THK THC User manual

Servo driver controller

INSTRUCTION MANUAL

THC

THK Electrical Actuator Controller Series

No.6080-2(0)E

www.thk.ru

тел. +7(499) 703-39-86

i

THC

Table of Contents

1.Introduction 1-2

1-1Acknowledgment ―――――――――――――――――――――――― 1-2

1-2About this manual―――――――――――――――――――――――― 1-2

1-3How to use this product ――――――――――――――――――――― 1-3

1-4About product support―――――――――――――――――――――― 1-3

1-5About related instruction manuals――――――――――――――――― 1-3

1-6Product and company information――――――――――――――――― 1-3

2.Safety precautions1-4

2-1About ranks of precautions―――――――――――――――――――― 1-4

2-2About description of precautions ――――――――――――――――― 1-4

2-3Safety precautions ――――――――――――――――――――――― 1-5

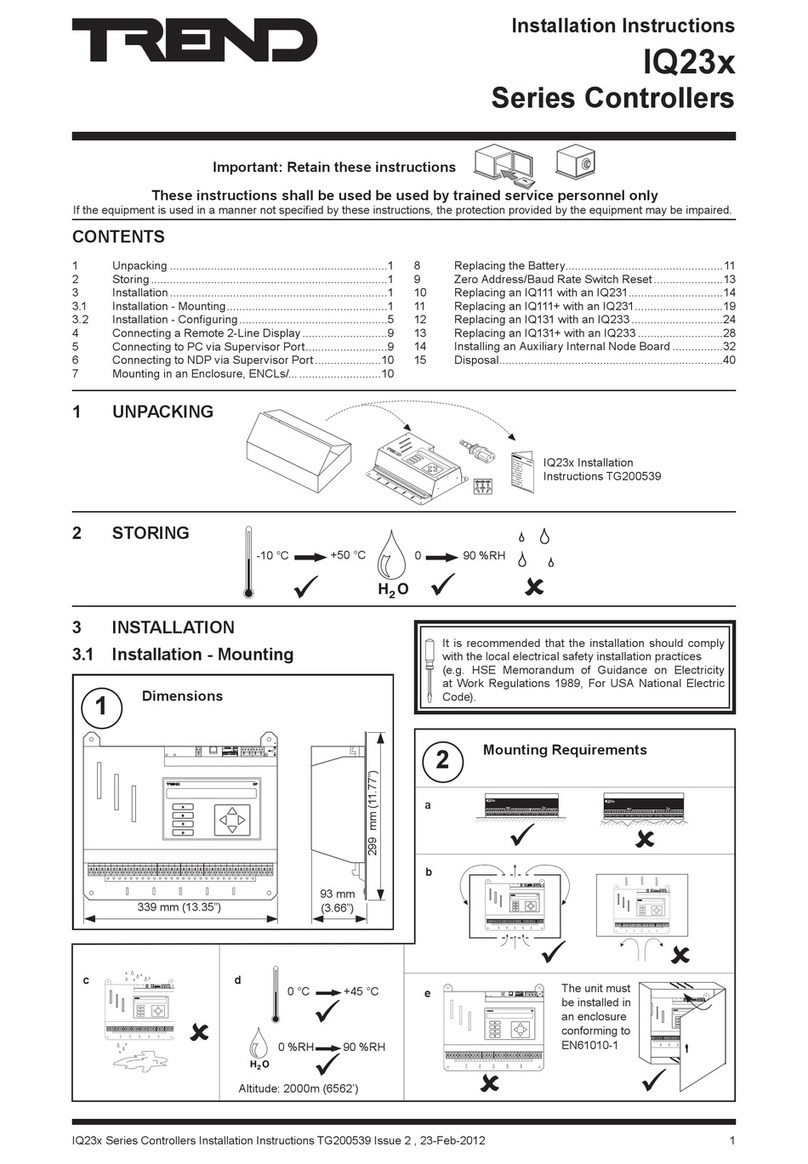

3.System configuration1-6

3-1System configuration diagram (Example)―――――――――――――― 1-6

4.Flow until using the product1-7

1.Check products2-2

1-1Check the package contents of THC―――――――――――――――― 2-2

1-2Option――――――――――――――――――――――――――――― 2-4

1-3Names of individual parts and functions ―――――――――――――― 2-6

1-4Store and dispose of products ―――――――――――――――――― 2-8

2.How to install2-9

2-1Installation environment ――――――――――――――――――――― 2-9

2-2Install THC ―――――――――――――――――――――――――― 2-10

1.How to wire3-2

1-1Entire wiring ―――――――――――――――――――――――――― 3-3

1-2Connect peripheral devices to power supply ―――――――――――― 3-4

1-3Connect to PC ―――――――――――――――――――――――― 3-10

1-4Connect to TDO―――――――――――――――――――――――― 3-10

1-5Peripheral devices――――――――――――――――――――――― 3-11

1. Introduction

1-1

2. Installation

2-1

3. Wiring

3-1

www.thk.ru

тел. +7(499) 703-39-86

ii

THC

Table of Contents

2.External input and output (CN1)3-12

2-1Electrical specification――――――――――――――――――――― 3-12

2-2Signal name ――――――――――――――――――――――――― 3-14

2-3Pin assignment ―――――――――――――――――――――――― 3-18

2-4Optional I/O cable――――――――――――――――――――――― 3-24

1.Overview4-3

1-1Type of function mode―――――――――――――――――――――― 4-3

1-2Selection by intended use ―――――――――――――――――――― 4-3

1-3Timing chart (Common to position move)―――――――――――――― 4-4

2.Function modes 0, 2 and 34-5

2-1Specify and execute STEP No. ―――――――――――――――――― 4-5

2-2How to specify STEP No.――――――――――――――――――――― 4-5

2-3How to obtain STEP No. whose operation has been completed―――― 4-5

