Thorne & Derrick KATRONIC KATflow 150 User manual

Operating Instructions

KA

Tflow 150

Ultrasonic Flowmeter

Katronic Technologies Ltd.

Earls Court

13 Warwick Street

Earlsdon, Coventry

West Midlands CV5 6ET

United Kin dom

Tel. +44 (0)2476 714111

Fax +44 (0)2476 715446

Internet www.katronic.co.uk

E-mail mail@katronic.co.uk

Operating Instructions KATflow 150

Version V21EN160420

Copyri ht © 2016

All ri hts reserved.

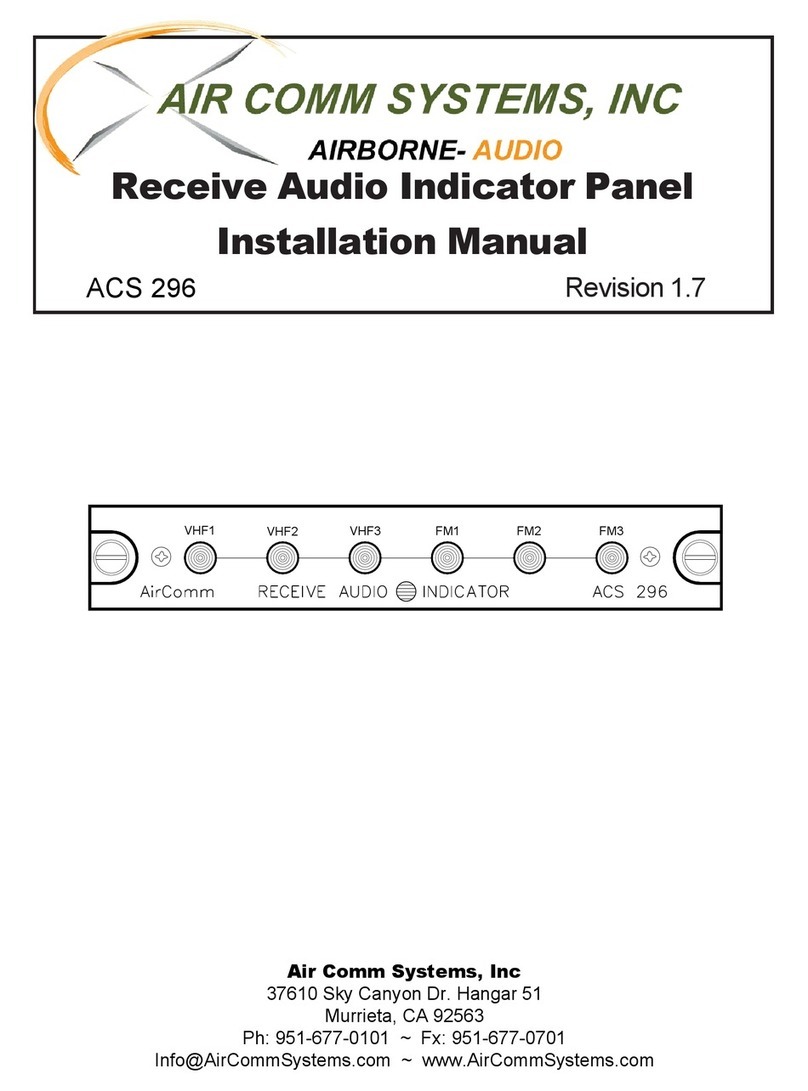

KATflow 150

Operatin Instructions

Ta le of Contents

Page

1 Safety instructions, legal requirements, warranty, return policy.................5

1.1 Symbols used in these operatin instructions........................................5

1.2 Safety instructions.................................................................................5

1.3 Warranty................................................................................................ 6

1.4 Return policy..........................................................................................6

1.5 Le islative requirements........................................................................6

2 Introduction......................................................................................................7

2.1 System Confi uration............................................................................8

3 Installation........................................................................................................9

3.1 Unpackin and stora e..........................................................................9

3.1.1 Unpacking..................................................................................9

3.1.2 Storage ......................................................................................9

3.1.3 Identification of components.......................................................9

3.2 Clamp-on sensor installation...............................................................10

3.3 Installation location..............................................................................10

3.4 Pipe preparation..................................................................................13

3.5 Clamp-on sensor mountin confi urations and sensor spacin ...........13

3.6 Flowmeter installation..........................................................................14

3.6.1 all mounting...........................................................................15

3.6.2 Electrical connections...............................................................16

3.7 Clamp-on sensor mountin ..................................................................17

3.7.1 Sensor pipe mounting configurations........................................17

3.7.2 Acoustic coupling gel................................................................17

3.7.3 Correct positioning of the sensors............................................18

3.7.4 Sensor mounting with tension straps........................................18

4 Operation.......................................................................................................... 20

4.1 Switchin On/Off..................................................................................20

4.2 Keypad and display..............................................................................20

4.2.1 Keypad key functions...............................................................20

4.2.2 Display functions......................................................................22

4.3 Quick setup wizard..............................................................................23

4.4 Measurements.....................................................................................25

4.4.1 Main process value (PV) display..............................................25

3-line display format.................................................................26

4.4.2 Diagnostic displays...................................................................26

4.4.3 Totalisers..................................................................................26

4.4.4 Dual channel display mode.......................................................27

4.4.5 Datalogger................................................................................27

5 Commissioning................................................................................................ 28

5.1 Menu structure.....................................................................................28

5.2 Dia nostics..........................................................................................34

5.3 Display settin s....................................................................................34

5.4 Output confi uration............................................................................34

5.4.1 Serial interface RS 232.............................................................34

5.4.2 Serial interface RS 485.............................................................34

5.4.3 HART compatible output...........................................................35

5.4.4 Analogue current output 0/4 ... 20 mA......................................35

5.4.5 Analogue voltage output 0-10 v................................................35

5.4.6 Analogue frequency output 2...10k Hz......................................36

5.4.7 Digital Open-Collector output....................................................36

5.4.85 Digital relay output..................................................................36

5.5 Input confi urations.............................................................................37

5.5.1 PT100 inputs............................................................................37

5.5.2 Analogue current input 0/4 ... 20 mA.........................................37

5.6 Heat quantity measurement (HQM).....................................................37

5.7 Sound velocity measurement (SVM)...................................................38

5.8 Dual-channel flow calculations (maths functions)................................38

5.9 Scope functions................................................................................... 38

6 Maintenance.....................................................................................................39

7 Trou leshooting............................................................................................... 40

8 Technical data...................................................................................................42

9 Specification.....................................................................................................48

10 Index................................................................................................................ 50

