1

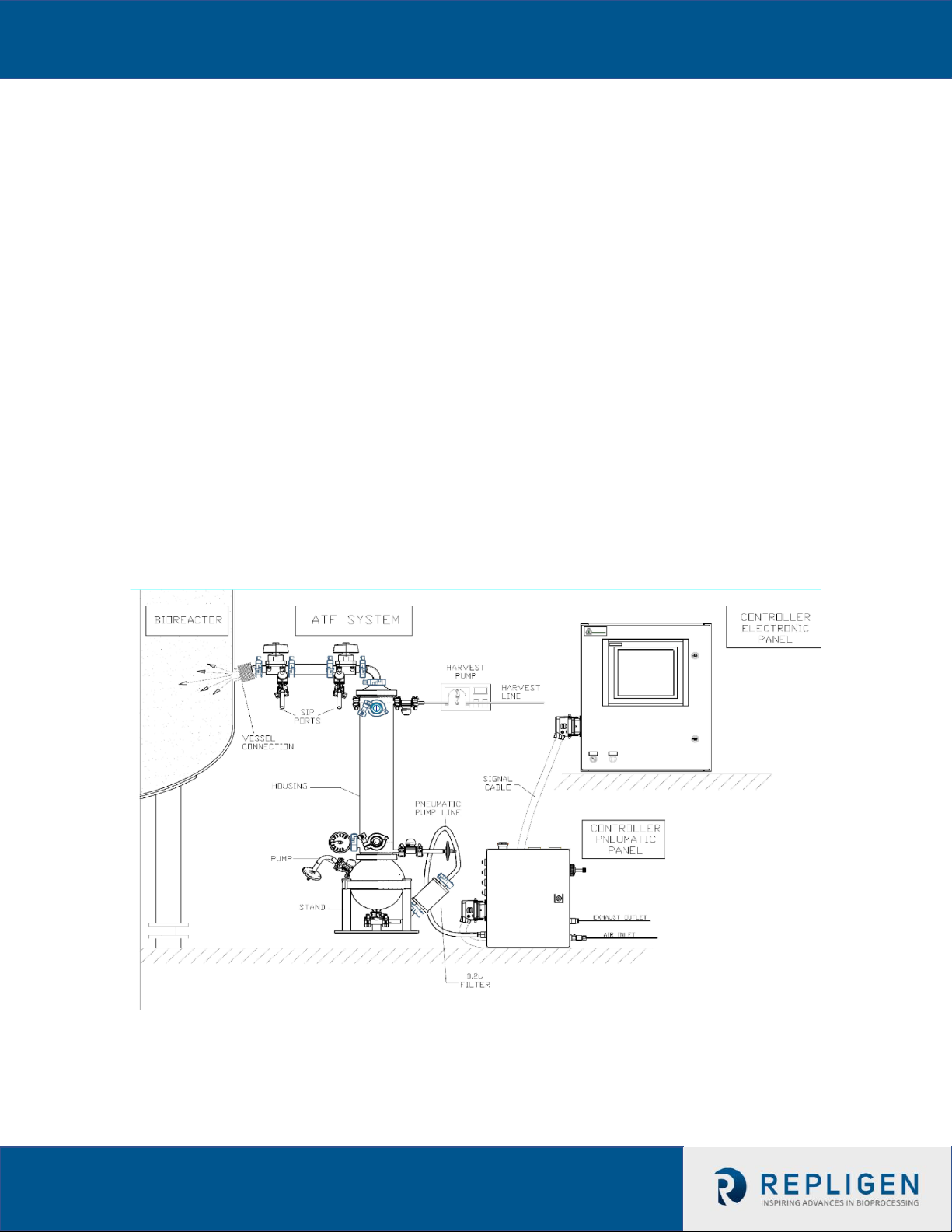

1.0 Description of the XCell™ ATF (Alternating Tangential Flow) System

and Process

The XCell™ ATF System provides an efficient means for fractionation of various mixtures. It may

include the separation of mammalian Cells (~ 10 microns in size) from culture medium, the

separation of large particles such as micro carriers (~ 200 microns in size) from a suspension

medium, or separation of some molecules from other molecules in a suspension. The user guide

details the use of the XCell™ ATF System, with the C410v4B Controller for the separation of such

components using hollow fiber filtration.

