THK ET Series User manual

INSTRUCTION MANUAL

ET

THK Electrical Actuator Economy Series

No.1050-3(0)E

iET

Table of Contents

1. Introduction 2. Installation 3. Wiring

1. Introduction

1-2

1-1 Acknowledgment 1-2

1-2 About this manual 1-2

1-3 How to use this product 1-3

1-4 About product support 1-3

1-5 About related instruction manuals 1-3

1-6 Product and company information 1-3

2. Safety precautions 1-4

2-1 About ranks of precautions 1-4

2-2 About description of precautions 1-4

2-3 Safety precautions 1-5

3. System configuration 1-6

3-1 System configuration diagram 1-6

4. Flow until using the product 1-7

1. Check products 2-2

1-1 Check the package contents of ET 2-3

1-2 Names of individual parts and functions 2-7

1-3 Store and dispose of products 2-9

2. Precautions on use 2-10

2-1 Precautions on use of ET 2-10

3. How to install 2-11

3-1 Installation environment 2-11

3-2 Setting of ET 2-12

1. How to wire 3-2

1-1 Entire wiring 3-3

1-2 Connect actuator cable 3-4

ii ET

Table of Contents

4. Maintenance and Warranty

5. Technical Materials

1. Maintenance 4-2

1-1 Daily inspection 4-2

1-2 Periodical inspection 4-3

1-3 How to apply grease 4-4

1-4 Check points when restoring from the long-term suspension 4-8

2. Repair/Replacement 4-9

2-1 How to replace the timing belt 4-9

3. Product warranty 4-13

3-1 Free warranty period 4-13

3-2 Usage conditions (range) 4-13

3-3 Warranty scope 4-13

3-4 Exclusion of warranty liability 4-14

3-5 Delivery conditions 4-14

1. Motor mounting method 5-2

1-1 Motor mounting example 5-2

2. Cables 5-6

2-1 Connection cable 5-6

3. Materials Required for Selecting 5-7

1-1 ET

1. Introduction ………………… 1-2

1-1 Acknowledgment…………………………… 1-2

1-2 About this manual ………………………… 1-2

1-3 How to use this product…………………… 1-3

1-4 About product support …………………… 1-3

1-5 About related instruction manuals ……… 1-3

1-6 Product and company information ……… 1-3

2. Safety precautions ………… 1-4

2-1 About ranks of precautions ……………… 1-4

2-2 About description of precautions ……… 1-4

2-3 Safety precautions ………………………… 1-5

3. System configuration ……… 1-6

3-1 System configuration diagram…………… 1-6

4. Flow until using the product 1-7

1. Introduction

This section includes

introduction about the

product and this manual.

This section includes

general precautions to

follow when using the

product.

Be sure to read this

section before use and

observe the precautions.

This section includes

introduction about

peripheral devices to be

used with this product.

This section describes

installation and setting

processes to make this

product ready for use.

About this chapter

This chapter describes the overview of the product.

This chapter includes information that we want you to check and understand before working with the product.

1. Introduction

1-2 ET

1-1 Acknowledgment

Thank you for purchasing our product.

This product is a lightweight, compact, and reasonably-priced actuator which ensures a long-term

maintenance-free operation.

This product is designed and manufactured to be incorporated in devices with a wide range of

applications including conveyance systems, implementing equipment, automated assemblers,

positioning equipment and more.

We hope our creative inventions and unique technologies contribute to your further prosperity.

1-2 About this manual

1-2-1 Intended audience

The person in charge of designing embedded systems of the product and installing, wiring, and

maintaining the product, and the person who actually uses the product.

1-2-2 Using this manual

This manual describes correct handling methods and precautions for the product.

For the maximum performance and long life of the product, carefully read and understand this manual to safely and

correctly use the product.

If you use the printed version of this manual, be sure to keep it in the place that the audience can refer to it when needed.

