TIC TR-220 User manual

TR-220

MULTIFUNCTION TEST SET

Transponder, TCAS, DME, TIS, and ADS-B

Test Set

Operational Manual

Software Revision 3.40 and Later

REVISION

A B C D E F G H J K L M N

P R S T U V W X Y Z

09 May 2007

Tel-Instrument Electronics Corp

728 Garden Street

Carlstadt, NJ 07072

(201) 933-1600

www.telinstrument.com

Leading the AVIONICS TEST industry into the 21st Century!

NOTICE:

The information contained in this manual is subject to change without notice.

Tel-Instrument Electronics Corp. makes no warranty of any kind to this material,

nor shall be liable including but not limited to, errors contained herein or for

incidental or consequential damages in connection with the furnishings,

performance, or use of this material.

Chapter I – Introduction

Chapter II – Preparation for Use and Operation

Chapter III – Theory of Operation

Chapter IV – General Maintenance and Servicing Procedures

Chapter V – Schematics

Chapter VI – Illustrated Parts Catalog

COPYRIGHT NOTICE

© 2007 Tel-Instrument Electronics Corp

Reproduction of this publication or any portion thereof by any means without the

express written permission of Tel-Instrument Electronics Corp. is prohibited. For

further information, contact the Customer Support Manager, 728 Garden Street,

Carlstadt, NJ 07072. (201) 933-1600

PART NUMBER VOLUMES INCLUDED CHAPTERS INCLUDED

90008088-1 VOLUME 1 CHAPTERS I&II

90008088-2 VOLUMES 1&2 CHAPTERS I-VI

Safety Precautions

The following are general safety precautions that are not related to a particular test or procedure.

These are recommended procedures that all personnel must apply during many phases of

operation and maintenance. It is assumed that the operator has general knowledge of electrical

theory and the dangers associated with it.

1. When performing any of the preceding; thoroughly read and understand all

procedures before actually performing them.

2. The various front panel connectors, switches, and controls specified can be

located by referring to Figure 2-1 on page 2-3.

3. Take the time to learn the proper operation and function of the Test Set as

outlined in Chapters 1, 2, and 3. Through knowledge of the Test Set and its

capabilities greatly improves the time it takes to complete the tests.

4. Pay particular attention to NOTES and WARNINGS that may accompany some

test and operational procedures.

NOTE

5. Observe all standard safety procedures when working with live voltages. The

potential for electric shock exists any time the Test Set is removed from its case.

6. DO-NOT service the unit or make adjustments alone. Always be in the presence

of another person when working with live voltages.

7. Thoroughly inspect the equipment and the local area for potential hazards. Loose

clothing and jewelry should be removed anytime the test set is being utilized or

being serviced.

8. Be familiar with general first aid procedures and CPR (Cardiopulmonary

Resuscitation). Contact your local Red Cross for more information.

9. Ensure the test equipment and the tools you utilize are in good operational

condition and not damaged in any way.

10. Use only specified replacement parts as listed in the IPB. Failure to utilize factory

approved parts may cause damage to personnel; the test set’s, and possibly void

the warranty.

WARNINGS

A

lerts the operator to potential dangers associated with a particular test.

Thoroughly understand the warning before proceeding to prevent a

potentially dangerous situation or damage to the Test Set.

NOTES

Provides supplemental information that enhances the procedure or

further explains in detail additional information to ensure understanding or

proper operation.

ESD Safety and Protection

Many parts contained in the Test Set are sensitive to ESD (Electro-Static Discharge) damage.

ESD can damage integrated circuits or semiconductors located within the Test Set. Only qualified

personnel should service the Test Set to prevent damage. The following are guidelines to avoid

ESD damage while still performing tests and or maintenance. These guidelines are meant only as

a reminder, consult local directives and follow standard operating procedures before servicing, or

repairing the Test Set.

•Wear a properly grounded wrist strap and remain in contact with an approved grounding

point.

•Do not touch the connector pins or backplanes of ESD Sensitive circuits or parts.

•Ensure soldering irons are grounded before use.

