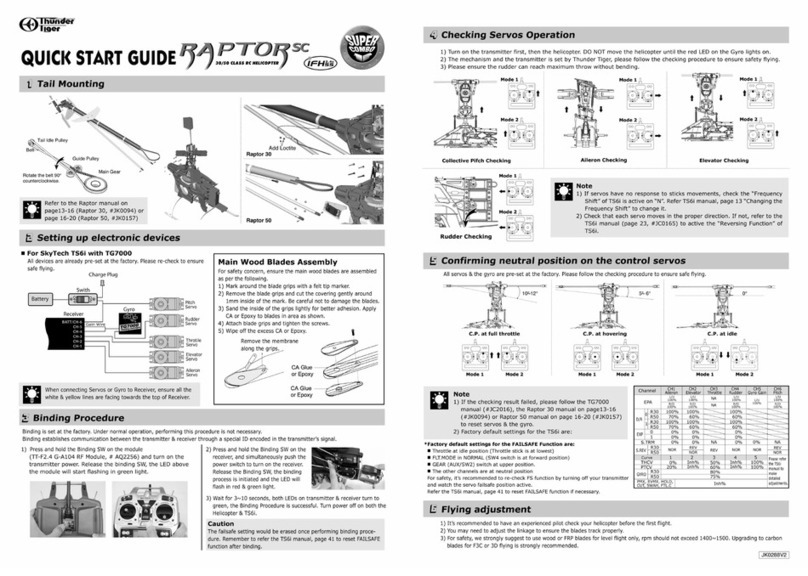

THUNDER TIGER Raptor SE 50 Size 3D Heli Quick guide

Other THUNDER TIGER Toy manuals

THUNDER TIGER

THUNDER TIGER Raptor50 Titan User manual

THUNDER TIGER

THUNDER TIGER TITAN X50 - User manual

THUNDER TIGER

THUNDER TIGER ConceptX 4369 User manual