1-2-3 Notice and attention

lDo not use or handle the product in the ways that are not described in this manual.

lDo not reproduce, reprint, or lend the whole contents or a part of this manual without permission.

lPlease note that the description in this manual is subject to change without prior notice in the

future, due to improvements of the product or other reasons.

We have made all possible efforts to make the content of this manual accurate. However, if you

find any mistake or uncertainty in this manual, please contact THK.

For the following information, please contact THK.

lDrawings throughout this manual are only intended as typical examples, and may differ from your product.

lNote that THK shall not be liable for any result incurred by applying this manual, regardless of the reason.

lThis manual is also applied to custom products. However, the descriptions provided in the delivery specification

drawings or delivery specification documents of those custom products take precedence over this manual.

×Custom products represent the products that have different materials and specifications from

those of the standard products on catalogs.

1-2-4 Notation of this manual

Notes that can lead to unsatisfactory functions, errors, or damages of the product if not observed while

using the product.

Supplementary information for the description.

Reference information for the description.

1.

Introduction

Important

Supplement

Reference

1. Introduction

1.

Introduction

1-3 ET

1-3 How to use this product

lThis product must not be used for the devices or systems that are used under the situations that

may be fatal to human life.

lIf you consider using this product for special applications such as passenger movement vehicle,

medical, aerospace, nuclear power, and electric power devices or systems, be sure to consult

with THK in advance.

l

This product is manufactured under the strict quality control, however, that does not mean that the product

is free from failure. For applications to the equipment that may suffer serious accidents or loss from the

failure of this product, install safety devices or backup devices that prevent such serious accidents or loss.

1-4 About product support

For the following information, please contact THK.

lTechnical support for this product

1-5 About related instruction manuals

lWhen you use the actuator ET, read the following instruction manuals as necessary.

• Controller series Driver controller TSC

• Controller series Setup tool D-STEP

If you purchase this product with a motor, TSC is the applicable driver controller. Please note that driver controllers

other than the above cannot be used. This excludes installations of the motor specified by the customer.

1-6 Product and company information

To find the latest product and company information, we recommend you to periodically

access our website.

lWebsite URL: https://www.thk.com

lTechnical support website URL: http://www.tech.thk.com/

Important

1. Introduction

1-4 ET

2-1 About ranks of precautions

This manual uses the classifications of “Danger,” “Warning,” and “Caution” for warning indications

for safety matters.

2-2 About description of precautions

Precautions are classified as “Prohibition,” “Instruction,” and “Precaution” according to the action.

This mark indicates

“prohibition” of the

action.

This mark indicates

“instruction” for

the action.

This mark indicates

“caution” about

the action.

Prohibited Do not

disassemble

Obligatory Provide grounding

connection

Caution Caution -

Electrical shock

Caution -

Flammable

Caution - High

temperature

Caution - Getting

caught

Danger Erroneous handling may urgently cause death or

serious injury to a person

Warning Erroneous handling may cause death or serious injury

to a person

Caution Erroneous handling may cause injury to a person or

property damage only

2.

Safety precautions

1. Introduction

2.

Safety precautions

1-5 ET

2-3 Safety precautions

While the actuator is operating or

operable, do not enter the working

area of any moving part including

the load.

Otherwise, it may cause you to touch

the moving part and get injured.

If the product fails or any abnor-

mality is observed, shut down the

power of the driver controller TSC.

Such abnormality may cause a

malfunction of actuator, resulting in

damage or injury.

Do not touch the internal part of

the driver controller TSC.

Otherwise, it may cause electric shock.

Do not damage, tuck, or apply

excessive stresses on the cable.

Otherwise, it may cause electric shock.

Do not modify, disassemble, or

alter the product.

Otherwise, it may cause injury or

failures.

Prohibited

Obligatory

Caution -

Electrical shock

Do not

disassemble

During the operation, or for a while

after turning the power off, do not

touch the driver controller TSC, or

motor cover because they should

be hot.