•Do not remove any components or disconnect any connectors located in the Test Set with

the power “ON”.

•Properly ground all test equipment being utilized. Refer to the test equipment operating

manual for information.

•Place all removed components or parts in or on an approved conductive package.

Most ESD devices or circuits and common points are readily identified utilizing several different

methods. Below are some examples.

CE (IEC) Marking

The Following Symbols may be utilized in different locations throughout the Manual and are also

located on and in the Test Set. Observe these warnings and markings and follow standard

electrical safety anytime you utilize live circuits.

Caution Alternating Current Caution,

risk of

electrical shock

Protective Conductor

Terminal

VOLUME 1

OPERATIONAL PROCEDURES

Rev E TR-220 90 008 088-1

i

TR-220 TABLE OFCHANGES1

Date REV ECO Page Description

Prelim. Initial Release

07 Sep 03 A Initial Release

15 July 04 B Updated procedure explanations

16 Mar 05 C 2-5 & 6, 13, 17,

22, 43-46 Provided Detailed EHS and ADS setup

and display info

01 Jul 05 D Chapter 3-6 Added CHAPTERS 3, 4, 5, &6

9 May 07 E Chapter 1 and 2 Add test capability for measuring reply

delay, jitter, MS P6 pulse amplitude

variation, and MS P5 pulse width

1Changes are also denoted with a solid bar in the Left margin of each affected page.

Rev E TR-220 90 008 088-1

ii

Table of Contents

Chapter Page

Table of Changes……………………………………………………………………. i

List of Illustrations…………………………………………………….……………… vii

List of Tables……………………………………………………….………………… viii

I INTRODUCTION

Section A- General Information

1.1 Scope of Manual…………………………………………………………… 1-1

1.2 Purpose and Function of Equipment…………………………………….. 1-1

1.3 Regulatory Responsibilities…………………………………………......... 1-2

1.4 Warranty…………………………………………………………………….. 1-3

1.4.1 Obtaining Warranty Service………………………………………… 1-3

1.4.1 Shipping and Packing the Test Set………………………………... 1-4

Section B- Equipment Description

1.5 Specifications………………………………………………………………… 1-5

1.6 Abbreviations, Acronyms, and Glossary of Terms…………………....... 1-7

II PREPARATION FOR USE AND OPERATION

Section A- General Information

2.1 General………………………………………………………………........... 2-1

2.2 Unpacking…………………………………………………………………… 2-1

2.3 Installation…………………………………………………………………… 2-1

2.4 Accessories…………………………………………………………………. 2-1

Rev E TR-220 90 008 088-1

iii

Table of Contents (continued)

