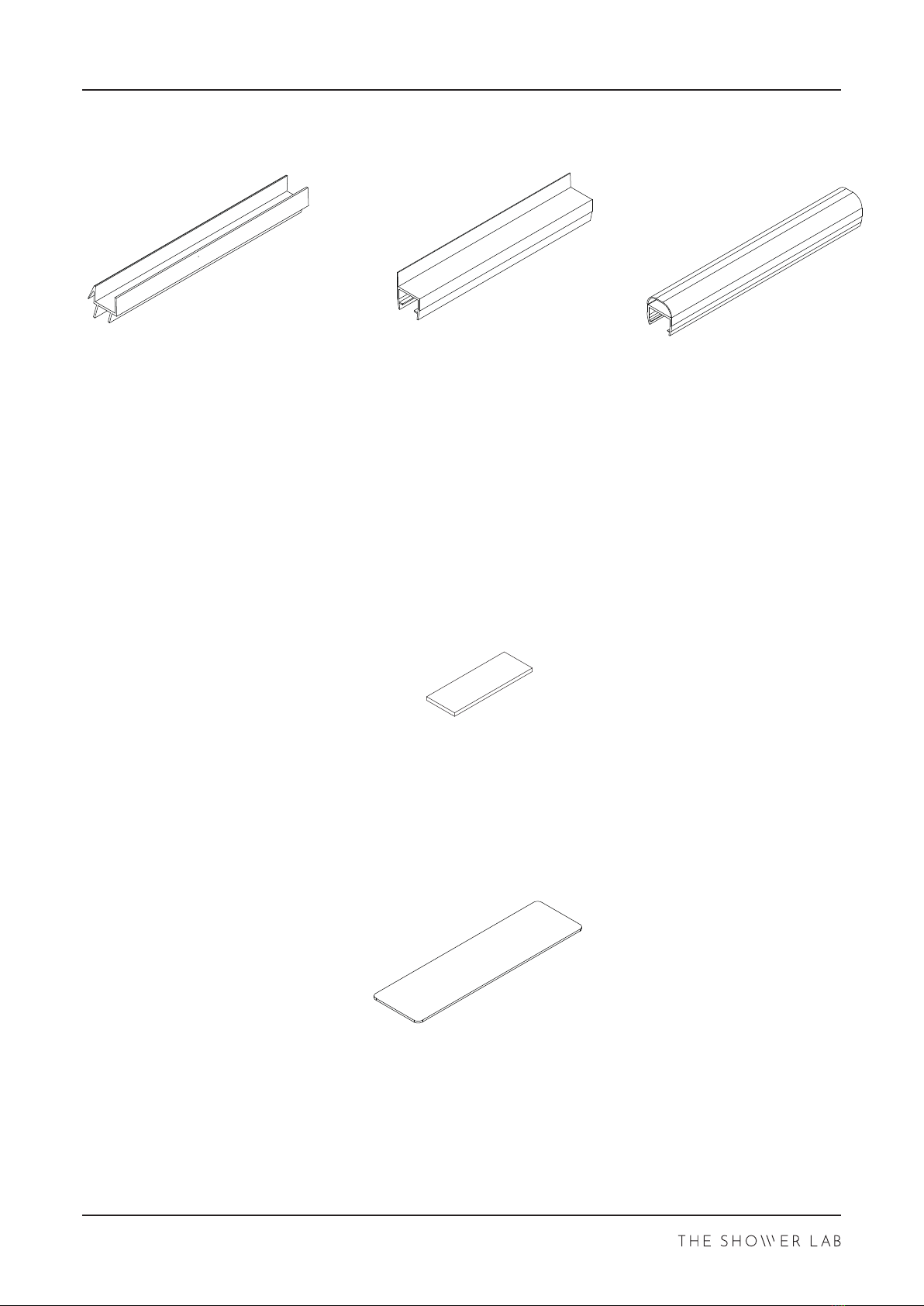

Supplied Parts

Bottom Door Seal

x1

Glass to Glass Seal

x1

Glass to Wall Bubble Seal

x1

Spacers

Packers

03/2021 V 1.0

VIEW 04

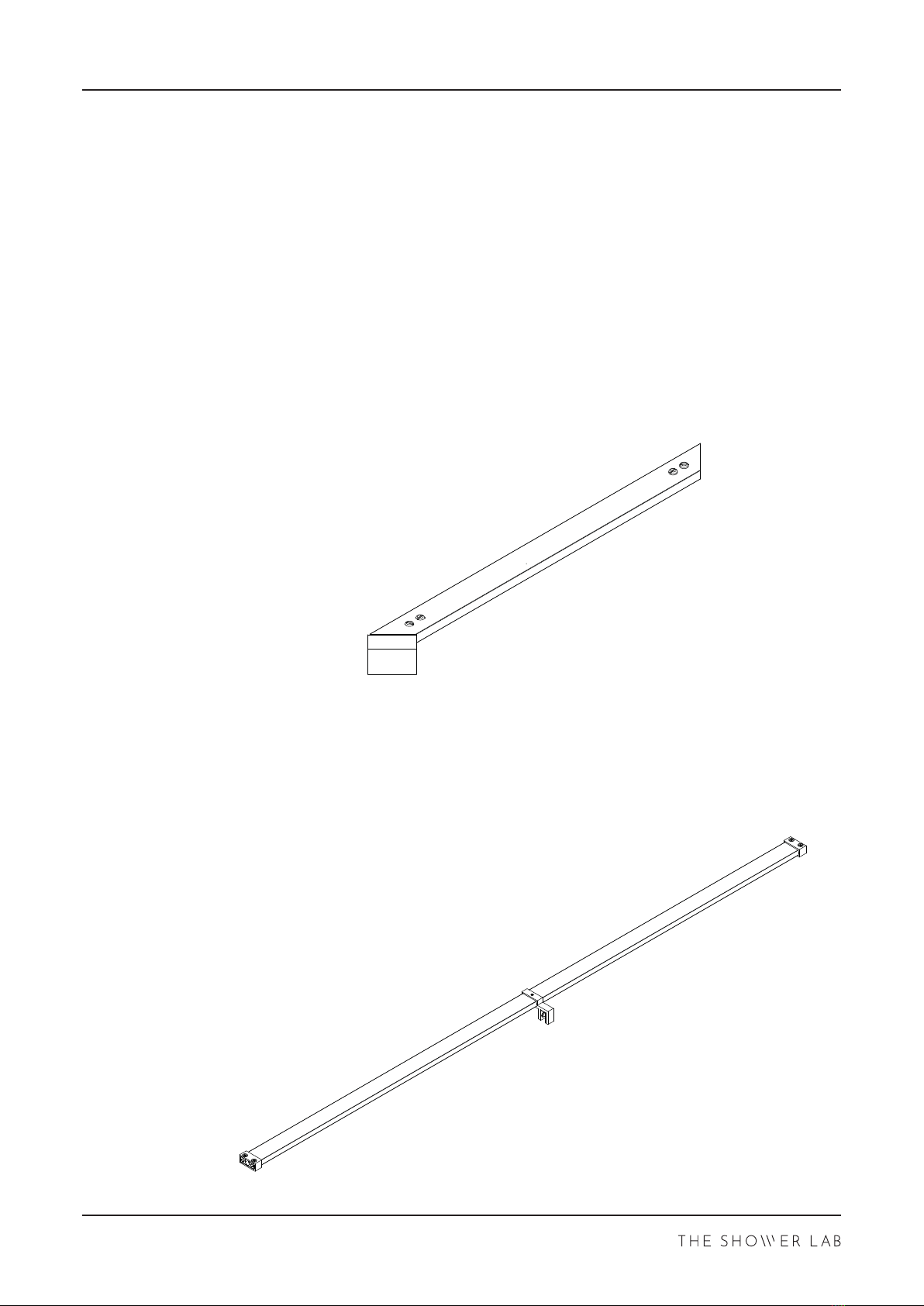

Supplied Parts

Please use this page to nd which stay bar your enclosure has been supplied with.

