Thermo Savant UVS400 User manual

A Thermo Electron business

UVS400/UVS400A

Universal Vacuum System

INSTRUCTION MANUAL

Table of Contents

Section Section Title — Description Page

1.0 Description 3

Section Section Title — Installation Page

2.0 Installation 4

Unpacking 4

Inspection 4

Set-up 4

2.1 Preparing the Vacuum System for use 5

2.2 Connection to Evaporation/Drying Equipment 6

Section Section Title — Operation Page

3.0 Operation 6

3.1 Emptying the Glass Condensation Flask 7-8

3.2 Optional Traps 8

Section Section Title — Specifications Page

4.0 Specifications 9

Section Section Title — Accessories Page

5.0 Accessories 9

Section Section Title — Warranty Page

6.0 Warranty and Liability 10

Disclaimer:

All statements, information and data given herein are believed to be accurate and reliable but are presented without guarantee, or responsibility of any kind,

expressed or implied. Statements or suggestions concerning possible use of our products are made without representation that any such use is free of patent

infringement and are not recommendations to infringe any patent. The user should not assume that all safety measures are indicated, or that other measures may

not be required.

VaporNet®, SpeedVac®, and CryoCool®are registered trademarks of Thermo Savant.

TEFLON®is a registered trademark of E.I. Dupont de Nemour & Co.

3

1.0 DESCRIPTION

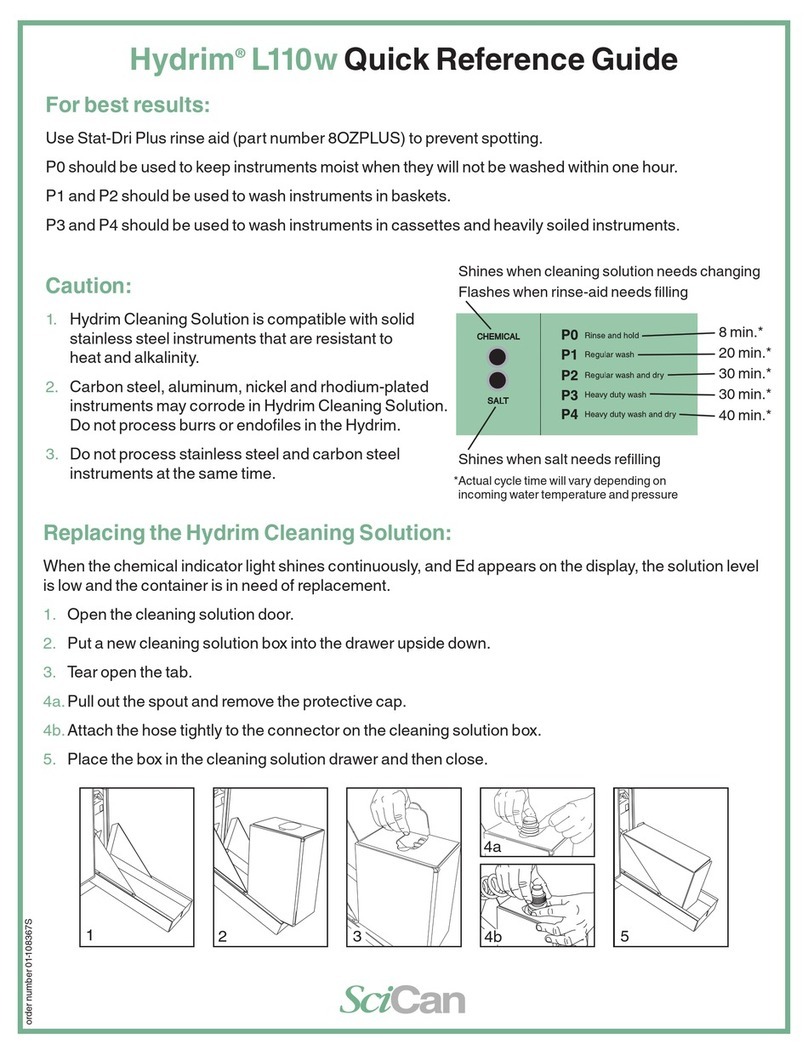

Thermo Savant’s Universal Vacuum System (UVS400/UVS400A) is a multipurpose vac-

uum source and solvent recovery system, combined in a single, integrated unit (Figure 1).

The system includes a refrigerated vapor trap, and oil-free vacuum pump; the UVS400A

version (220 V/60 Hz or 230 V/50 Hz) also includes a VaporNet®controller. Together,

these elements form a low-maintenance vacuum system that offers improved reliability

over those based on oil-filled vacuum pumps, which require frequent maintenance and

can easily be damaged by contaminating liquids.