Appendix A..........................................................................................................51

Appendix B..........................................................................................................52

KATflow 150 1 Safety instructions, legal requirements, warranty, return policy

1 Safety instructions, legal requirements, war-

ranty, return policy

1.1 Sym ols used in these operating instructions

Danger

This symbol represents an immediate hazardous situation which could result in

serious injury, death or damage to the equipment. Where this symbol is shown,

do not use the equipment further unless you have fully understood the nature of the

hazard and have taken the required precautions.

Attention

This symbol indicates important instructions which should be respected in order to

avoid dama in or destroyin the equipment. Follow the the precautions iven in

these instructions to avoid the hazard. Call our service team if necessary.

Call service

Where this symbol is shown call our service team for advice if necessary.

Note

This symbol indicates a note or detailed set-up tip.

Information point.

Operator keys are printed in bold typeface and placed in pointed brackets.

1.2 Safety instructions

Do not install, operate or maintain this flowmeter without readin , under-

standin and followin these operatin instructions, otherwise injury or

dama e may result.

Study these operatin instructions carefully before the installation of the

equipment and keep them for future reference.

Observe all warnin s, notes and instructions as marked on the packa in ,

on the equipment, and detailed in the operatin instructions.

Do not use the instrument under wet conditions with the battery cover re-

moved or opened.

Follow the unpackin , stora e and preservation instructions to avoid dam-

a e to the equipment.

Install the equipment and cablin securely and safely accordin to the rel-

evant re ulations.

If the product does not operate normally, please refer to the service and

troubleshootin instructions, or contact KATRONIC for help.

5

!

<BRK>

!

•

KATflow 150 1 Safety instructions, legal requirements, warranty, return policy

1.3 Warranty

Any product purchased from KATRONIC is warranted in accordance with

the relevant product documentation and as specified in the sales contract

provided it has been used for the purpose for which it has been desi ned

and operated as outlined in these operatin instructions. Misuse of the

equipment will immediately revoke any warranty iven or implied.

Responsibility for suitability and intended use of this ultrasonic flowmeter

rests solely with the user. Improper installation and operation of the flow-

meter may lead to a loss of warranty.

Please note that there are no operator-serviceable parts inside the equip-

ment. Any unauthorised interference with the product will invalidate the

warranty.

1.4 Return policy

If the flowmeter has been dia nosed to have a problem, it can be returned to KAT-

RONIC for repair usin the Customer Returns Note (CRN) attached to the Ap-

pendix of this manual. KATRONIC re ret that for safety reasons we cannot accept

the return of the equipment unless accompanied by the completed CRN.

1.5 Legislative requirements

The flowmeter is desi ned to meet the safety requirements in accordance with

sound en ineerin practice. It has been tested and has left the factory in a condi-

tion in which it is safe to operate. The equipment is in conformity with the statutory

requirements of the EC directive and complies with applicable re ulations and

standards for electrical safety EN 61010 and electro-ma netic compatibility EN

61326. A CE Declaration of Conformity has been issued in that respect, a copy of

which can be found in the Appendix of these operatin instructions.

The Waste Electrical and Electronic Equipment Directive (WEEE Directive) aims to

minimise the impact of electrical and electronic oods on the environment by in-

creasin re-use and recyclin and by reducin the amount of WEEE oin to land-

fill. It seeks to achieve this by makin producers responsible for financin the col-

lection, treatment, and recovery of waste electrical equipment, and by obli in dis-

tributors to allow consumers to return their waste equipment free of char e.

KATRONIC offers its customers the possibility of returnin unused and obsolete

equipment for correct disposal and recyclin . The Dustbin Symbol indicates that

when the last user wishes to discard this product, it must be sent to appropriate fa-

cilities for recovery and recyclin . By not discardin this product alon with other

household-type waste, the volume of waste sent to incinerators or landfills will be

reduced and natural resources will be conserved. Please use the Customer Return

Note (CRN) in the Appendix for return to KATRONIC.

All products manufactured by KATRONIC are compliant with the relevant aspects of

the RoHS Directive.

