thermopatch.com

9

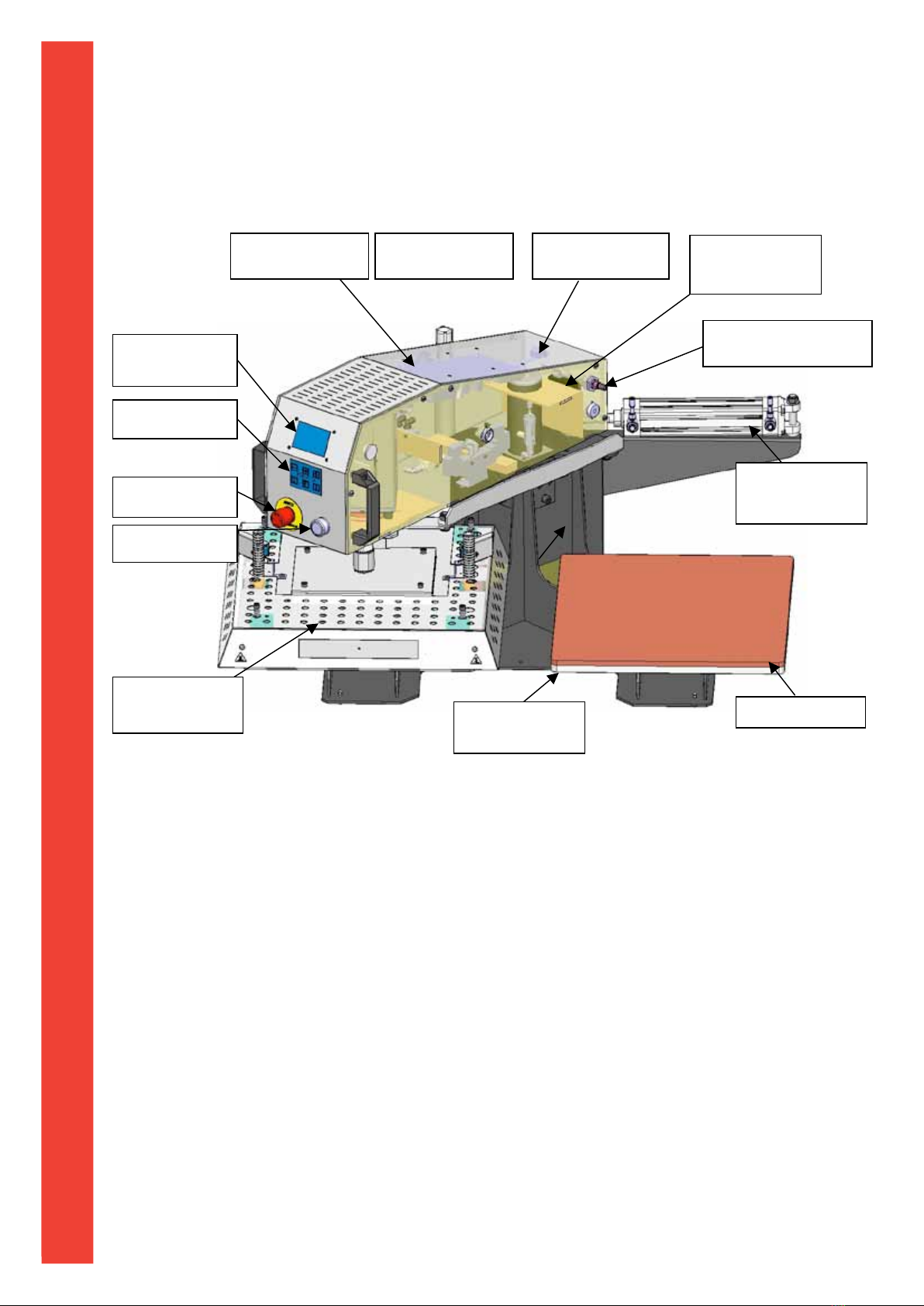

II. Installation

2.1 INSTRUCTION FOR HANDLING

The NL-33 AUTO has been packed in a wooden crate and xed

to a pallet. If you need to relocate the machine at a later

point, we advise you to pack the machine in a similar fashion.

Let the machine cool down completely before packing and

moving it.