THUNDER TIGER

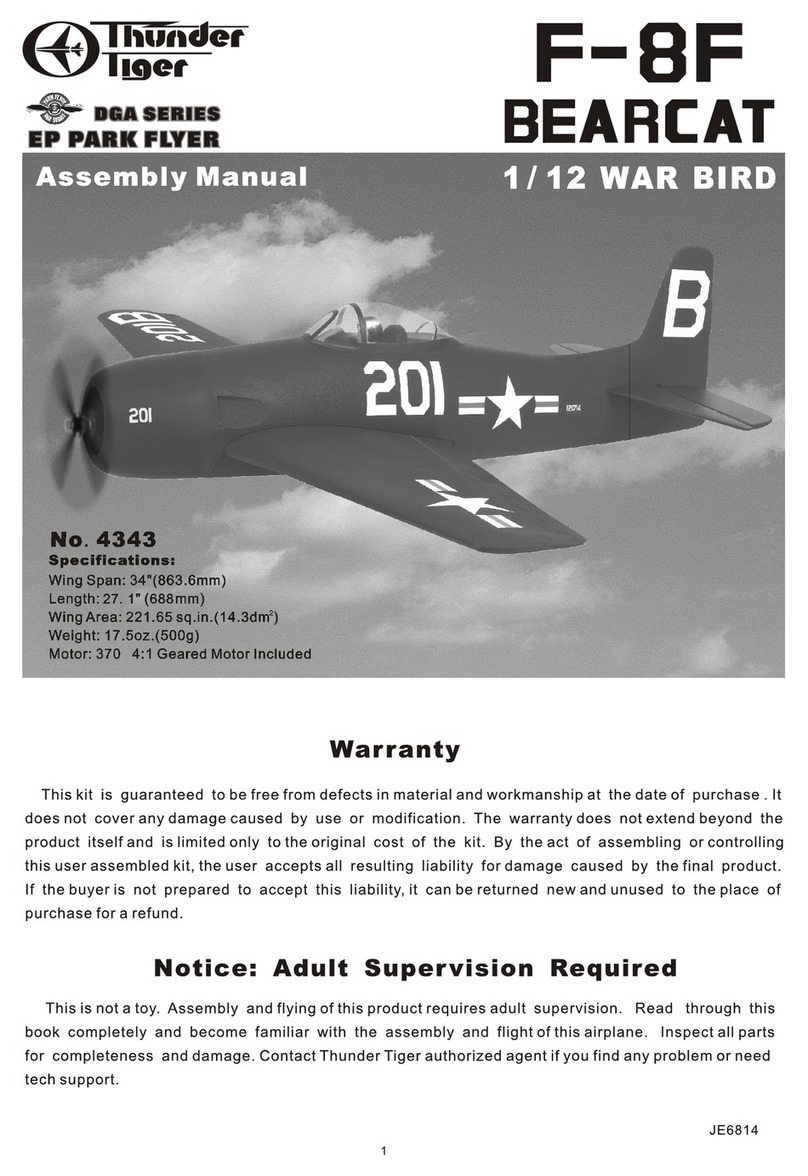

THUNDER TIGER F-8F BEARCAT - ASSEMBLY User manual

THUNDER TIGER

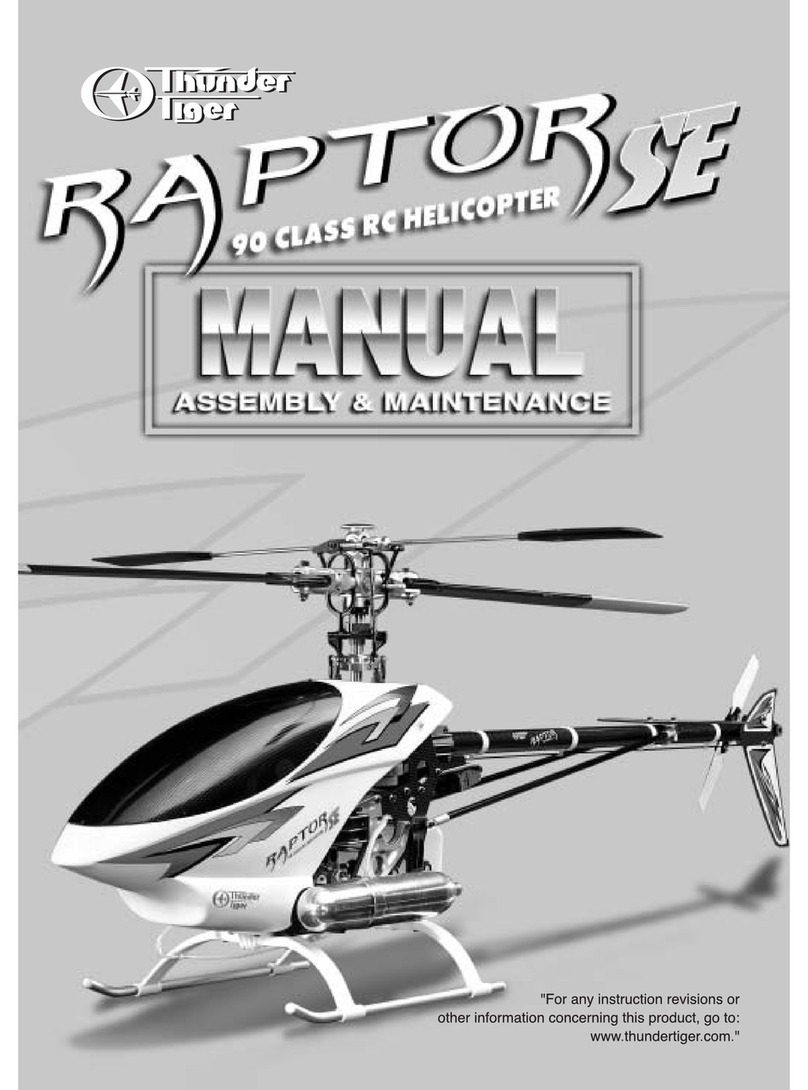

THUNDER TIGER RAPTOR 90 CLASS RC HELI User manual

THUNDER TIGER

THUNDER TIGER tiger trainer 60 MKII User manual