The Universal Vacuum System is ideal for applications that evaporate solvents from sam-

ples or substances. It is used with Thermo Savant’s SpeedVac®vacuum concentrator, Gel

Dryer, or other vacuum-dependent equipment such as vacuum ovens or rotary evapora-

tors. The vapor trapping efficiency and thermal capacity of the UVS400/UVS400A pro-

vides evaporation rates equivalent to or better than component systems relying on main-

tenance-intensive rotary vane oil vacuum pumps. At the same time, the

UVS400/UVS400A is the most energy efficient and environmentally safe vacuum system

available, providing complete recovery of evaporated solvents.

Three major elements are incorporated within the UVS400/UVS400A. The refrigerated

vapor trap features a Glass Condensation Flask that collects condensing solvent vapors

generated by the attached equipment. Recovered condensate can then be safely handled

for proper disposal or recycling. The oil-free vacuum pump eliminates frequent mainte-

nance required by oil-filled pumps, and is corrosion-resistant for long life.

Features:

•-50 ˚C operating temperature, 4-liter vapor trap, CFC-free refrigerant

• Wide-mouth Glass Condensation Flask (GCF400)

• 34.6 cm (13.6 in) of bench width used

• VaporNet controller (UVS400A, version only)

•TEFLON®coated oil-free vacuum pump, 36 l/min displacement

(@ 60 Hz), 10 torr ultimate vacuum

•Automatic vacuum start sequence

•Optional traps for ammonia vapors, acids, and volatile

radioactivity/organics

Inlet port

Refrigerated

Vapor Trap

Stainless Steel

Refrigerated Chamber

Oil-Free

Vacuum Pump

Solvent Exhaust Port

Flask Cover

Insulating Foam Ring

Glass Condensation Flask

Vacuum On/Off switch

Figure 1. Universal Vacuum System UVS400

4

2.0 INSTALLATION

Unpacking. Carefully remove the instrument from its shipping carton. Lift and carry

with two people, holding securely underneath with both hands. Use proper lifting tech-

nique (lift with the legs, not the back) to avoid personal injury. Compare the packing list

to the box contents. If there is a discrepancy, call Thermo Savant at 1-800-634-8886 or

631-244-2929, (fax) 631-244-0606 or contact your distributor.

Inspection. Inspect the unit for any damage that may have occurred during shipment.

Should there be damage, report it to the carrier and contact Thermo Savant or your dis-

tributor immediately. Make sure the carrier inspects the damage and leaves an inspec-

tion report. Register any claims for shipping damage against the carrier or his agent.

Save the shipping carton and all packing materials in the event a return is necessary.

Set-up. To assure safe operation and best results, read this manual in its entirety

before operating the UVS400/UVS400A Universal Vacuum System.

•Place the Universal Vacuum System on a stable, level laboratory counter or

heavy duty cart near a power outlet of the required voltage. The bench depth

should be at least 66 cm (26 inches). The outlet must have a rating of at least

10 A for 230 V operation. The system draws high current when first switched

on; therefore, other high-power equipment, or equipment that will be affected by

a momentary drop in power, should not be placed on the same circuit. The

UVS400 is air-cooled, requiring at least 10 cm (4 inches) clearance for ambient

air circulation. The ambient temperature must not exceed 32 ˚C (90 ˚F) for

optimum function.

Warning: Before connecting the UVS400/UVS400A to an outlet, check

voltage, frequency, and amperage to be sure they match

the power requirements indicated on the label on the right

side of the instrument (115 V/60 Hz, 6 A; 230 V/50 Hz, 3 A).

If there are questions, please consult an electrician.

•As a safety feature, units are equipped with a three-prong grounded plug that fits

a grounding-type power outlet. Consult an electrician to replace outlet if neces-

sary. Do not defeat this safety feature by modifying the plug.

•This unit is “FOR INDOOR USE ONLY”. Avoid operating in areas of excessive

humidity or extremes of temperature.

5

2.1 PREPARING THE VACUUM SYSTEM FOR USE

CryoCool.

Prepare the vapor trap by dispensing the correct level of CryoCool®Heat Transfer

Fluid (SCC1); available separately. Pour 800 ml of CryoCool into the stainless steel

trap chamber. A line scribed in the wall of the stainless steel chamber indicates the

minimum appropriate CryoCool level (with glass flask not yet inserted). When replen-

ishing CryoCool, add more fluid until the level reaches the scribed line.

Glass Condensation Flask (GCF400).