SB10 - With Wall Connectors

and T connector

SB2 45° - With Glass Clamp

03/2021 V 1.0

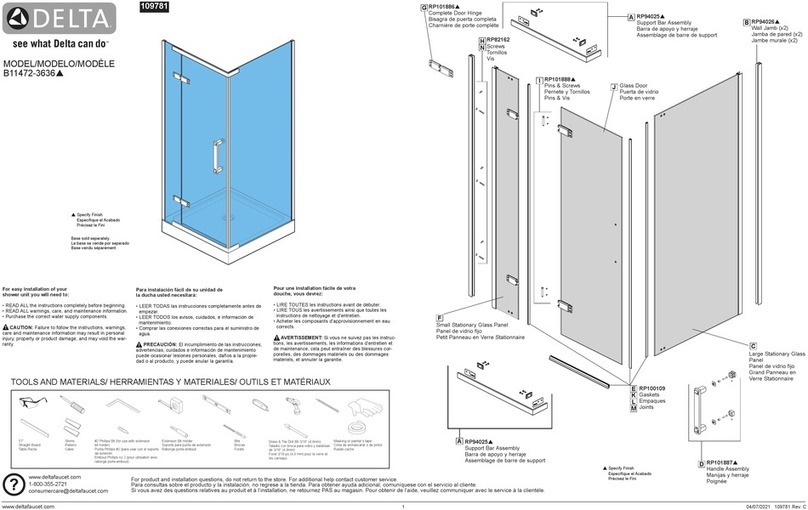

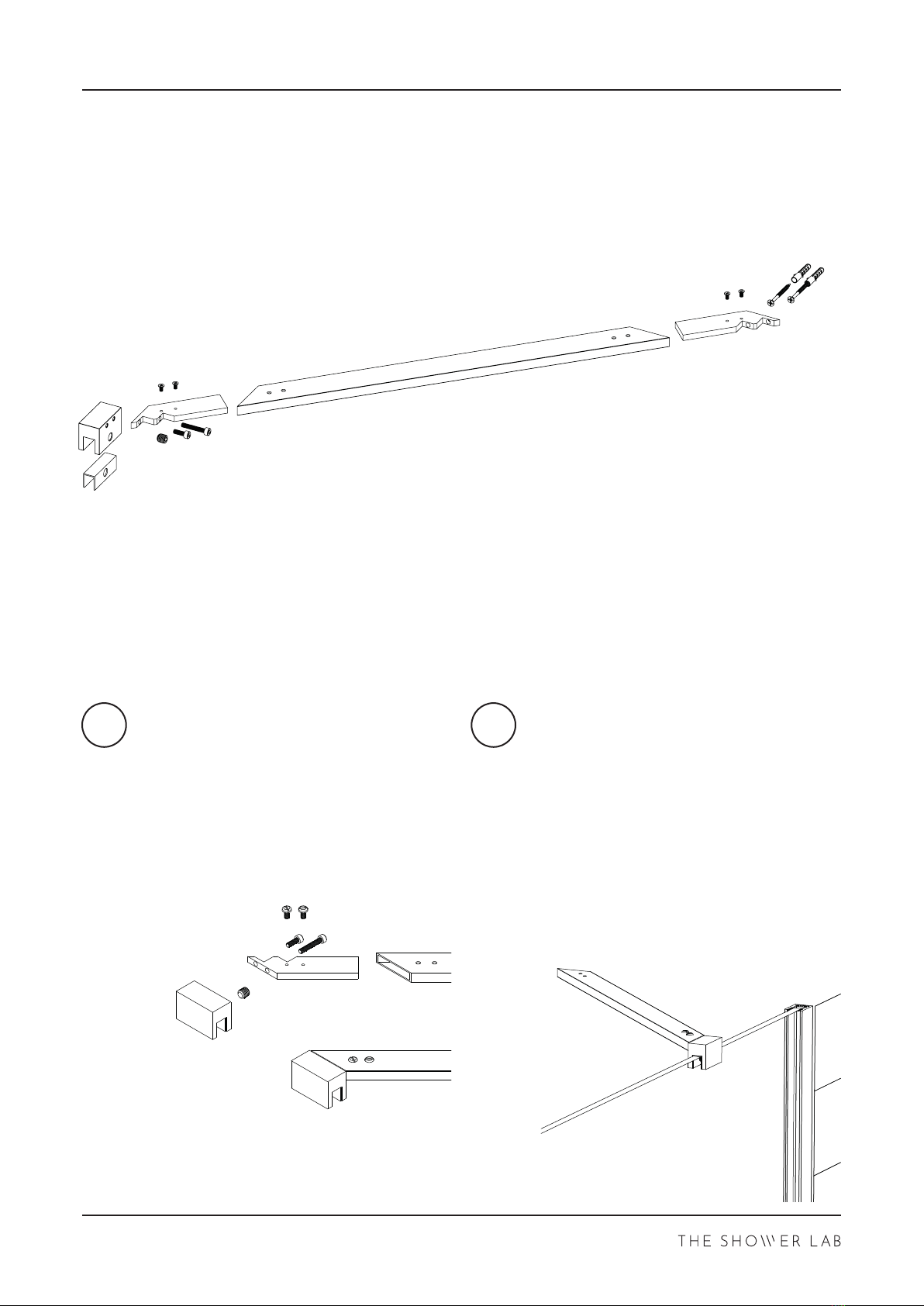

VIEW 04

These instructions are for the View 04. An SB2 Stay Bar is used for this illustration.

The following instructions are valid for both the 20mm and 30mm proles. The 30mm prole is

used in the following instructions.

Please use the below diagram to reference the list of parts.

A

B

I

C

H

D

F

E

G

Door Panel

Inline Fixed Panel

Wall Prole

Wall Prole Soft Seal

Wall Prole Rigid Seal

Underframe Wedge Gasket

Underframe

Underframe Gasket

JBottom Door Seal

Wall Prole End Cap

N

M

K

L

Underframe Top

Glass to Wall Bubble Seal

Glass to Glass Seal

Glass to Glass Hinge

OHandle (H1 Shown)

PStay Bar (SB2 Shown)

A

P

D

E

C

H

I

K

L

F

B

G

J

M

N

O

03/2021 V 1.0

VIEW 04

]GI 7QGjP IQOPj

6.ÁÅ/ÉÁ ÈÇÇÈÉÁ ÃÁÁÁ

6.ÁÅ/ÊÁ ÉÇÇÉÉÁ ÃÁÁÁ

6.ÁÅ/ÂÁÁ ÊÇÇÊÉÁ ÃÁÁÁ

6.ÁÅ/ÂÂÁ ÂÁÇÇÂÁÉÁ ÃÁÁÁ

6.ÁÅ/ÂÃÁ ÂÂÇÇÂÂÉÁ ÃÁÁÁ

6.ÁÅ/ÂÄÁ ÂÃÇÇÂÃÉÁ ÃÁÁÁ

6.ÁÅ/ÂÅÁ ÂÄÇÇÂÄÉÁ ÃÁÁÁ

6.ÁÅ/ÂÆÁ ÂÅÇÇÂÅÉÁ ÃÁÁÁ

6.ÁÅ/ÂÇÁ ÂÆÇÇÂÆÉÁ ÃÁÁÁ

6.ÁÅ/ÂÈÁ ÂÇÇÇÂÇÉÁ ÃÁÁÁ

6.ÁÅ/ÂÉÁ ÂÈÇÇÂÈÉÁ ÃÁÁÁ

ADJUSTMENT SHEET

STANDARD ENCLOSURES

Please Note

Only Standard Enclosures are shown above. If you have a Bespoke Enclosure, reference the delivery

note for the panel specificaons of the Enclosure.