Chapter Page

Section B- Operating Controls, Indicators, and Connectors

2.5 General………………………………………………………………........... 2-3

2.6 Controls, Indicators, and Connectors……………………………………. 2-3

Section C- Operating Instructions

2.7 General………………………………………………………………........... 2-5

2.8 Battery Operation…………………………………………………………… 2-5

2.8.1 Auto-Shutdown………………………………………………….. 2-6

2.9 TR-220 Supplied Antenna…………………………………………………. 2-6

2.9.1 Directional Antenna…………………………………………….. 2-6

2.9.2 Direct Connect………………………………………………….. 2-9

2.9.3 TAP-200 Antenna Coupler…………………………………….. 2-9

2.10 Initial Startup and Self-Test……………………………………………….. 2-12

2.11 Transponder Test Sequence……………………………………………… 2-13

2.12 Transponder Manual Sequence of Tests………………………………… 2-14

2.12.1 ATCRBS, Mode A/C Manual Testing………………………… 2-14

2.12.2 Mode S Manual Testing……………………………………….. 2-17

2.13 Transponder Automatic Sequence of Tests…………………………….. 2-24

2.13.1 ATCRBS, Mode A/C Automatic Testing……………………… 2-24

2.13.2 Mode S Automatic Testing…………………………………….. 2-26

2.14 Testing a Transponders “IDENT” Function……………………………… 2-28

2.15 TCAS Tests…………………………………………………………........... 2-29

2.15.1 Typical TCAS Concepts……………………………………….. 2-29

2.15.2 TCAS Scenario Selection and Setup …….………………….. 2-29

2.15.3 Erasing the TCAS Scenario Memory………………………… 2-35

2.15.4 Testing a TCAS Equipped Aircraft……………………………. 2-36

2.16 DME Tests………………….……………………………………………….. 2-41

2.16.1 DME Setup…….………………………………………………… 2-41

2.17 Mode S Enhanced Surveillance…………………………………………... 2-43

Rev E TR-220 90 008 088-1

iv

Table of Contents (continued)

Chapter Page

2.18 ADS-B and TIS Testing……………………………………………………. 2-47

2.18.1 ADS-B TX……………………………………………………….. 2-47

2.18.2 ADS-B RX………………………………………………………. 2-50

2.19 RS-232 Download Procedures…………………………………………… 2-52

2.19.1 Setting Up your Computer for RS-232 Download………….. 2-53

2.19.2 Downloading the Data…………………………………………. 2-54

2.19.3 Loading the Data to a Microsoft Excel File………………….. 2-55

List of Illustrations (Figures)

Figure Title Page

1-1 TR-220 Multifunction Test Set…………………………………………………. 1-1

2-1 TR-220 Accessories…………………………………………………………….. 2-2

2-2 Controls, Indicators, and Connector Locations………………………………. 2-3

2-3 Directional Antenna Gain……………………………………………………….. 2-7

2-4 Directional Antenna Setup……………………………………………………… 2-8

2-5 TAP-200………………………………………………………………………….. 2-10

2-6 TAP-200 Placement…………………………………………………………….. 2-11

2-7 TAP-200 Adjustment……………………………………………………………. 2-11

2-8 Sequence of Tests………………………………………………………………. 2-13

2-9 Caution, Warning, and Collision Areas……………………………………….. 2-29

2-10 Typical TCAS I Display…………………………………………………………. 2-30

List of Tables

Table Title Page

2-1 TR-220 Accessories……………………………………………………………. 2-2

2-2 Controls, Indicators, and Connectors………………………………………… 2-4

2-3 Preprogrammed TCAS Scenarios……………………………………………. 2-30

2-4 TCAS Intruder Parameters…………………………………………………….. 2-33

2-5 Additional TCAS Intruder Scenarios…….……………………………………. 2-34

2-6 TIS Intruders…………………………………………………………………….. 2-51

Rev E TR-220 90 008 088-1

1-1

CHAPTER I

INTRODUCTION

SECTION A

1.1 Scope of Manual

This manual is intended to familiarize the operator with the operating and maintenance

procedures necessary to utilize the TR-220 Multifunction Test Set. Here-in after known as the

T/S, Test Set, or TR-220.

Figure 1-1

TR-220 Multifunction Test Set

1.2 Purpose and Function of the Equipment

The TR-220 Test Set tests airborne ATCRBS, MODE A/C, and MODE S transponders, TCAS I/II

systems, DME equipment, and ADS-B and TIS Transponders. It is self-contained and battery

operated that requires no direct hardware connection to the Unit Under Test (UUT).

For transponder testing, the Test Set simulates secondary radar to receive and radiate signals to

the UUT from antennas supplied with the Test Set. For accurate power and frequency

Rev E TR-220 90 008 088-1

1-2

measurements, the Test Set can be directly connected to the UUT without the use of additional

hardware.

For TIS testing, the Test Set transmits simulated Intruder Flight Data, which is then shown on the

TIS display to verify results.

The Test Set will receive and Decode 1090 MHz ADS-B data including squitter type, airborne

position, surface position, aircraft IDENT category, Airborne velocity, Latitude/Longitude,

North/South velocity, and East/West Velocity. The ADS-B TX function allows the operator to

receive, decode, and display ADS-B squitters. The ADS-B RX function permits the operator to

simulate a 1090MHz squitter. The TR-220 can be configured to transmit an airborne or surface

position squitter containing position, altitude, velocity, heading, aircraft category, flight ID, and

Mode S address.