2-4Timing chart ―――――――――――――――――――――――――― 4-6

3.Function mode 14-7

3-1Manual operation ―――――――――――――――――――――――― 4-7

3-2Position instruction ――――――――――――――――――――――― 4-7

3-3Methods of position instruction ―――――――――――――――――― 4-8

3-4Specify and execute STEP No. ―――――――――――――――――― 4-8

3-5How to obtain STEP No. whose operation has been completed―――― 4-8

3-6Timing chart (Normal mode) ――――――――――――――――――― 4-8

3-7Timing chart (Instruction mode) ―――――――――――――――――― 4-9

4.Function mode 44-10

4-1Specify and execute STEP No. ――――――――――――――――― 4-10

4-2Move command method―――――――――――――――――――― 4-10

4-3How to obtain STEP No. whose operation has been completed――― 4-11

4-4Timing chart ――――――――――――――――――――――――― 4-11

3. Wiring

3-1

4. THC Functions

4-1

www.thk.ru

тел. +7(499) 703-39-86

iii

THC

Table of Contents

5.Function mode 54-12

5-1Specify and execute STEP No. ――――――――――――――――― 4-12

5-2Move command method―――――――――――――――――――― 4-12

5-3Position detection signal―――――――――――――――――――― 4-12

5-4Timing chart ――――――――――――――――――――――――― 4-13

1.Operation mode5-4

1-1MANUAL mode――――――――――――――――――――――――― 5-5

1-2AUTO mode ―――――――――――――――――――――――――― 5-5

1-3MANUAL mode switching ―――――――――――――――――――― 5-5

2.Standstill mode5-6

2-1Invalid ――――――――――――――――――――――――――――― 5-6

2-2Auto servo OFF 1 (ASO 1) ―――――――――――――――――――― 5-6

2-3Auto servo OFF 2 (ASO 2) ―――――――――――――――――――― 5-6

2-4Auto servo OFF 3 (ASO 3) ―――――――――――――――――――― 5-6

2-5Full servo control (SERVO) ―――――――――――――――――――― 5-7

3.Servo ON5-7

3-1Servo ON ――――――――――――――――――――――――――― 5-7

4.Zero return5-8

4-1Sensor zero return method―――――――――――――――――――― 5-8

4-2Pressing zero return method ―――――――――――――――――― 5-11

4-3Positive/negative of moving direction ―――――――――――――― 5-11

5.Pause5-12

5-1Pause ―――――――――――――――――――――――――――― 5-12

6.Manual operation5-13

6-1Manual operation ――――――――――――――――――――――― 5-13

7.Positioning operation5-14

7-1Positioning operation ――――――――――――――――――――― 5-14

4. THC Functions

4-1

5. Operation and Adjustment

5-1

www.thk.ru

тел. +7(499) 703-39-86

iv

THC

Table of Contents

8.Pressing operation5-15

8-1Pressing operation ―――――――――――――――――――――― 5-15

9.Torque determination5-16

9-1Torque determination ――――――――――――――――――――― 5-16

10.Area determination5-17

10-1Area determination ―――――――――――――――――――――― 5-17