BESPOKE ENCLOSURES

LH RH

03/2021 V 1.0

VIEW 04

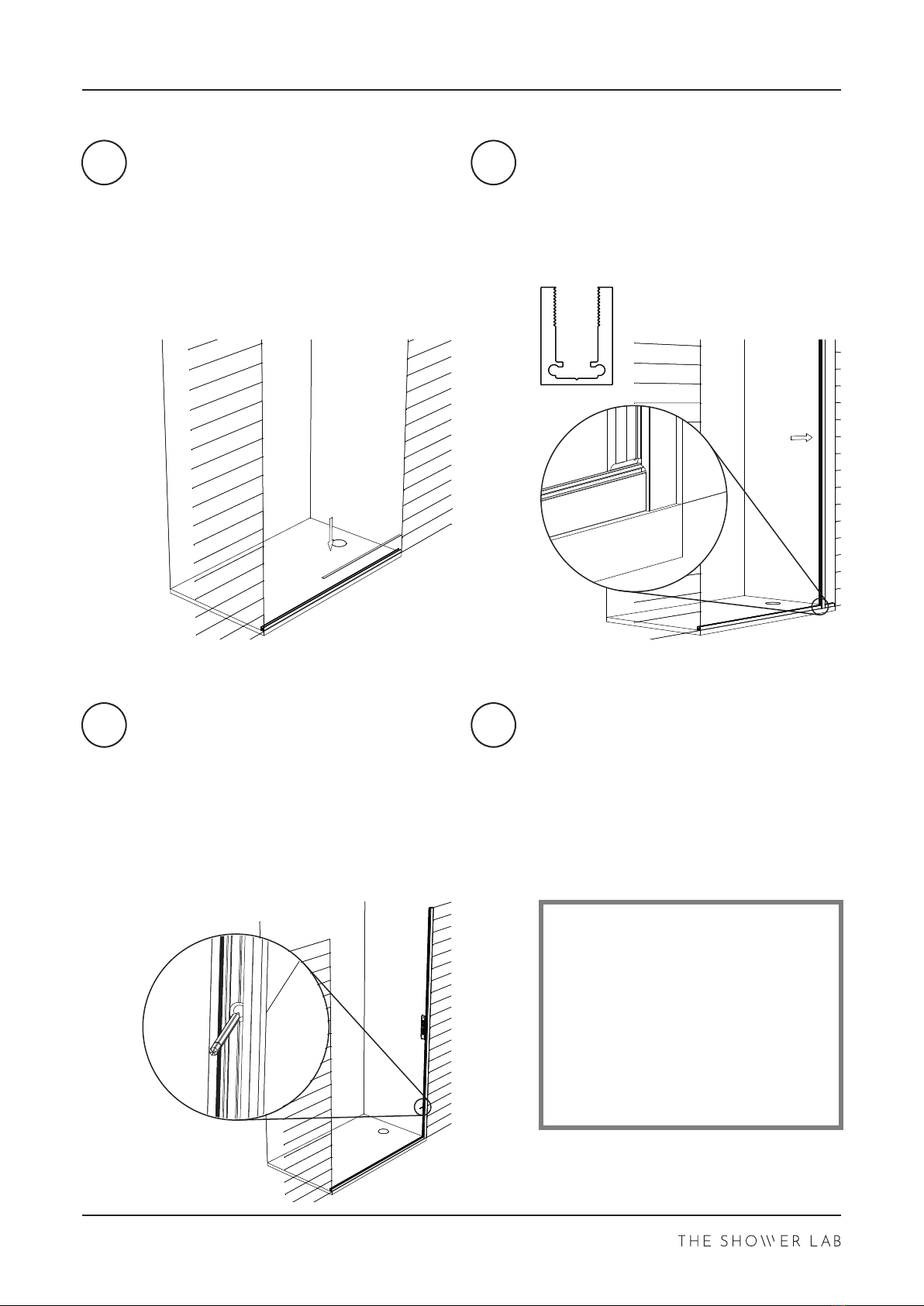

01/17

Ensure the base is level.

Measure the width of the opening

where the door is to be fied.

Mark this measurement on the

Underframe boom.

It is recommended to use masking tape

on the Underframe to mark your

measurement.

Cut squarely using a chop saw.

Use a fine toothed file to remove any

burrs, be careful not to damage the

surface finish.

Posion the Underframe parallel to

tray edge.

If using a raised shower tray, leave a