Otherwise, it may cause burns.

Do not impact the product and

do avoid rough handling such as

throwing it.

Otherwise, it may cause the failures or

damage that leads to injury.

Do not frequently switch the power

between on and off.

Otherwise, it may generate heat from

the internal parts of the driver controller

TSC, which results in fault or burns.

Do not set the speed or

acceleration setting or place the

load on the table that exceed the

actuator specification.

Otherwise, it may cause motor failure,

which leads to unexpected accidents

or damages.

If an alarm is generated, remove

the cause, check the safety, de-

activate the alarm, and restart the

operation.

Failure to do so may result in failure,

which leads to injury.

Use this product with a combina-

tion that is specified beforehand.

Otherwise, it may cause fire or failures.

Observe the specified input

voltage.

Otherwise, it may cause fire or failures.

Caution - High

temperature

Prohibited

Obligatory

Caution -

Flammable

Warning

Caution

1. Introduction

1-6 ET

3-1 System configuration diagram

lThe diagram below shows the specification of a combination with the driver controller TSC.

lCables for connecting the devices indicated with ★should be prepared by the customer.

3.

System configuration

PC (D-STEP) (-> ×1)

Host controller

Emergency

stop switch

(This should

be prepared by

the customer.)

(-> ×2)

Driver controller

TSC

Actuator cables are

provided with the main unit.

(-> P.5-6)

24 VDC power

★

★

★Power supply

should be prepared

by the customer.

Power connector is

provided with TSC.

(-> ×2)

CN1

CN2

CN4

CN3

CN5

PC communication

cables are provided

as an option.

(-> ×2)

★

I/O connector for CN1

is provided with TSC.

I/O cables are provided

as an option.

(-> ×2)

★

×1 See the separate D-STEP Instruction Manual.

×2 See the separate TSC Instruction Manual.

×When you use 10 m actuator cables,

please install a noise filter for the TSC

power supply.

RSAN-2003 from TDK-Lambda is

recommended for the noise filter.

Actuator

★

Wire to the I/O

connector of sensor

CN1.

1. Introduction

1-7 ET

1. Safety Check

(1) Safety statement check -> P.1-4

(2) Safety check of the installation location

-> P.2-11

(3) Installation check -> P.2-12

2. Preparation (1) Preparation of required devices -> P.1-6

(2)

Package contents check

->

P.2-3 to 2-9

3. Installation (1) Installation environment check -> P.2-11

(2) Installation -> P.2-11 to 2-19

4. Wiring (1) Connection between each device and

cable -> P.3-2 to 3-6

5.

Trial Run and Adjustment

(1) For details of setup tool preparation and

program input, see the separate D-STEP

Instruction Manual.

6. Setup tool setting (1) For details of setup tool setting, see the

separate D-STEP Instruction Manual.

4.

Flow until using the product

2-1 ET

2. Installation

This section describes the

package contents check

and parts of this product.

This section describes the

installation procedures of

this product.

About this chapter

This chapter describes how to check the package contents and to install it to the machine and facilities.

This section is primarily intended for those in charge of installation of this product to a machine and facilities.

1. Check products ……………… 2-2

1-1 Check the package contents of ET …… 2-3

1-2 Names of individual parts and functions 2-7

1-3 Store and dispose of products…………… 2-9

2. Precautions on use ……… 2-10

2-1 Precautions on use of ET ………………… 2-10

3. How to install ……………… 2-11

3-1 Installation environment ………………… 2-11

3-2 Setting of ET ………………………………… 2-12

This section describes the

precautions on use of this

product.

2. Installation

2-2 ET

Do not stand on the packaging box

or this product.

Otherwise, it may cause the failures or

damage that leads to injury.

Do not touch the rotating table.

It may injure you.

Do not let finger or hands touch or

become caught in rotating parts such

as the table.

Do not grip the edges of this

product’s pulley cover and motor

cover.

It may injure you.

