THK Economy Series User manual

ACTUATOR

UNITS

ES/EC

CATALOG No.373-9E-EU

Economy series

NEW

For details, visit THK at www.thk.com

∗Product information is updated regularly on the THK website.

ELECTRIC ACTUATOR

1

Economy series

Lightweight, Compact

Features

Electrical Actuator

Economy series

ES/EC

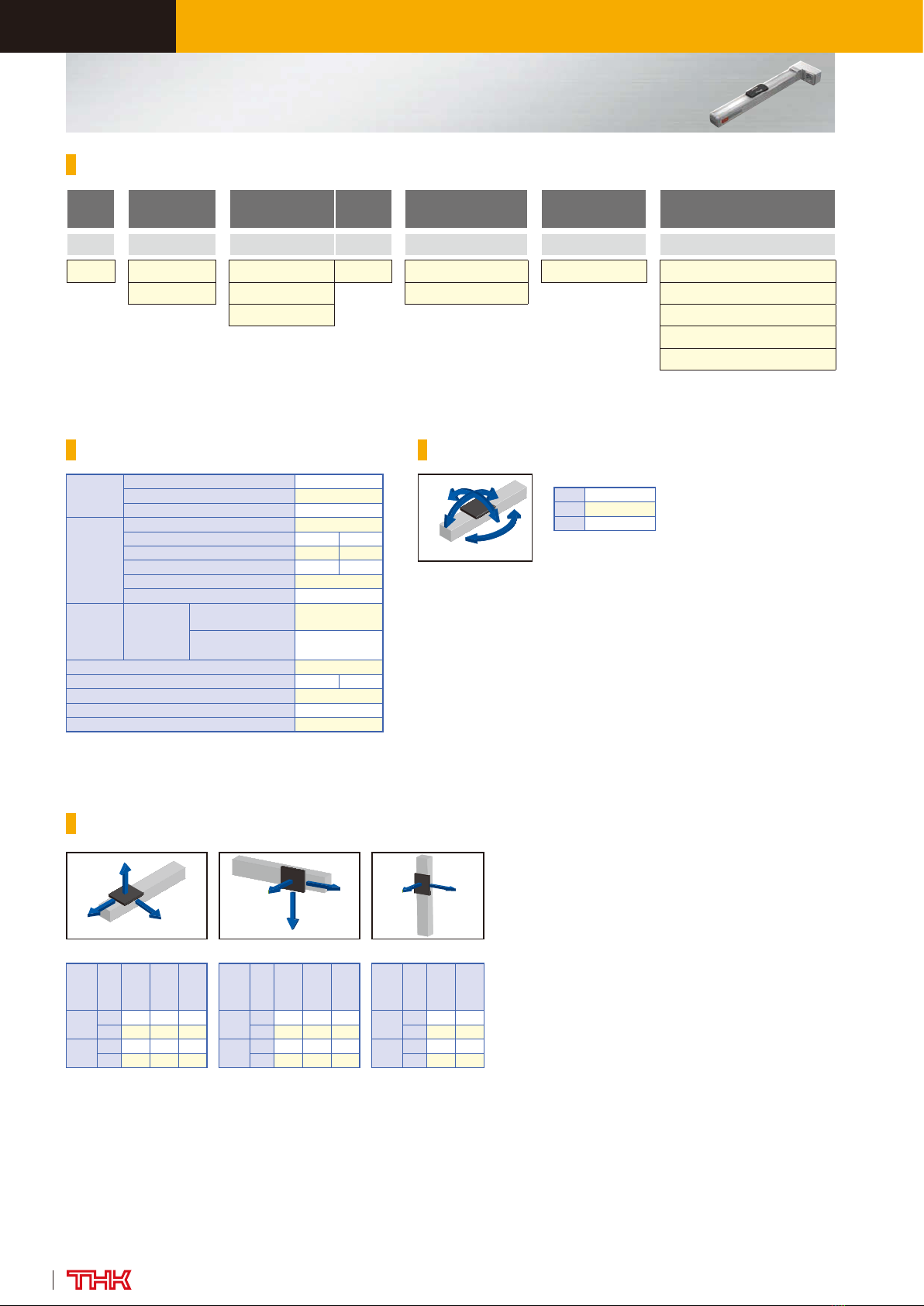

Cylinder Type

EC

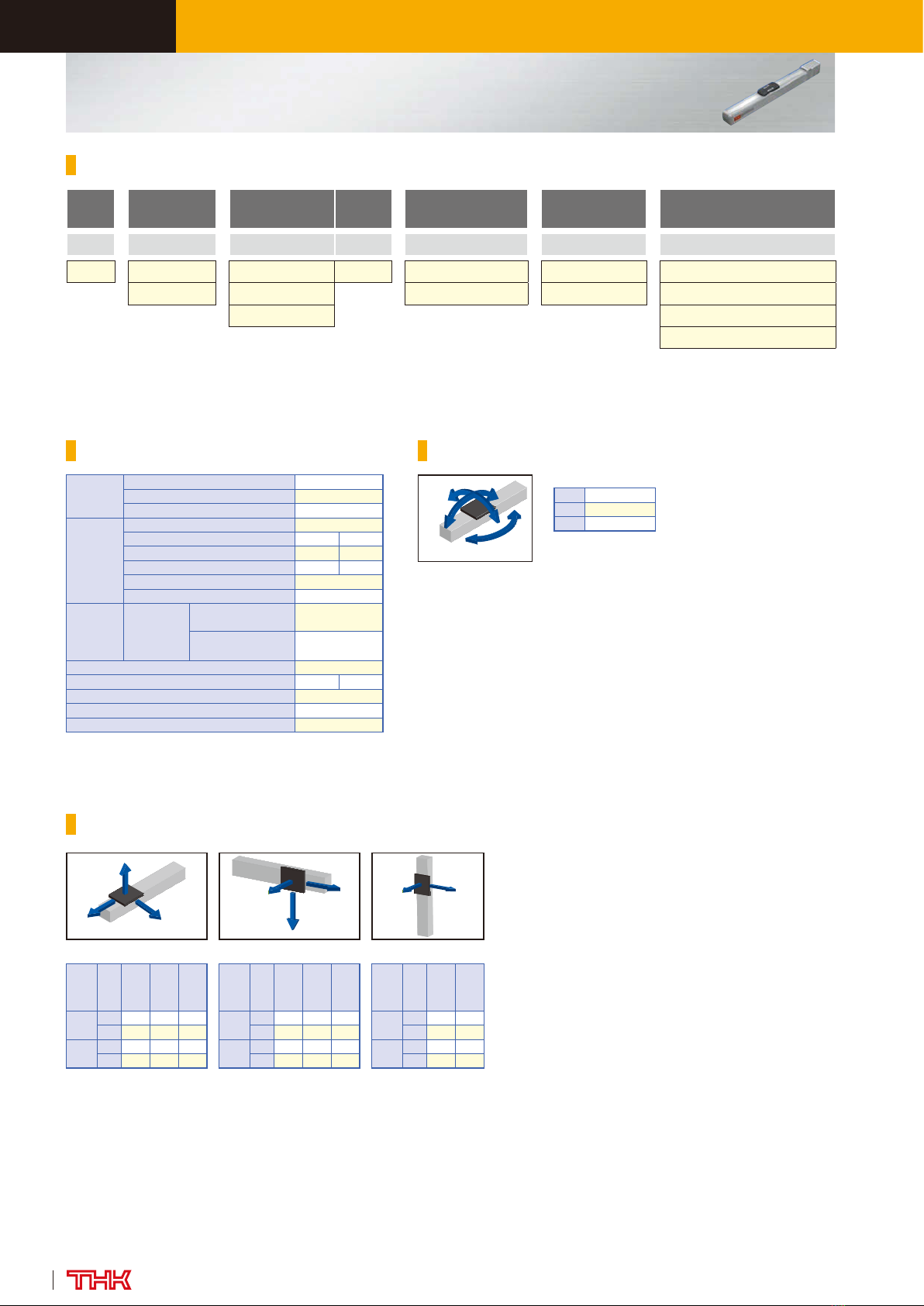

Slider Type

ES Table

Table cover

Housing A

Strip seal

Grease lid

Base

Rod

Housing B

Side cover

Housing-B cover

When GR is selected: gray

Housing A

By incorporating an LM Guide within its rectilinear guide, the ES provides both compactness and reliability.

