Table of contents

1Preparations......................................................................................................................4

1.1 At the branch..............................................................................................................4

1.2 At the customer’s home...............................................................................................4

2Installing the rail.................................................................................................................5

2.1 Fitting the legs and brackets.........................................................................................5

2.2 Connecting the rail sections with a section bush .............................................................7

2.3 Installing the feeder cable ............................................................................................7

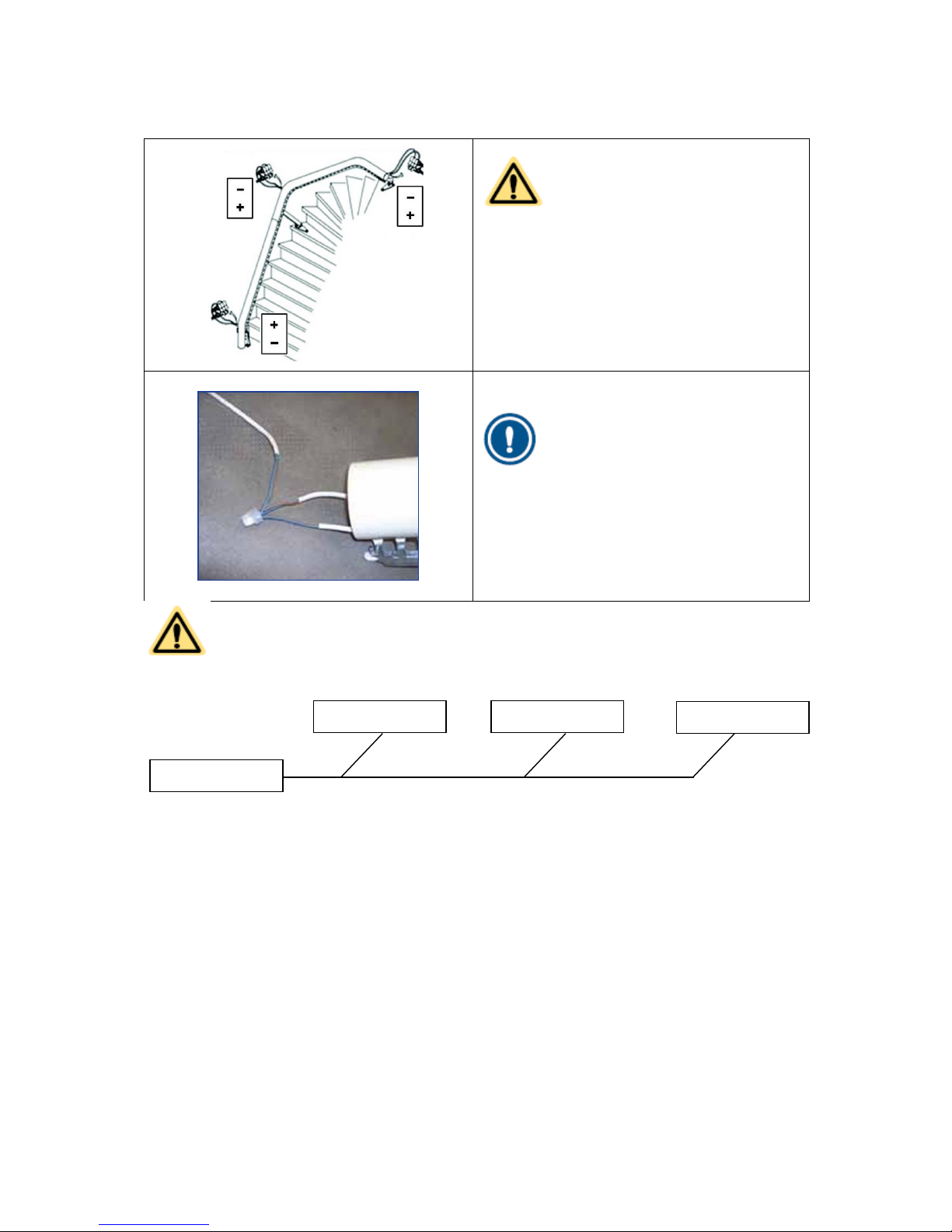

2.4 Fitting and installing the charging contacts.....................................................................8

2.4.1 Fixed charging contacts ........................................................................................8

2.4.2 Movable charging contacts....................................................................................9

2.4.3 Connection of charging contacts..........................................................................10

2.5 Connecting and mounting the transformer ...................................................................11

2.6 Positioning the rail.....................................................................................................11

2.7 Greasing the rail........................................................................................................11