THUNDER TIGER

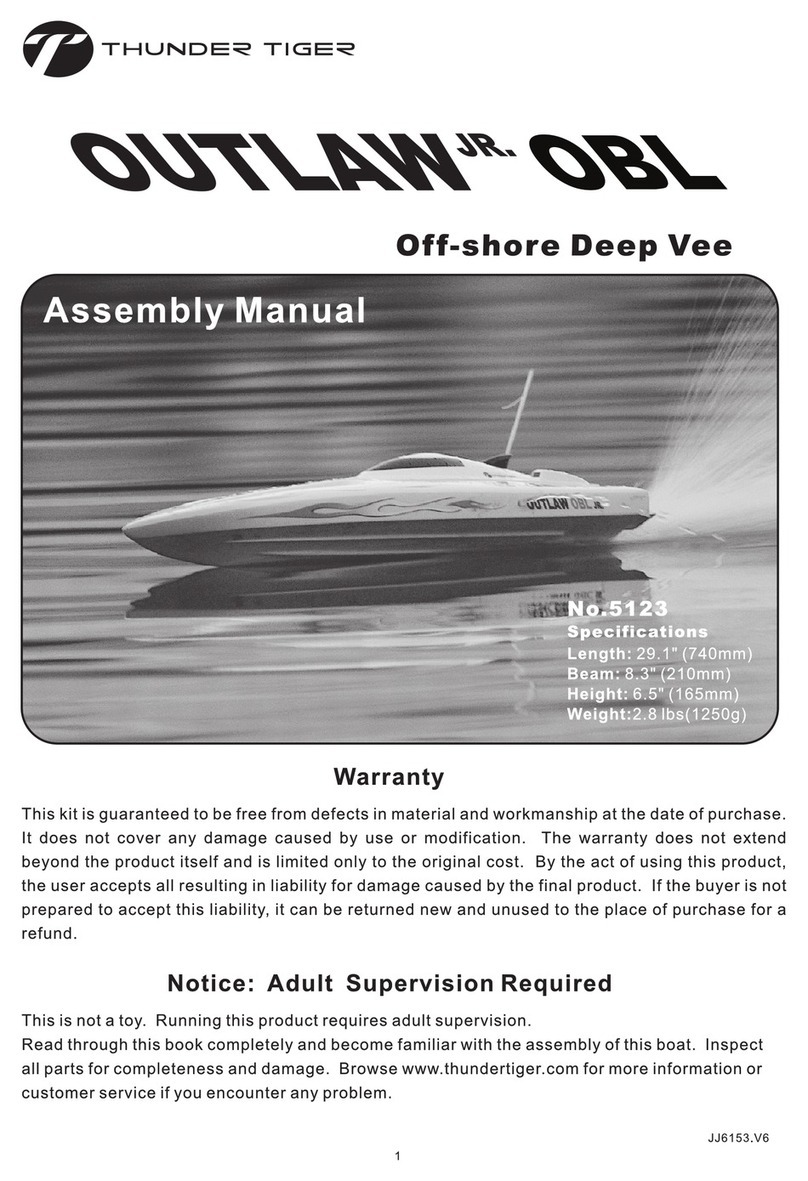

THUNDER TIGER Outlaw JR. OBL 5123 User manual

THUNDER TIGER

THUNDER TIGER RAPTOR SE User manual

THUNDER TIGER

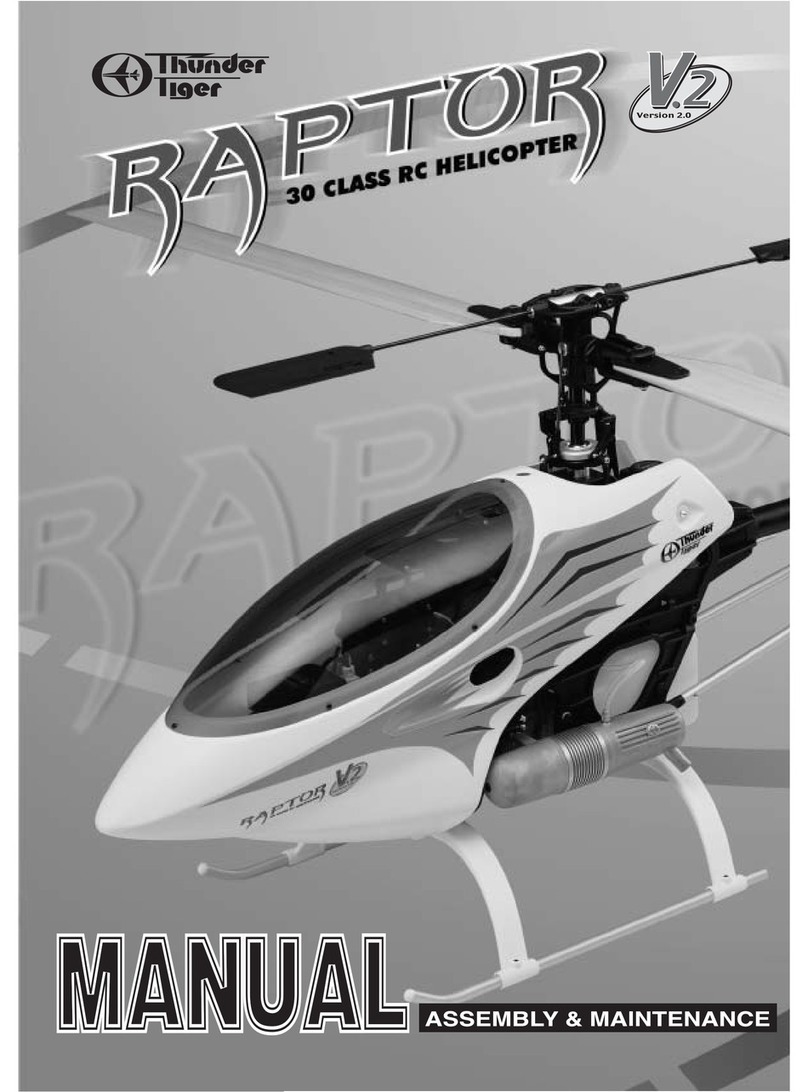

THUNDER TIGER RAPTOR User manual

THUNDER TIGER