11.Speed switching5-18

11-1Speed switching ――――――――――――――――――――――― 5-18

12.Brake release5-19

12-1Release with switch ―――――――――――――――――――――― 5-19

12-2Release with external input and output―――――――――――――― 5-19

13.General precautions5-20

13-1General precautions―――――――――――――――――――――― 5-20

14.Parameters5-21

14-1Parameter: Actuator information ―――――――――――――――― 5-21

14-2Parameter: Actuator operation settings ――――――――――――― 5-21

14-3Parameter: External interface―――――――――――――――――― 5-24

14-4Parameter: Servo gain――――――――――――――――――――― 5-25

1.Alarm lists6-2

1-1Alarm lists ――――――――――――――――――――――――――― 6-2

1-2About the status of the servo when an alarm sounds ―――――――― 6-3

2.Alarm code6-4

2-1Alarm code――――――――――――――――――――――――――― 6-4

3.Causes and counter measures of alarms6-5

3-1Causes and counter measures of alarms―――――――――――――― 6-5

5. Operation and Adjustment

5-1

6. Troubleshooting

6-1

www.thk.ru

тел. +7(499) 703-39-86

v

THC

Table of Contents

1.Maintenance and inspection7-2

1-1Periodical inspection ―――――――――――――――――――――― 7-2

1-2Standard of durability of consumables for driver controller THC―――― 7-2

2.Repair/Replacement7-3

2-1How to replace the battery ―――――――――――――――――――― 7-3

3.Product warranty7-5

3-1Free warranty period――――――――――――――――――――――― 7-5

3-2Usage conditions (Range) ―――――――――――――――――――― 7-5

3-3Warranty scope――――――――――――――――――――――――― 7-5

3-4Exclusion of warranty liability――――――――――――――――――― 7-6

3-5Delivery conditions ――――――――――――――――――――――― 7-6

1.Driver controller THC8-2

1-1Specifications and dimensional drawing ―――――――――――――― 8-2

2.Cables8-3

2-1Connection cable ―――――――――――――――――――――――― 8-3

3.Option8-4

3-1Regeneration resistance ――――――――――――――――――――― 8-4

4.Gain adjustment (auto tuning)8-7

4-1Method of gain adjustment―――――――――――――――――――― 8-7

Revision history

7. Maintenance and Warranty

7-1

8. Technical Materials

8-1

Appendix

www.thk.ru

тел. +7(499) 703-39-86

1-1

1. Introduction

THC

This section includes intro-

duction about the product

and this manual.

This section includes gen-

eral precautions to follow

when using the product.

Be sure to read this sec-

tion before use and ob-

serve the precautions.

This section includes intro-

duction about peripheral

devices to be used with

this product.