6

RoHS Directive

CE marking

WEEE Directive

KATflow 150 2 Introduction

2 Introduction

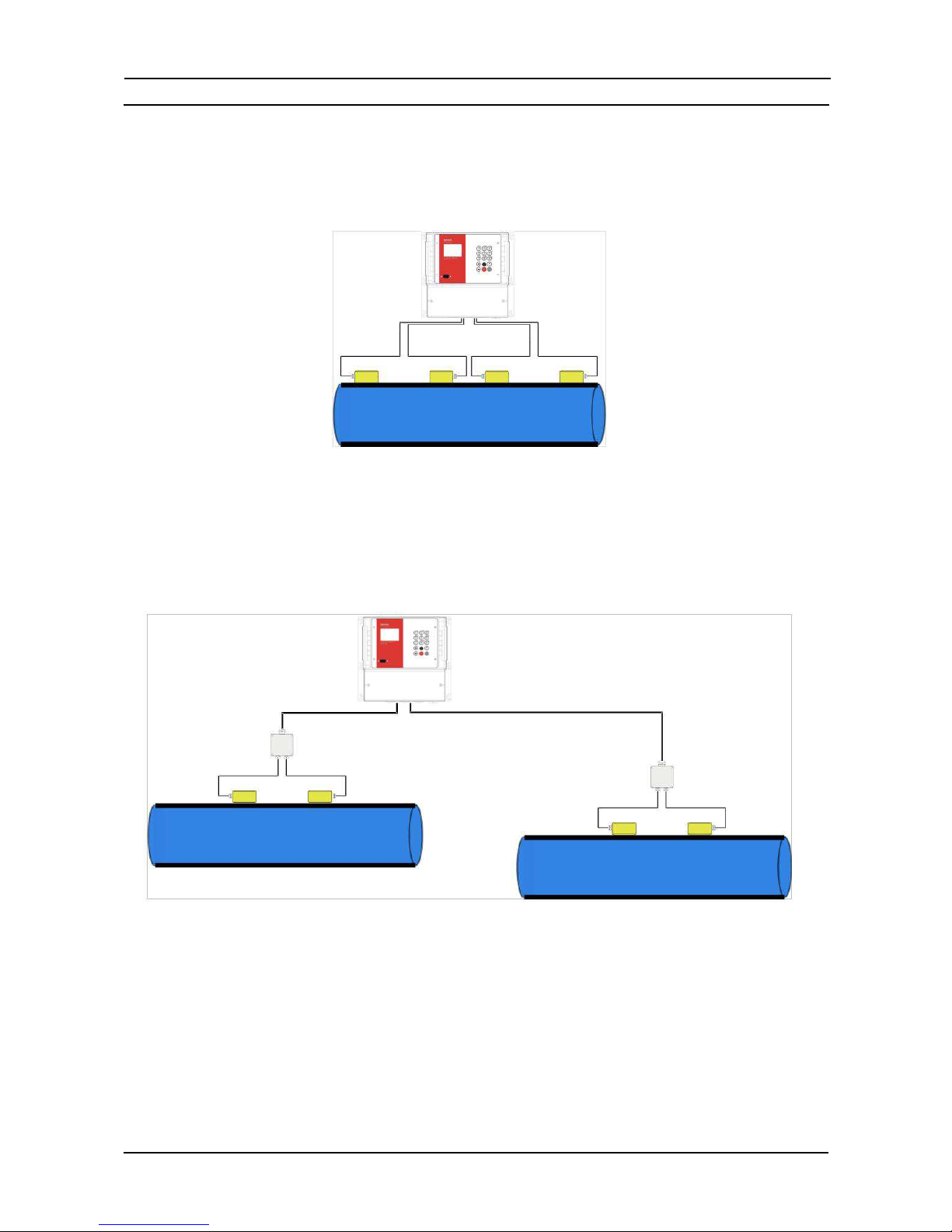

The KATflow 150 is an ultrasonic flowmeter employin clamp-on sensors for the

measurement of liquids in full, enclosed pipes. Flow measurements can be under-

taken without interruption of the process or interference with the inte rity of the

pipeline. The clamp-on sensors are attached to the outside of the pipes. The KAT-

flow 150 uses ultrasonic si nals for measurement of the flow, employin the transit-

time method.

Ultrasonic si nals are emitted by a transducer installed on a pipe and received by a

second transducer. These si nals are emitted alternately in the direction of flow and

a ainst it. Because the medium is flowin , the transit time of the sound si nals

propa atin in the direction of flow is shorter than the transit time of the si nal

propa atin a ainst the direction of flow. The transit-time difference ΔT is meas-

ured and allows the determination of the avera e flow velocity alon the path of

acoustic propa ation. A profile correction is then performed to obtain the avera e

flow velocity over the cross-sectional area of the pipe, which is proportional to the

volumetric flow rate.

7

Illustration 1: Clamp-on ultrasonic flowmeter configuration

Measuring principle

Illustration 2: Transit-time measuring principle

Clamp-on trans-

it-time flowmeter

KATflow 150 2 Introduction

System confi uration

A maximum of 2 sensor pairs can be installed - if two pairs are installed these can

be confi ured either in a 1-pipe dual-path or a 2-pipe sin le path confi uration.

8

Illustration 4: KF150 2-pipe 1-path configuration using optional junction boxes

Illustration 3: KF150 with direct sensor connection in a 1 pipe 2 path configuration

KATflow 150 3 Installation

3 Installation

3.1 Unpacking and storage

3.1.1 Unpacking

Care should be taken when openin the box containin the flowmeter, any mark-

in s or warnin s shown on the packa in should be observed prior to openin . The

followin steps should then be taken:

Unpack the flowmeter in a dry area.

The flowmeter should be handled with care and not left in an area where it

could be subject to physical shocks.

If usin a knife to remove packa in care should be taken not to dama e

the flowmeter or cables.

The flowmeter packa e and contents should be checked a ainst the deliv-

ery note supplied and any missin items reported immediately.

The flowmeter packa e and contents should be checked for si ns of dam-

a e durin transport and any problems reported immediately.

The vendor accepts no responsibility for dama e or injury caused durin

the unpackin of the instrumentation supplied.

Excess packin materials should be either recycled or disposed of in a suit-

able way.

3.1.2 Storage

If stora e is necessary, the flowmeter and sensors should be stored:

in a secure location,

away from water and harsh environmental conditions,

in such a way as to avoid dama e,

small items should be kept to ether in the ba s provided to avoid loss.

3.1.3 Identification of components

The followin items are typically supplied (please refer to your delivery note for a

detailed description):

KATflow 150 ultrasonic flowmeter

Clamp-on sensors (one pair for sin le channel operation, two pairs for dual

channel operation)

Sensor connection cable(s) if not direct sensor connection

Sensor mountin accessories

Couplin component

Operatin instructions

Project and/or hazardous area documentation (optional)

Calibration certificate(s) (optional)

Temperature measurement probes (optional)

9

KATflow 150 3 Installation

3.2 Clamp-on sensor installation

The correct selection of the sensor location is crucial for achievin reliable meas-

urements and hi h accuracy. Measurement must take place on a pipe in which

sound can propa ate (see Acoustic propa ation) and in which a rotationally sym-

metrical flow profile is fully developed (see Strai ht pipe len ths).