Compact and reliable

The use of LM Guides reduces the number of components required, making the ES available at a reasonable cost.

Reasonably priced

The ES incorporates the model SRS LM Guide, equipped with ball retainers, as well as Lubricator QZ, for optimal

ball-screw lubrication. The combined effect provides for long-term maintenance-free operation.

Long-term maintenance-free operation

The service life of the LM Guide and ball screw can be calculated based on usage conditions.

Contact THK for details.

Predictable service life

ELECTRIC ACTUATOR

2

Economy series

Change the cover color to gray

You can change the color of ES housing cover to

gray.

No symbol: red

When GR is selected: gray

If the GR is not included in the model

configuration, cover will be red.

ES/EC (without motor)

Model Ball screw

lead Stroke Design

symbol

With/without

motor

Intermediate

flange Option

ES4R

-

06

-

0150 B

-

0

-

A

-

MR−GR−FL−LB

(1) (2) (3) (4) (5) (6) (7)

ES3 06: 6mm

0050

:

50mm B

0: Without motor N: None No symbol: ES : Red cover

ES4 12: 12mm

0100

:

100mm

1: With motor

(Prepared by THK)

A: EC : None

ES5

0150

:

150mm

B

MR

:

Motor right wrap

×1

ES6

0200

:

200mm

C

ML

:

Motor left wrap

×

1

ES3R

0250

:

250mm

GR:

Change the cover color to gray

ES4R

0300

:

300mm

SB: With slider base

×

2

ES5R

0350

:

350mm

CB: With cylinder base

×

3

ES6R

0400

:

400mm

FL: With flange

×

3

×

4

EC3

0450

:

450mm

LB: With link ball

×

3

×

4

EC4

0500

:

500mm

£1£2: Sensor

×

2

EC3R

0550

:

550mm

EC4R

0600

:

600mm

EC3H

EC4H

/

Option symbol ML: Motor left wrap Option symbol MR: Motor right wrap

R represents motor

wrap, and H

represents with

linear bush.

When 0 is selected, a coupling is not provided

for motor direct coupled specification. Timing

pulley and timing belt are provided for motor

wrap configuration. When 1 is selected, THK

will prepare a motor and install it.

For ES3, ES3R, EC3, EC3R and

EC3H, have ball screw lead of

6mm only.

Maximum stroke

differs depending on

models.

ES3: 300mm

ES4: 400mm

ES5: 500mm

ES6: 600mm

EC3: 200mm

EC4: 300mm

Specify the option symbol by

writing in the order of

description from left adding "−".

×1 Valid only when ES£R or EC£R

is selected in model (1).

×2 Valid only when ES is selected in

model (1).

×3 Valid only when EC is selected in

model (1).

×4 If you select EC£H for model (1),

FL and LB cannot be selected.