This section describes

installation and setting

processes to make this

product ready for use.

About this chapter

This chapter describes the overview of the product.

This chapter includes information that we want you to check and understand before working with the product.

1. Introduction ………………… 1-2

1-1. Acknowledgment…………………………… 1-2

1-2. About this manual ………………………… 1-2

1-3. How to use this product…………………… 1-3

1-4. About product support …………………… 1-3

1-5. About related instruction manuals ……… 1-3

1-6. Product and company information ……… 1-3

2. Safety precautions ………… 1-4

2-1. About ranks of precautions ……………… 1-4

2-2. About description of precautions ……… 1-4

2-3. Safety precautions ………………………… 1-5

3. System configuration ……… 1-6

3-1.

System configuration diagram (Example)

… 1-6

4.

Flow until using the product

… 1-7

www.thk.ru

тел. +7(499) 703-39-86

1. Introduction

1-2

THC

1-1 Acknowledgment

Thank you for purchasing our product.

This product is designed and manufactured to be incorporated in devices with wide range of

application including conveyance system, implementing equipment, automated assemblers, and

positioning equipment, etc.

We hope our creative inventions and unique technologies contribute to your further prosperity.

1-2 About this manual

1-2-1 Intended audience

The person in charge of designing embedded systems of the product and installing, wiring, and

maintaining the product, and the person who actually uses the product.

1-2-2 Using This Manual

This manual describes correct handling methods and precautions for the product.

For the maximum performance and long life of the product, carefully read and understand this

manual to safely and correctly use the product.

If you access our website or use the printed version of this manual, be sure to keep it in the place

that the intended audience can refer to it when needed.

1-2-3 Notice and attention

Do not use or handle the product in the ways that are not described in this manual.

Do not reproduce, reprint, or lend the whole contents or a part of this manual without permission.

Please note that description in this manual is subject to change without prior notice in the future,

due to improvements of the product or other reasons.

We have made all possible efforts to make the content of this manual accurate. However, if you

find any mistake or uncertainty in this manual, please contact our Customer Support (refer to

back cover).

Drawings show representative examples, and may differ from your product.

Note that THK shall not be liable for any result incurred by applying this manual, regardless of the reason.

This manual can be applied to special types. However, the descriptions defined in the delivery

specification drawings or the delivery specification documents of those special types should take

precedence over this manual.

* Special types represent the products that have different materials and specifications from those

of the standard products on catalogs.

1-2-4 Notation of this manual

• Notes that can lead to unsatisfactory functions, error, or damage of the product if not observed while using the product.

• Supplementary information for the description.

• Reference information for the description.

1.

Introduction

Important

Reference

Note

www.thk.ru

тел. +7(499) 703-39-86

1. Introduction

1.

Introduction

1-3

THC

1-3 How to use this product

This product cannot be used for the devices or systems that are used under the situations that

can affect human life.

If you consider using this product for special applications such as passenger movement vehicle,

medical, aerospace, nuclear power, and electric power devices or systems, be sure to consult

with THK in advance.

This product is manufactured under the strict quality control, however, that does not mean that

the product is free from failure. For applications to the equipment that may suffer serious acci-

dents or loss from the failure of this product, install safety devices or backup devices that prevent

such serious accidents or loss.

1-4 About product support

For the following information, please contact our Customer Support (refer to back cover).

Technical support for this product

1-5 About related instruction manuals

When you use the driver controller THC, read the following instruction manuals as necessary.

• Controller series Setup tool D-STEP

• Controller series Digital operator TDO

1-6 Product and company information

To find the latest product and company information, we recommend you to periodically access our

website.

Website URL: http://www.thk.com/

Technical support website URL: https:/tech.thk.com/

• For the driver controller THC, select the electrical actuator to use when purchasing it. Use them in the

prescribed combination. ( →P.2-2)

Important

www.thk.ru

тел. +7(499) 703-39-86

1-4

1. Introduction

THC

2-1 About ranks of precautions

This manual uses the classifications of "Danger," "Warning," and "Caution" for warning indications for

safety matters.