The GCF400 is a wide-mouth flask which facilitates removal of condensed solvent. A

rubber Flask Cover (FC400) fits over the top, and tubing attaches to this by means of

fittings pushed into molded ports on the rubber cover. This forms the vacuum connec-

tion. An insulating foam cover fits over the flask to seal in the cold and seal out atmos-

pheric condensation from the refrigerated chamber.

Place a clean, dry Glass Condensation Flask into the stainless steel chamber. Fit the

insulating cover (white foam ring) over the flask. Seal flask mouth with the black rubber

Flask Cover. Press down flask and insulating cover so that the level of CryoCool®rises

around the flask, and so that the flask, its cover, and insulation are seated to operating

position. This will fully seal the chamber. Withdraw the flask again and verify that the

level of CryoCool came to within about a half-inch (12–15 mm) from the top (shoulder)

of the flask. If the level is low, carefully pour more CryoCool into the chamber while

holding down the flask.

Immediately wipe clean any CryoCool that spills onto the rubber chamber seal or Flask

Cover.

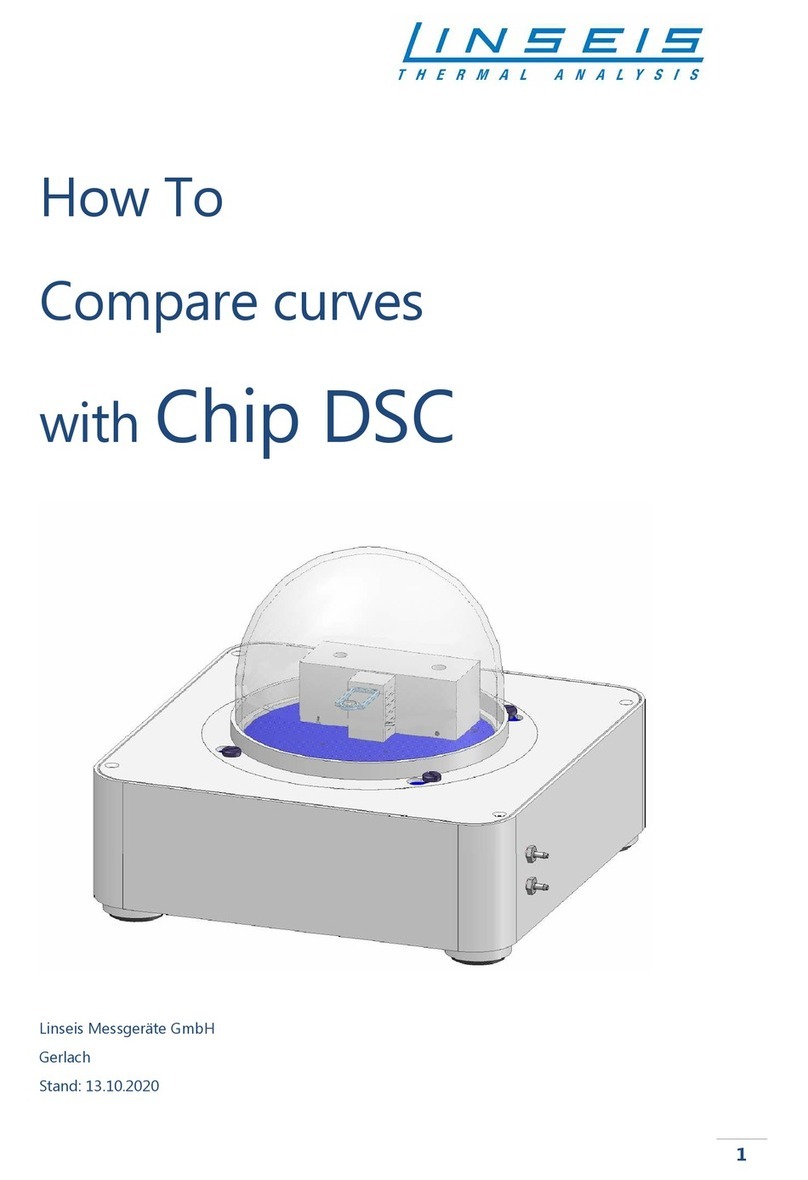

Muffler and Optional Trays.

Attach the muffler to the solvent vapor exhaust port on the right side of the Universal

Vacuum System. For applications requiring post-pump gas trapping, attach instead the

optional Post-Trap Assembly (ANT100) or Chemical Trap Kit (DTK120; Figure 2). The

ANT100 is used with either Ammonia Neutralizing Solution (ANS121), which neutral-

ized ammonia vapors and reduces ammonia smell in the laboratory, or NSA300TF

which neutralizes acids. The DTK120 comes with a DC120R Disposable Cartridge for

adsorbing volatile radioactivity and trace organics. It may also be fitted with a DC120A

Disposable Cartridge (available separately) for neutralizing acid vapors.