minimum 3mm gap from the edge of

the tray (5mm is recommended). This is

the lip distance.

DO NOT fix the Underframe channel to

the tray at this stage.

Temporarily fix the Underframe into

the correct posion using double sided

tape.

DO NOT use the exisng tape. This tape

is for final posioning of Underframe.

3mm minimum

Shower Tray

X

01 02

03 04

03/2021 V 1.0

VIEW 04

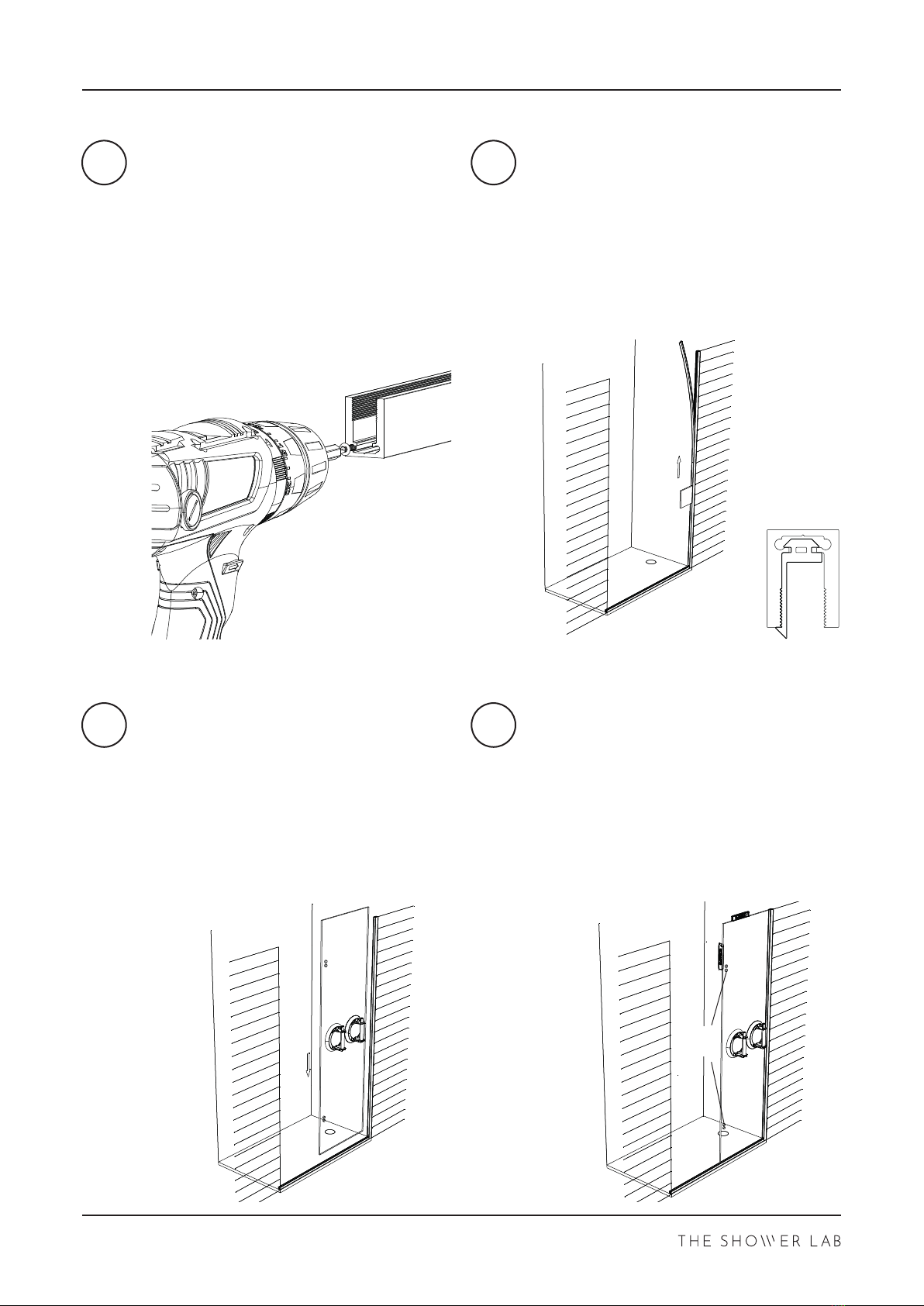

02/17

Place the Underframe Gasket into the

Underframe and bu up against the

wall.