2-2 About description of precautions

Precautions are classified as "Prohibition," "Instruction," and "Precaution" according to the action.

This mark indicates

"Prohibition" of the

action.

This mark indicates

"Instruction" for

the action.

This mark indicates

"Caution" about

the action.

Prohibited Do not

disassemble

Obligatory Provide grounding

connection

Caution Caution -

Electrical shock

Caution –

Flammable

Caution – High

temperature

Caution – Getting

caught

DANGER Erroneous handling may urgently cause

death or serious injury to a person

WARNING Erroneous handling may cause death or

serious injury to a person

CAUTION Erroneous handling may cause injury to a

person or property damage only

2.

Safety precautions

www.thk.ru

тел. +7(499) 703-39-86

1-5

1. Introduction

2.

Safety precautions

THC

2-3 Safety precautions

While the actuator is operating or

operable, do not enter the working

area of any moving part including

the load.

You might touch the moving part and

get injured.

If the product fails or any abnor-

mality is observed, shut down the

power of the driver controller THC.

Such abnormality may cause a mal-

function of actuator, resulting in dam-

age or injury.

Do not touch the internal part of

the driver controller THC.

It may cause an electric shocks.

Do not damage, tuck, or apply ex-

cessive stresses on the cable.

It may cause an electric shocks.

Do not modify, disassemble, or al-

ter the product.

Doing so may cause injury or fault.

During the operation, or for a while

after turning the power off, do not

touch the driver controller THC,

motor or motor cover because they

should be hot.

Doing so may cause burns.

Prohibited

Obligatory

Caution -

Electrical shock

Do not

disassemble

Caution – High

temperature

Do not impact the product and

do avoid rough handling such as

throwing it.

Doing so may cause the fault or dam-

age that leads to injury.

Do not frequently switch the power

between on and off.

Doing so may generate heat from the

internal parts of the driver controller

THC, which results in fault or burns.

Do not set the speed or accelera-

tion setting or place the load on the

actuator that exceed the actuator

specification.

Doing so may cause motor failure,

which leads to unexpected accidents

or damages.

If an alarm is generated, remove

the cause, check the safety, de-

activate the alarm, and restart the

operation. ( →P.6-2)

Failure to do so may result in failure,

which leads to injury.

Use this product with a combina-

tion that is specified beforehand.

Failure to do so may cause fire or fault.

Observe the specified input volt-

age.

Failure to do so may cause fire or fault.

Prohibited

Obligatory

Caution –

Flammable

CAUTION

WARNING

www.thk.ru

тел. +7(499) 703-39-86

1-6

1. Introduction

THC

3.

System configuration

3-1 System configuration diagram (Example)

The diagram below shows a representative example for using the compact series SKR with the

driver controller THC.

Cables used for connecting the devices shown with ★should be prepared by yourself.

The I/O connector for

CN1 is provided with

THC.

I/O cables are provided

as an option.

(→P.2-4)

PC (D-STEP) ( →* 1)

★Higher device

Driver controller THC

Encoder sensor cable

This is provided with the unit.

(→P.8-3)

★Noise filter

(→P.3-11)

★A power supply

(100/200V) should be

prepared by yourself.

The Power connector

is provided with THC.

(→P.3-4)

CN1

Actuator

★PC communication cables are

provided as an option.

(→P.2-4)

Motor brake cable

This is provided with the unit.

(→P.8-3)

Battery

(→P.3-9)

Power

switchboard

CN2

CN3

CN4

CN5

CN7

CN8

CN9

To higher devices

★Breaker for wiring

(→P.3-11)

★Electromagnetic

contactor

(→P.3-11)

★

CN6

★

Power connector for brake

The connector is provided

with THC.

(→P.3-6)

Regeneration resistance

This is provided as an option.