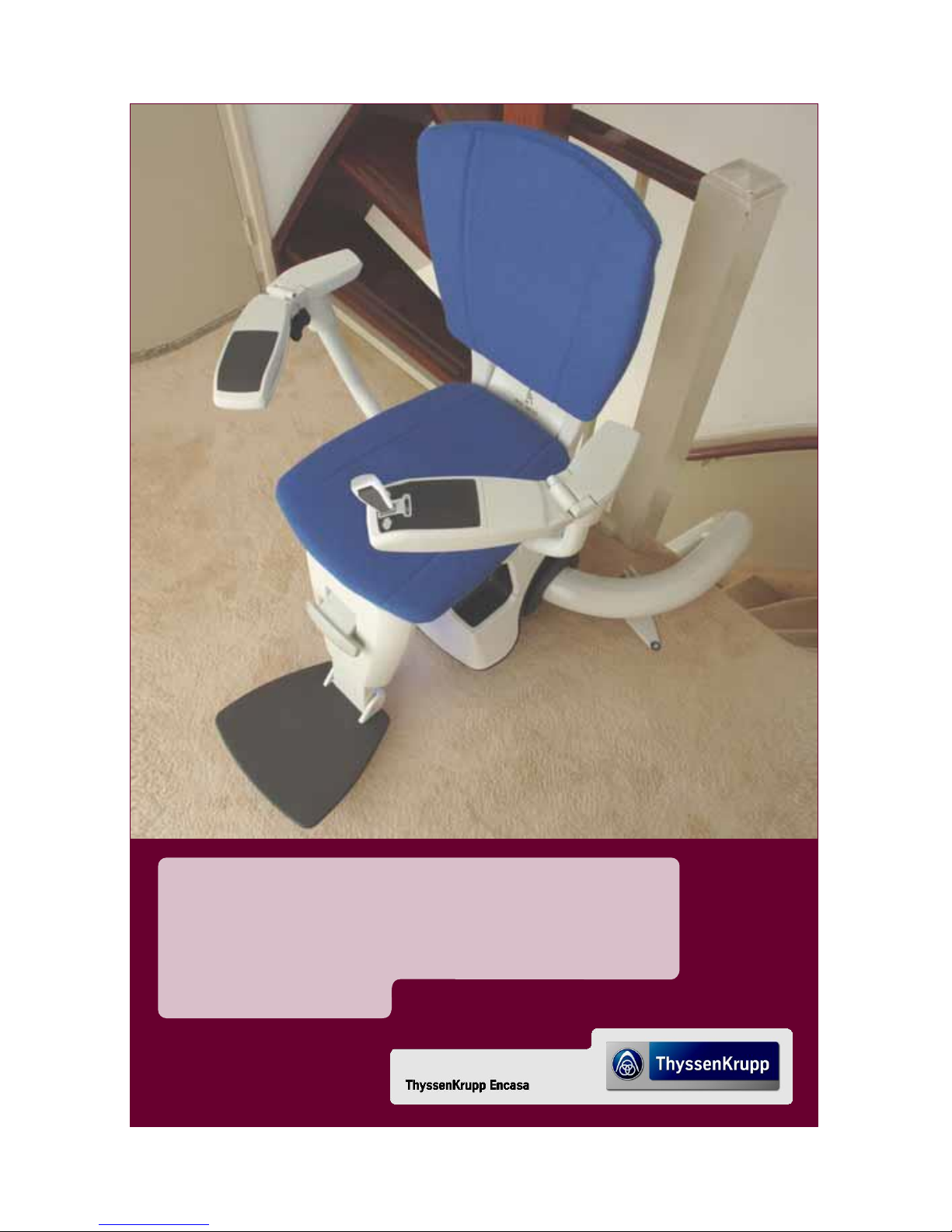

3Assembly ........................................................................................................................12

3.1 Prepare drive unit......................................................................................................12

3.2 Drive onto the rail......................................................................................................14

3.3 Calibration of level sensors.........................................................................................15

3.4 Basic installation with rail data....................................................................................15

3.5 Preparing the drive unit for use...................................................................................16

3.6 Fit the chair base ......................................................................................................16

3.7 Installing the manual swivel seat fitting........................................................................17

3.8 Chair base height adjustment .....................................................................................18

3.9 Height of the footrest.................................................................................................19

3.10 Adjusting the length of the safety belt..........................................................................20

3.11 Fixing the rail to the stairs ..........................................................................................20

3.12 Registering controls...................................................................................................21

3.13 Setting mode -8-, Assign Call/Park..............................................................................22

3.14 Safe point ................................................................................................................23

3.15 Installation without raildata provided ...........................................................................23