Place the Wall Profile over the

Underframe and up against the wall.

Ensure the Wall Profile is vercal by

using a spirit level. Mark the posions

of the pre-drilled holes.

Remove the Wall Profile and drill holes

with a 6mm high quality drill bit for a

clean and precise hole.

Fully insert the wall plugs.

Professional Tip

If drilling ceramic tiles, place

masking tape on the tiles before

marking and drill through the

tape to prevent the drill bit from

skidding.

DO NOT use Hammer Action as

this will break the tiles.

05 06

07 08

03/2021 V 1.0

VIEW 04

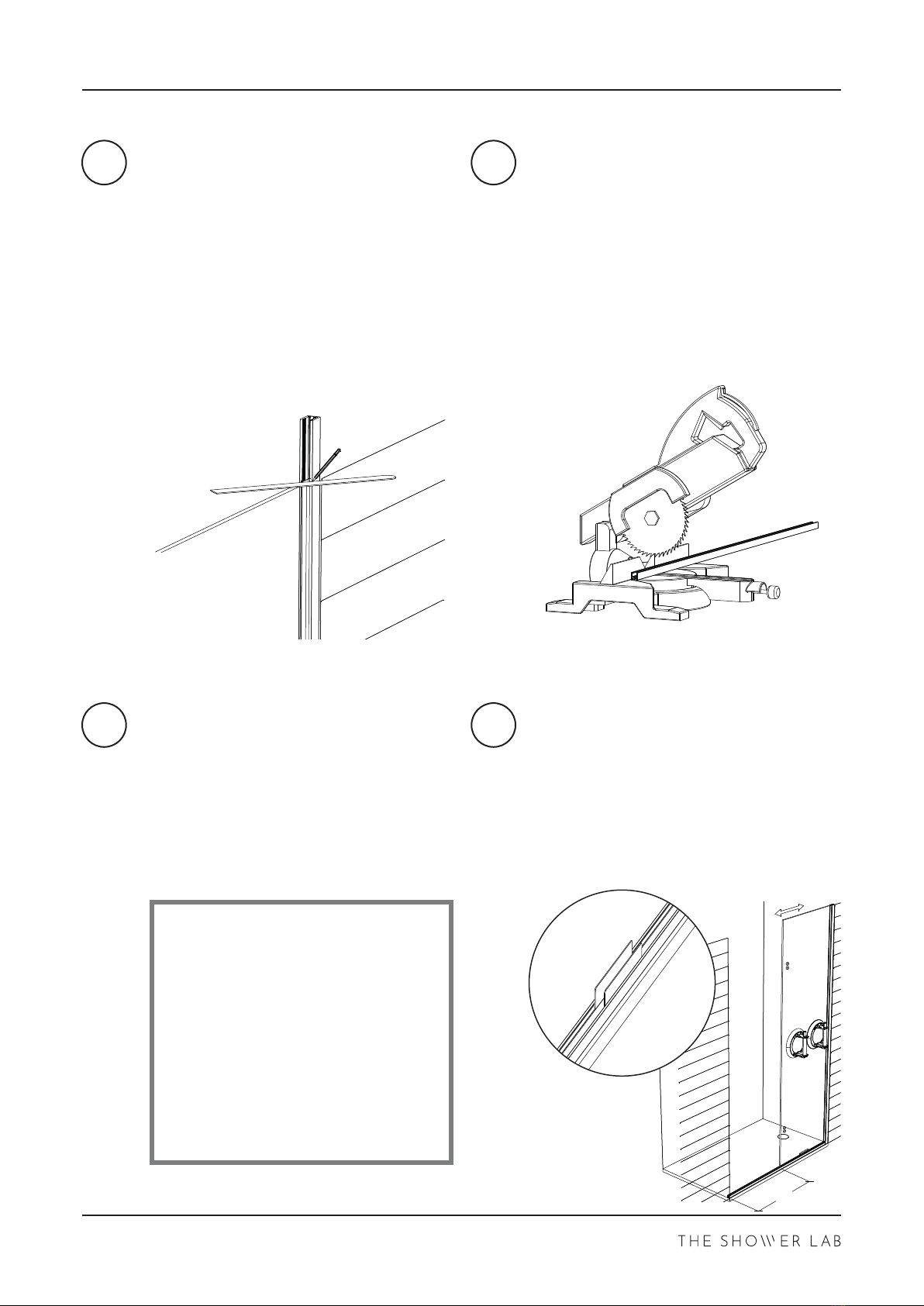

03/17

Pre drill the screws in to the Wall

Profile to create the thread to ease

later steps.

Remove screws aer drilling.

Fix the Wall Profile in place.

Take the Wall Profile So Seal and push

the seal into place on the vercal Wall

Profile to cover the screws.

Ensure the fin is on the inside (wet

side).

Use the Nylon Block to help.

Using purpose built "Glass Liers",

posion and sit the Inline Glass Panel

on to the Underframe Gasket and push

against the Wall Profile.

Note the orientaon and posion of

the Panel, this can be determined by

any holes or aached labels.

