insize ISU-250C User manual

www.insize.com

ISU-250C

ULTRASONIC THICKNESS GAUGE

OPERATION MANUAL

MN-ISU-250C-E

1

Attention

In order to obtain good measurement precision, you need to clear

away the rusty, sundry, grease, etc. on the working surface.

Please use the couplant on the working surface, measure

repeatedly around the target area and take average value.

Please clean the couplant on the transducer and working surface

after measure.

Please don’t pull the transducer cable when use the instrument.

Technical Specification

2

Measurement range

Resolution

Velocity range

Measurement rate

Average mode

Limited setting

Measuring Units

Memory

Data output

Display

Battery

Operating temperature

Measuring temperature

Dimensions

Weight 0.22kg

116mm L)×64mm(W)×27mm H( ( )

-20℃ ~+350℃(according to the probes)

-20℃ ~+50℃

2 x AAA Batteries

128×64 LCD with back light

USB to PC

Memory of 5000 readings with location number

mm / inch

With Low-high indication and alarm

2 to 9 times average measurement

4 /s and 10/s in fast mode

1000m/s~9999m/s

0.01mm(0.001〞), 0.1mm (0.01〞)

0.8mm~300mm

Standard delivery

1pc

1pc

2pcs

1bottle

1pc of each

Main unit

Transducer ISU-T08

Battery(AAA)

Couplant (for ISU-T06, ISU-T08, ISU-T12)

USB cable and software disc

ISU-T06, ISU-T12, ISU-T13

Transducer

Couplant (for ISU-T13)

ISU-HT5-COUPLANT

Optional Accessory

3

Codel Frequency

ISU-T12

ISU-T06

ISU-T08

ISU-T13

Measuring Range Temperature

2.0MHZ

7.5MHZ

5.0MHZ

5.0MHZ

<60℃/ 140°F

<60℃/ 140°F

<60℃/ 140°F

<350℃/662°F

2.0-400mm/0.08-16.00"

0.7-50mm/0.03-2.00"

0.8-300mm/0.03-12.00"

3.0-100mm/0.08-4.00"

3

1

2

5

4

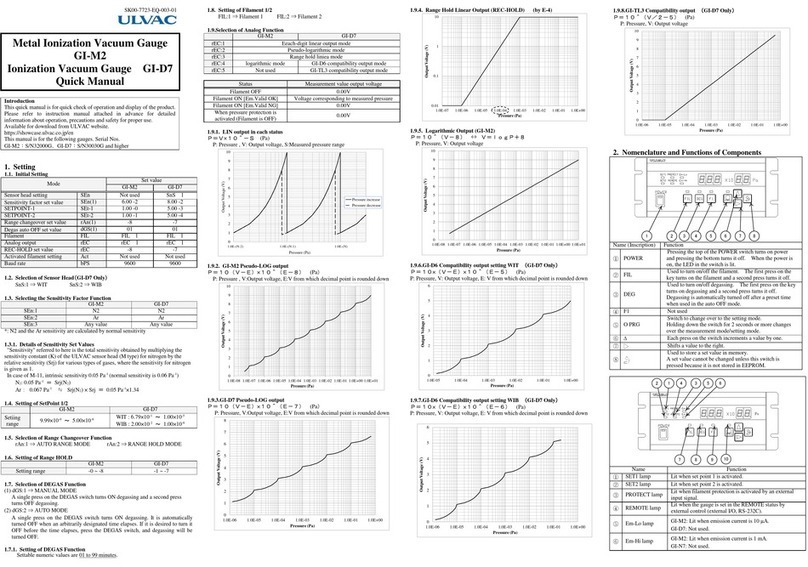

1. LCD Screen 2. Key Pad 3. Battery Pack 4. Transducer Port

5. 4.00mm Block

Overview the display unit

Key Functions

4

Key Function

- - M e n u Ke y

--Confirm Key

--On/Off Key

--Esc. Menu

--Up Arrow Key

--Backlight Key

(Under the measurement)

(Under the measurement)

--Down Arrow Key

--Calibration Key

(Under the measurement)

(Under the measurement)

--Left Arrow Key

--Storage Key

--Right Arrow Key

--Read data

①

②

③

④

⑤

Display screen

5

Battery indicator

①

②

③

④

⑤

Current velocity

Current transducer model

Measurement value and measurement mode

Current memory location

Switch on

Press key to turn on the gauge.

Probe zero

The gauge does an automatic zeroing of the transducer thus

eliminating the need for an on-block zero. And then the gauge

came into the measurement mode directly.

Please make sure the transducer is not coupled to the test

piece when the gauge is first turned on and that there is no

coolant on the end of the transducer. The transducer should

also be at the room temperature, clean without any noticeable

wear.

Backlight

Press to turn on / off the backlight.

Parameters setting

Measurement mode

Press into the measurment mode setting.

Press or to select desired measurment mode.

I S U - 2 5 0 C U l t r a s o n i c T h i c k n e s s G a u g e o f f e r s t w o

measurment modes, they are T-E Mode and Scan.

T-Mode

STANDARD - It is available for the normal measurement.

MINIMUM -The gauge will catch and display the minimum

measured thickness during one measurement process. It is

available for measuring the thickness of curve surface or

pipe.

6

DIFFERENCE - The gauge will display a thickness value as

an absolute number of what has been inputted. For

AVERAGE - The gauge will display the average thickness of

2-9 measurements.

LIMITATION – The gauge will alarm you of low or high

thresholds via audible sound.