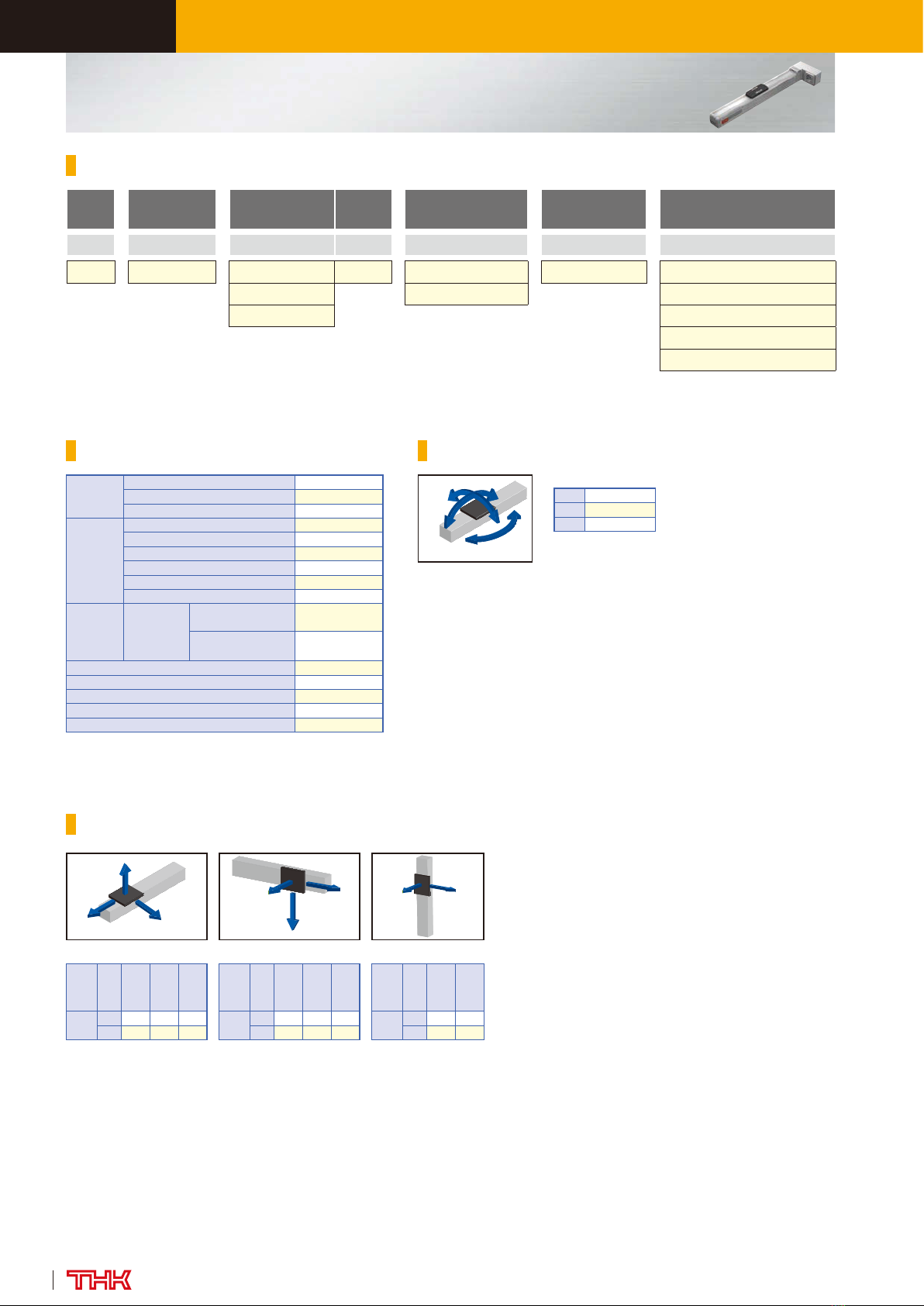

Slider type ES Cylinder type EC

(6) Intermediate flange P. 33

(7) Options

GR: Change the cover color to gray

P. 33

SB: With slider base P. 34

CB: With cylinder base P. 38

FL: With flange P. 38

LB: With link ball

P. 38

£1£2: Sensor P. 36

Pages for detailed

description

Motor wrap direction

Model Conguration

Page 06: Folded direction for EC

Option symbol ML: Motor left wrap Option symbol MR: Motor right wrap

ELECTRIC ACTUATOR

3

Economy series

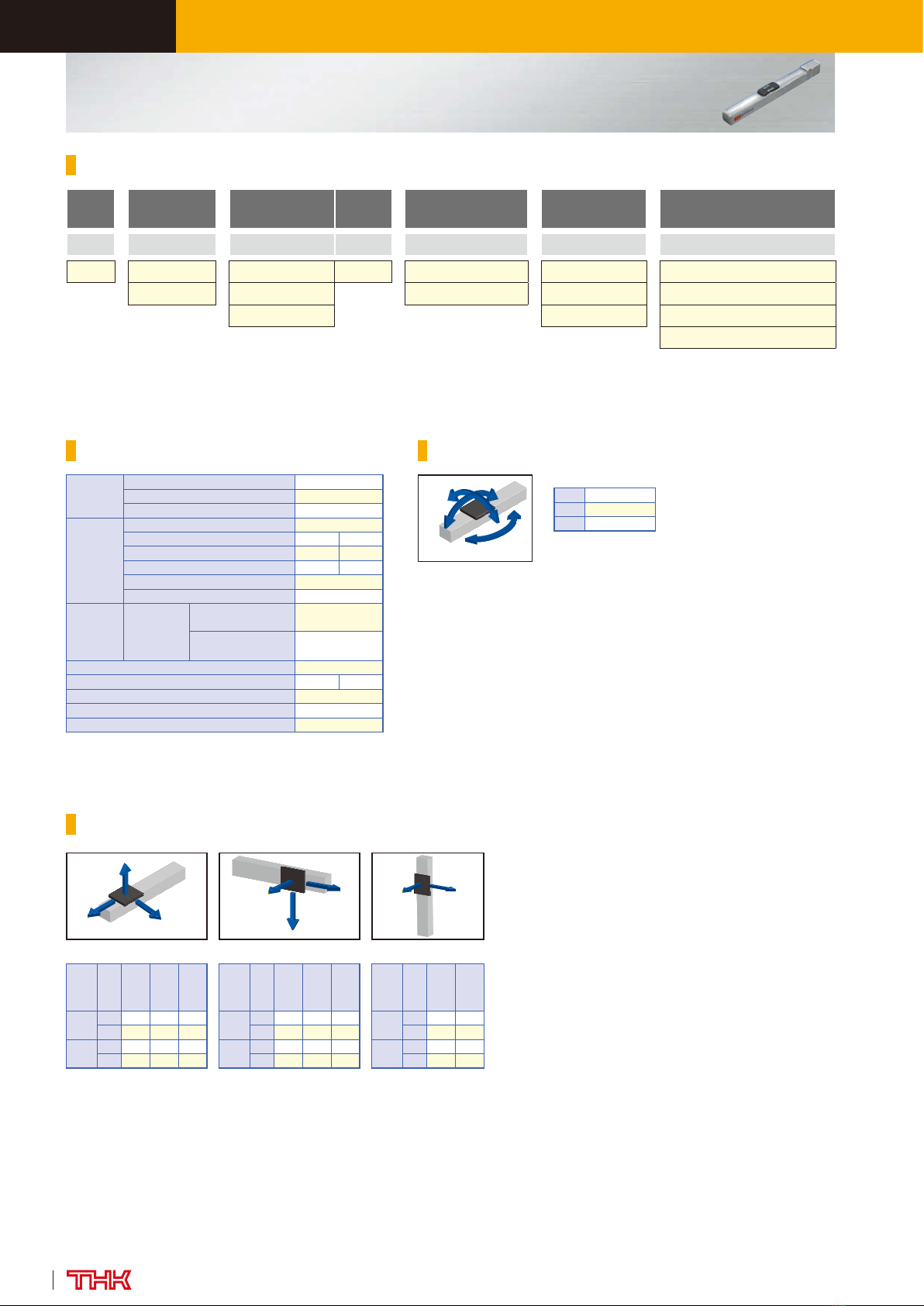

Lineup List

Model Ball screw lead

[mm]

Stroke

[mm]

Rated speed

×

1

[mm/s]

The reference motor Maximum load capacity

×

1[kg]

Maximum speed for each stroke

×

3[mm/s]

Stroke [mm]

Stepper motor Servo motor [W]

Horizontal mount

Vertical mount 50 100 150 200 250 300 350 400 450 500 550 600

ES3 6 50 to 300 — £28 — 1 0.5 300

ES4

6

50 to 400 — £35 —

to 9 to 4 300

12 to 7.5 to 1.5 600

ES5

6

50 to 500

300

— 50

10 5 300

12 600 6 2 600

ES6

6

50 to 600

300

— 50

10 5 300 270 230

12 600 6 2 600 540 460

ES3R 6 50 to 300 — £28 — 1 to 0.5 300

ES4R

6

50 to 400 — £35 —

4 to 1.5 300

12 2 1 600

ES5R

6

50 to 500

300

— 50

8 2 300

12 600 6 1 600

ES6R

6

50 to 600

300

— 50

8 2 300 270 230

12 600 6 1 600 540 460

EC3 6 50 to 200 — £35 — 15 6 300 250

EC4

6

50 to 300

300

— 50

14 6 300 230 170

12 600 7 3 600 460 340

EC3R 6 50 to 200 — £35 — 15 3 300 250

EC4R

6

50 to 300

300

— 50

14 6 300 230 170

12 600 7 3 600 460 340

EC3H 6 50 to 200 — £35 — 15 6 300 250

EC4H

6

50 to 300

300

— 50

14 6 300 230 170

12 600 7 3 600 460 340

×

1Based on rated motor speed (3,000min-1).

×

2Load mass represents values with THK control devices used. Determine load mass according to specications of the motor you

actually use. For selecting a motor, see Reference Materials for Selecting on page 39 and 40.

×

3Maximum speed is dependent on motor speed of 3,000min-1 and, if applicable, permissible rotation speed of ball screw.

ELECTRIC ACTUATOR

4

Economy series

Model Ball screw lead

[mm]

Stroke

[mm]

Rated speed

×

1

[mm/s]

The reference motor Maximum load capacity

×

1[kg]

Maximum speed for each stroke

×

3[mm/s]

Stroke [mm]

Stepper motor Servo motor [W]

Horizontal mount

Vertical mount 50 100 150 200 250 300 350 400 450 500 550 600

ES3 6 50 to 300 — £28 — 1 0.5 300

ES4

6

50 to 400 — £35 —

to 9 to 4 300

12 to 7.5 to 1.5 600

ES5

6

50 to 500

300

— 50

10 5 300

12 600 6 2 600

ES6

6

50 to 600

300

— 50

10 5 300 270 230

12 600 6 2 600 540 460

ES3R 6 50 to 300 — £28 — 1 to 0.5 300

ES4R

6

50 to 400 — £35 —

4 to 1.5 300

12 2 1 600

ES5R

6

50 to 500

300

— 50

8 2 300

12 600 6 1 600

ES6R

6

50 to 600

300

— 50

8 2 300 270 230

12 600 6 1 600 540 460

EC3 6 50 to 200 — £35 — 15 6 300 250

EC4

6

50 to 300

300

— 50

14 6 300 230 170

12 600 7 3 600 460 340

EC3R 6 50 to 200 — £35 — 15 3 300 250

EC4R

6

50 to 300

300

— 50

14 6 300 230 170

12 600 7 3 600 460 340

EC3H 6 50 to 200 — £35 — 15 6 300 250

EC4H

6

50 to 300

300

— 50

14 6 300 230 170

12 600 7 3 600 460 340

ELECTRIC ACTUATOR

5

Economy series

ES3 Slider type Directly coupled without motor

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES3 –06 –0150 B –0–A–GR–SB

ES3 06: 6mm 0050: 50mm B 0: Without motor ANo symbol: Red cover

to 1: With motor B GR:

