Rev 5.2/9-19 1 MRTALP4-DC3: 35058

TABLE OF CONTENTS

SPECIFICATIONS............................................................................................................ 3

SAFETY............................................................................................................................ 4

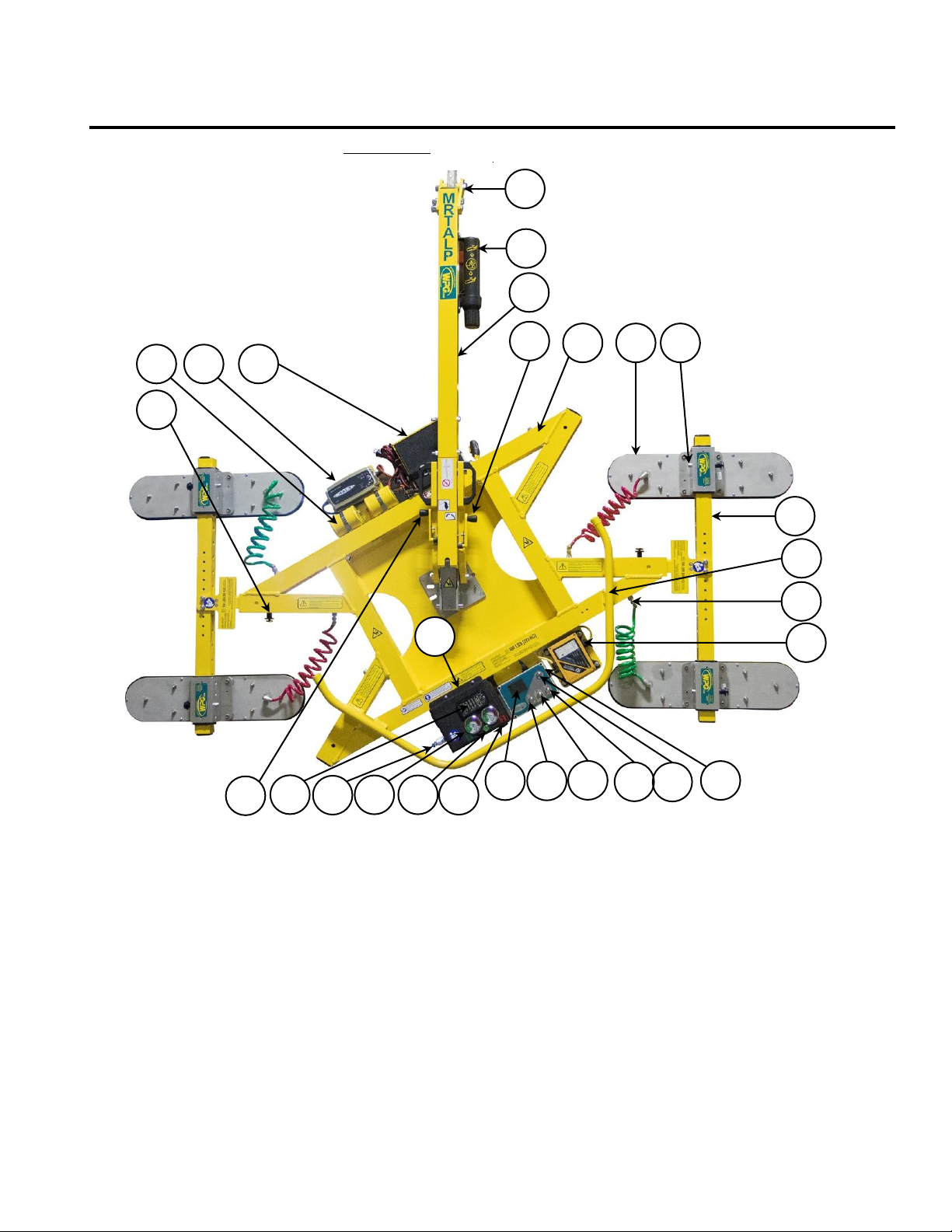

OPERATING FEATURES................................................................................................... 5

ASSEMBLY....................................................................................................................... 6