The simulation of an intruder aircraft converging on the Aircraft Under Test (AUT) accomplishes

TCAS testing. The simulated target will be displayed on the TCAS display so the operator can

ensure proper advisories.

DME tests simulate an aircraft at a simulated speed converging to or from a selected distance. By

comparing the Test Set displayed distance to the DME under test display, the operator can

confirm proper DME operation.

1.3 Regulatory Responsibilities

Effective April 6, 1987, The Federal Aviation Administration (FAA) has required certain tests be

performed on transponders, both conventional ATCRBS and MODE S. In preparation for the

installation of new air traffic control radar facilities, the FAA required new measurements to be

performed on existing transponders and instituted required tests for MODE S transponders. FAR

(Federal Aviation Regulation) Part 43, Maintenance, Preventive Maintenance, Rebuilding and

Alteration section has been modified to reflect current technologies and improvements. Tel-

Instruments has met all FAA requirements and recommends that the user of this type of

equipment review the appropriate FAR or contact the manufacturer of their particular model of

transponder to ensure that the current procedures and limitations are being correctly adhered to.

Eurocontrol has also incorporated new regulations for Mode S Elementary and Enhanced

Surveillance. These requirements include Selective Identifiers for high-density traffic areas and

will become mandatory beginning in May of 2003 for Elementary Surveillance and March 2005 for

Enhanced Surveillance. The TR-220 Test Set has the capability to thoroughly test these new

functions to comply with upcoming requirements. If you would like further information regarding

these requirements, visit www.eurocontrol.int/.

Rev E TR-220 90 008 088-1

1-3

1.4 Warranty

The Tel-Instrument Electronics Corporation warrants that each product it manufactures is free

from defective material and workmanship for a period of two (2) years subject to the following

terms and conditions. Tel-Instrument Electronics Corp. will remedy any such warranted defect

subject to the following:

This warranty requires the unit to be delivered by the owner to Tel-Instrument intact for

examination, with all transportation charges prepaid to the factory, within two (2) years from the

date of sale to original purchaser. Tel-Instrument will solely determine when such defect exists.

This warranty does not extend to any of Tel products which have been subject to misuse, neglect,

accident, improper installation, or used in violation of operating instructions. This warranty does

not extend to units which have been repaired, calibrated, or altered in any way by a facility that is

not approved, in writing, by Tel-Instrument Electronics Corp. to perform such work. This warranty

does not apply to any product where the seals or serial number thereof has been removed,

defaced or changed, nor to accessories not of our own manufacture.

Repair parts will be made available for a minimum period of five (5) years after the manufacture

of this equipment has been discontinued.

This warranty is in lieu of all other warranties expressed or implied and all such other warranties

are hereby expressly excluded. No representative or person is authorized to assume for us any

other liability or warranty in connection with the sale of Tel’s products.

This warranty does not cover or include batteries (batteries have a separate 90 day warranty).

Additional information with regard to the applications and maintenance of this equipment will be

available from time to time.

1.4.1 Obtaining Warranty Service

In the event the Test Set may require service or repair that is included under the

warranty provided with the Test Set; the following is necessary to ensure proper

handling:

1. Contact Tel-Instrument Customer Support before shipping any Test Set

back under a warranty condition.

Tel-Instrument Electronics Corp. Customer Support can be reached by

calling:

¾(201) 933-1600 (telephone)

¾(201) 933-7340 (fax)

2. The Customer Support Department will discuss the matter and if validated,

issue an RMA (Return Material Authorization) number and form. Do not

return any product without first receiving this authorization.

3. The Test Set must be returned with the completed RMA form. This will

ensure prompt handling and expedited service.

4. Products must be returned in the Original Shipping Container (see

Paragraph 1.4.1). If the original container is no longer available, please

contact Tel-Instrument for guidance. Include in or on the shipping container

the following information:

Rev E TR-220 90 008 088-1

1-4

•RMA Form on top of the product

•The assigned RMA number written in bold letters on the

outside of the shipping container

•Model, Serial Number, and specific details regarding the

problem

•POC name, return address, telephone number, and

email address

5. Freight Charges to the factory are the responsibility of the owner/operator.

Tel-Instrument will provide return shipping if the problem is determined to be

warranty covered.