(→P.2-5)

* 1: See the separate D-STEP instruction manual.

* 2: See the separate TDO instruction manual.

* 3: An emergency stop circuit should be prepared by yourself. (→P.3-7)

The connector for CN7 is provided with THC. (→P.3-5)

TDO( →* 2)

24 V power supply

★Emergency

stop circuit *3

www.thk.ru

тел. +7(499) 703-39-86

1-7

1. Introduction

THC

1. Safety check

①Safety statement check →P.1-4

②Safety check of the installation location

→P.2-9

③Installation check →P.2-10 to 2-12

2. Preparation ①Preparation of required devices →P.1-6

②Package contents check →P.2-2 to 2-3

3. Installation ①Installation environment check →P.2-9

②Installation →P.2-10 to 2-12

4. Wiring ①Connection between each device and

cable →P.3-1 to 3-24

5. Trial run and adjustment

①Preparation of setup tool D-STEP

(see the separate instruction manual of

D-STEP)

②Trial run →P.5-4 to 5-20

③Parameter setting →P.5-21 to 5-25

6. Setup tool setting

①Setup tool setting

(see the separate instruction manual of

D-STEP)

4.

Flow until using the product

www.thk.ru

тел. +7(499) 703-39-86

2-1

2. Installation

THC

1. Check products ……………… 2-2

1-1. Check the package contents of THC …… 2-2

1-2. Option ………………………………………… 2-4

1-3.

Names of individual parts and functions

… 2-6

1-4. Store and dispose of products…………… 2-8

2. How to install ………………… 2-9

2-1. Installation environment ………………… 2-9

2-2. Install THC …………………………………… 2-10

This section describes the

package contents check

and parts of this product.

This section describes the

installation procedures of

this product.

About this chapter

This chapter describes how to check the package contents and to install it to the machine and facilities.

This section is primarily intended for those in charge of installation of this product to a machine and facilities.

www.thk.ru

тел. +7(499) 703-39-86

2. Installation

1.

Check products

2-2

THC

3KDVH+]

2XWSXW 9$&$

3KDVH+]

,FVN9$

9HU

6(5,$/

02'(/7+&$&02'

$

,QSXW9$&

,3&RGH,3

1-1 Check the package contents of THC

1-1-1 Check the model/type of the product

Check the model indicated on the product label against the purchase information.

Model number

(See the following)

Serial number

<Model configuration>

THC -010 -100AC -MOD -A-SKR33 -20 -D-B-0395 -1-A-P-J

①Model THC : Servo driver controller THC

②Capacity 010 : 100W, 020: 200W, 040: 400W, 075: 750W

③Power supply voltage 100 AC : 100V AC

200 AC : Single phase, 200V AC (750W is available only for single phase

200V AC)

④Type MOD : Mode switching type

⑤Encoder type A : Absolute

⑥Actuator model number

SKR33, SKR46, SKR55, SKR65, KR30H, KR33, KR45H, KR46, KR55, KR65 (Direct motor coupling)

SKR33W, SKR46W, SKR55W, SKR65W, KR30HW, KR33W, KR45HW, KR46W, KR55W, KR65W (Motor return)

KRF6 (Direct motor coupling), KRF6R, CKRF6 (Motor return)

KSF4, KSF5, KSF6, KSF8, KSF10, CSKR33, CSKR46, CKSF4, CKSF5, CKSF6, CKSF8, CKSF10 (Direct motor coupling)

KSF4R, KSF5R, KSF6R, KSF8R, KSF10R, GL15N, GL20N, TH20, TH25, CGL15, CGL20, TY20 (Motor return)

US6T, US8T, USW12T, USW16T, USW20T, GL15NR, GL20NR, TH20R, TH25R (Direct motor coupling)

US6RT, US8RT, USW12RT, USW16RT, USW20RT, VLAST60, VLACT55 (Motor return)

PCT25 (Direct motor coupling), PCT25R, PC30, PC40 (Motor return)

⑦Lead, reduction ratio 05 : 5mm, 06 : 6mm, 10 : 10mm, 12 : 12mm, 16 : 16mm

20 : 20mm, 25 : 25mm, 30 : 30mm, 40 : 40mm, 50 : 50mm

04N : 4mm, 06N : 6mm (When selecting PCT)

06A : 6mm, 06B : 6mm (When selecting PC)

* The selectable lead varies depending on respective actuator model number. For more information, see respective actuator catalogs.