Change the cover color to gray

0300: 300mm SB: With slider base

£1£2: Sensor

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×

1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×

2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

60.5 200 200 200

1 200 160 200

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

60.5 200 200 200

1 170 150 200

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

60.3 200 200

0.5 200 200

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

LM Guide

(SRS9)

Basic dynamic load rating C [N] 2690

Basic static load rating C0[N] 2310

Radial clearance [mm] −2 to +2

Ball screw

portion

Shaft diameter [mm] f6

Lead [mm] 6

Basic dynamic load rating Ca [N] 1400

Basic static load rating C0a [N] 2440

Root diameter [mm] f5.1

Ball center-to-center diameter [mm] f6.3

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 6550

Static permissible load

P0a [N] 2310

Permissible rotational speed [min-1] 3000

Starting torque [N·mm] 8

Positioning repeatability [mm]

×

2±0.020

Lost motion [mm]

×

20.1

Maximum input torque [N·m] 0.065

MA6.0

MB7.5

MC5.9

[N·m]

M

M

MC

B

A

Static Permissible Moment ×1

×

1Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×

2When the appropriate motor is used.

ELECTRIC ACTUATOR

6

Economy series

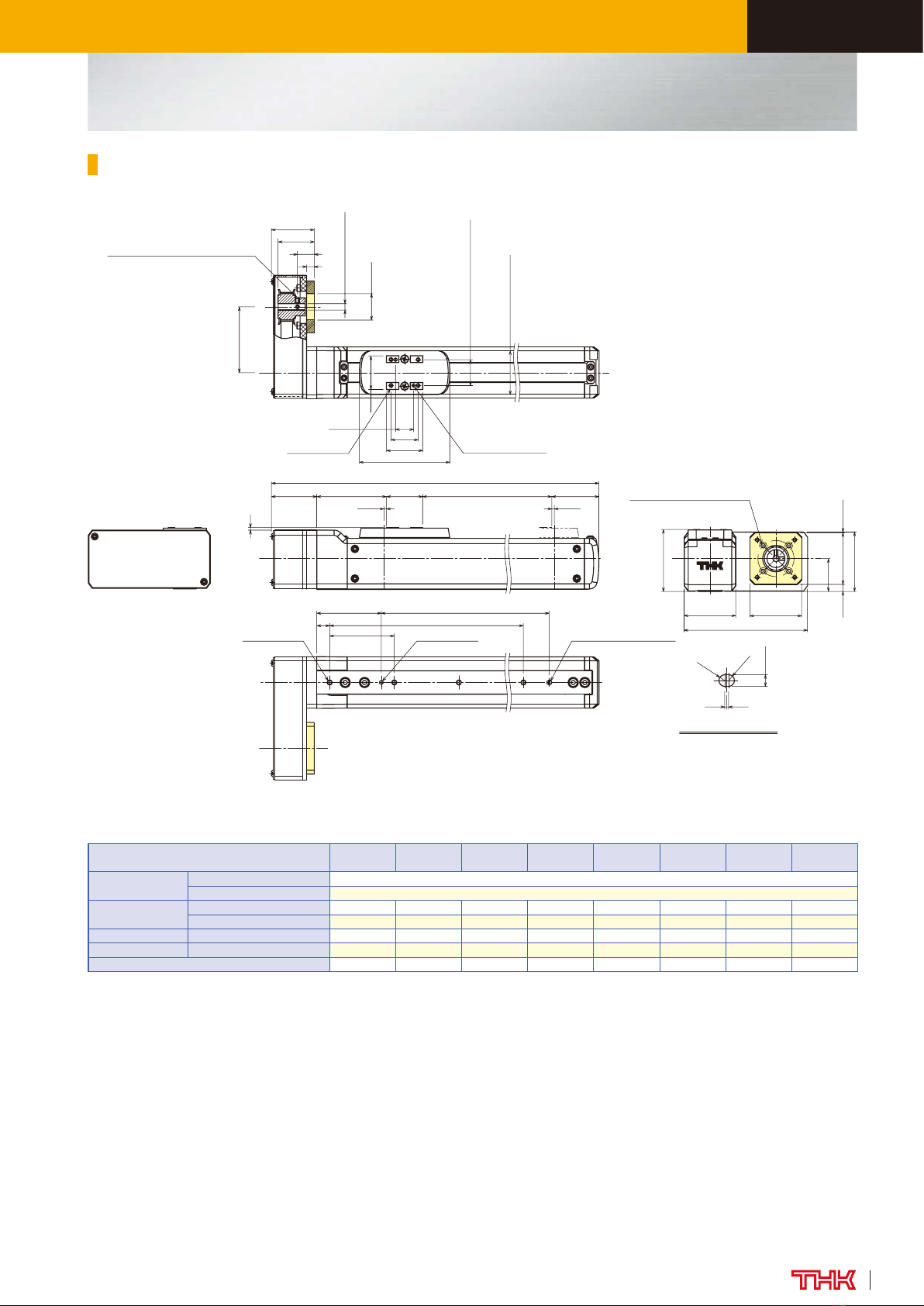

Dimensions

×

1Load capacity and maximum speed vary depending on the motor used.

×

2Dependent on the permissible rotational speed of the ball screw.

Stroke [mm]

(Stroke between mechanical stoppers) 50

(56)100

(106)150

(156)200

(206)250

(256)300

(306)

Maximum speed

×1 ×2

[mm/s]

Ball screw lead: 6mm 300

Dimensions [mm]L 209.2 259.2 309.2 359.2 409.2 459.2

L185 135 185 235 285 335

Mounting pitch count N 2 3 4 5 6 7

Mounting hole count n 3 4 5 6 7 8

Weight [kg] 0.65 0.7 0.8 0.85 0.9 0.95

×1Stroke up to mechanical stopper.

×2indicates an opening.

Intermediate flange symbol BIntermediate flange symbol A

(PCD28, from the back surface)

A

Arrow A view

11±0.02

17

(66.4)

(28)

(Table cover width)

17±0.02

(Tolerance is applicable to φ2)

48

23 Nx50

50 φ2H7 Depth 4

2 +0.03

0

n-M3 depth 4.5

21.4

21.4

0.50.5

R1

R1

L1

Elongated hole depth 2

1

21.4(37.5)

32

40

2-φ2H7 Depth 5

4-M3 depth 5

(3)1

Stroke

(3)1

φ22H7 (Intermediate flange symbol B)

φ20H7 (Intermediate flange symbol A)

φ6h7

φ20

24.6

φ15

2.5 (Intermediate flange symbol B)

3 (Intermediate flange symbol A)

10

23

23

45°

22.5

39

22.5

39

(L)

49 (51.3)

8

(34)

2

(From the back surface)

(See drawing below)

B

φ6h7

0.5

7.5

Detailed Diagram: Section B

4-3.4 drill through

φ6 counter bore depth 3.3

4-2.9 drill through

φ5.5 counter bore depth 2.8

Elongated hole (detail)

ES3

ELECTRIC ACTUATOR

7

Economy series

ES3R Slider type Motor wrap

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES3R –06 –0150 B –0–A–MR–GR

ES3R 06: 6mm 0050: 50mm B 0: Without motor A MR: Motor right wrap

to 1: With motor ML: Motor left wrap

0300: 300mm GR:

Change the cover color to gray

SB: With slider base

£1£2: Sensor

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

60.5 200 200 200

1 200 160 200

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

60.5 200 200 200

1 170 150 200

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

60.3 200 200

0.5 200 200

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

LM Guide

(SRS9)

Basic dynamic load rating C [N] 2690

Basic static load rating C0[N] 2310

Radial clearance [mm] −2 to +2

Ball screw

portion

Shaft diameter [mm] f6

Lead [mm] 6

Basic dynamic load rating Ca [N] 1400

Basic static load rating C0a [N] 2440

Root diameter [mm] f5.1

Ball center-to-center diameter [mm] f6.3

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 6550

Static permissible load

P0a [N] 2310

Permissible rotational speed [min-1] 3000

Starting torque ×1[N·mm] 8

Positioning repeatability [mm] ×3±0.020

Lost motion [mm] ×30.1

Maximum input torque [N·m] 0.065

MA6.0

MB7.5

MC5.9

[N·m]

M

M

MC

B

A

Static Permissible Moment ×2

×1Pulley and timing belt not included.