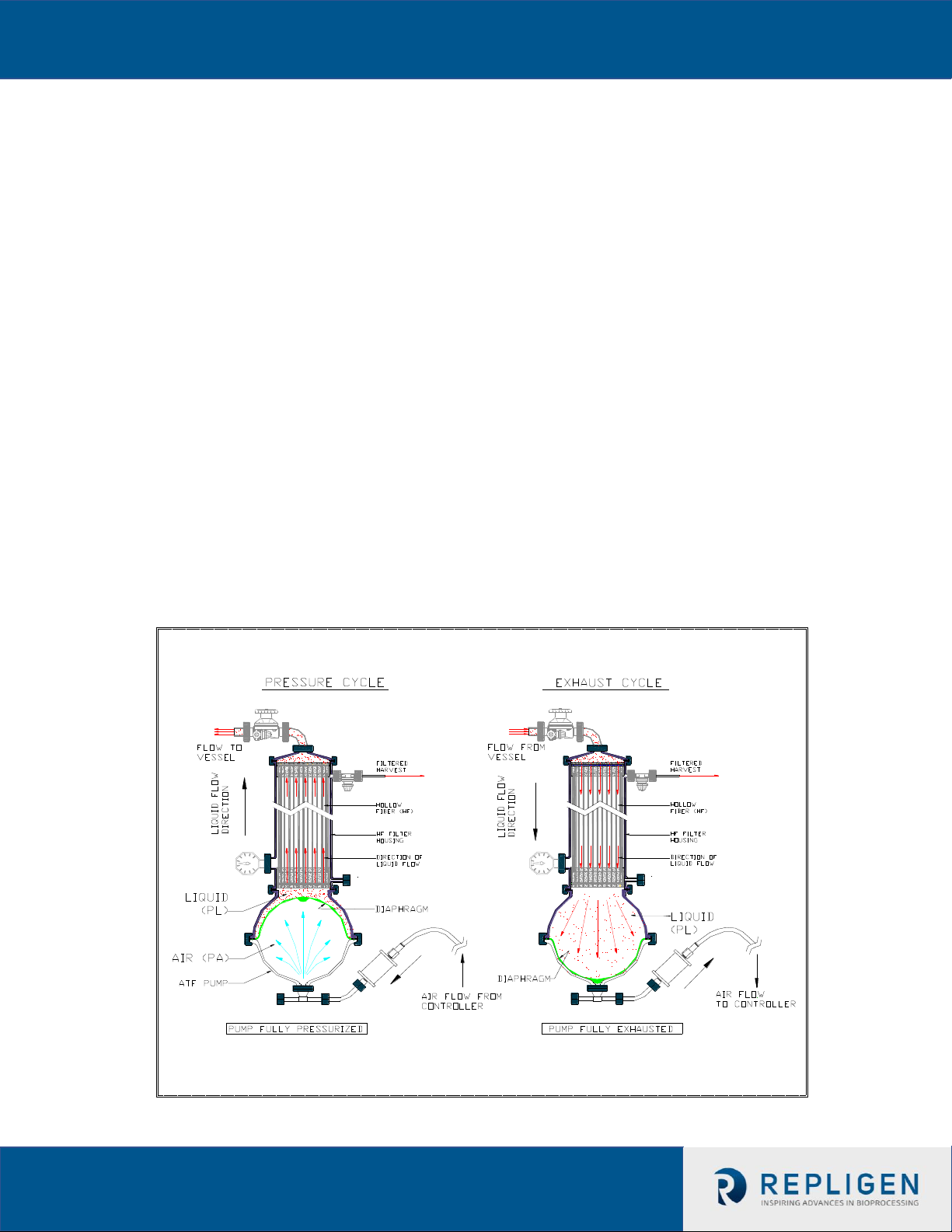

The system is designed to improve the efficiency of cell culture processing by allowing for the

generation of high viable cell densities. The system can enable continuous processing and is

available in stainless steel and single-use formats. Two primary components, the C410v4B

controller and the ATF pump housing, which in comprised of a diaphragm pump, filter housing

and a hollow fiber filter, are used for desired operation. The controller functions to control the

ATF (Alternating Tangential Flow) action by controlling the movement of the diaphragm pump,

through control of pressurization and exhaust (vacuum) to allow the up and down motion of the

diaphragm in the pump housing. This action displaces a known volume of cell culture material

within the retentate side of the hollow fibers. A separate pump continuously removes cell-free

permeate from the system. Primary components of the current controller include a PLC

(Programmable Logic Controller) with a HMI (Human Machine Interface) to control the

components used in generating the alternating tangential flow action.