Take care not to cut your hands or

fingers on the cover’s edge.

Prohibited

When carrying the product, do not

hold the cable.

The cable bush or cable could break

and possibly cause an injury.

Do not use the product if you find

any abnormality.

Using a fractured product may cause

malfunction that could lead to injury

or fault. If you find any defect, please

contact THK.

Prohibited

Caution

1.

Check products

Warning

For the combination of the actua-

tor ET and the driver controller

TSC, do not use actuators with

models other than TSC. Otherwise,

it may cause unexpected motions, ac-

cidents or failures.

Prohibited

Be cautious of the cover edge

indicated by the red line.

330° specification

Actuator model number: ET20-45-330-TS/20P-D00-S3

Controller model number: TSC-015B-MOD-ET20-45-330-D

360° specification

Actuator model number: ET20-45-360-TS-U/20P-S3

Controller model number: TSC-015B-MOD-ET20-45-360

2. Installation

1.

Check products

2-3 ET

1-1 Check the package contents of ET

1-1-1 Check the model/type of the product

Check the model indicated on the product label against the purchase information.

Product label

Model number (-> P.2-4)

Serial number

Necessary for exchanging or repairing

the product.

2. Installation

1.

Check products

2-4 ET

ET model configuration

TSC specifications

ET20-45-330-TS-/ 20P D00 S3

(1) Model number ET20, ET35

(2) Reduction ratio 20: 1/20 (ET35 only)

30: 1/30 (ET35 only)

45: 1/45 (ET20 only)

(3) Stroke 330: 330°

360: Multi-rotation (360° or more)

(4) Control device type TS: Stepper driver controller TSC

(5) Sensor U :

Magnetic proximity switch (Asa Electronics Industry Co., Ltd. AH003)

No symbol : None

(6) Motors used 20P: □ 20 stepper motor (ET20)

(Made by Oriental Motor Co., Ltd.)

35P:

□35 stepper motor (ET35)

(Made by Oriental Motor Co., Ltd.)

(7) Origin D00: CCW rotation during return to home position

R00: CW rotation during return to home position

No symbol: None (Multi-rotation specification has no symbol)

(8) Cable length No symbol : None

S3 : 3 m standard

S5 : 5 m standard

SA : 10 m standard

(1) (2) (3) (4) (5) (6) (7) (8)

2. Installation

1.

Check products

2-5 ET

ET model configuration

Type without motor

ET35-30-360-0-B-U

(1) Model number ET20, ET35

(2) Reduction ratio 20: 1/20 (ET35 only)

30: 1/30 (ET35 only)

45: 1/45 (ET20 only)

(3) Stroke 330: 330°

360: Multi-rotation (360° or more)

(4) With/without motor 0: Without motor

1: With motor (Customer specified motor purchased/mounted by THK)

(5) Motor plate A: For stepper motor

B: For servo motor

(6) Option U :

Magnetic proximity switch (Asa Electronics Industry Co., Ltd. AH003)

No symbol : None

(1) (2) (3) (4)(5)(6)

2. Installation

1.

Check products

2-6 ET

1-1-2 Checking the type and number of accessories

Actuator

Type of parts Qty.

Actuator main unit 1

○TSC specification

○No motor specification

Motor plate symbol: A

Type of parts Qty.

Actuator main unit 1

Pulley cover 1

Flat nut 1

Timing pulley 1

Timing belt 1

Hexagonal socket-head setscrew

Half-point

2

Hexagonal-socket-head type button bolt

4

○

ET20 No motor specification

Motor plate symbol: B

Type of parts Qty.

Actuator main unit 1

Pulley cover 1

Intermediate plate 1

Timing pulley 1

Timing belt 1

Hexagonal socket-head setscrew

Half-point

2

Hexagonal-socket-head type button bolt

4

Hexagon socket head cap screw (M2.5)

2

Hexagon socket head cap screw (M3)

2

Flat washer Small washer

2

○

ET35 No motor specification

Motor plate symbol: B

Type of parts Qty.