The correct positionin of the transducers is an essential condition for error-free

measurements. It ensures that the sound si nal will be received under optimal con-

ditions and evaluated correctly. Because of the variety of applications and the differ-

ent factors influencin the measurement, there can be no standard solution for the

positionin of the transducers.

The correct position of the transducers will be influenced by the followin factors:

diameter, material, linin , wall thickness and eneral condition of the pipe,

the medium flowin in the pipe,

the presence of as bubbles and solid particles in the medium.

Check that the temperature at the selected location is within the operatin temper-

ature ran e of the transducers (see Specification).

After the sensor location has been selected, make sure that that supplied cable is

lon enou h to reach the flow transmitter mountin location. Ensure that the tem-

perature at the selected location is within the ambient operatin temperature ran e

of the flow transmitter (see Specification).

Acoustic propa ation is achieved when the flowmeter is able to receive sufficient

si nal from the transmitted ultrasonic pulses. The si nals are attenuated in the

pipe material, the medium and at each of the interfaces and reflections. External

and internal pipe corrosion, solid particles and as content in the medium contribute

heavily to si nal attenuation.

Sufficient strai ht len ths of pipe on the inlet and outlet of the measurin location

ensure an axi-symmetrical flow profile in the pipe, which is required for ood meas-

urement accuracy. If insufficient strai ht len ths of pipe are available for your ap-

plication measurements are still obtainable, but the certainty of the measurement

can be reduced.

3.3 Installation location

Select an installation location followin the recommendations in Table 1 and try to

avoid measurin

in the vicinity of deformations and defects of the pipe,

near weldin seams,

where deposits could be buildin up in the pipe.

For a horizontal pipe:

Select a location where the transducers can be mounted on the side of the pipe, so that the sound waves emitted by

the transducers propa ate horizontally in the pipe. In this way, the solid particles deposited on the bottom of the pipe

and the as pockets developin at the top will not influence the propa ation of the si nal.

Correct Incorrect

10

Acoustic propagation

Straig t pipe lengt s

KATflow 150 3 Installation

For a free inlet or outlet pipe section:

Select the measurin point at a location where the pipe cannot run empty.

Correct Disadvantageous

Correct Disadvantageous

For a vertical pipe:

Select the measurin point at a location where the liquid flows upward to ensure that the pipe is completely filled.

Correct Incorrect

Look for a sensor installation location with sufficient strai ht pipe to obtain accurate

measurements. Please refer to Table 2 as a uideline for recommended distances

from disturbance sources.

Distur ance source: 90°-el ow

Inlet Outlet

L ≥ 10 D L ≥ 5 D

Distur ance source: 2 x 90°-el ows in one plane

Inlet L ≥ 25 D Outlet L ≥ 5 D

11

Table 1: Recommendations for sensor mounting location

KATflow 150 3 Installation

Distur ance source: 2 x 90°-el ows in different planes

Inlet Outlet

L ≥ 40 D L ≥ 5 D

Distur ance source: T-section

Inlet Outlet

L ≥ 50 D L ≥ 10 D

Distur ance source: diffuser

Inlet Outlet

L ≥ 30 D L ≥ 5 D

Distur ance source: reducer

Inlet Outlet

L ≥ 10 D L ≥ 5 D

Distur ance source: valve

Inlet Outlet

L ≥ 40 D L ≥ 10 D

Distur ance source: pump

Inlet

L ≥ 50 D

Table 2: Recommended distances from disturbance sources

12

KATflow 150 3 Installation

3.4 Pipe preparation

Clean dirt and dust from around the area of the pipework where the

sensors are to be placed.

Remove loose paint and rust with a wire brush or file.

Firmly bonded paint does not necessarily need to be removed provided the flow-

meter dia nostics indicate sufficient si nal stren th.