1.4.2 Shipping and Packing the Test Set

1. Repackage the Test Set in the Original container utilizing the provided

packing material. Do Not Ship the Test Set with out using a shipping

container, this will prevent damage to the case and or finish during transit.

2. Wrap the Test set within plastic sheeting and firmly seat the Test Set in

the original corner molds. Place all necessary documentation (RMA Form,

POC, etc…), on top of the Test Set.

3. Utilize Package Tape and seal all seams. If the use of an industrial box

stapler is used, be sure that they do not protrude through the box to

prevent injury to personnel handling the package.

4. Firmly affix a shipping label and mail the Test Set to the following:

Tel-Instrument Electronics Corp.

728 Garden Street

Carlstadt, NJ 07072

Attn: Repair Department

Rev E TR-220 90 008 088-1

1-5

SECTION B

EQUIPMENT DESCRIPTION

1.5 Specifications

Transponder Transmitter

Frequency 1030 MHz ± 10 kHz

Output Power > 4dBm

Modes A, C, S, ADS B TX/RX,

and TIS

Transponder Receiver

Frequency Frequency 1086.5 to 1093.5 MHz

Accuracy ± 200 kHz

Power Range 47 to 64 dBm

Accuracy ± 2 dB (direct connect)

± 3 dB (radiated)

Sensitivity Range. -50 to -87 dBm

Accuracy ± 2 dB (direct connect)

± 3 dB (radiated)

Reply Percent Range 0 to 100%

Accuracy ± 1%

DME

DME Receiver

Frequency Frequency Channel Freq +3.5 MHz

Accuracy ± 200 kHz

Sensitivity Range < -35 dB

DME Transmitter

Frequency Frequency 962 to 1213 MHz

Accuracy ± 100 kHz

Power ≥4 dB

TCAS

TCAS Transmitter

Frequency 1090 MHz ± 10 kHz

Output Power > 4dB

Modes C & S

Antenna Beamwidth…. 15° Sum & Diff Ports

30°Sumonly

Rev E TR-220 90 008 088-1

1-6

TCAS Receiver

Frequency 1026.5 to 1033.5 MHz

Power 47 to 64 dBm

Physical Characteristics

Packaging MIL-PRF-28800 Style C

Size 14.5 x 9.4 x 6.5 inches

Weight. 20 pounds

Operating Temperature -28° to +55° C

Battery Operation. 8 hours at a 20%

DutyCycle

AC Operation/Charging 100 – 240 VAC

47 – 440 Hz

Rev E TR-220 90 008 088-1

1-7

1.6 Abbreviations, Acronyms and Glossary of Term1

A/A Air to Air

A/A B Air to Air Beacon

ac or AC Alternating Current

A/D Analog to Digital

ADS-B Automatic Dependent Surveillance - Broadcast

Address The unique code to which a MODE S transponder replies. This is not to

be confused with the 4096 code used for identifying ATCRBS

transponders. The address of a MODE S transponder is not alterable by

the pilot or crew.

Altitude The pressure altitude of the aircraft as transmitted by an ATCRBS or

MODE S transponder. This information is obtained from an external

sensor and transmitted to the transponder.

AM Amplitude Modulation

ATCRBS Air Traffic Control Radar Beacon System

ATCRBS/MODE S All Call Interrogation that causes all ATCRBS/MODE S transponders to reply.

ATC Air Traffic Control

AUT Aircraft Under Test

BIT Built in Test

Comm Refers to the communications and data-link capability of a MODE S

transponder. There are four (4) capabilities: No Comm, Comm A/B,

Comm A/B/C and Comm A/B/C/D. The Comm. capability is displayed

when the transponder is determined to be a MODE S.