⑧Zero point D : Motor side

R : Reverse motor side

⑨Brake No symbol : No brake

B : With brake

⑩Stroke Enter the stroke of ⑥Actuator model

⑪Sensor No symbol : Not included

1 : N.O. contact [1 pce.], N.C. contact [2 pcs.]

⑫Slider type* A : A type, B : B type, C : C type, D : D type

⑬Accuracy* No symbol : Normal grade, High accuracy grade

P : Precision grade or higher

⑭Bellows* No symbol : Without bellows

J

:

With bellows (Only for SKR33 and 46, sensor type is available in "J".)

⑦⑥⑤④③②① ⑧ ⑩⑨ ⑫⑪ ⑬ ⑭

* ⑫, ⑬, and ⑭are selectable only when selecting KR/SKR in ⑥.

www.thk.ru

тел. +7(499) 703-39-86

2. Installation

1.

Check products

2-3

THC

1-1-2 Checking the type and number of accessories

No cable is provided, so please separately prepare a cable.

1-1-3 Check the product for any damage or abnormality

After the checking, keep the product packed in the packaging box until the start of installation work.

Type of parts Model number Qty.

Driver controller * See the product label 1

Power connector 8EDGKGB-5.0-05P-11-01A(H)

(DEGSON ELECTRONICS CO.,LTD) 1

Power connector for brake FK-MC0,5/2-ST-2,5

(PHOENIX CONTACT) 1

Connector for emergency stop FK-MC0,5/2-ST-2,5 OG

(PHOENIX CONTACT) 1

Lithium ion battery ER6V C4

(Toshiba Home Appliances Corporation) 1

I/O connector

Current product Conventional product

1

Plug

HD-44SP

(MISUMI)

Plug

DBH44MCA

(NSXD)

Cover

RDA-25H-UNC

(MISUMI)

Cover

DT44PB

(NSXD)

1

• For any special type, check against the delivery specification documents.

Reference

www.thk.ru

тел. +7(499) 703-39-86

2. Installation

1.

Check products

2-4

THC

1-2 Option

1-2-1 D-STEP

Driver controller

THC side (CN3)

PC side

USB

A setup tool. This can be downloaded from our website free of charge.

* Registration with the technical support is required to download.

URL: http://www.ea-thk.com

In addition, a PC communication cable is required to use D-STEP.

For details, see the separate D-STEP instruction manual.

1-2-2 TDO

The digital operator for driver controller.

Model number: TDO-N

For details, see the separate TDO instruction manual.

1-2-3 I/O cable

A cable with a soldered I/O connector for external input and output signals (CN1).

Model number: CBL-CON-IO- □□ (03: 3 m, 05: 5 m, 10: 10 m)

For details, see (→P.3-13)( →P.3-24)

A PC communication cable for use with D-STEP.

Model number: CBL-COM-03

For details, see the separate D-STEP instruction manual.

1-2-4 PC communication cable

□□

(Cable length)

Driver controller side Host controller side

www.thk.ru

тел. +7(499) 703-39-86

2. Installation

1.

Check products

2-5

THC

1-2-5 Regeneration resistance

Regeneration resistance may be required depending on the operating condition. Please purchase

the product with model number shown below as needed.

Regeneration resistance (Power-type cement resistor)

For details, see (→P.8-4).