3.5 Clamp-on sensor mounting configurations and separ-

ation distance

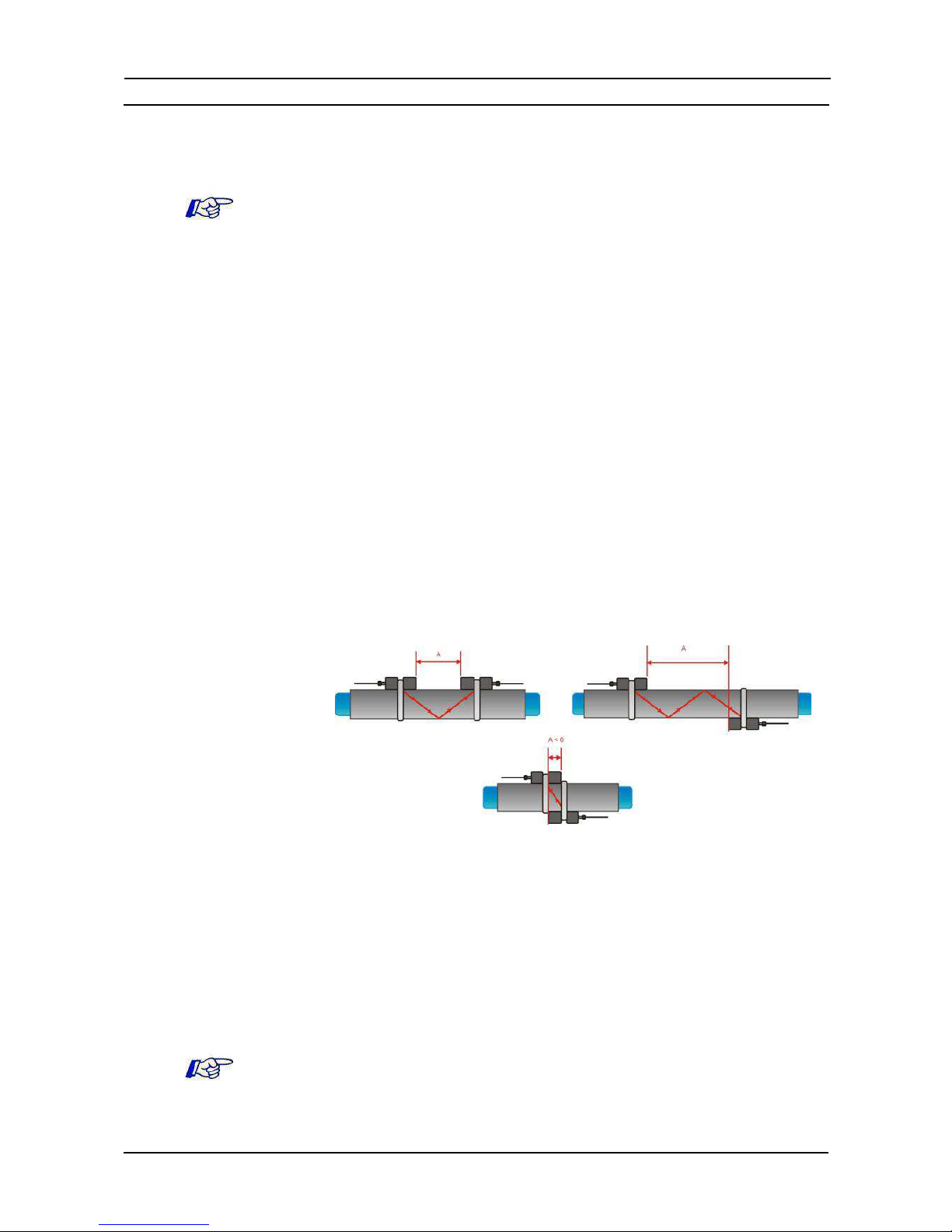

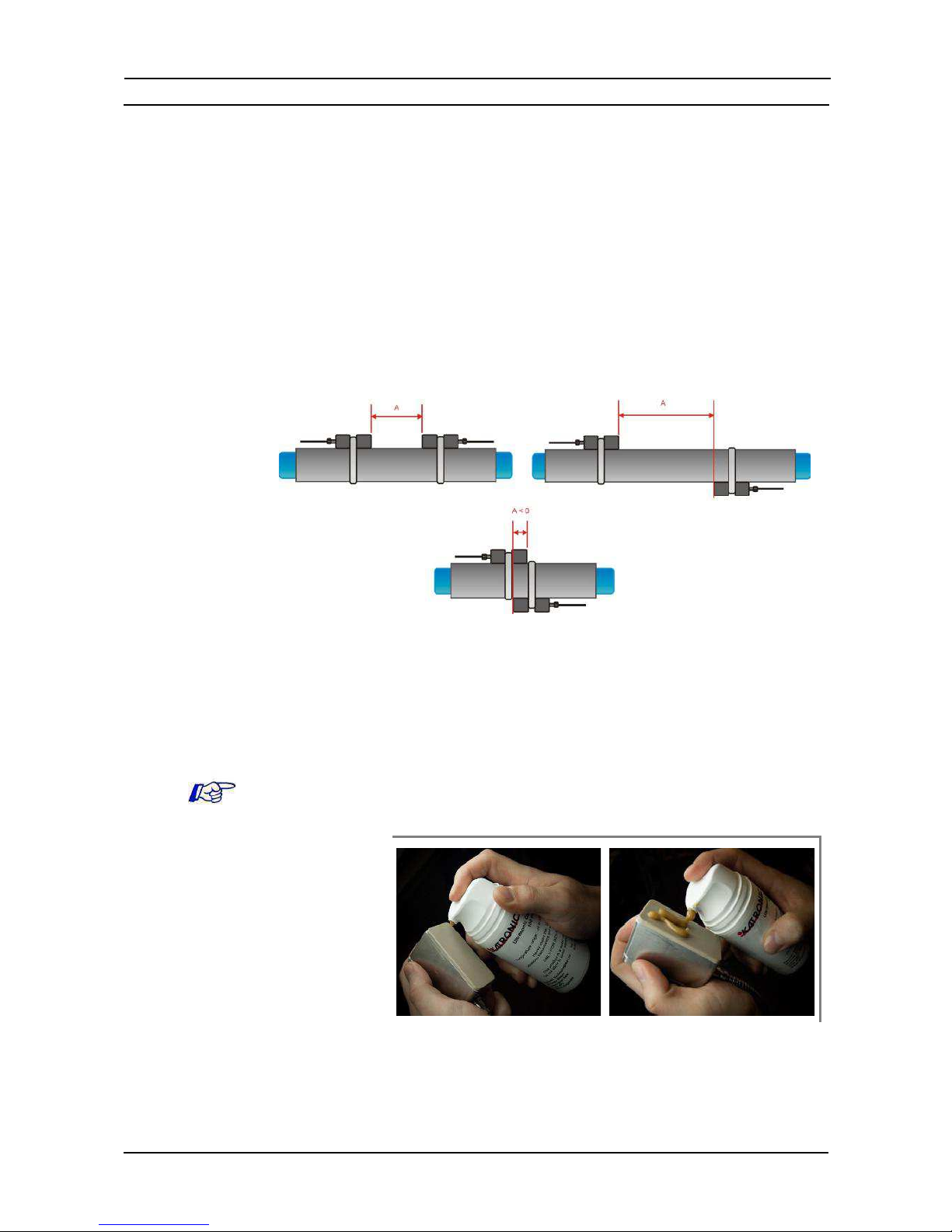

The most common clamp-on sensor mountin confi uration is the Reflection Mode,

sometimes known as V-Mode (see Illustration 3, sketch (1). Here, the ultrasonic

si nal passes twice throu h the medium (2 si nal passes). The Reflection Mode is

the most convenient mountin method as the transducer separation distance can

be measured easily and the sensors can be accurately ali ned. This method

should be used whenever possible.