Remove and replace the Panel adding

or subtracng spacers as necessary to

level the Panel (to a maximum height

of 5mm inside the Underframe).

Check the Panel is level using a Spirit

Level.

Wet Side

20mm

Holes

09 10

11 12

03/2021 V 1.0

VIEW 04

x

04/17

If the Wall Profile is flush with the

Inline Glass Panel, move on to step 16.

If the end of the Wall Profile is not flush

with the top of the Inline Glass Panel,

mark the Wall Profile using a straight

edge.

To protect the channel finish, it is

recommended to mark on masking

tape.

Remove the Inline Panel, Wall Profile

So Seal, and the Wall Profile.

Trim the Wall Profile.

Use a fine file to remove any burrs. Be

careful not to damage the channel

finish.

Re drill the screws in to the Wall Profile

and remove aer drilling.

Reinstall the Wall Profile, Wall Profile

So Seal, and Glass Inline Panel.

Measure the width of the Door. Add

11mm to this dimension. This is your

door gap. Adjust the Inline Panel to

achieve the door gap.

To centre the panel, add 1mm Packers

on both sides of Inline Panel in the

Underframe.

WARNING

The glass is heavy and may

damage the oor or underframe if

handled incorrectly. It is advisable

to use a suitable non-slip

protective mat or piece of carpet.

Never rest the glass across the

underframe as this may cause

damage.

13 14

15 16

03/2021 V 1.0

VIEW 04

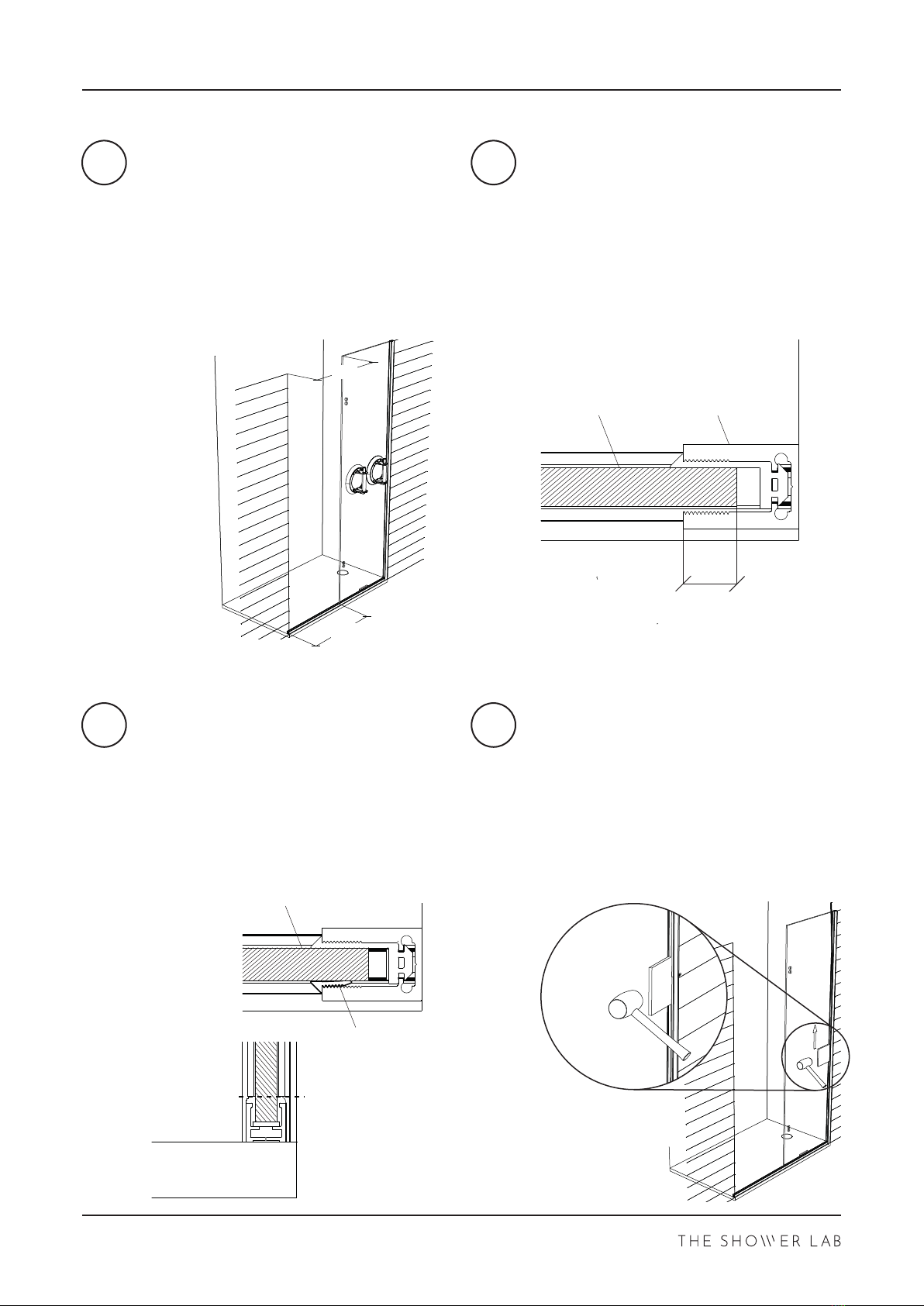

05/17

Measure and check the distance from

the Inline Panel to the opposite wall

ling at the boom and at the top are

equal.

Ensure there is adequate glass in the

Wall Profile. (6mm is recommended)

Apply Rigid Seal to dry side of the Wall

Profile starng from the archway of the

Wall Profile up to the top face of the

Wall Profile.

Gently tap the Wall Profile Rigid Seal

into place using a rubber mallet with

the Nylon Block to protect the Glass

and the Wall Profile.

=

=

Flush

6mm min

Wall ProleGlass Panel

Rigid Seal

Glass Panel

17 18

19 20

03/2021 V 1.0

VIEW 04

06/17

Remove Packers and feed the

Underframe Wedge Gasket into the

archway gap of the Fixed Panel and

trace along the Glass on both sides.