Model number Manufacturer

A RH150 100Ω J Iwaki Musen Kenkyusho Co.,Ltd.

B RH150 50 Ω J

THC capacity and type and required number of regeneration resistance based on actuator orientation

For details, see (→P.8-4).

THC capacity Actuator orientation

Horizontal Vertical

100W A x 1 pce. A x 1 pce.

200W A x 1 pce. A x 1 pce.

400W B x 2 pcs. B x 2 pcs.

750W B x 2 pcs. B x 2 pcs.

Regeneration resistance connection cable

Wiring on regeneration resistance side must be conducted on your side.

Model number : CBL-REG00-01F (1 m)

For details, see (→P.8-4).

Driver controller

THC side (CN8)

Regeneration

resistance side

Connector (female)

F32FSS-02V-KY

(J.S.T. Mfg. Co., Ltd.)

Connector (female)

8EDGK-5.0-02P

(DEGSON)

Connector (male)

8EDGKR-5.0-02P

(DEGSON)

+

Insertion jig

DG010-01P-19-00AH

(ɸ2) x 2 pcs.

www.thk.ru

тел. +7(499) 703-39-86

2. Installation

1.

Check products

2-6

THC

1-3-1 Driver controller THC

Connectors for CN1, CN5, CN7, and CN9 are provided with this product. No cable is provided,

so please separately prepare it. For I/O of CN1, an optional package with a cable is available.

(→P.2-4) ( →P.3-24)

A cable to connect to CN3 and PC is available as an option. (→P.2-4)

•100/200 W specification-based model

•400/750 W specification-based model

1-3 Names of individual parts and functions

www.thk.ru

тел. +7(499) 703-39-86

2. Installation

1.

Check products

2-7

THC

CN4

Actuator's motor brake connector is

connected.

ID

The ID (identification) number is

selected.

CN3

Communication cable for PC and

TDO is connected.

CN5

A power supply is connected to

here.

SV/ALM

It lights in green when the servo

is turned ON. In the alarm state, it

lights in red.

BRK OFF

When the brake is turned OFF

(released), it lights in yellow.

CN1

External input and output signals

are connected.

(FG)

Ground wire is connected.

BRK OFF/MANU/AUTO

The brake is turned ON/OFF and the

mode is switched.

DBK OFF

When the dynamic brake is turned

OFF (released), it lights in yellow.

CN6

Battery connector is connected.

P5C

It lights in yellow when 5 V for control

power is generated within THC.

P24E

It lights in yellow when 24 V for TDO

is generated within THC.

CN2

Actuator's encoder sensor

connector is connected.

CN9

A power connector for brake is

connected to here.

P5P

It lights in yellow when 5 V for IPM is

generated within THC.

P15P

It lights in yellow when 15 V for IPM

is generated within THC.

CN8

Regeneration resistance unit is

connected to here.

CHAR

When charging into a capacitor is

performed, it lights in red.

CN7

A connector for emergency stop is

connected to here.

(FG)

Ground wire is connected.

Battery case

www.thk.ru

тел. +7(499) 703-39-86

Table of contents

Other THK Controllers manuals

Popular Controllers manuals by other brands

Novatech

Novatech MC9200 Series Technical reference guide

Scratch Live

Scratch Live PIONEER MEP-7000 quick start guide

Light Emotion

Light Emotion DMX36 User instruction manual

Genasun

Genasun GV-10 quick start guide

ECO-WORTHY

ECO-WORTHY Solar Power Controller user manual

TechGrow

TechGrow Clima Eco user manual

Ltech

Ltech T-PWM SE-12-100-400-W1Y manual

EIM

EIM HQ Series Installation & maintenance manual

sauter

sauter flexotron 800 Series manual

Trango Systems

Trango Systems PTZ-900TX Installation and operating instructions

TOHO

TOHO TTM-00BT Series Detailed manual

Duff-Norton

Duff-Norton SK-2389 Installation, operation & maintenance instructions