An alternative mountin confi uration (Illustration 3, sketch (3)) is the Dia onal

mode (Z-Mode). The si nals travel only once throu h the pipe. This method is of-

ten used for lar er pipes where reater si nal attenuation mi ht occur.

Further variation of the Reflection and the Dia onal Modes are possible by alterin

the number of passes throu h the pipe. Any even number of passes will require

mountin the sensors on the same side of the pipe, while with an odd number of

passes, the sensors must be mounted on opposite sides of the pipe. Commonly,

for very small pipes, sensor mountin confi urations such as 4 passes (W-mode)

or 3 passes (N-mode) are used (Illustration 3, sketch (2)).

The transducer separation distance A is measured from the inside ed es of the

sensor heads as shown in illustration 3. It is automatically calculated by the flow-

meter based on the parameter entries for pipe outside diameter, wall thickness, lin-

in material and thickness, medium, process temperature, the sensor type and the

selected number of si nal passes.

A ne ative separation distance A < 0 can occur for mountin confi urations on

small pipes where dia onal mode operation has been selected (see Illustration 3,

sketch (3). Ne ative separation distances may be su ested for reflection mode in-

stallations, but are not possible. In these cases, use dia onal mode or a lar er

number of passes.

13

Illustration 5: Clamp-on sensor mounting configurations and sensor spacing

Sensor spacing

Diagonal Mode

Reflection Mode

Transducer separa-

tion distance

KATflow 150 3 Installation

3.6 Flowmeter installation

3.6.1 Wall mounting

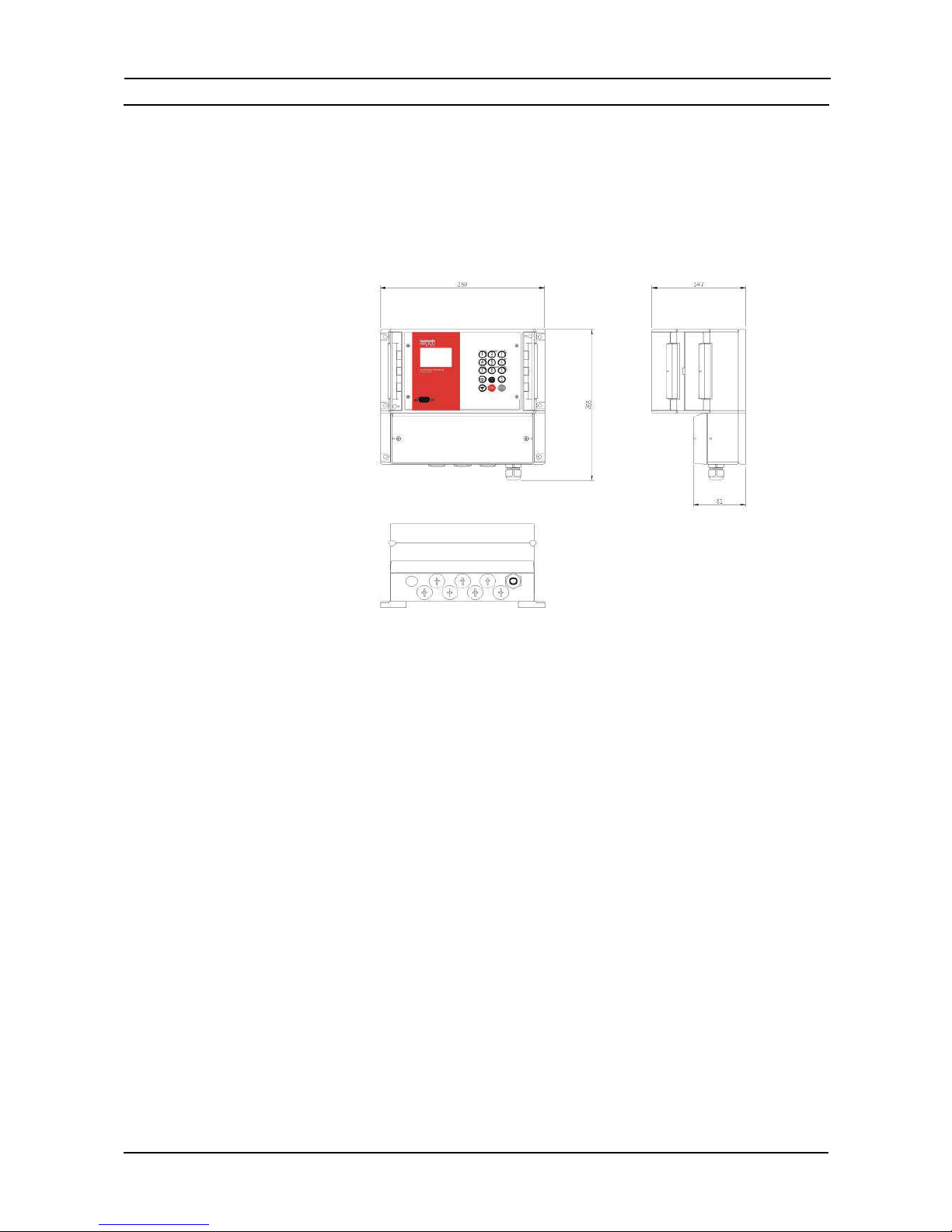

The KATflow 150 is a wall mounted device and can be installed usin suitable

screws and wall plu s accordin to the followin drawin s.

14

Drawing 1: Outline dimensions KATflow 150 ultrasonic flowmeter

Flowmeter outline di-

mensions

KATflow 150 3 Installation

Make sure that the ambient temperature is within the -10 ... 60 °C operatin tem-

perature ran e specified for the flowmeter unit.

15

Drilling aid for wall

mounting

243.5

120

CRS

90

CRS

!

