Manuale Utente Osmomaxi ENG 2014-02-24 - 18 -

INDEX

1. GENERAL INFORMATIONS .................................................................................................................................. 19

1.1 MANUFACTURER / ASSISTANCE ............................................................................................ 19

1.2. CERTIFICATION ............................................................................................................... 19

1.3. PURPOSE OF THE MANUAL AND ITS CONTENTS .......................................................................... 19

1.4 CARE AND STORAGE OF THE MANUAL ..................................................................................... 19

1.5 IMPORTANT SYMBOLS TO REMEMBER ...................................................................................... 19

2. CHARACTERISTICS OF THE DEVICE .................................................................................................................. 20

2.1. RECOMMENDED USE.......................................................................................................... 20

2.2 DESCRIPTION ................................................................................................................. 20

2.3 TECHNICAL SPECIFICATIONS................................................................................................ 20

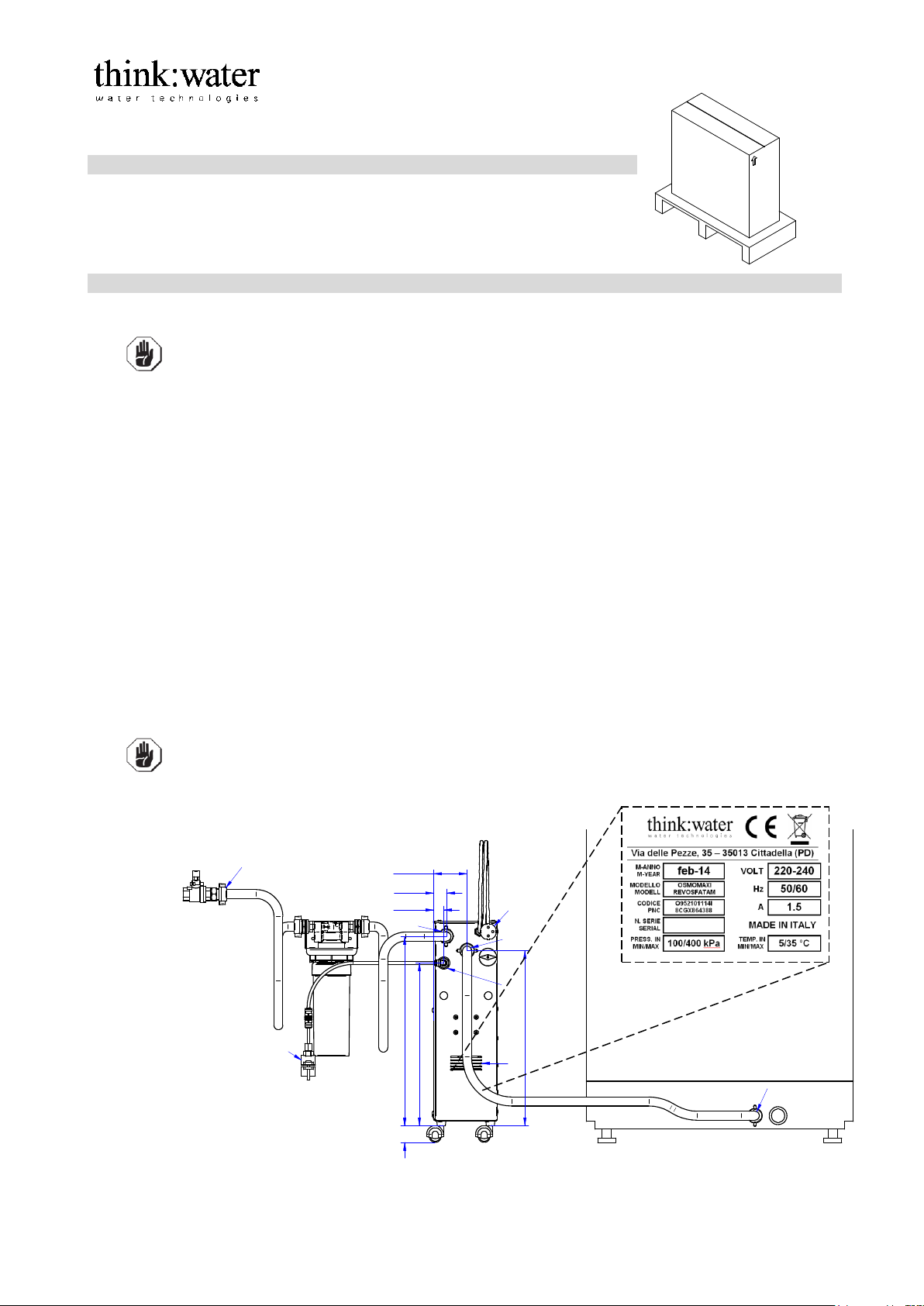

2.4 GENERAL DIMENSIONS ....................................................................................................... 21