Spray water on Glass Panel and use

Nylon Block to help feed Gasket.

Mark the Wedge Gaskets at the edge of

the Inline Panel.

Remove both Wedge Gaskets and trim.

Reinstall both Wedge Gaskets aer

trimming.

Trim both of the Wall Profile seals at

the top face of the Wall Profile using a

blade.

Place the Door Supports evenly over

the Frame.

Check the orientaon against your door

direcon.

Outward opening Inward opening

21 22

23 24

03/2021 V 1.0

VIEW 04

07/17

Aach the Glass to Glass Hinges in the

direcon your door will open and

ghten to the Inline Panel.

Evenly ghten the screws unl the

Gaskets are just “nipping” the Glass.

Tighten all the screws to 15.6N.

Check the orientaon of the Cover

Plates. Adjust Clamping Plate to Suit.

DO NOT fit the Cover Plates yet.

With one person inside the enclosure,

posion the Door onto the Door

Supports as indicated. Ensure there is a

6mm gap between the Door and the

wall and 5mm between the two Panels.

Add Spacers to the Glass Supports in

order to level the door.

Check both Panels are level and square.

Aach the Glass to Glass Hinges to the

door and ghten.

Use 5mm Packers in gap and evenly

ghten the screws unl the gaskets are

just “nipped”.

Tighten all screws to 15.6N.

DO NOT fit the Cover Plates yet.

5mm Gap

(Hinge Side)

6mm Gap

(Wall Side)

Cover Plate

Clamping

Plate

25 26

27 28

03/2021 V 1.0

VIEW 04

Inside Enclosure

Inward Opening

Outward Opening

Inside Enclosure

08/17

Aach the Glass to Wall Bubble Seal to

the Door. Ensure the seal is gently

compressed against the wall and that it

provides a complete seal with no gap.

Aach the Glass to Glass seal to the

Inline Panel.

Ensure a good seal along the edge of

the door.

Check the orientaon is correct.

Remove the seals aer checking.

Measure the distance between the

Inline Panel and the le.

Mark and cut the Underframe Top.

Snap the Underframe Top on to the

Underframe.

Outside of

enclosure

29 30

31 32

x

03/2021 V 1.0

VIEW 04

Trim the aps

Notch

Tray

09/17

Aach the Handle if included. Secure in

place with the grub screws provided.

The Handle should be oriented so that

the grub screws are not visible when

looking down on the handle.

Measure the width of the Door and

trim the Boom Door Seal accordingly

with a fine toothed junior hacksaw.

Aach the Seal ensuring the Seal is

correctly oriented.

Check the Glass to Wall “Bubble” Seal

orientaon and trim a notch to fit

around the Boom Door Seal.

Push both Vercal Seals down as far as

they can go.

With a straight edge, mark where the

Seals will be trimmed. Remove the

Seals and trim with a fine toothed

junior hacksaw so they are flush with

the tops of the Glass Panels.

Replace the seals.

Outside of

enclosure

33 34

35 36

03/2021 V 1.0

VIEW 04

10/17

Tighten all screws.

Fit all Cover Plates to the Hinges.

Using a sharp modelling knife, trim any

excess gasket material from the Hinges

that may have squeezed out when

ghtening.

Take care not to scratch the glass

surface.

Check which Stay Bar configuraon

your screen has been supplied with and

refer to the relevant instrucons below.

(You can find this out at the front of

these instrucons).