KATflow 150 3 Installation

3.6.2 Electrical connections

Please note that in order to supply the unit with MAINS POWER, the equipment

must be protected by suitably sized switches and circuit breakers.

100 ... 240 V AC, 50/60 Hz 10 W

9 ... 36 V DC 10 W

16

!

Electrical wiring

!

KATflow 150 3 Installation

3.7 Clamp-on sensor mounting

Before the sensors can be mounted

the installation location should have been determined,

a sensor mountin method should be chosen,

the flowmeter must be mechanically and electrically installed,

the sensors must be connected to the flowmeter.

Dependin on which sensor mountin method is bein used, the clamp on sensors

are either mounted on the same side of the pipe (Reflection Mode) or on opposite

sides of the pipe (Dia onal Mode). The sensor spacin is calculated by the flow-

meter from the pipe parameters entered.

3.7.1 Sensor pipe mounting configurations

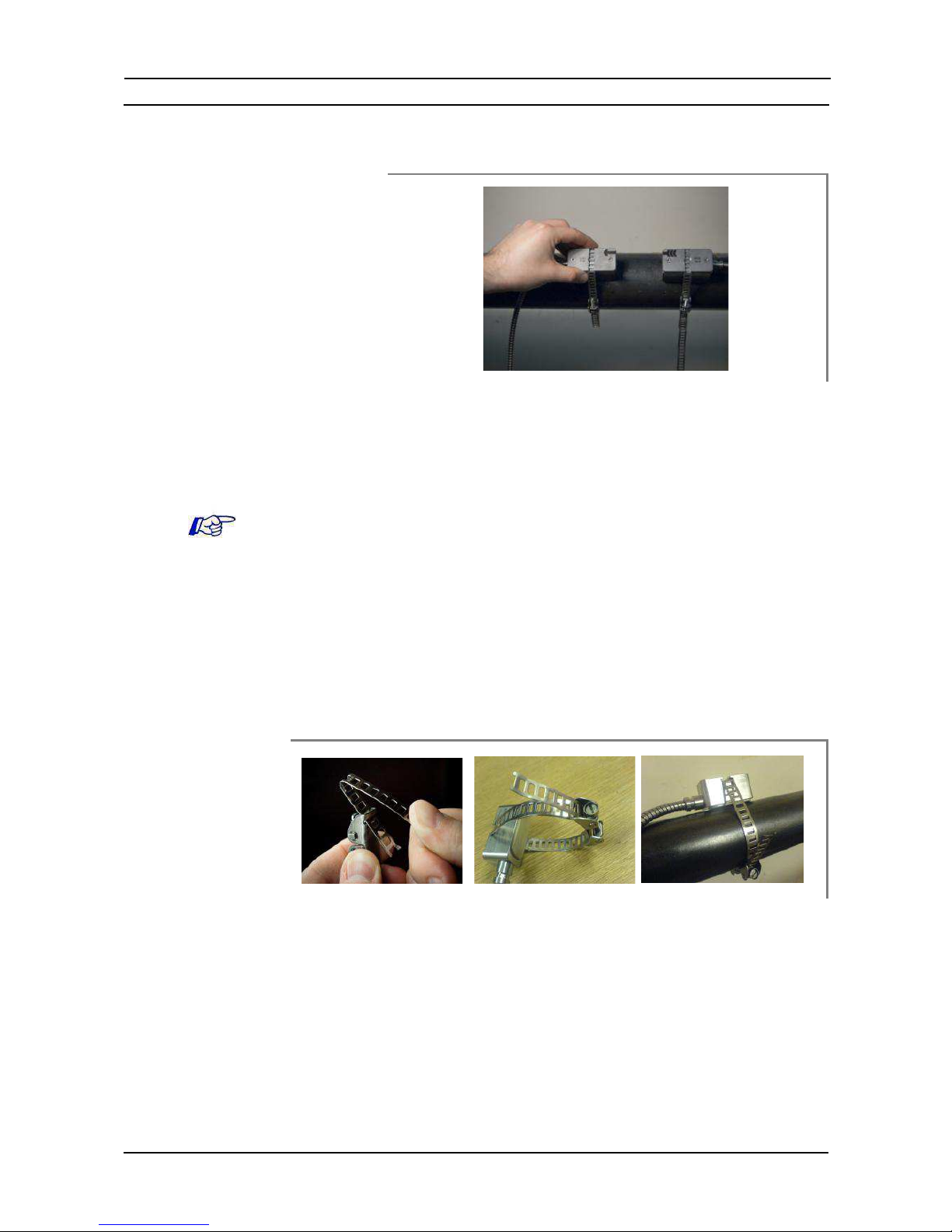

3.7.2 Acoustic coupling gel

In order to obtain acoustical contact between the pipe and the sensors, apply a

bead of acoustic couplin el len thwise down the centre of the contact area of the

sensors.

17

Sensor mounting

Illustration 6: Sensor pipe mounting configuration

Illustration 7: Application of acoustic coupling gel

KATflow 150 3 Installation

3.7.3 Correct positioning of the sensors

Always mount the transducer pair so that the free front ed es of the sensors face

each other.

There is a different en ravin on the top of each transducer. The transducers are

mounted correctly if the en ravin s on the two transducers form an arrow. The

transducer cables should point in opposite directions.

Later, the arrow, in conjunction with the indicated measured value, will help to de-

termine the direction of flow.

The sensor separation distance is automatically calculated by the flowmeter based

on the parameter entries for pipe outside diameter, wall thickness, linin material

and thickness, medium, process temperature, the sensor type and the selected

number of si nal passes.

3.7.4 Sensor mounting with tension straps

Cut the tension straps to the appropriate len th.

Pull at least 2 cm of the tension strap throu h the slot in the clamp and

bend the strap back to secure the clamp to the tension strap.

Guide the other end of the tension strap throu h the roove on top of the

sensor.

Ensure sensors have adequate acoustic couplant.

Place the sensor onto the prepared pipe section.