THUNDER TIGER Raptor 90 3D Quick guide

THUNDER TIGER

THUNDER TIGER E325 SE mini Titan User manual

THUNDER TIGER

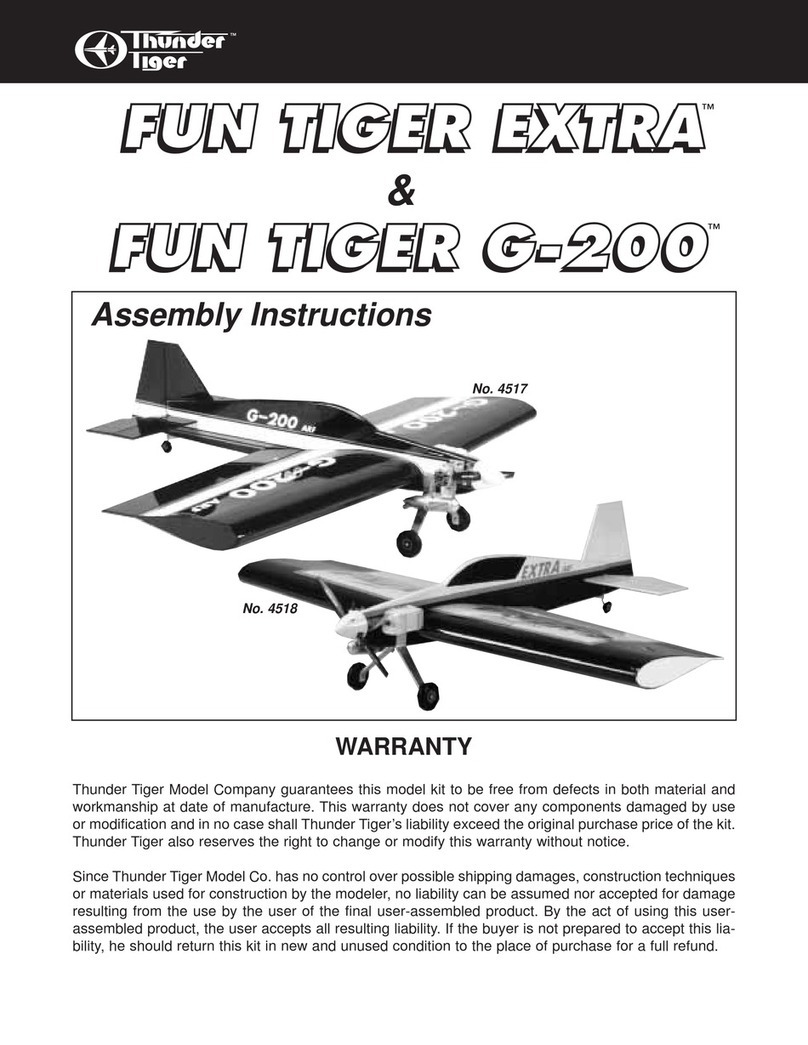

THUNDER TIGER Fun Tiger Extra User manual

THUNDER TIGER

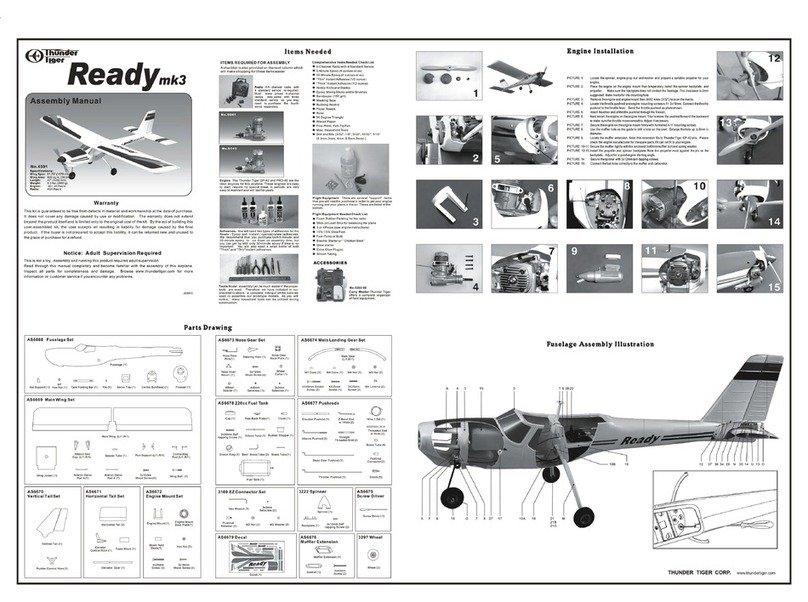

THUNDER TIGER Ready mk3 User manual