3TRANSPORT .......................................................................................................................................................... 22

4INSTALLATION ...................................................................................................................................................... 22

5FUNCTIONING........................................................................................................................................................ 23

5.1 NORMAL USE.................................................................................................................. 23

5.2 USE OF REAR BY-PASS VALVE............................................................................................... 23

5.3 BEHAVIOR IN THE EVENT OF FAILURE ..................................................................................... 23

5.4 INACTIVITY.................................................................................................................... 24

5.5 HIGH CONDUCTIVITY ALARM ............................................................................................... 24

5.6 REPLACEMENT FILTERS ALARM ............................................................................................. 24

5.7 MINIMUM PRESSURE ALARM ................................................................................................. 24

5.8 LEAKAGE ALARM ............................................................................................................. 24

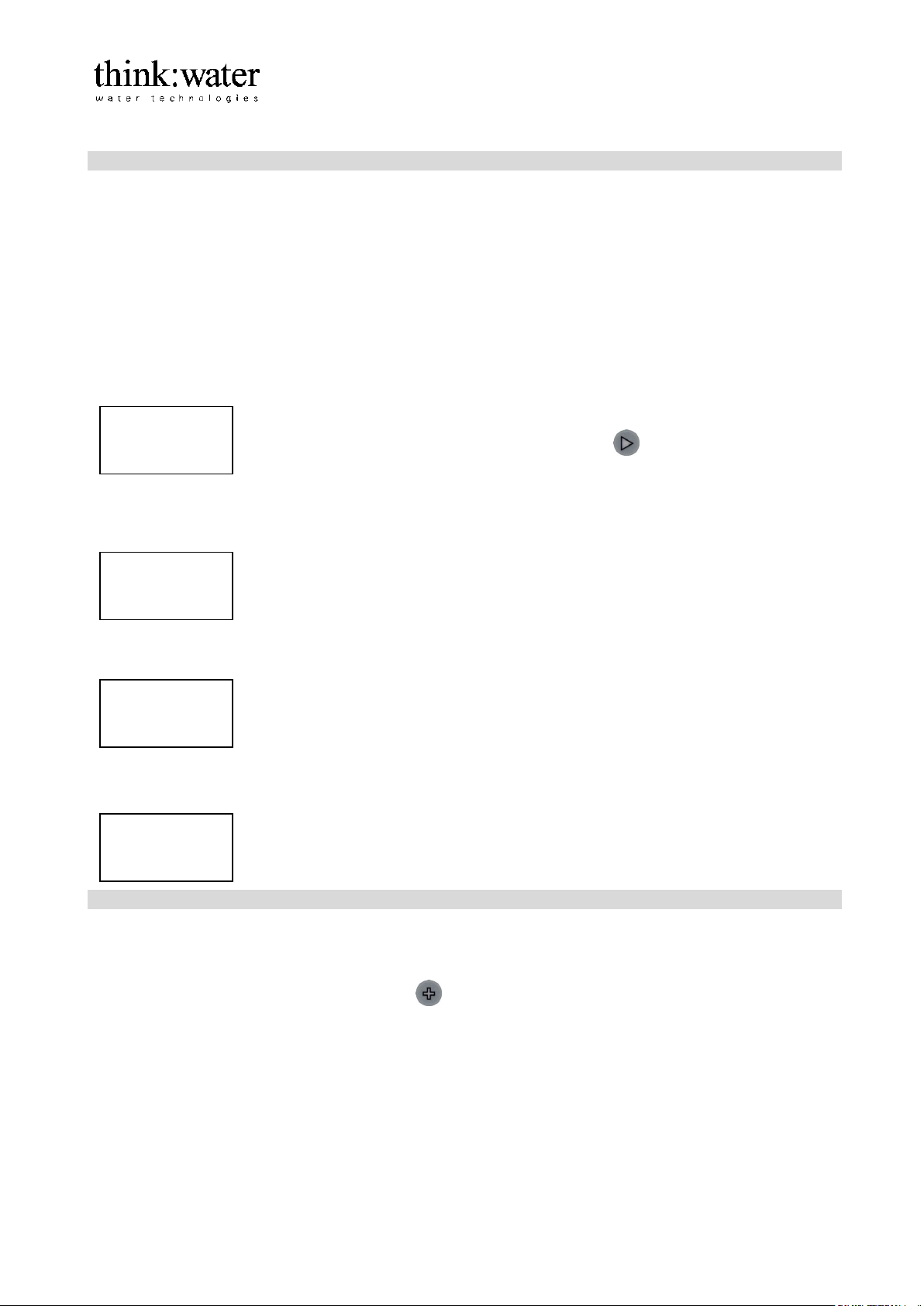

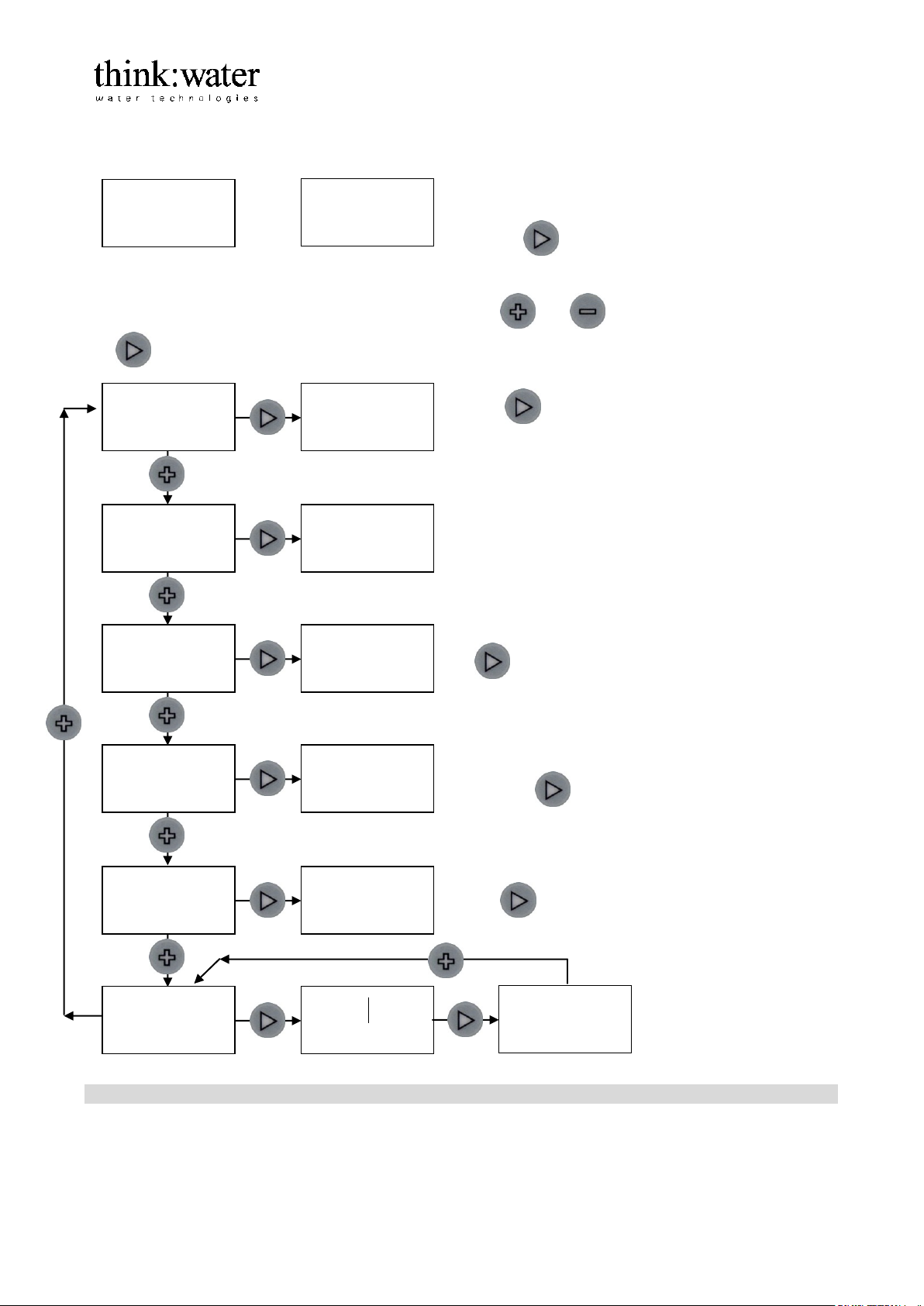

5.9 ELECTRONIC BOARD OPERATION........................................................................................... 25