CW Continuous Wave

D/A Digital to Analog

DAP Downlinked Aircraft Parameter

dB Decibel

dBm Decibels above 1 milliwatt

dc or DC Direct Current

DME Distance Measuring Equipment

DPSK Differential Phase Shift Keying. The method of modulation used for the

selective MODE S uplink interrogations.

DF Downlink Format. The format included in a MODE S transponder reply to

an interrogation or squitter message that indicates the type of message.

ELM Extended Length Messages

FAA Federal Aviation Administration

FAR Federal Aviation Regulation

FIFO First In First Out

FREQ Frequency

ft. Feet

G/A Ground to Air

Hz Hertz

IF Intermediate Frequency

IFF Identify Friend or Foe

KHz Kilohertz

kts. Knots

LCD Liquid Crystal Display

LED Light Emitting Diode

1Further definitions may be found in the following reference books and documents: Helfrick, A.D. Principles of Avionics.

Leesburg: Quality Books, 2000. RTCA/DO-181B. Minimum Operational Performance Standards for Air Traffic Control

RADAR Beacon System/Mode Select (ATCRBS/Mode S) Airborne Equipment. Washington D.C.: 1999. United States.

Federal Aviation Administration. Federal Register Fed 3, 1987 FAA rules Part 91.

Rev E TR-220 90 008 088-1

1-8

MODE S A secondary radar system where transponders can be individually

interrogated or selected (the “S” in MODE S) so that in a crowded air

traffic area, the amount of interference or garble can be reduced to a

minimum.

MHz Megahertz

nmi. Nautical mile

ns Nanosecond

PAM Pulse Amplitude Modulation

PDME Precision Distance Measuring Equipment

PMCS Preventative Maintenance Checks and Services

PPM Pulses per Minute

PRF Pulse Repetition Frequency

PW Pulse Width

PWR Power

RA Resolution Advisories

Receiver Efficiency The Test Set’s Measurement of valid replies received. Displayed as a

Percentage.

Reply Codes A transmitted response, from the airborne transponder, to an

interrogation. Commercial transponders responses are designated as

either ATCRBS/A where the reply includes the pilot selected 4096 ID

code, or ATCRBS/C, where the reply includes the aircraft pressure

altitude. These same responses for military transponders are designated

as MODE 3A and MODE 3C. See Mode S for further information.

RF Radio Frequency

RMS Root Mean Square

R/T Receiver Transmitter

SIF Selective Identification Feature

SLS Side Lobe Suppression. A pulse transmitted from an omni-directional

antenna used as a reference level to prevent replies to interrogations

received from the secondary radar antenna side lobes.

Squitter The self-generated transmissions made by a MODE S transponder, not in

reply to an interrogation, for the use of the collision avoidance system.

And ADS-B Receivers and Transmitters.

SSR Secondary Surveillance Radar

Surveillance Altitude An interrogation that causes only the addressed MODE S transponder to

reply.

Surveillance ID An interrogation that causes only the addressed MODE S transponder to

reply to its “4096” code.

TA Traffic Advisories

TACAN Tactical Air Navigation

TCAS Traffic Alert and Collision Avoidance System

TIS Traffic Information System

TX Transmitter

UF Uplink Format. The format in a MODE S interrogation that indicates the

type of reply expected.

VORTAC VOR and TACAN (co-located)

VOR VHF Omni-Directional Range

VSWR Voltage Standing Wave Ratio

WOW Weight On Wheels

UUT Unit Under Test

XPDR Transponder

XPDR UT Transponder Under Test

4096 Code This refers to the octal number dialed into either an ATCRBS MODE A or

MODE S transponder by the pilot. This is to be distinguished from the

address of the MODE S transponder, which cannot be changed.

Rev E TR-220 90 008 088-1

2-1

CHAPTER II

PREPARATION FOR USE AND OPERATION

SECTION A

GENERAL INFORMATION

2.1 General

This Chapter contains all necessary information on the initial unpacking, inspection, and set-up of

the TR-220 Multifunction Test Set (Hereinafter called the TR-220, Test Set, or T/S).