Actuator main unit 1

Pulley cover 1

Intermediate plate 1

Timing pulley 1

Timing belt 1

Hexagonal socket-head setscrew

Half-point

2

Hexagonal-socket-head type button bolt

4

Hexagon socket low head cap screw

4

Hexagonal-socket-head type bolt

2

Flat washer Small washer

(3 x 6 x 0.5)

4

Flat washer Small washer

(4 x 8 x 0.8)

2

After the checking, keep the product packed in the packaging box until the start of installation work.

1-1-3 Check the product for any damage or abnormality

Cable list

Type of parts Type Qty.

Actuator cable CBL-TSC-AC-àà-B 1

àà indicates the cable length. (03: 3 m, 05: 5 m, 10: 10 m)

For any custom product, check against the delivery specification drawings.

Reference

Model numbers of parts supplied with no motor specification (motor plate symbol: A)

Model ET20-45 ET35-20 ET35-30

Timing pulley P26-1.5GT-3-33F P30-2GT-6-33F

(P26-2GT-6-33F)

Made by Gates Unitta Asia Company

Timing belt 100.5-1.5GT-3 142-2GT-6

(134-2GT-6)

158-2GT-6

(148-2GT-6)

Made by Gates Unitta Asia Company

Hexagonal socket-head setscrew half-point

M2.6 x 3L M3 x 4L

Hexagonal-socket-head type button set bolt

M2.5 x 5L M3 × 5L

Model numbers of parts supplied with no motor specification (motor plate symbol: B)

Model ET20-45 ET35-20 ET35-30

Timing pulley P28-1.5GT-3-33F P30-2GT-6-33F

Made by Gates Unitta Asia Company

Timing belt 103.5-1.5GT-3 142-2GT-6 158-2GT-6

Made by Gates Unitta Asia Company

Hexagonal socket-head setscrew half-point

M2.6 x 3L M3 x 4L

Hexagonal-socket-head type button bolt

M2.5 x 5L M3 × 5L

Hexagonal-socket-head type bolt

M2.5 x 6L

M3 x 8L M4 x 12L

Hexagon socket low head cap screw

- M3 x 6L (head height: 2 mm)

Flat washer Small washer 2.5 x 5 x 0.5 3 x 6 x 0.5

4 x 8 x 0.8

Note) The model numbers for ET35 timing pulleys and timing belts dier according to shipment period. The conventional model number is in parentheses.

2. Installation

1.

Check products

2-7 ET

1-2 Names of individual parts and functions

Direct motor coupled TSC specification Sensor origin mode

Direct motor coupled TSC specification Pressing origin mode

1-2-1 Thin lightweight turntable ET

Pulley cover

Do not touch the cover as it

gets very hot while it is running.

Motor cover

ケーブルを引っ張らないでください。

Please don’t pull on the cable.

Base

Rotating table

Origin sensor

Pulley cover

取扱説明書をお読みください。

Review the manual.

Do not touch the cover as it

gets very hot while it is running.

Motor cover

ケーブルを引っ張らないでください。

Please don’t pull on the cable.

Base

Rotating table

Origin stopper

取扱説明書をお読みください。

Review the manual.

2. Installation

1.

Check products

2-8 ET

• Sensor origin mode

• Pressing origin mode

No motor specification

Pulley cover

取扱説明書をお読みください。

Review the manual.

Base

Rotating table

Origin sensor

Pulley cover

取扱説明書をお読みください。

Review the manual.

Base

Rotating table

Origin stopper

2. Installation

1.