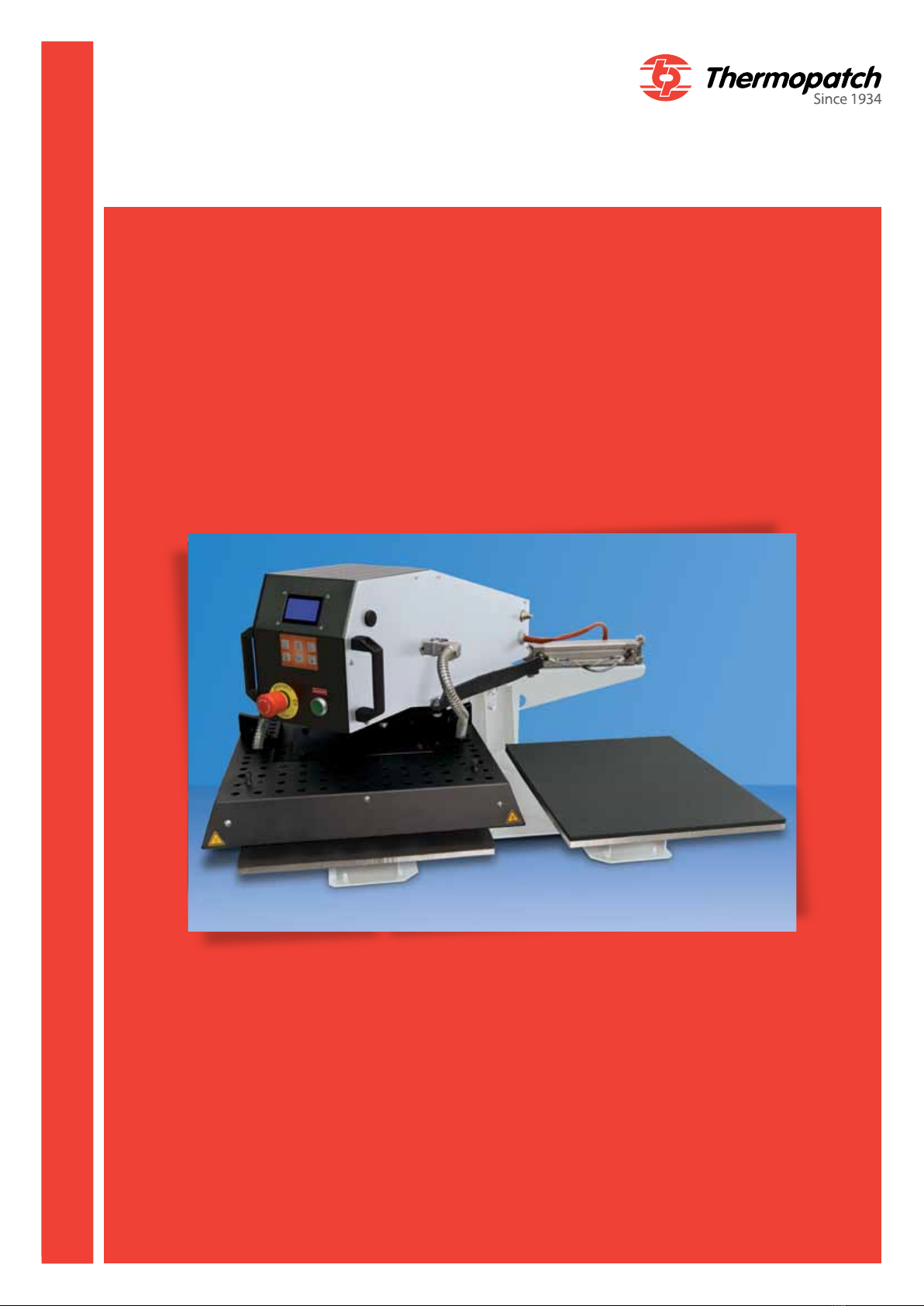

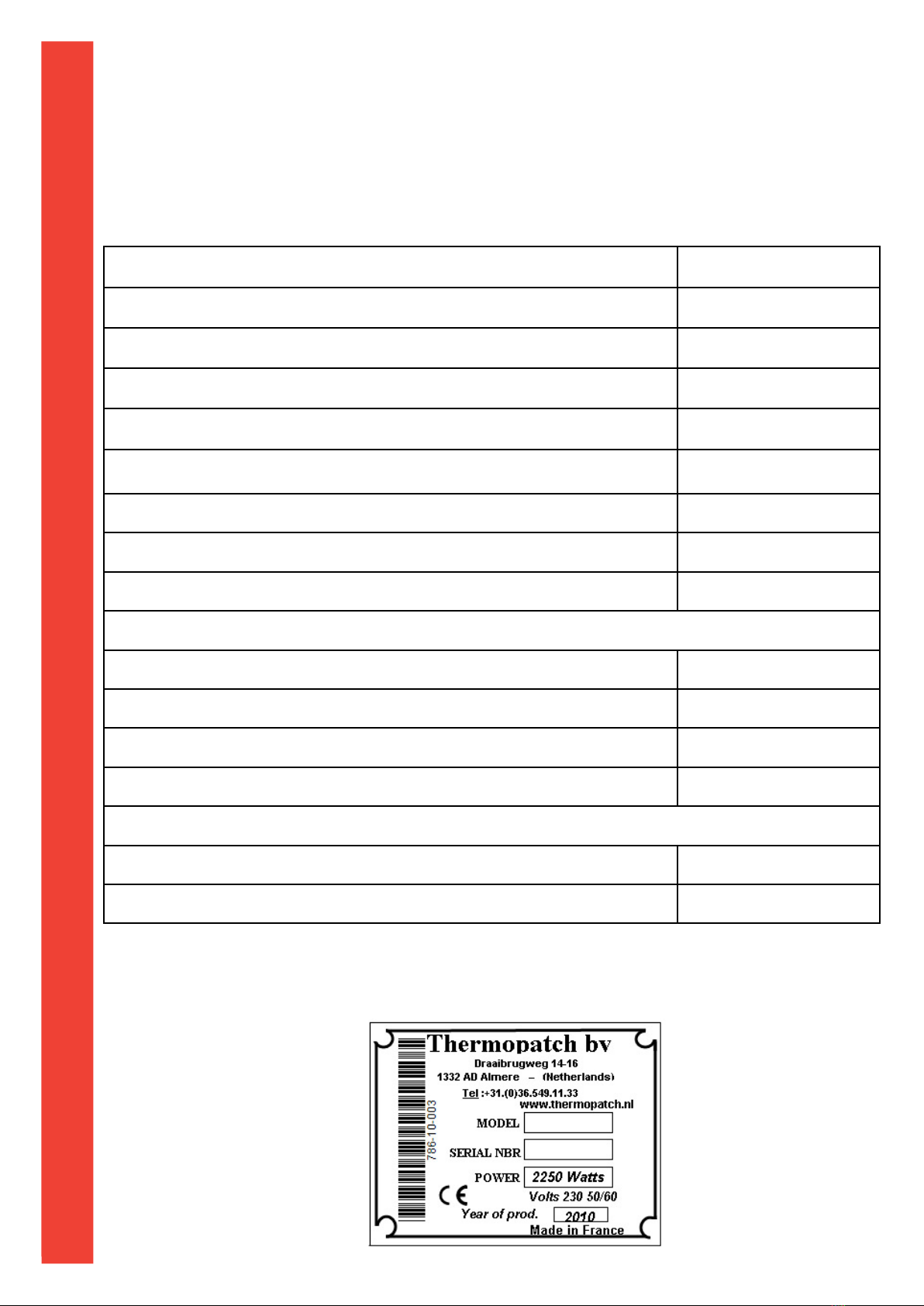

2.2 INSTALLING AND CONNECTING THE NL-33 AUTO

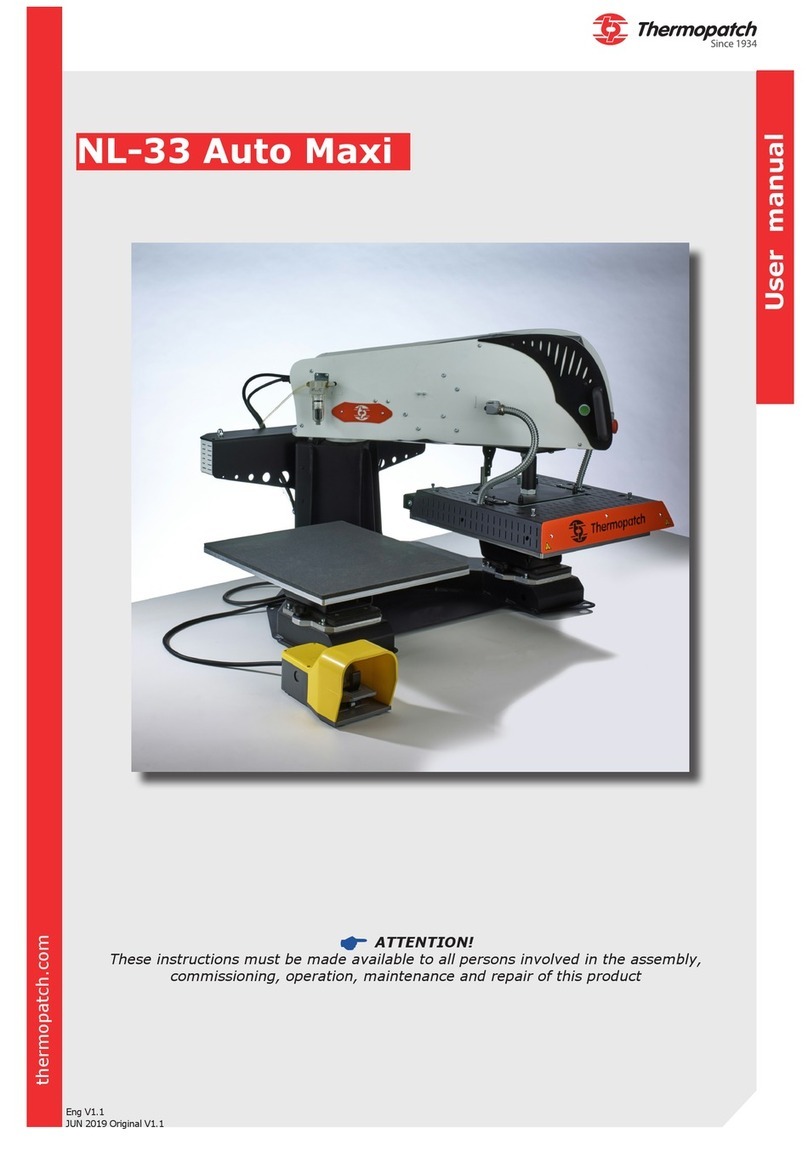

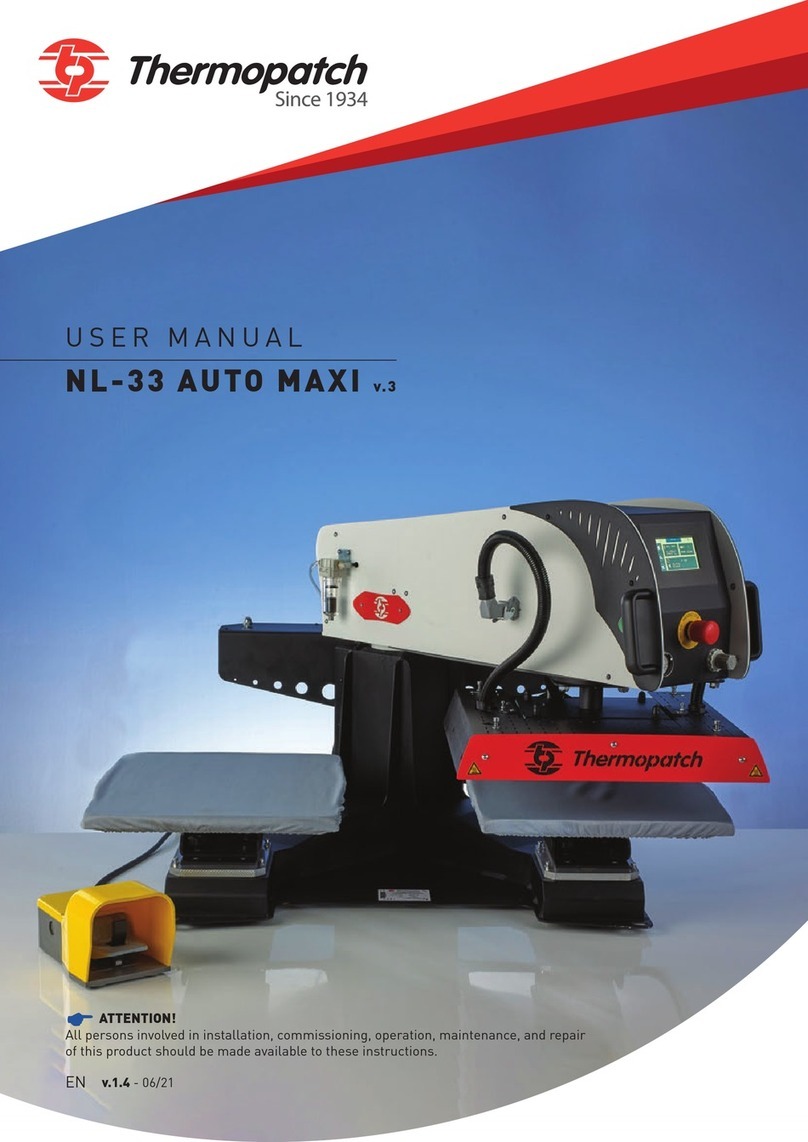

Take the Thermoseal NL-33 AUTO from its box and place it

on a stable worktop near an earthed wall socket. Connect the

machine with the supplied power cord to the electrical current

(230 Volt, alternating current). The NL-33 AUTO is earthed

and provided with a fuse (11 Amps).

2.3 ASSEMBLY

To ensure a problem-free operating of your NL-33 AUTO,

it is essential to work with dry, clean compressed air. The

supplied pressure regulator with water condenser is only an

added protection of the machine. The user has to make sure

that the pressure on the machine does not exceed 6 Bars.

Connect a 6 mm air tubing with the compressor or the local

compressed air system and connect this subsequently to the

water condenser / pressure regulator mounted on the

NL-33 AUTO. The NL-33 AUTO is tted with a foot pedal for

its operation. Connect the foot pedal by inserting the

connector into its slot, which is placed underneath power

entry on the back of the machine. Fasten the securing ring

after inserting the connector.