2.2 Unpacking

When receiving the TR-220 for the first time, ensure that there is no damage to the shipping

container. Carefully unpack the unit and save the shipping container in a safe location for

shipping or extended storage.

Examine the unit for obvious signs of damage. Check all displays, switches, and connectors

before utilizing the Test Set.

If any damage is found, DO NOT use the Test Set until a determination of the Test Sets functions

can be assessed. Contact Tel-Instrument as soon as possible for further instructions.

The TR-220 Test Set batteries were installed and fully charged when shipped from the factory.

2.3 Installation

The Test Set is fully functional and ready to use from the factory. There are no installation

procedures applicable.

2.4 Accessories

Once opening the Test Set Cover, ensure all the accessories that were purchased with the Test

Set are accounted for. The TR-220 comes standard with the following (See next page):

Rev E TR-220 90 008 088-1

2-2

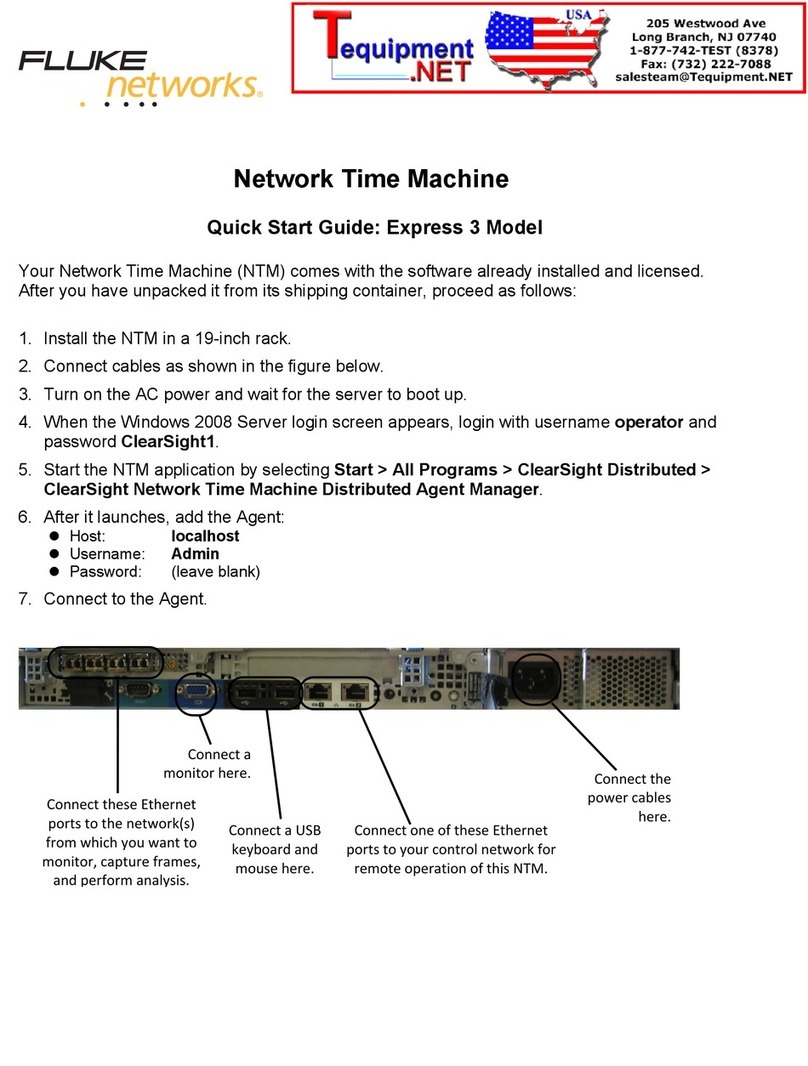

# NOMENCLATURE P/N QTY

1 Test Set 90000088 1

2 Cable Assembly, AC Power Cord 75010025 1

3 Cable Assembly, Direct Connect 75010186 1

4 Extender Cable Assembly, Directional

Antenna 75010078 1

5 Directional Antenna Cable Assembly 75010208-02 1

6 Directional Antenna Assembly 89001158-07 1

7 Directional Antenna Handle Assembly 88001002 1

X TAP-200 Antenna Coupler Optional

XX TR-220 Manual (Not Shown) 90008088-1 1

TR-220 Accessories

Table 2-1

TR-220 Accessories

Figure 2-1

1

2

3

4

7

65

Rev E TR-220 90 008 088-1

2-3

SECTION B

OPERATING CONTROLS, INDICATORS, AND CONNECTORS

2.5 General

This section covers location and function of the operating controls, indicators, and connectors. All

controls, indicators, and connectors are located on the front panel of the Test Set.