Hold the clamp on the transducer with one hand and uide the tension

strap around the pipe.

Pull the tension strap and uide the free end throu h the clamp so that the

clamp hooks en a e. Sli htly ti hten the screw on the clamp.

Mount the second sensor in the same way.

18

Correct sensor

position

Illustration 8: Correct positioning of the sensors

Illustration 9: Metallic mounting straps

KATflow 150 3 Installation

Press the sensors firmly onto the pipe. There should be no air pockets

between the transducer surface and the pipe wall.

Usin a measurin tape, adjust the sensor separation distance as su es-

ted by the flowmeter. When the sensor positionin screen (Section 3.3) is

displayed, the middle bar allows fine adjustment of the sensor location.

Ensure that the narrower side of the clip is above and inside the wider side

and that the two sides of the clip do not come into contact while ti htenin ,

as this will prevent the strap from bein correctly tensioned.

19

Illustration 10: Sensor mounting with tension straps and clamps

Illustration 11: Clip arrangement for correct tensioning

KATflow 150 4 Operation

4 Operation

4.1 Switching On/Off

The flowmeter is switched on by connectin the power supply to the instrument.

Disconnectin the external supply switches off the flowmeter.

4.2 Keypad and display

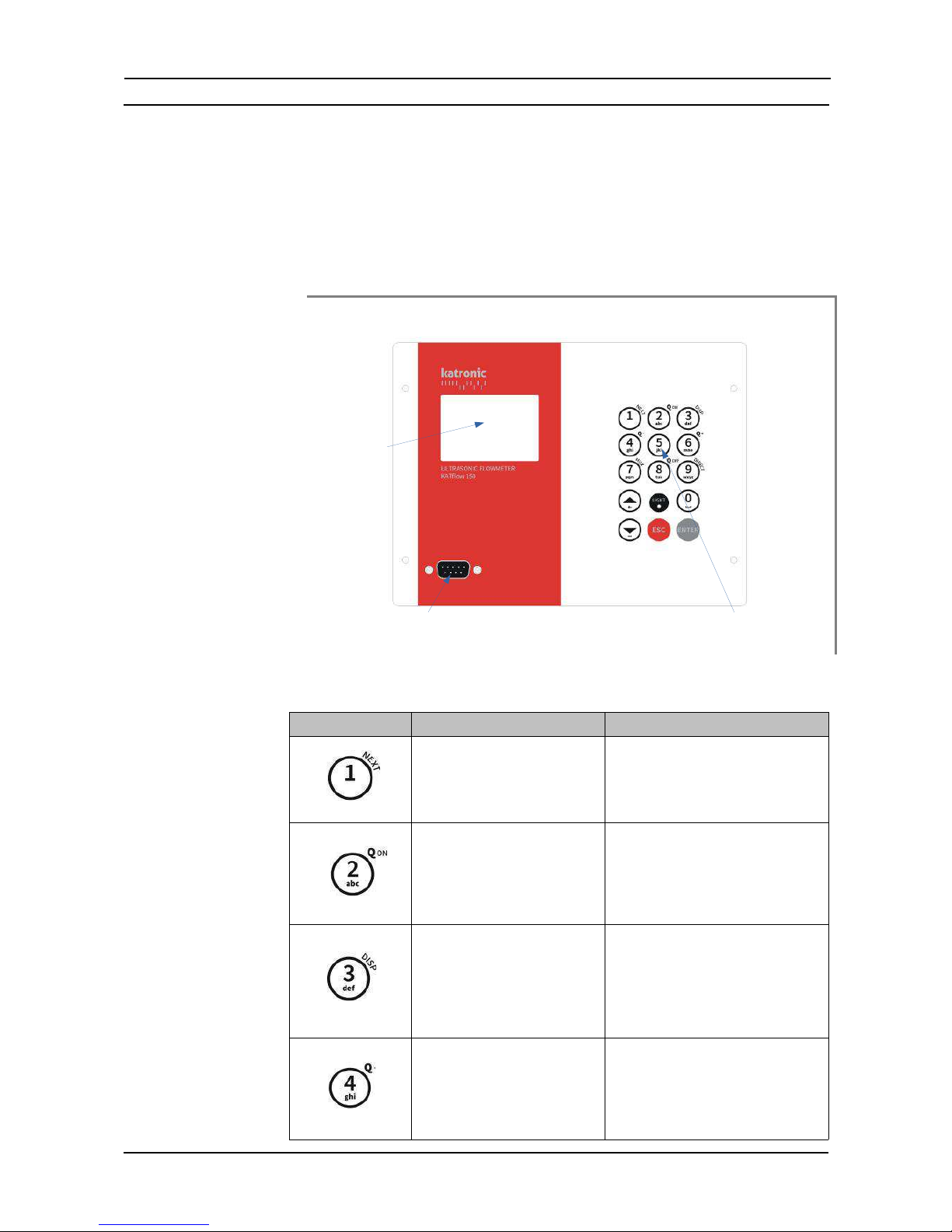

4.2.1 Keypad key functions

Key Main function Secondary function

Character entry:

1 (1 short key stroke)

, (2 short key strokes)

. (3 short key strokes)

_ (4 short key strokes)

Show NEXT available item

Character entry:

A

B

C

2

/

QON = Start and reset totaliser

Character entry:

D

E

F

3

?

Show next DISPlay

Character entry:

G

H

I

4

<

Q- = Reset ne ative total value

20

Switc ing On/Off

RS 232 Serial Interface

Display

Keypad

Table of contents

Other Thorne & Derrick Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Braun Messtechnik

Braun Messtechnik HZ 3 Mounting instructions

KSJ Photoelectrical Instruments Co.

KSJ Photoelectrical Instruments Co. MG6-S1 user manual

Associated Research

Associated Research HYPOTULTRA III 7620 quick start guide

HP

HP 68302 user guide

Sensitron

Sensitron STS3REL manual

FarmChem

FarmChem GRIZZLY Operation manual