SCAN

The gauge will alarm for each fast measurement. And will

display the all measured thickness upon the complete

measurement finished. It is available for measuring the

thickness of test piece with high temperature surface.

Press to confirm selection.

Press to Esc. Menu and into the measurment.

Other parameters setting

Press and then press into the setting.

Velocity rate

1)Velocity Setting

Press into“ VEL. SETTING” state.

There are 9 velocities for materials pre-stored in gauge.

You can select one by pressing or .

Press to confirm.

2)Velocity measurement

Measuring the sample which thickness is known.

Press key into“ Velocity measurement ”state.

Basic gauge operations

1

3

4

2

Press or to up and down the value of velocity to

determine the thickness as the same as the value of

sample that is measured.

Press key to confirm.

Resolution

Press key into“ Resolution ”.

Press or to select resolution and unit.

1.0.1mm 2.0.01mm

3.0.01in 4.0.001in

example, input value = 5.00mm and the real thickness is

5.03mm, the display will show diff 0.03mm. If the real value

is 4.97 m, the gauge will display, -0.03mm.

3)Velocity store

After you set the velocity, the instrument can store the

velocity value.

7

Memory

Press into the menu.

Press or into “ Memory”, the screen will display.

1. Memory Unit 2. Delete ALL Memory

Press or into the selected item, press to

1)Memory unit

The gauge has a memory capacity of 5000 measurements.

The memory location was composed by alphabet A-Z +

0000-4999. You can select an Alphabet + an initial number

freely for beginning to store the value and the next number

will be followed automatically.

confirm.

After taking every measurement, press key to store the

value with a location number.

2)Memory read

press Read (Under the measurement).

Into the “Memory Read”, Press and to select desired

Alphabet, Press and to select initial number. Then the

desired group of value can be readable beginning from this

initial number.

3)Delete all memory

Delete all memory.

Date transfer

Press into the menu.

Press or into “Date Transfer”, the screen will display.

The data can be transferred to PC using the data view and

can be stored as DOC. ,TXT. Or Excel.

For more detailed information, refer to the “Installation

Manual” enclosed in the CD.

8

Press or to select desired item.

Press confirm.

Default

When the “ Default ”is selected , the gauge will recover the

default parameter.

Information

The screen display the supplier info, version number and

transducer number.

Sound velocity

Material Sound Velocity

Inch/µS M/s

Air

Aluminum

Beryllium

Boron Carbide

Brass

Cadmium

Copper

Glass(crown)

0.013

0.250

330

6300

0.390 9900

0.510 12900

0.430 11000

4300

2800

4700

5300

Alumina Oxide

0.170

0.110

0.180

0.210

If measured value is different than the known value of the

test piece, adjust the measured value by pressing or

and then press . The gauge will return to measure mode.

Press key to enter/confirm.

Calibration

Press into menu.

Press or into “Calibration”.

Measure the test piece with known thickness.

Function

Press into the menu,press or into “FUNCTION”,

the screen will display:

1. Power off 2. Gain adjustment 3. Language

6. Information

Press or into the selected item, press to confirm.

Power off

Auto shut down after 1 Min. 3 Min. 5 Min. or Never can be

selectable.

Gain adjustment

Press into the “Gain adjustment”, the screen will display:

1. High 2. Medium 3. Low 4. Automatic

5. Default

4. Contrast

To change the language: English, Portuguese, Czech.

Language

To change the contrast of the screen.

Contrast

9

Glycerin

Gold

Ice

Inconel

Iron

Iron (cast)

Lead

Magnesium

Mercury

Molybdenum

Monel

Neoprene

Nickel

Nylon, 6.6

Oil (SAE 30)

Platinum

Plexiglass

Polythylene

Polystyrene

Polyurethane

Quartz

Rubber, Buty

Silver

Steel, Mild

Steel, Stainless

Teflon

Tin

Titanium 0.240

0.130

0.060

0.228

0.233

0.140

0.070

0.230

0.0700

0.093

0.070

0.110

Tungsten

Uranium

Water

Zinc

0.200

0.130

0.584

0.170 4200

1480

3400

5200

6100

3300

1400

5800

5920

3600

1800

5800

1900

2400

1900

1700

3300

1700

2600

5600

1600

5400

6300

1400

5800

2200

4600

5900

5700

4000

3200

19000.075

0.130

0.160

0.220

0.230

0.180

0.085

0.230

0.057

0.250

0.210

0.063

0.220

0.100

0.067

0.130

10

Specification Of Transducers

Code Frequency

Application

Measuring range

Diameter( )Ød

Applicable

temperature

Minimum size of

measurement

(diameter × wall thickness)

pipe for

ISU-T06

ISU-T12

ISU-T13

ISU-T08

5.0MHz

7.5MHz

2.0MHz

5.0MHz

3-100mm

0.7-50mm

3-350mm

0.8-300mm

<350°C

<60°C

<60°C

<60°C

for high

temperature

for thin material

for casting steel

general use

30×4mm

25×3mm

15×1.2mm

20×1.2mm

13mm

8.5mm

16.3mm

10.8mm

Code

ISU-T06

ISU-T12

ISU-T13

ISU-T08

Table of contents

Other insize Measuring Instrument manuals

insize

insize ISF-DF Series User manual

insize

insize 1149 Series Technical manual

insize

insize PLUS 3631 Series User manual

insize

insize ISU-200D User manual

insize

insize ISQ-TS120K User manual

insize

insize ISU-300D User manual

insize

insize 1113INS Technical manual

insize

insize ISH-SDM Installation manual

insize

insize ISF-1DF Series User manual

insize

insize ISN-L70 User manual