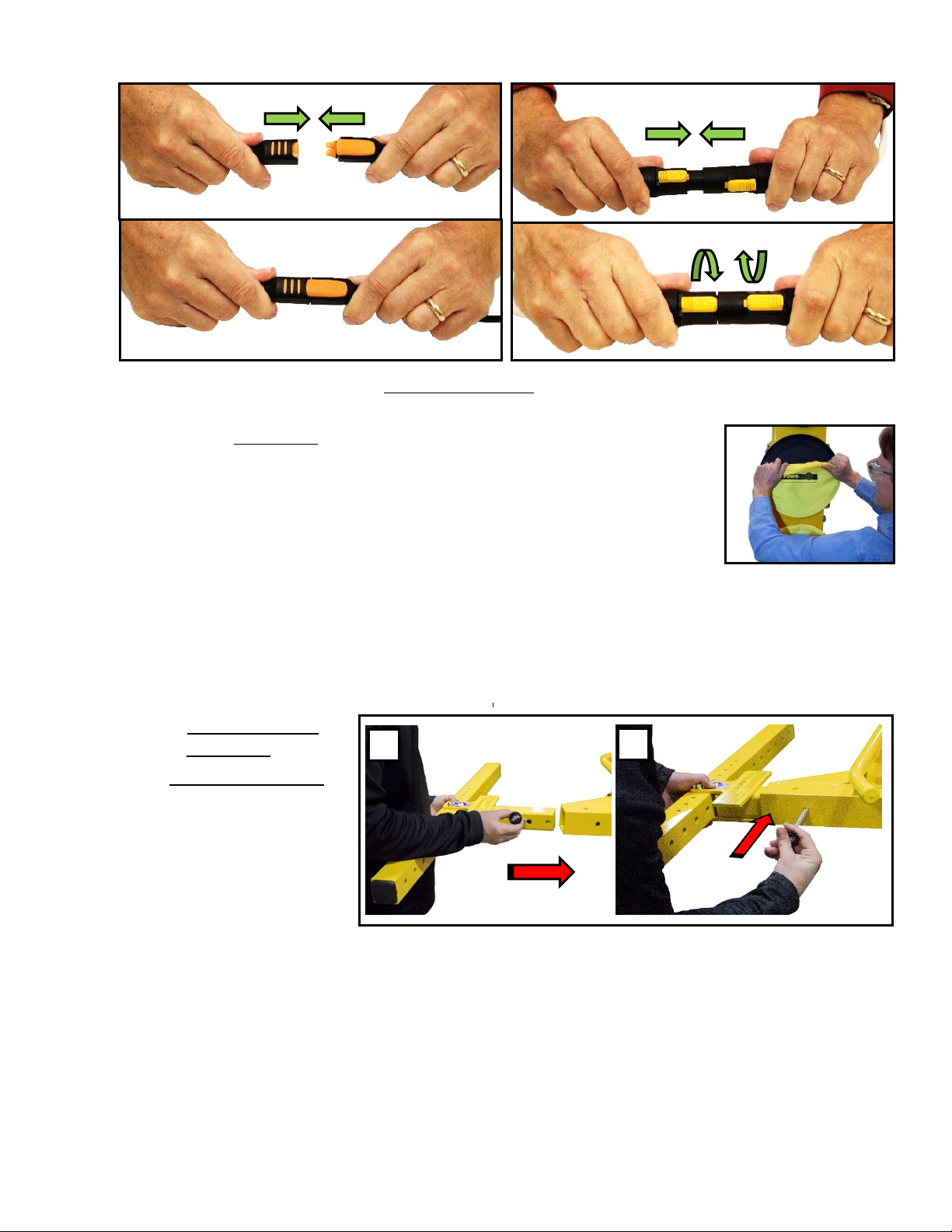

TO INSTALL/REMOVE T-ARM ASSEMBLIES ....................................................................................7

TO INSTALL/REMOVE VACUUM PADS ............................................................................................ 8

TO POSITION VACUUM PADS ....................................................................................................... 8

TO REPOSITION THE T-ARM CROSS MEMBERS ...............................................................................8

Connecting/Disconnecting Vacuum Hoses...............................................................................................................................9

INTENDED USE ............................................................................................................. 10

LOAD CHARACTERISTICS .......................................................................................................... 10

OPERATING ENVIRONMENT .......................................................................................................10

DISPOSAL OF THE LIFTER..........................................................................................................11

OPERATION .................................................................................................................. 12

BEFORE USING THE LIFTER .......................................................................................................12

Taking Safety Precautions ..................................................................................................................................................... 12

Selecting a Screen Language ..................................................................................................................................................12

Performing Inspections and Tests ..........................................................................................................................................13

Preparing to Use the Remote Control System ...................................................................................................................... 13

TO ATTACH THE PADS TO A LOAD ...............................................................................................14

Positioning the Lifter on the Load ..........................................................................................................................................14

Powering up the Lifter............................................................................................................................................................15

Sealing the Pads on the Load .................................................................................................................................................16

Reading the Vacuum Gauges..................................................................................................................................................16

Vacuum Level on Optimal Surfaces ........................................................................................................................................17

Vacuum Level on Other Surfaces ...........................................................................................................................................17

TO LIFT AND MOVE THE LOAD.................................................................................................... 18

About the Tilt Linkage ............................................................................................................................................................18

Interpreting the Lift Light .......................................................................................................................................................18

Watching Vacuum Indicators ................................................................................................................................................. 18

Controlling the Lifter and Load...............................................................................................................................................19

In Case of Power Failure.........................................................................................................................................................19

TO ROTATE THE LOAD ..............................................................................................................20

TO TILT THE LOAD ...................................................................................................................21

TO RELEASE THE PADS FROM THE LOAD....................................................................................... 22

AFTER USING THE LIFTER ......................................................................................................... 23

Storing the Lifter.....................................................................................................................................................................23