×2Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×3When the appropriate motor is used.

Note: If the GR is not included in the

model configuration, cover will

be red.

ELECTRIC ACTUATOR

8

Economy series

Dimensions

×1Load capacity and maximum speed vary depending on the motor used.

×2Dependent on the permissible rotational speed of the ball screw.

Stroke [mm]

(Stroke between mechanical stoppers) 50

(56)100

(106)150

(156)200

(206)250

(256)300

(306)

Maximum speed

×1×2

[mm/s]

Ball screw lead: 6mm 300

Dimensions [mm]L 195.4 245.4 295.4 345.4 395.4 445.4

L185 135 185 235 285 335

Mounting pitch count N 2 3 4 5 6 7

Mounting hole count n 3 4 5 6 7 8

Weight [kg] 0.65 0.7 0.8 0.85 0.9 0.95

×1This is a stroke between mechanical stoppers.

×2indicates an opening.

2

48

50

0.50.5

23

17

(66.4)

21.4 (37.5)

(28)

(Table cover width)

Nx50

n-M3 depth 4.5

L1

21.4

21.4

1

R1

R1

Elongated hole depth 2

Stroke

4-M3 depth 5

(3)1

(3)1

(L)

(35.2) (51.3)

6

(12.7)

(28)

(33.2)

(45)

11±0.02

2-φ2H7 Depth 5

17 ±0.02

2+0.03

0

φ2H7 Depth 4

2-M3 (Hexagon socket set screw)

(90° equipartition)

(Distance between shafts)

(Tolerance is applicable to φ2)

(See drawing below)

φ5

(Pulley internal diameter)

φ20.5

2-3.4 through

φ

6 counter bore depth 3.4

(PCD28, from the back surface)

32

40

81

39

22

(1)

32

32

(6)

Elongated hole (detail)

ES3R

ELECTRIC ACTUATOR

9

Economy series

ES4

Slider type Directly coupled without motor

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

6 4.5 300 50 100

9 160 20 40

12 3.8 260 60 100

7.5 110 20 40

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

6 4.5 60 30 300

9 10 5 70

12 3.8 70 40 220

7.5 10 10 50

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

6 2 100 110

4 30 40

12 0.8 260 300

1.5 130 150

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES4 –06 –0150 B –0–A–GR–SB

ES4 06: 6mm 0050: 50mm B 0: Without motor ANo symbol: Red cover

12: 12mm to 1: With motor B GR:

Change the cover color to gray

0400: 400mm SB: With slider base

£1£2: Sensor

LM Guide

(SRS9W)

Basic dynamic load rating C [N] 3290

Basic static load rating C0[N] 3340

Radial clearance [mm] −2 to +2

Ball screw

portion

Shaft diameter [mm] f8

Lead [mm] 6 12

Basic dynamic load rating Ca [N] 1770 920

Basic static load rating C0a [N] 3040 1600

Root diameter [mm] f6.8

Ball center-to-center diameter [mm] f8.4

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 8000

Static permissible load

P0a [N] 3240

Permissible rotational speed [min-1] 3000

Starting torque [N·mm] 12 21

Positioning repeatability [mm]

×

2±0.020

Lost motion [mm]

×

20.1

Maximum input torque [N·m] 0.16

MA9.3

MB13.5

MC17.7

[N·m]

M

M

MC

B

A

Static Permissible Moment ×1

×1Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×2When the appropriate motor is used.

Note: If the GR is not included in the

model configuration, cover will

be red.

ELECTRIC ACTUATOR

10

Economy series

Dimensions

Stroke [mm]

(Stroke between mechanical stoppers) 50 ( 54)100 ( 104)150 ( 154)200 ( 204)250 ( 254)300 ( 304)350 ( 354)400 ( 404)

Maximum speed ×1 ×2

[mm/s]

Ball screw lead: 6mm 300

Ball screw lead: 12mm 600

Dimensions [mm]L 220 270 320 370 420 470 520 570

L180 130 180 230 280 330 380 430

Mounting pitch count N 2 3 4 5 6 7 8 9

Mounting hole count n 3 4 5 6 7 8 9 10

Weight [kg] 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9

×1Load capacity and maximum speed vary depending on the motor used.

×2Dependent on the permissible rotational speed of the ball screw.

×Stroke up to mechanical stopper.

50

10

50 φ3H7 Depth 5

n-M4 depth 6

L1

14 ±0.02

21

(70)

(34)

(Table cover width)

28

Nx50

20±0.02

(Tolerance is applicable to φ2.5)

28

26

3 +0.03

0

0.50.5

R1.5

R1.5

Elongated hole depth 3

2

40

48

2-φ2.5H7 Depth 6

4-M3 depth 6

(2)

(2)

Stroke (36.5)

(54)

(PCD28, from the back surface)

(From the back surface)

29

29

φ6h7

φ22H7 (Intermediate flange symbol B)

φ20H7 (Intermediate flange symbol A)

φ15

26.5 11

(42)

25.5

46

25.5

46

45°

6.5

51.5

(L)

Intermediate flange symbol A Intermediate flange symbol B

A

Arrow A view

φ20

B

Detailed Diagram: Section B

φ6h7

0.5

9

4-3.4 drill through

φ6 counter bore depth 3.3

4-3.4 drill through

φ6.5 counter bore depth 3.3

(See drawing below)

2.5 (Intermediate flange symbol B)

3 (Intermediate flange symbol A)

Elongated hole (detail)

ES4

ELECTRIC ACTUATOR

11

Economy series

ES4R Slider type Motor wrap

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

6 2 300 120 240

4 300 50 110

12 1 300 240 300

2 300 120 200

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

6 2 210 110 300

4 80 40 300

12 1 300 260 300

2 170 110 300

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

6 0.8 280 300

1.5 140 160

12 0.5 300 300

1 210 240

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES4R –06 –0150 B –0–A–MR–GR

ES4R 06: 6mm 0050: 50mm B 0: Without motor A MR: Motor right wrap

12: 12mm to 1: With motor ML: Motor left wrap

0400: 400mm GR:

Change the cover color to gray

SB: With slider base

£1£2: Sensor

LM Guide

(SRS9W)

Basic dynamic load rating C [N] 3290

Basic static load rating C0[N] 3340

Radial clearance [mm] −2 to +2

Ball screw

portion

Shaft diameter [mm] f8

Lead [mm] 6 12

Basic dynamic load rating Ca [N] 1770 920

Basic static load rating C0a [N] 3040 1600

Root diameter [mm] f6.8

Ball center-to-center diameter [mm] f8.4

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 8000

Static permissible load

P0a [N] 3240

Permissible rotational speed [min-1] 3000

Starting torque ×1[N·mm] 12 21

Positioning repeatability [mm] ×3±0.020

Lost motion [mm] ×30.1

Maximum input torque [N·m] 0.16

MA9.3

MB13.5

MC17.7

[N·m]

M

M

MC

B

A

Static Permissible Moment ×2

×1Pulley and timing belt not included.