Config A - SB2 Page 11

Config B - SB9 Page 13

Trim

37 38

39

03/2021 V 1.0

VIEW 04

11/17

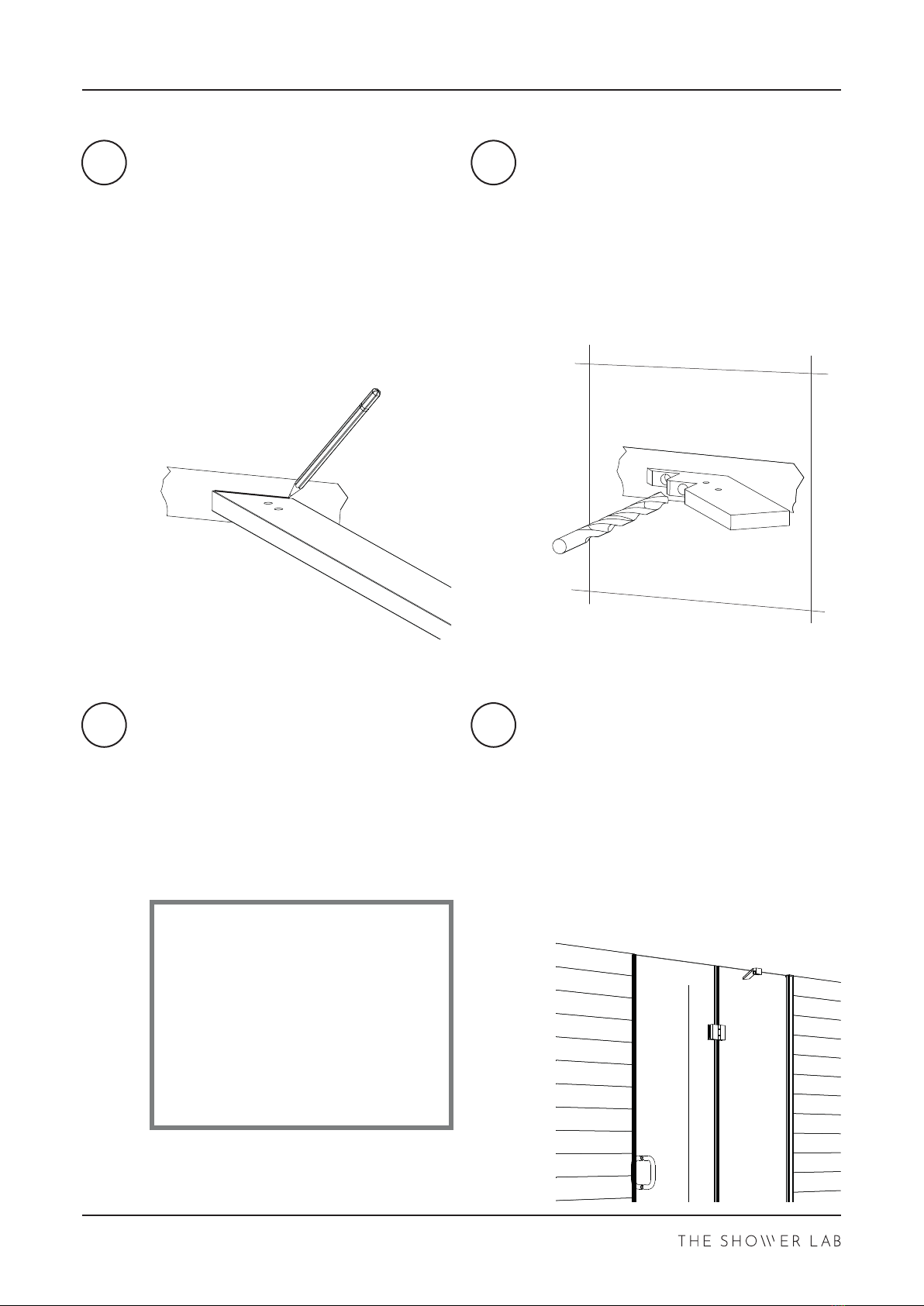

Assemble the Glass Clamp to the Stay

Bar.

Secure the Glass Clamp over the panel,

ensuring it is flush against the wall

(le).

STAY BAR CONFIGURATION A - SB2

A1 A2

03/2021 V 1.0

VIEW 04

12/17

Ensure the Stay Bar is level and square.

Mark the locaon on the wall and

remove the Stay Bar.

Posion the Stay Bar Connector central

to the marking. Mark the holes for

drilling.

Use masking tape on the les to help.

STAY BAR CONFIGURATION A - SB2

Using a 5mm high quality drill bit for a

clean and precise hole, drill the marked

areas, fully insert the wall plugs and fix

the Connector to the wall.

Fix Glass Clamp over the Glass and

aach the Stay Bar to the Wall

Connector with screws provided.

Professional Tip

If drilling ceramic tiles, place

masking tape on the tiles before

marking and drill through the

tape to prevent the drill bit from

skidding.

DO NOT use Hammer Action as

this will break the tiles.

A3 A4

A5 A6

Table of contents

Other THE SHOWER LAB Shower Cabin manuals

Popular Shower Cabin manuals by other brands

Disenia

Disenia ONDA manual

INR

INR BRIC 2 manual

Jacuzzi

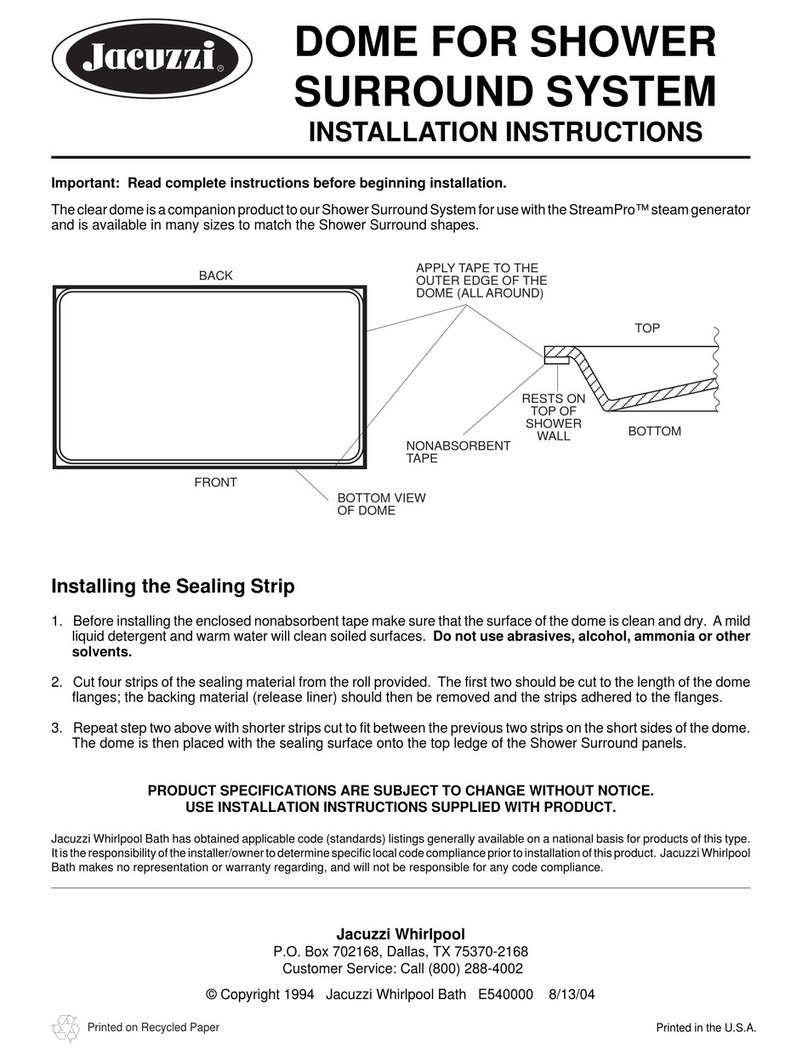

Jacuzzi Dome For Shower Surround System None installation instructions

RAVAK

RAVAK Nika PIVOT Series installation instructions

KERRA

KERRA Splash Assembly and maintenance instructions

American Bath Factory

American Bath Factory Sistine Stone Single Alcove-Hsf installation guide