6ROUTINE MAINTENANCE (USER)........................................................................................................................ 26

6.1 MAINTENANCE PLAN ......................................................................................................... 26

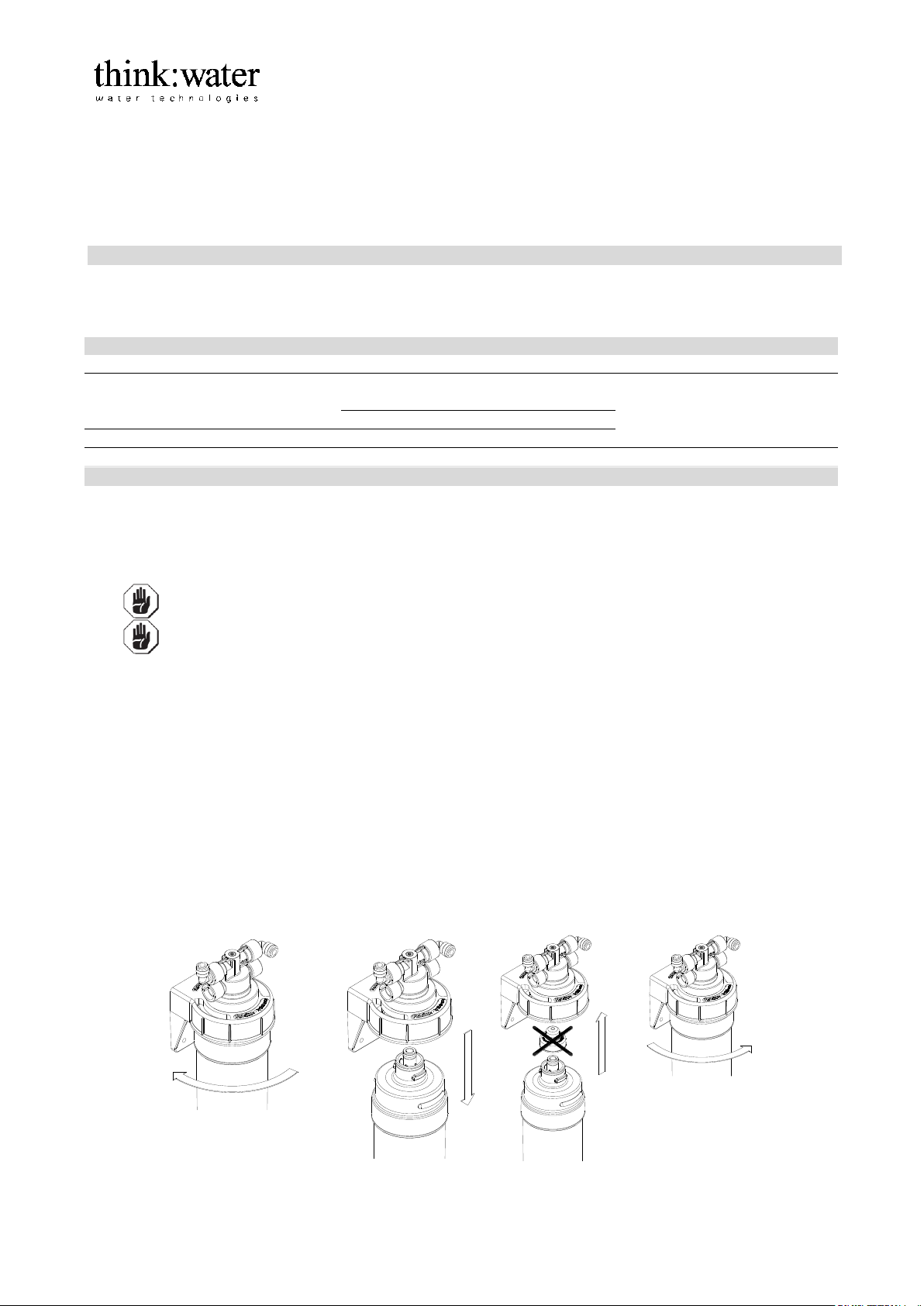

6.2 PROFINE® CARTRIDGE PREFILTER REPLACEMENT ....................................................................... 26

7TROUBLESHOOTING (USER)............................................................................................................................... 27

8DISPOSAL (USER) ................................................................................................................................................. 29

9MAINTENANCE LOG ............................................................................................................................................. 29