×2Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×3When the appropriate motor is used.

Note: If the GR is not included in the

model configuration, cover will

be red.

ELECTRIC ACTUATOR

12

Economy series

Dimensions

Stroke [mm]

(Stroke between mechanical stoppers) 50 ( 54)100 ( 104)150 ( 154)200 ( 204)250 ( 254)300 ( 304)350 ( 354)400 ( 404)

Maximum speed ×1 ×2

[mm/s]

Ball screw lead: 6mm 300

Ball screw lead: 12mm 600

Dimensions [mm]L 203.7 253.7 303.7 353.7 403.7 453.7 503.7 553.7

L180 130 180 230 280 330 380 430

Mounting pitch count N 2 3 4 5 6 7 8 9

Mounting hole count n 3 4 5 6 7 8 9 10

Weight [kg] 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9

×1Load capacity and maximum speed vary depending on the motor used.

×2Dependent on the permissible rotational speed of the ball screw.

×Stroke up to mechanical stopper.

14±0.02

(70)

21

(34)

(Table cover width)

20±0.02

2-φ2.5H7 Depth 6

(2)

(54) Stroke

R1.5

Elongated hole depth 3

0.5 0.5

R1.5

3 +0.03

0

2

(36.5)28

L1

Nx50

(2)

10

50

n-M4 depth 6 φ3H7 Depth 5

50

26

28

(35.2)

(L)

φ5

(Pulley internal diameter)

6

(13)

φ20.5

(33.2)

(28)

(PCD28, from the back surface)

(51)

(Distance between shafts)

4-3.4 through

φ6 counter bore depth 3.4

2-M3 (Hexagon socket set screw)

(90° equipartition)

4-M3 depth 6

48

95.5

40

46

25.5

40 (0.5)

40

(5.5)

(Tolerance is applicable to φ2.5)

(See drawing below)

Elongated hole (detail)

ES4R

ELECTRIC ACTUATOR

13

Economy series

ES5

Slider type Directly coupled without motor

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

65 400 90 200

10 270 40 90

12 3 400 160 280

6 320 70 130

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

65 160 70 400

10 50 20 220

12 3 260 130 400

6 100 50 250

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

62.5 160 160

5 70 70

12 1 400 400

2 200 200

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES5 –06 –0150 B –0–B–GR–SB

ES5 06: 6mm 0050: 50mm B 0: Without motor N: None No symbol: Red cover

12: 12mm to 1: With motor B GR:

Change the cover color to gray

0500: 500mm C SB: With slider base

£1£2: Sensor

LM Guide

(SRS12W)

Basic dynamic load rating C [N] 5480

Basic static load rating C0[N] 5300

Radial clearance [mm] −3 to +3

Ball screw

portion

Shaft diameter [mm] f8

Lead [mm] 6 12

Basic dynamic load rating Ca [N] 1770 920

Basic static load rating C0a [N] 3040 1600

Root diameter [mm] f6.8

Ball center-to-center diameter [mm] f8.4

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 8000

Static permissible load

P0a [N] 3240

Permissible rotational speed [min-1] 3000

Starting torque [N·mm] 14 27

Positioning repeatability [mm] ×2±0.020

Lost motion [mm] ×20.1

Maximum input torque [N·m] 0.35

MA10.5

MB22.0

MC22.1

[N·m]

M

M

MC

B

A

Static Permissible Moment ×1

×1Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×2When the appropriate motor is used.

Note: If the GR is not included in the

model configuration, cover will

be red.

ELECTRIC ACTUATOR

14

Economy series

14 ±0.02

22

(71)

26±0.02

(Tolerance is applicable to φ2.5)

(44)

(Table cover width)

54 L1

29 L 2Nx100

100

φ3H7 depth 5

2xn-M4 depth 8

33

28

3 +0.03

0

0.50.5

Elongated hole depth 3

R1.5

R1.5

28

(36.5)

(56)

50

57

2-φ2.5H7 Depth 54-M4 depth 8

(3)

Stroke

14

2

(3)

8.5

12

φ6h7

26.5

φ30H7

45°

38

(52.4)

30.5

4-M4 depth 7

(PCD46, 90° equipartition)

7.5

2-φ4.5 through

55

51.5

(L)

50

31

45

55

30.5

31

(From the back surface)

12

φ6h7

φ22H7

15

33

6.5

50

45

4-M3 effective depth 6

(PCD45, 90° equipartition)

55

30.5

A

15

φ6h7

33 12

φ30H7

6.5

3.5

φ26

φ6h7

0.5

9

D

D

D

4-3.4 drill through

φ6.5 counter bore depth 4

(See drawing below)

Elongated hole (detail)

Intermediate flange symbol CIntermediate flange symbol B

Arrow A view

Detailed Diagram: Section D

Dimensions

Stroke [mm]

(Stroke between mechanical stoppers) 50 ( 56)100 ( 106)150 ( 156)200 ( 206)250 ( 256)300 ( 306)350 ( 356)400 ( 406)450 ( 456)500 ( 506)

Maximum speed ×1 ×2

[mm/s]

Ball screw lead: 6mm 300

Ball screw lead: 12mm 600

Dimensions [mm]

L 222 272 322 372 422 472 522 572 622 672

L190 140 190 240 290 340 390 440 490 540

L2100 50 100 50 100 50 100 50 100 50

Mounting pitch count N 0 1 1 2 2 3 3 4 4 5

Mounting hole count n 2 3 3 4 4 5 5 6 6 7

Weight [kg] 1.5 1.7 1.8 1.9 2.0 2.2 2.4 2.5 2.6 2.8

×1Load capacity and maximum speed vary depending on the motor used.

×2Dependent on the permissible rotational speed of the ball screw.

×Stroke up to mechanical stopper.

ES5

ELECTRIC ACTUATOR

15

Economy series

ES5R Slider type Motor wrap

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

64 400 110 260

8 340 50 120

12 3 400 160 280

6 320 70 130

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

64 220 90 400

8 80 30 320

12 3 260 130 400

6 100 50 250

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

61 400 400

2 210 210

12 0.5 400 400

1 400 400

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES5R –06 –0150 B –0–A–MR–GR

ES5R 06: 6mm 0050: 50mm B 0: Without motor A MR: Motor right wrap

12: 12mm to 1: With motor ML: Motor left wrap

0500: 500mm GR:

Change the cover color to gray

SB: With slider base

£1£2: Sensor

LM Guide

(SRS12W)

Basic dynamic load rating C [N] 5480

Basic static load rating C0[N] 5300

Radial clearance [mm] −3 to +3

Ball screw

portion

Shaft diameter [mm] f8

Lead [mm] 6 12

Basic dynamic load rating Ca [N] 1770 920

Basic static load rating C0a [N] 3040 1600

Root diameter [mm] f6.8

Ball center-to-center diameter [mm] f8.4

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 8000

Static permissible load

P0a [N] 3240

Permissible rotational speed [min-1] 3000

Starting torque ×1[N·mm] 14 27

Positioning repeatability [mm] ×3±0.020

Lost motion [mm] ×30.1

Maximum input torque [N·m] 0.35

MA10.5

MB22.0

MC22.1

[N·m]

M

M

MC

B

A

Static Permissible Moment ×2

×1Pulley and timing belt not included.

×2Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×3When the appropriate motor is used.

Note: If the GR is not included in the

model configuration, cover will

be red.