6

2.2 CONNECTION TO EVAPORATION/DRYING EQUIPMENT

The UVS400 Universal Vacuum System is designed for use in single or multifunction

operation, with such instruments as the SpeedVac, Gel Dryer, Vacuum Oven, or Rotary

Evaporator. Use the tubing and fitting kit (TFK120) to arrange the components in a con-

venient, space saving configuration. If necessary, place the UVS400/UVS400A on a

shelf below the evaporation/drying components. Connect instrument(s) to the port on

the left side of the UVS400/UVS400A. Install manual bleeder valve (BV130; available

separately) in the tubing between the instrument and UVS400/UVS400A. This valve

can be used to apply vacuum to the instrument, and to bleed the system back to

atmosphere pressure at the end of a run.

3.0 OPERATION

A two-position power switch (OFF/ON) is found on the right side panel. The system

should be switched ON at least 30 minutes before using to ensure that it has reached

its proper operating temperature of -50 ˚C. It is suggested that the trap be left on at all

times.

When samples or gels are in place and the evaporation/drying component is activated,

switch the vacuum switch to ON. This two-position switch (ON/OFF) is located on the

lower right-hand side of the front panel.

VAPORNET

On the UVS400A, the two-position SOLVENT switch (VOLATILE/AQUEOUS) is located

left-most on the front panel. If volatile, low boiling solvents (bp<95 ˚C) are being evapo-

rated, activate VaporNet by switching to VOLATILEto maximize solvent recovery. If non-

volatile, high boiling solvents (bp>95 ˚C) are evaporated, select Aqueous (VaporNet off).

NOTE: With VOLATILE selected, occasional clicking will be heard from the

system. This indicates that the VaporNet Controller is functioning properly.

When the concentration process is complete, switch the UVS400/UVS400A vacuum

pump OFF. Shut off VaporNet when not in use by setting to AQUEOUS.

Figure 2. a. ANT100 Post-trap Assembly b. DTK120R Chemical Trap Kit

a. b.

7

3.1 EMPTYING THE GLASS CONDENSATION FLASK

During system operation, solvent vapors from the SpeedVac or other attached instru-

ment will collect in the glass condensation flask. The flask must be regularly emptied to

keep the entire system operating at peak efficiency. If the flask is not maintained, it may

become so full that sample drying rate is adversely affected. Another consequence of a

full vessel is that solvent vapors are more likely to contaminate the oil-sealed vacuum

pump bypass the trap and be released to the atmosphere.

Empty the glass flask before it is half full. Often it is convenient and good practice to

change the flask at the end of the workday or workweek, no matter the depth of fill. For

aggressive solvents, you may wish to remove the flask at the end of each run for maxi-

mum protection of the system components.

CAUTION: The UVS400 and UVS400A reach low operating temperatures that can

cause severe damage to unprotected skin. Wear protective gloves

and clothing when removing glass flasks.

To remove the GCF400 for cleaning, bleed the system back to atmospheric pressure.

Remove rubber Flask Cover from flask, leaving tubing attached to cover. Withdraw the

flask partially from the chamber and allow CryoCool to drain briefly. Fully remove flask

and insulating foam ring. Avoid thermal shock by placing the flask on several thickness-

es of absorbent paper toweling and allow to come to room temperature. Insert a spare

GCF400, which is clean and dry, into the chamber. Cover with insulating foam ring, and

seal with rubber Flask Cover. Make sure rubber cover is seated firmly for a good vacu-

um seal. This easy system maintenance can be done in a matter of minutes; the power

(refrigeration) switch need not be shut off during this process. When the used flask has

defrosted, dispose of contents in an environmentally responsible manner. Clean and dry

flask for next use.

IMPORTANT: Check the Glass Condensation Flask before each run and

replace with clean flask if approaching half full. Immediately wipe

dry any CryoCool®Heat Transfer Fluid that falls on the rubber

seal. Be sure Flask Cover is seated firmly on the flask.

NOTE: Collected solvents may be purified for reuse or disposed of safely

according to applicable regulations.

If working with radioactive samples, test condensate for presence of

radioactivity. If found to be radioactive, dispose of as radioactive

liquid according to all applicable regulations.