Check products

2-9 ET

1-3 Store and dispose of products

1-3-1 For storage

If the product is not used for a while, put the product with packing materials in a packaging box for

transportation and store it in the following places:

lIndoors at the ambient temperature between -10°C and 50°C

lThe ambient humidity must be 20 to 80% RH or less

lLocation where no direct sunlight nor radiation heat reaches

lLocation where the product is not exposed to water

lLocation where no flammable substance exists in the vicinity

lLocation where no strong electric field nor powerful magnetic field generates

lLocation where vibration or shock does not transmit to the product

lLocation where liquid containing impurities such as conductive iron dust, powder such as solid

abrasive, dust, oil mist, cutting oil, water content, salt content, organic solvent, or corrosive/

flammable gas is not generated or does not float

1-3-2 Restore from the long-term storage

See (-> P.4-8) to check each part and take actions as needed before using the product.

1-3-3 For disposal

Disposal of the product should be consigned to a certified industrial-waste disposer.

Do not put the product into fire to dispose of it.

Otherwise, it may lead to bursting of the product, generation of noxious gas, or injury due to

bursting.

Do not dispose of the product by yourself.

Be sure to consign disposal of the product as an industrial waste to a certified industrial-waste

disposer.

Warning

2. Installation

2-10 ET

2.

Precautions on use

2-1 Precautions on use of ET

Caution

Be sure to follow the installation

procedure, method, and direction

described in this manual.

Failure to do so may cause a

malfunction or an alarm generation.

Wear gloves when handling.

Touching the product corner by your

bare hands may injure you.

Do not let finger or hands

become caught in movable parts

such as the table.

It may injure you.

Use the product within the stroke

range.

Failure to do so may cause a

malfunction or an alarm generation.

For 330° specifications, when

returning to origin, be careful not

to interfere with the surroundings

because it strokes to the stopper

position on the origin return side.

Otherwise, it may cause failures or

damage.

For 330° specifications, do not

perform positioning by pressing

the mecha stopper.

Since it becomes a mecha stopper

for origin detection, impact from

positioning or overrun may cause

malfunction or damage.

(It does not include the pressing

operation with a combination motor

at origin return when using TSC.)

Prohibited

Obligatory Obligatory

This manual suits for next models

5

Table of contents

Other THK Controllers manuals

Popular Controllers manuals by other brands

BIFFI

BIFFI EFS2000v4 Instructions and operating manual

Kutai electronics

Kutai electronics ADVR-250 Operation manual

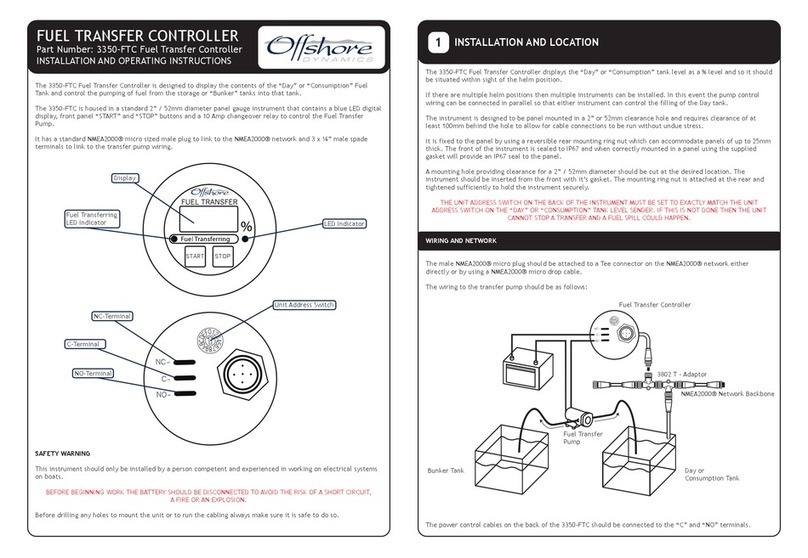

Offshore

Offshore 3350-FTC Installation and operating instructions

Kirby Morgan

Kirby Morgan SuperFlow 350 Regulator manual

Centork

Centork 482 Series Installation and Maintenance user Manual

Milnor

Milnor MilTouch MWF27Z8 Series Operator's guide