THUNDER TIGER

THUNDER TIGER RAPTOR 30 Quick guide

THUNDER TIGER

THUNDER TIGER RAPTOR User manual

THUNDER TIGER

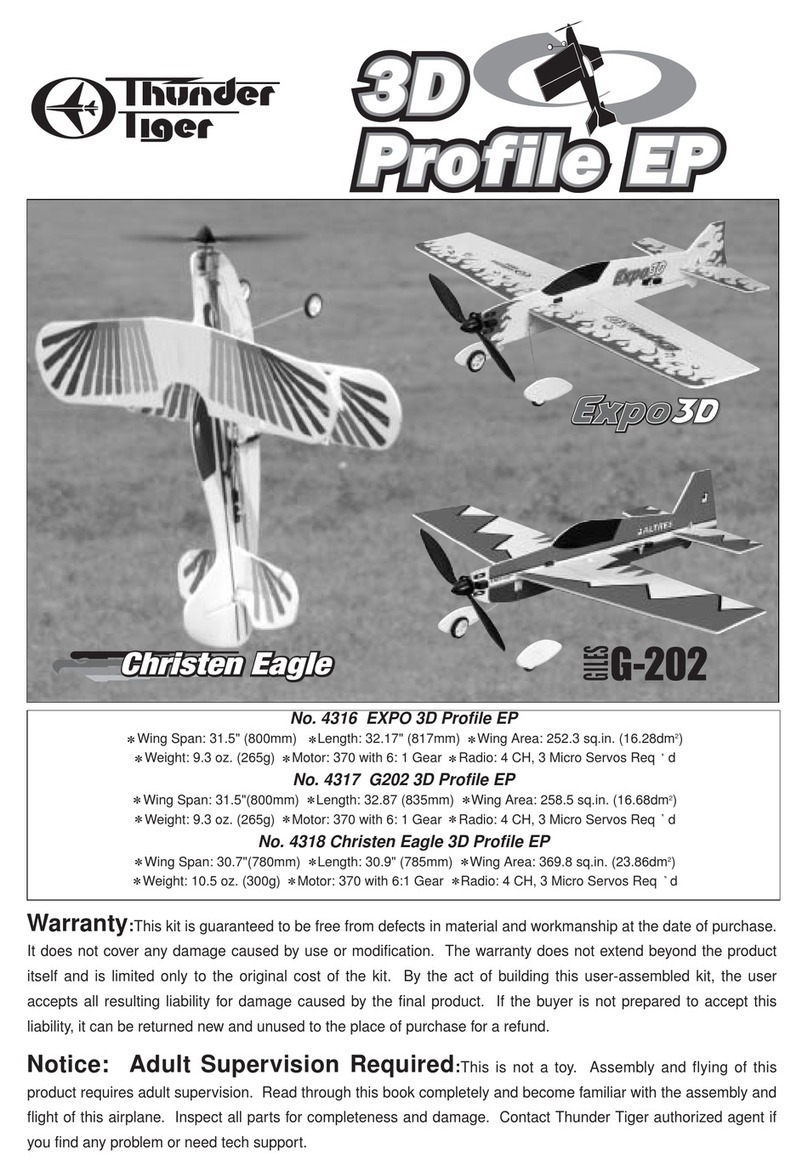

THUNDER TIGER 4318 Christen Eagle 3D Profile EP User manual

THUNDER TIGER

THUNDER TIGER INNOVATOR - Instruction Manual