8

3.2 OPTIONAL TRAPS

Optional traps (described in Section 2.1, Figure 2) must be maintained for optimal sys-

tem performance. The ANT100 utilizes neutralizing solutions which exhibit a color

change when depleted. Ammonia Neutralizing Solution (ANS121) changes from pink to

blue; Neutralizing Solution for Acids (NSA300TF) changes from blue to pale yellow

when depleted. Replace solution bottle when a color change is observed. If using solid

chemical cartridge with DTK120R, the DC120A cartridge for acids turns white to blue;

change when depleted. DC120R cartridge for radioactivity/organics has no color indica-

tor; replace monthly.

3.1 EMPTYING THE GLASS CONDENSATION FLASK (cont’d)

NOTE: If the Refrigerated Vapor Trap is not needed for several weeks, you

may wish to shut it off between uses. Before switching on again,

always remove the used glass vessel and replace with a clean, dry

trap. Check the condition of the CryoCool; if a layer of water is

visible under the CryoCool, remove with a pipette. Failure to follow

these precautions may cause the glass vessel to break when the

trap returns to operating temperature.

NOTE: Periodically check Flask Cover for signs of wear or perishing, and

replace if necessary.

9

4.0 SPECIFICATIONS

Vacuum Source:

Type: Oil-free diaphragm, TEFLON®coated heads,

with built in VaporNet Controller

Displacement: 36 liters/min (@60 Hz), 32 liters/ min (@50Hz)

Maximum vacuum: 29.5 in Hg (10 torr)

Refrigerated Vapor Trap:

Capacity 4 liters

OperatingTemperature: -50 ˚C

Dimensions (W x D x H): 35 x 61 x 45 cm (13.6 x 24 x 18 in)

Weight: 41 kg (90 lbs)

Power Requirements: 115 V, 50/ 60 Hz, 6A

230 V, 50 Hz, 3 A

5.0 ACCESSORIES

ANT100 Post-trap Assembly

ANS121/4 Ammonia neutralizing solution, (package or 4 bottles)

DTK120R Chemical Trap Kit for radioactive samples

DC120A Disposable cartridge for acid vapor neutralization

DC120R Disposable cartridge for radiolabeled vapor adsorption

FC400 Flask Cover (black rubber)

GCF400 Glass Condensation Flask, 4 liters

BV130 Bleeder Valve

SCC1 CryoCool®Heat Transfer Fluid (1 liter)

DVG50 Digital Vacuum Gauge 0-50 Torr < 1 millitorr

CC120/DX Deluxe Convenience Cart

NSA300TF/4 Neutralizing Solution for acid (pack of 4 bottles)

10

6.0 WARRANTY AND LIABILITY STATEMENTS

All Thermo Savant products (excluding glassware) are warranted against defects in mate-

rial and workmanship for one year after the date of delivery to the original purchaser.

Thermo Savant’s warranty is limited to defective materials and workmanship, and does

not cover incidental or consequential damages.

Thermo Savant will repair free of charge any apparatus covered by this warranty. If a new

component fails to work, Thermo Savant will replace it, absorb all charges, and continue

the one-year warranty period. Warranty work is subject to our inspection of the unit. No

instruments, equipment or accessories will be accepted without a Return Material

Authorization (RMA) number issued by Thermo Savant. Cost of shipping the unit are not

covered under warranty. The warranty obliges you to follow the precautions in this manu-

al.

When returning apparatus that may contain hazardous material, you must pack and label

them following U.S. Department of Transportation (DOT) regulation applying to trans-

portation of hazardous materials. Your shipping documents must also meet DOT regula-

tions. All returned units must be decontaminated and free of radioactivity.

Use of this equipment in manner other than those specified in this manual may jeopard-

ize personal safety. Under no circumstances shall Thermo Savant be liable for damages

due to the improper handling, abuse, or unauthorized repair of its products. Thermo

Savant assumes no liability, express or implied, for use of this equipment.

11

145-3001-00 Rev.A

© 2001 Thermo Savant

100 Colin Drive • Holbrook, NY 11741-4306 USA

Tel: 631-244-2929 • 1-800-634-8886 • Fax: 631-244-0606

A Thermo Electron business

This manual suits for next models

1

Table of contents

Other Thermo Savant Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Integra

Integra VIAFLO 4011 VIAFLO 4012 operating instructions

Elastocon

Elastocon Gehman Tester ET02-II manual

Hanna Instruments

Hanna Instruments Groline HI981413 instruction manual

IKA

IKA MICROSTAR control Series user manual

Kolver

Kolver EDU2AE Operational manual

TANNER Scientific

TANNER Scientific TN1500 user manual