2007.03.07Flow2 stairliftTab 04: Install, adjust and release

www.ThyssenKruppAccessibility.nl1

Table of Contents

1 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 At the branch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 At the customer’s home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Preassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

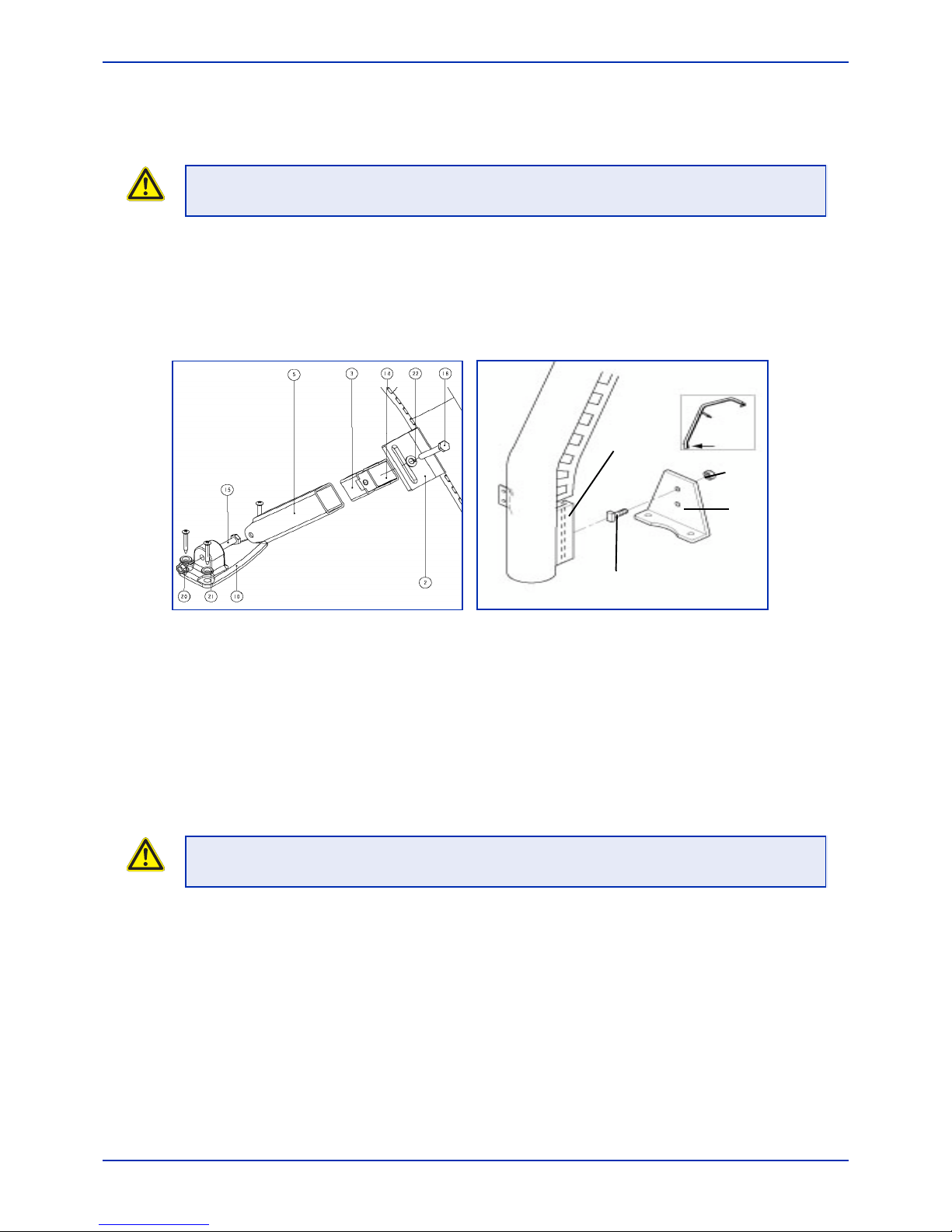

2.1 Fitting the legs and brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Connecting the rail sections with a section bush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Installing the feeder cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Fitting and installing the charging contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5 Connecting and mounting the transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Positioning the rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Greasing the rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Prepare the drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Preparing to drive onto the rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Driving onto the rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Registering the radio frequency equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.1 Registering control boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.2 Re-registering a control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.3 Registering a repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.4 Setting the call and park positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5 Preparing the drive unit for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6 Fit the chair base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6.1 Installing the fixed seat and manual swivel seat . . . . . . . . . . . . . . . . . . . . . . . 20

3.6.2 Chair base height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6.3 Adjusting the length of the safety belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7 Fixing the rail to the stairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Making a test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Fitting the RF equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Call and park unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Releasing the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Completing the CE inspection form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Clearing up the workplace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 Instructing the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4 Inspecting the installation and the safety measures (checklist) . . . . . . . . . . . . . . . . . . 31

7 Installation without Flash card data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1 Rail sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2 Determining the speed profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Determining the seat rotation profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37