ELECTRIC ACTUATOR

16

Economy series

Dimensions

Stroke [mm]

(Stroke between mechanical stoppers) 50 ( 56)100 ( 106)150 ( 156)200 ( 206)250 ( 256)300 ( 306)350 ( 356)400 ( 406)450 ( 456)500 ( 506)

Maximum speed ×1 ×2

[mm/s]

Ball screw lead: 6mm 300

Ball screw lead: 12mm 600

Dimensions [mm]

L 209.7 259.7 309.7 359.7 409.7 459.7 509.7 559.7 609.7 659.7

L190 140 190 240 290 340 390 440 490 540

L2100 50 100 50 100 50 100 50 100 50

Mounting pitch count N 0 1 1 2 2 3 3 4 4 5

Mounting hole count n 2 3 3 4 4 5 5 6 6 7

Weight [kg] 1.5 1.7 1.8 1.9 2.0 2.2 2.3 2.5 2.6 2.8

×1Load capacity and maximum speed vary depending on the motor used.

×2Dependent on the permissible rotational speed of the ball screw.

×

Stroke up to mechanical stopper.

54

28

14

100

2

(71)

14 ±0.02

26±0.02

28

Elongated hole depth 3

Stroke

φ3H7 depth 5

33

22

(3)

(3)

2-φ2.5H7 depth 5

29

2xn-M4 depth 8 L1

L2Nx100

(44)

(Table cover width)

R1.5

0.50.5

R1.5

3+0.03

0

(39.2) (56) (36.5)

(L)

(64)

φ8

(Pulley internal diameter)

φ30.5

2-M4 effective depth 4.5

(PCD46, 180° equipartition)

(Distance between shafts)

(Tolerance is applicable to φ2.5)

5

(18.4)

(33.2)

(25)

2-M3 (Hexagon socket set screw)

(90° equipartition)

4-M4 depth 8

117

50

57

(5)50

55

30

45°

50

(See drawing below)

Elongated hole (detail)

ES5R

ELECTRIC ACTUATOR

17

Economy series

ES6

Slider type Directly coupled without motor

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

65 500 90 200

10 260 40 90

12 3 500 160 280

6 320 70 130

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

65 160 70 500

10 40 20 210

12 3 250 130 500

6 90 50 240

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

62.5 160 160

5 60 60

12 1 420 420

2 190 190

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES6 –06 –0150 B –0–B–GR–SB

ES6 06: 6mm 0050: 50mm B 0: Without motor N: None No symbol: Red cover

12: 12mm to 1: With motor B GR:

Change the cover color to gray

0600: 600mm C SB: With slider base

£1£2: Sensor

Static Permissible Moment ×1

LM Guide

(SRS12W)

Basic dynamic load rating C [N] 5480

Basic static load rating C0[N] 5300

Radial clearance [mm] −3 to +3

Ball screw

portion

Shaft diameter [mm] f8

Lead [mm] 6 12

Basic dynamic load rating Ca [N] 1770 920

Basic static load rating C0a [N] 3040 1600

Root diameter [mm] f6.8

Ball center-to-center diameter [mm] f8.4

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 8000

Static permissible load

P0a [N] 3240

Permissible rotational speed [min-1] 3000

Starting torque [N·mm] 15 29

Positioning repeatability [mm] ×2±0.020

Lost motion [mm] ×20.1

Maximum input torque [N·m] 0.35

MA10.5

MB22.0

MC22.1

[N·m]

M

M

MC

B

A

×1Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×2When the appropriate motor is used.

Note: If the GR is not included in the

model configuration, cover will

be red.

ELECTRIC ACTUATOR

18

Economy series

Dimensions

Stroke [mm]

(Stroke between mechanical stoppers)

50

(56)

100

(106)

150

(156)

200

(206)

250

(256)

300

(306)

350

(356)

400

(406)

450

(456)

500

(506)

550

(556)

600

(606)

Maximum speed ×1 ×2

[mm/s]

Ball screw lead: 6mm 300 270 230

Ball screw lead: 12mm 600 540 460

Dimensions [mm]

L 228 278 328 378 428 478 528 578 628 678 728 778

L190 140 190 240 290 340 390 440 490 540 590 640

L2100 50 100 50 100 50 100 50 100 50 100 50

Mounting pitch count N 0 1 1 2 2 3 3 4 4556

Mounting hole count n 2 3 3 4 4 5 5 6 6 7 7 8

Weight [kg] 1.9 2.0 2.2 2.3 2.5 2.6 2.7 2.9 3.0 3.2 3.3 3.5

×1Load capacity and maximum speed vary depending on the motor used.

×2Dependent on the permissible rotational speed of the ball screw.

0.5

R1.5

0.5

R1.5

62.5

60

φ6h7

φ30H7

(62.4)

32.5

60.5

48

45°

16

2-φ4.5 through

4-M4 depth 7

(PCD46, 90° equipartition)

1026.5

7

60

31

55

60.5

32.5

17 31

(From the back surface)

φ6h7

33

φ22H7

10

13.5

6.5

60

55

60.5

32.5

4-M3 effective depth 6

(PCD45, 90° equipartition)

45°

φ30H7

33

φ6h7

10

13.5

φ26

6.5

3.5

DD

D

φ6h7

0.5

9

4-3.4 drill through

φ6.5 counter bore depth 4

L1

L2

15 ±0.02

31

±0.02

3

+0.03

0

(3)

32(56) (38.5)

φ3H7 depth 5

2xn-M4 depth 8

54

29

100

Nx100

(3)

2

Stroke

25

(75)

(Tolerance is applicable to φ3)

(53)

(Table cover width)

14

40

Elongated hole depth 3

32

2-φ3H7 depth 54-M5 depth 8

(L)

51.5

A

(See drawing below)

Elongated hole (detail)

Intermediate flange symbol CIntermediate flange B

Arrow A view

Detailed Diagram: Section D

×

Stroke up to mechanical stopper.

ES6

ELECTRIC ACTUATOR

19

Economy series

ES6R Slider type Motor wrap

Model Conguration

Basic Specications

Reference Permissible Overhang Length ×1 ×2

×1Distance from the center of the top face of the table to the load center of gravity

under the following conditions: 5,000km running life, single-direction load, 0.3G

horizontal or vertical, 150mm stroke.

×2Value when THK control device is used. Actual load mass should be determined

based on the specifications of the motor used. See "Reference Materials for Selecting

ES" in P.39.

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

64 500 110 260

8 340 50 120

12 3 500 160 280

6 320 70 130

Horizontal mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A B C

64 210 90 500

8 70 30 300

12 3 250 130 500

6 90 50 240

Wall mount [mm]

Ball

screw

lead

[mm]

Load

mass

[kg]

A C

61 450 450

2 210 210

12 0.5 500 500

1 420 420

Vertical mount [mm]

C

B

A

Horizontal use

AB

CWall use

AC

Vertical use

Model Ball screw lead Stroke Design

symbol With/without motor Intermediate

ange Option

ES6R –06 –0150 B –0–A–MR–GR

ES6R 06: 6mm 0050: 50mm B 0: Without motor A MR: Motor right wrap

12: 12mm to 1: With motor ML: Motor left wrap

0600: 600mm GR:

Change the cover color to gray

SB: With slider base

£1£2: Sensor

LM Guide

(SRS12W)

Basic dynamic load rating C [N] 5480

Basic static load rating C0[N] 5300

Radial clearance [mm] −3 to +3

Ball screw

portion

Shaft diameter [mm] f8

Lead [mm] 6 12

Basic dynamic load rating Ca [N] 1770 920

Basic static load rating C0a [N] 3040 1600

Root diameter [mm] f6.8

Ball center-to-center diameter [mm] f8.4

Bearing

portion

(xed side)

Axial direction

Basic dynamic load

rating Ca [N] 8000

Static permissible load

P0a [N] 3240

Permissible rotational speed [min-1] 3000

Starting torque ×1[N·mm] 15 29

Positioning repeatability [mm] ×3±0.020

Lost motion [mm] ×30.1

Maximum input torque [N·m] 0.35

MA10.5

MB22.0

MC22.1

[N·m]

M

M

MC

B

A

Static Permissible Moment ×2

×1Pulley and timing belt not included.