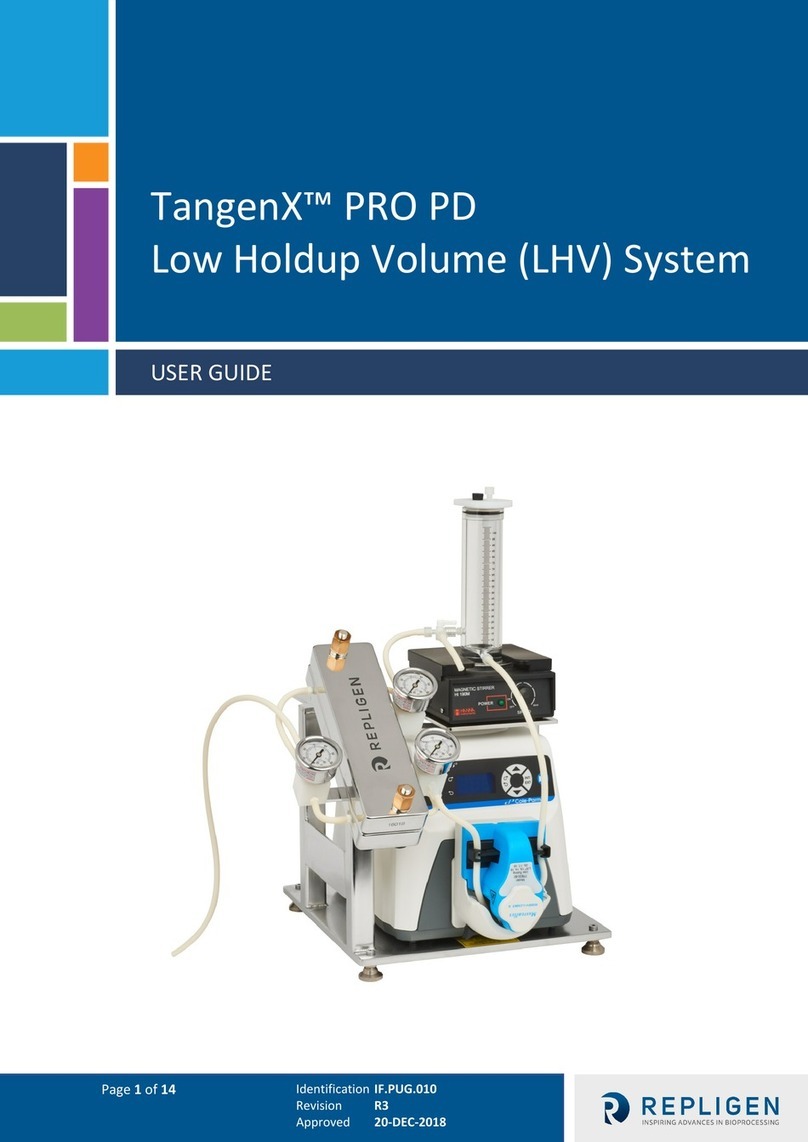

This User Guide pertains to both the Stainless Steel Filtration Assemblies and the XCell™ ATF

Single-use devices, meaning that the C410v4B Controller information relates to the operation of

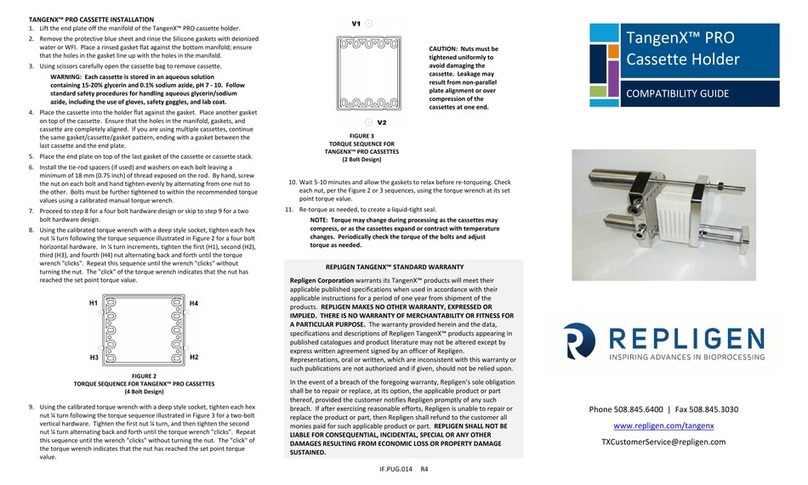

both the stainless steel and single-use ATF devices. (Figure 1).

•Controller: a dedicated controller used to control and monitor XCell ATF System activity. It

also provides the means for connecting to and controlling pressure and vacuum utilities.

•Filtration Assembly: an assembly of two major elements, a stainless steel filter housing and

a silicone diaphragm pump:

-Filter Housing: housing containing the filtration element, either a hollow fiber module (HFM) or

screen module (SM).

-Diaphragm Pump: spherical housing in which a diaphragm membrane is moved up and down by

pressurized air or vacuum, creating alternating flow.

-Single-use Device: the filter housing, hollow fiber filter and diaphragm pump are combined into

a single polycarbonate device. At this point in time the SM is not available as a single-use device.

Please see the XCell™ ATF Start-Up Guide for additional information on the single-use devcies.

The Filtration Assembly includes the following components for each process application:

-A2B Connection Assembly:tubing assembly connecting the Filtration Assembly to a bioreactor or

process vessel

-Bioreactor Adaptor: adaptor between the Connection Assembly and bioreactor port. Typical

ports/connectors/adaptors for stainless steel bioreactors include an Ingold-type port, triclamp

or, if a single use bioreactor (SUB), then, a disposable aseptic connector (DAC) or equivalent.