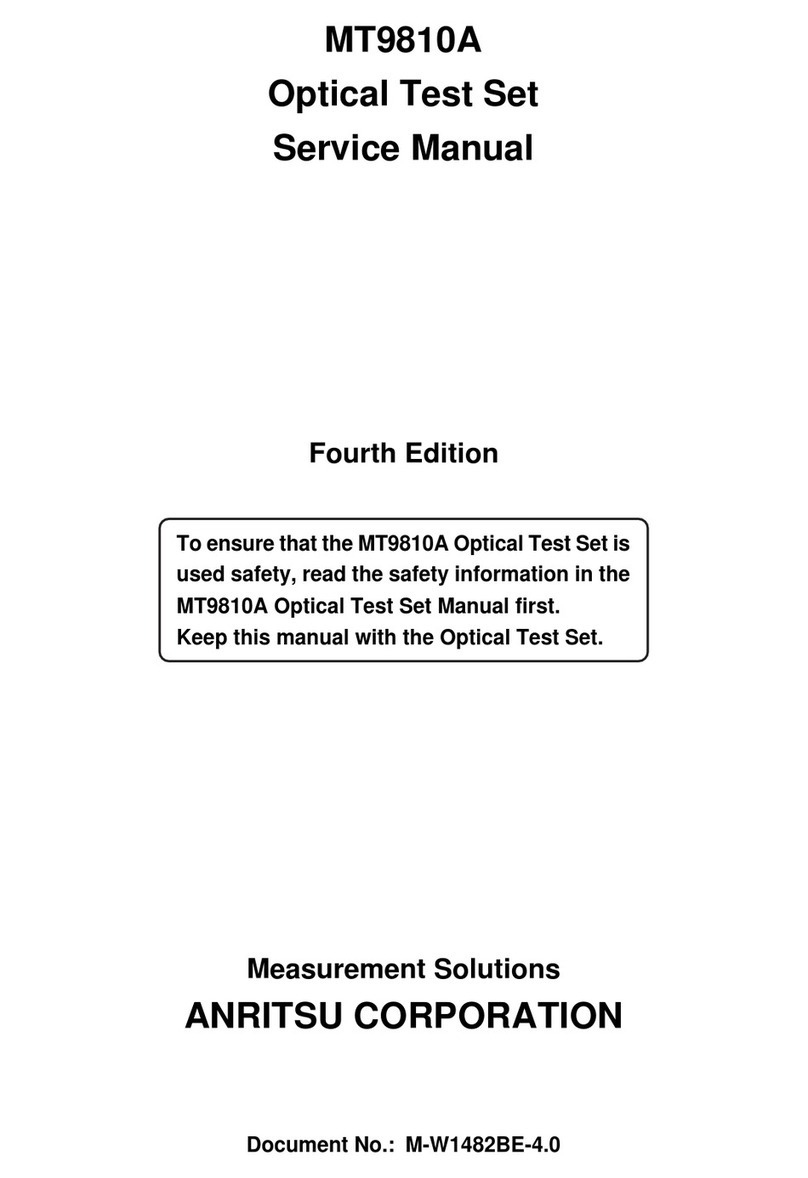

2.6 Controls, Indicators, and Connectors

Figure 2-2 and Table 2-2 indicates the location and the function of each item on the front panel of

the Test Set.

Controls, Indicators, and Connectors

Figure 2-2

1 2 3 4 5 6 7 8 9 10 11 12

1314151618 17

Table of contents

Other TIC Test Equipment manuals