×2Static maximum permissible moment when unit is stationary. Moment standards: MAand MC: top of table; MB: center of table.

×3When the appropriate motor is used.

Note: If the GR is not included in the

model configuration, cover will

be red.

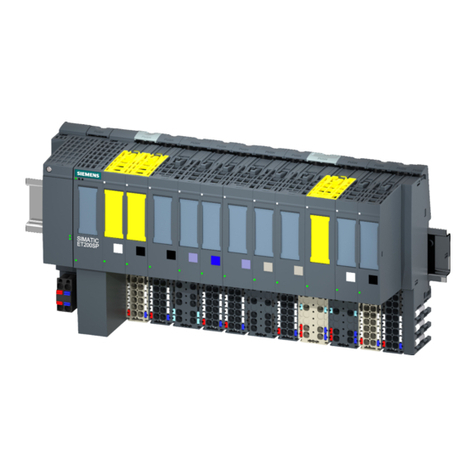

This manual suits for next models

2

Table of contents

Other THK Controllers manuals

Popular Controllers manuals by other brands

Performance Motion Devices

Performance Motion Devices Magellan DK58113 user manual

DINGO

DINGO 4040P Reference manual

Hanna Instruments

Hanna Instruments HI 8001 instruction manual

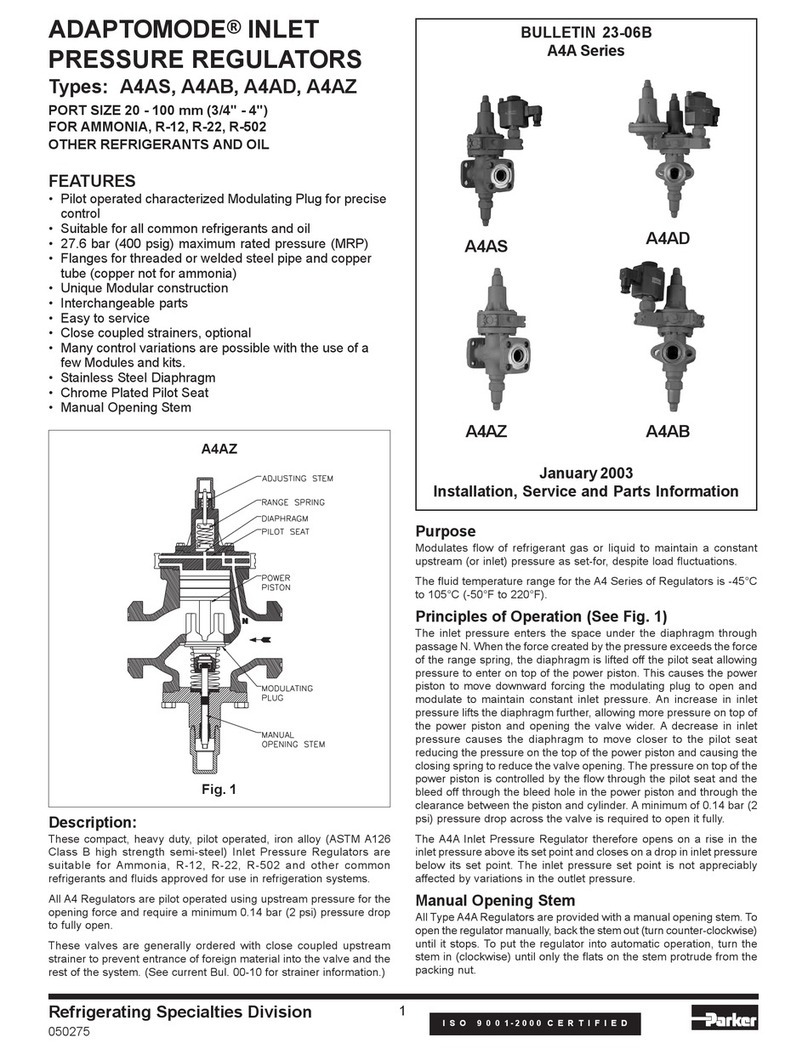

Parker

Parker ADAPTOMODE A4AS Installation, Service and Parts Information

Panasonic

Panasonic FP7 Series user manual

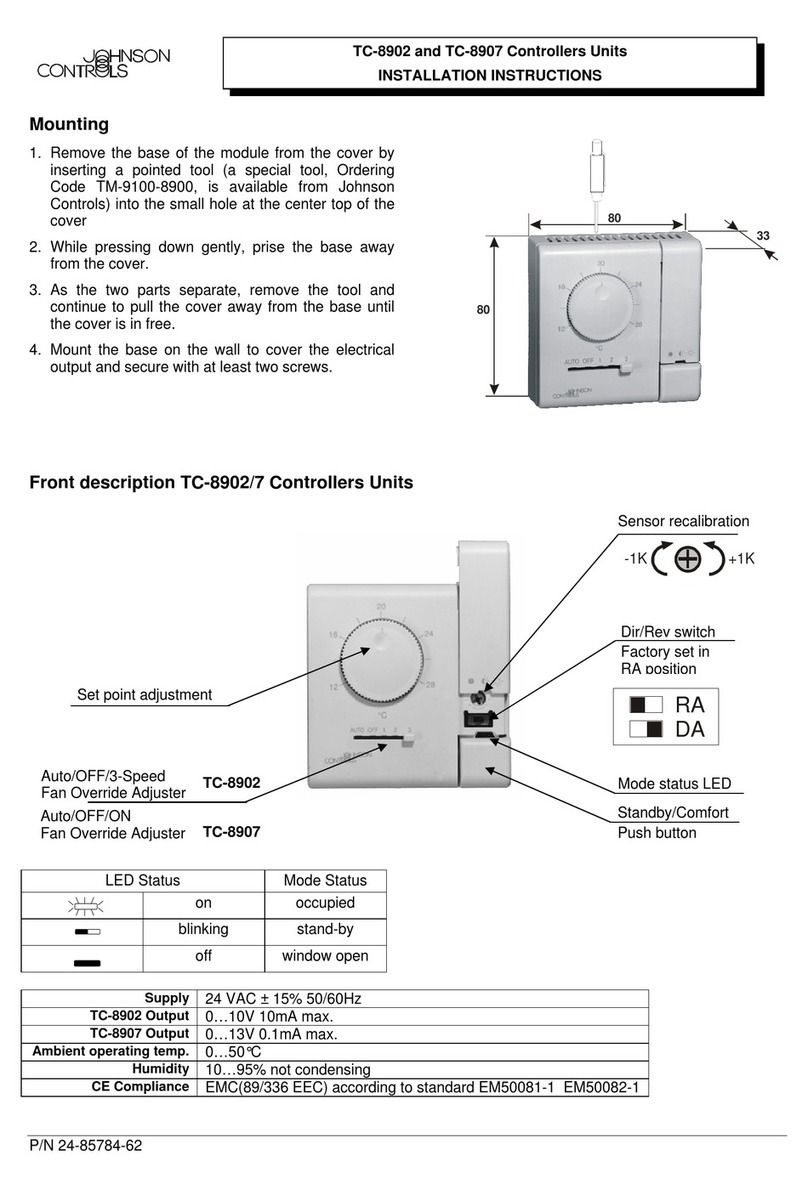

Johnson Controls

Johnson Controls TC-8902 installation instructions