THUNDER TIGER

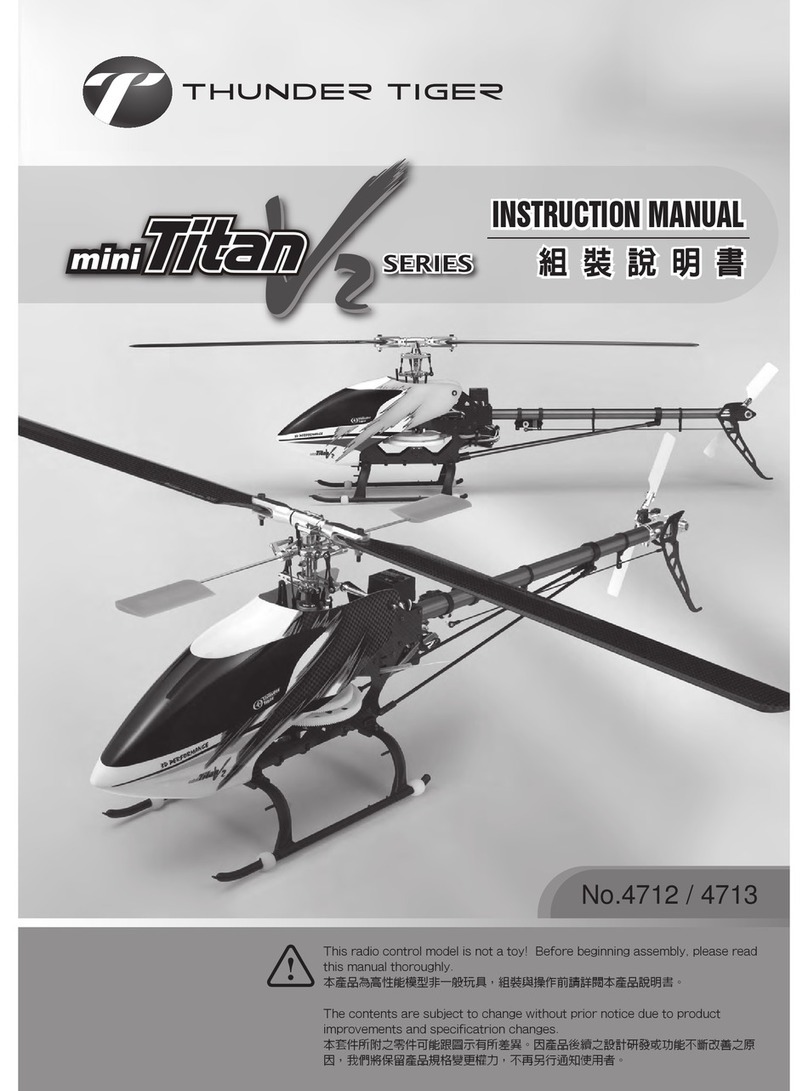

THUNDER TIGER miti titan v2 User manual

THUNDER TIGER

THUNDER TIGER Avanti 5129 User manual

THUNDER TIGER

THUNDER TIGER Raptor E550 Quick guide

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions