TiEmme MB250 User manual

Pag. 1 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Date: 09/11/2018

TECHNICAL MANUAL

MB250 HYDRO

WOOD-PELLET STD11

Pag. 2 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Revision Date

Description

09/11/2018

Condition to enter Modulation and Standby in hydraulic plant 11 have been modified

Cleaning Engine and Cleaning Engine 2 in Check up have been added

Night Modality has been added

Parameter A25 has been added

14/09/2018

Added Service, Cleaning, Working Hours, Ignition entries in Monitor Menu

24/07/2018

Introduction of V14 parameter

12/07/2018

Introduction of the Brazier Cleaning Engine in Check Up (P51 parameter)

Introduction of T25 timer. During this time exhaust fan2 works at power VS14 after

transition from Pellet to Wood in Combi 2 modality

Introduction of A49 parameter in order to remove Buffer Thermostat management

in Wood modality

Introduction of A51 enabling parameter for the management of Er02 error during

Wood modality

The management of Thermostat L01 validation while decreasing has been modified

during the Stabilization phase

Introduction of the Cleaning On message during periodic cleaning phase

Configuration 11 has been added

20/04/2018

Boiler probe thermostat maximum range increased, NTC 231K probe added

Automatic Extinguishing function modified

Door management modified

Pag. 3 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

1INTRODUCTION ...................................................................................................................... 5

2LANGUAGE PACKAGES............................................................................................................. 5

3INSTALLATION ........................................................................................................................ 6

CONNECTIONS ............................................................................................................................. 6

FIRST CONFIGURATION .................................................................................................................. 9

DIGITAL INPUTS......................................................................................................................... 13

High Voltage1 (Safety Thermostat) .................................................................................... 13

High Voltage 2 (Pressure Switch) ....................................................................................... 13

Encoder Auger .................................................................................................................. 13

Encoder Combustion Fan ................................................................................................... 13

Grid Sensor....................................................................................................................... 13

Door Sensor...................................................................................................................... 13

Pellet Thermostat.............................................................................................................. 13

Flow Switch ...................................................................................................................... 14

Room Thermostat ............................................................................................................. 14

Pellet Level ....................................................................................................................... 14

Limit Switch Cleaning Engine ............................................................................................. 15

Limit Switch Cleaning Engine 2 .......................................................................................... 15

Limit Switch Brazier Cleaning Engine .................................................................................. 15

External Chrono ................................................................................................................ 15

ANALOG INPUTS ......................................................................................................................... 15

Exhaust Probe (Thermocouple) .......................................................................................... 15

Boiler Probe ...................................................................................................................... 15

Buffer Probe / Top Buffer Probe......................................................................................... 15

Bottom Buffer Probe.......................................................................................................... 15

Boiler Return Probe / Flow................................................................................................. 15

DHW Probe....................................................................................................................... 16

External Probe .................................................................................................................. 16

Water Pressure Sensor ...................................................................................................... 16

Photo Resistance............................................................................................................... 16

Primary Air Flow or Vacuum Sensor.................................................................................... 16

Room Probe...................................................................................................................... 17

4KEYBOARDS........................................................................................................................... 18

LCD100 .................................................................................................................................. 18

DISPLAY K100........................................................................................................................... 18

DISPLAY K400........................................................................................................................... 19

Home Page 1 .................................................................................................................... 19

Home Page 2 .................................................................................................................... 20

ERROR MESSAGES AND VIEWS ........................................................................................................ 20

5USER MENU ........................................................................................................................... 22

USER MENU 1............................................................................................................................ 22

USER MENU 2............................................................................................................................ 26

6FUNCTIONING STATES..........................................................................................................27

PELLET MODALITY ...................................................................................................................... 28

Off ................................................................................................................................... 28

Check Up.......................................................................................................................... 28

Ignition ............................................................................................................................ 28

Stabilization ...................................................................................................................... 30

Ignition Recovery.............................................................................................................. 30

Run Mode......................................................................................................................... 31

Modulation........................................................................................................................ 32

Standby............................................................................................................................ 33

Safety .............................................................................................................................. 35

Extinguishing .................................................................................................................... 35

Block................................................................................................................................ 36

WOOD MODALITY ....................................................................................................................... 36

Block and Off Wood .......................................................................................................... 36

Pag. 4 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Wood Run Mode ............................................................................................................... 36

Wood Modulation .............................................................................................................. 37

Wood Standby .................................................................................................................. 38

Wood Safety ..................................................................................................................... 38

Wood Extinguishing........................................................................................................... 38

COMBI MODALITY....................................................................................................................... 40

7OTHER FUNCTIONS ............................................................................................................... 42

INTERNAL CHRONO MANAGEMENT................................................................................................... 42

COMBUSTION STANDBY ................................................................................................................ 42

AUTOMATIC COMBUSTION POWER................................................................................................... 42

CHANGE POWER DELAY................................................................................................................ 42

SYSTEM MAINTENANCE 1FUNCTION................................................................................................ 42

SYSTEM MAINTENANCE 2FUNCTION................................................................................................ 43

FAST EXTINGUISHING .................................................................................................................. 43

EXTINGUISHING IN IGNITION PHASE................................................................................................ 43

AUTOMATIC SWITCH OFF FUNCTION................................................................................................ 43

SUPPLY VOLTAGE LACK MANAGEMENT.............................................................................................. 43

AUGER FEEDING IN WOOD MODALITY.............................................................................................. 43

PERIODICAL CLEANING OF BRAZIER................................................................................................. 44

CONFIGURABLE OUTPUTS MANAGEMENT ........................................................................................... 44

Safety Valve ..................................................................................................................... 44

Load Pellet Engine............................................................................................................. 44

Output under Thermostat .................................................................................................. 44

Cleaning Engine ................................................................................................................ 44

Combustion Fan 2 ............................................................................................................. 45

Heating Fan ...................................................................................................................... 45

Air Valve........................................................................................................................... 45

Error Signalling ................................................................................................................. 45

Cleaning Engine 2 ............................................................................................................. 45

Auger 2 in On-Off mode................................................................................................. 46

Auger 2 Always On ........................................................................................................ 46

Air Valve 3..................................................................................................................... 46

Air Valve 2..................................................................................................................... 46

Mixer Valve ................................................................................................................... 47

Pump P3 ....................................................................................................................... 48

Brazier Cleaning Engine.................................................................................................. 48

Auger block ................................................................................................................... 50

CLIMATIC FUNCTION ................................................................................................................... 50

PRIMARY AIR FLOW SENSOR ......................................................................................................... 50

HYDRO -AIR MODALITY............................................................................................................... 52

Air Exchanger Fan Management......................................................................................... 52

Plumbing Plant Management.............................................................................................. 52

Pump and Valve Anti-Lock Function............................................................................. 60

Sanitary Function ....................................................................................................... 60

Pressure Sensor Selection ........................................................................................... 60

8SYSTEM MENU PARAMETERS ................................................................................................ 61

AUGER MENU ............................................................................................................................ 61

COMBUSTION FAN MENU .............................................................................................................. 61

COMBUSTION FAN 2MENU ........................................................................................................... 62

HEATING FAN MENU.................................................................................................................... 62

THERMOSTATS MENU .................................................................................................................. 63

TIMERS MENU ........................................................................................................................... 64

ENABLE MENU ........................................................................................................................... 66

PRIMARY AIR FLOW SENSOR MENU ................................................................................................. 68

WATER PRESSURE SENSOR THRESHOLD MENU ................................................................................... 69

COUNTERS MENU ....................................................................................................................... 69

OUTPUT’S TEST MENU ................................................................................................................. 69

RESTORE PARAMETER’S FACTORY VALUE MENU .................................................................................. 70

Pag. 5 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

1Introduction

The MB250 Controller is a device to manage stoves and boilers with automatic ignition and pellet loading.

The operation of the heating system is determined by reading the exhaust temperature, water temperature,

and through the acquisition of the parameters setup by the user. The parameters of the controller are fully

configurable inside the menu. By setting the parameters it is possible to:

modify the operation of the heating system according to the user’s specific requirements

modify the operation of the controller to a suit any stove or boiler

This manual illustrates in detail the controller installation steps, the configuration, the functioning and the

technical characteristics.

2Language Packages

Languages

K100, K400 and K700 have the following languages available:

Italian

Polish

Dutch

Latvian

Portuguese

Serbian

Danish

Estonian

German

Romanian

Swedish

Hungarian

French

Czech

Turkish

Lithuanian

Spanish

Russian

Greek

Slovak

English

Bulgarian

Croatian

Slovenian

LCD100 and LCD100 touch keyboards have the following languages available:

Set 1

Set 2

Set 3

English

English

English

Italian

Slovenian

Turkish

French

Serbian

Czech

German

Romanian

Polish

Spanish

Greek

Russian

Portuguese

Hungarian

Bulgarian

Firmware Codes

Control Board

MB250

FSYSD01000174

K Series Keyboard

K100

FSYSF04000027

K400

FSYSF13000005

K700

FSYSF18000005

LCD Series Keyboard

Set 1

Set 2

Set 3

LCD100

FSYSF01000292

FSYSF01000293

FSYSF01000294

LCD100 Touch

FSYSF03000084

FSYSF03000085

FSYSF03000086

Pag. 6 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

3Installation

Connections

In the below picture is showed the connections of the main board and its outputs and inputs.

Follow the indications of the connection modalities for a correct installation.

For a correct and secure functioning connect always ground connection

For a correct operation follow carefully the modalities of connection indicated to

avoid damage to electronics

Make connection in a tidy way; keep separated cables of low voltage (probes,

contacts, control panel flat) and cables of high voltage (power source, loads) to

reduce interference problems

Pag. 7 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Pag. 8 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Pin

Function

Technical Specifications

1-2

Line

Version 230Vac 10% 50/60 Hz

Version 110Vac 10% 50/60 Hz

Fuse T 6,3 A

3-4

Combustion Fan

Triac, feeding output (Max 0.8 A)

5-6

Output V2 configurable

Configuration parameter: P44

Triac, feeding output (Max 0.8 A)

7-8

Pump

Relay, feeding output (Max 3 A)

9-10

Ignition Resistance

Relay, feeding output (Max 3 A)

11-12

High Voltage 1 Input

Short-circuit if not used

High voltage input, contact open/closed

13-14

High Voltage 2 Input

Short-circuit if not used

High voltage input, contact open/closed

15-16

Auger Motor

Triac, feeding output (Max 0.5 CV)

17

-

Neutral

18

-

Phase

19-20-21

Output Aux2 configurable

Configuration parameter: P48

Relay, free contact output (Max 3 A)

19: COM

20: N.C.

21: N.O.

22-23-24

Electrovalve

Relay, feeding output (Max 3 A)

22: N

23: FOFF

24: FON

25-26

Exhaust Probe

Thermocouple K

25: Red (+)

26: Green (-)

27-28

Input IN2 configurable

Configuration parameter: P74

Analog Input (NTC 10K probe)/Digital Input

29-30

Input IN3 configurable

Configuration parameter: P75

Analog Input (NTC 10K probe)/Digital Input

31-32

Boiler Probe

Analog Input NTC 10K if PA44=0

Analog Input NTC 231K if PA44=1

33-34-35

Input IN5 configurable

Configuration parameter: P76

Analog Input (NTC 10K probe)/Digital Input

36

Not used

-

37-38-39

Water Pressure Sensor

Analog Input

40-41-42

Encoder Sensor (see parameter A57)

40: +5V

41: GND

42: signal

43-44-45

Input IN8 configurable

Configuration parameter: P71

43: +12V

44: signal

45: GND

46-47

Output Aux3 configurable

Configuration parameter: P36

Relay, free contact output (Max 3 A)

47: N.O.

48: COM

48-49-53

Input IN9 configurable

Configuration parameter: P70

48: signal

49: GND

53: +12V

50-51-53

Input IN10 configurable

Configuration parameter: P73

50: signal

51: GND

53: +12V

51-52-54

Encoder Sensor (see parameter A57)

51: GND

52: signal

54: +5V

CN1

Local Keyboard Connection

-

RS232

Serial Port Connection

Serial Port RS232

RS485

Serial Port Connection

Serial Port RS485

Connect to the Earth

CONNECT ALWAYS

-

Pag. 9 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

First Configuration

First of all, set parameter P42 to choose the Hydro or Air modality (see par. 7.15). If the Hydro modality is

set, select the plumbing plant (parameter P26 in the Default Settings Menu of the Technical Menu). Then

set the configurable outputs via parameters of the Default Settings Menu P44, P48and P36, then set the

parameters P70, P71,P73, P74, P75 and P76. Finally set the parameters P25 to choose the Combustion

Fan type (with or without encoder) and P81 to choose the Auger type (with or without encoder).

Set also the parameter PA44 to define the NTC probe to connect to input IN4.

Plumbing Plants (for more details see section 7.16.2):

Configuration 0 (P26=0)

FL P1 P2

S1

FL

P1 P2

S1

Configuration 1 (P26=1)

S1FL P1

P2

FL

P1

P2

S1

Configuration 2 (P26=2)

Configuration 3 (P26=3)

Configuration 4 (P26=4)

S2

P1 P2

S1

Configuration 5 (P26=5)

Configuration 6 (P26=6)

Configuration 7 (P26=7)

Configuration 8 (P26=8)

P1 P2-3

mix

S1

S3

A

B

C

S2

Configuration 9 (P26=9)

Configuration 10 (P26=10)

S3

S2

P1 P3

S1 P2

Configurazione 11 (P26=11)

Pag. 10 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Whenever you select plant 10, properly shorting Puffer Probe Inputs (Probe S2) and ACS Probe (Probe S3),

it is possible to select one of the following plant automatically:

Probe

Condition

Setted Plant

Probe

Condition

Setted Plant

Puffer

Short circuit

Plant 5

Puffer

Short circuit

Plant 2

DHW

Short circuit

DHW

Probe

P1

S1

P1 Pump: pins 7-8

To more details see the par. 7.16.27.16.2 -

Plumbing Plant Management, Configuration 5.

S3

P1

S1 P2

P1 Pump: pins 7-8, P2 Valve: Pins 22-24

To more details see the par. 7.16.2 - Plumbing Plant

Management, Configuration 2.

Probe

Condition

Setted Plant

Probe

Condition

Setted Plant

Puffer

Probe

Plant 4

Puffer

Probe

Plant 10

DHW

Short circuit

DHW

Probe

S2

P1 P3

S1

P1 Pump: pins 7-8, System Pump P3

To more details see the par. 7.16.2 - Plumbing Plant

Management, Configuration 4.

N.B. In paragraph 7.17 P3 Pump is identified as P2

Pump.

S3

S2

P1 P3

S1 P2

Recirculation Pump P1: pins 7-8, P2 Valve: pins 22-

24, System Pump P3

To more details see the par. 7.16.2 - Plumbing Plant

Management, Configuration 10.

When the system detects a different input configuration error message Er56. For the actual setting of the

system, if plant 10 is selected or the existing probes configuration is modified, follow this steps:

1. set the parameters: P26=10

P74 or P75 or P76=8

P74 or P75 or P76=9

P36 or P44 or P48=14

2. put the system in Off state

3. cut off the power

4. make the appropriate changes to the inputs Buffer probe and DHW probe

5. restore power

6. control in Views menu if the temperature detected by the present probes coincides with the setting

made

7. repeat all operation from step one if necessary

Configurable Output (for more details see section 7.13):

Connected Devices

Parameter

Value

Output

V2

(

P44

)

Aux2

(

P48

)

Aux3

(

P36

)

Output not used

0

√

√

√

Safety Valve (see 7.13.1)

1

√

√

√

Loading Engine (see 7.13.2)

2

√

√

√

Output under thermostat (see 7.13.3)

3

√

√

√

Cleaning Engine (see 7.13.4)

4

√

√

√

Combustion Fan 2 (see 7.13.5)

5

√

–

–

Heating Fan (see 7.13.6)

6

√

–

–

Air Valve (see 7.13.7)

7

√

√

√

Error Signalling (see 7.13.8)

11

√

√

√

Cleaning Engine 2 (see 7.13.9)

13

√

√

√

Pump P3

14

√

√

√

Auger 2 Pause-Work (see 7.13.10)

16

√

–

–

Auger 2 always On (see 7.13.11)

17

√

√

√

Pag. 11 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Air Valve 3 (see 7.13.12)

20

√

√

√

Air Valve 2 (see 7.13.14)

22

√

√

√

Mixer Valve (see 7.13.15)

23

–

–

√

Brazier Cleaning Engine (see7.13.16)

25

√

√

√

Auger Block (see 7.13.17)

26

–

√

√

Brazier Cleaning Engine (direction) (see 7.13.16)

33

–

√

–

The Aux2 output is a free contact output; in case it is necessary to use it to control a supplied load 230 Vac,

follow the diagram below. If the output is activated, there is 230 Vac between the connectors 19-21.

If the output is deactivated, there is 230 Vac between the connectors 19-20.

Even the Aux3 output is a free contact output; in case it is necessary to use it to control a supplied load 230

Vac, follow the diagram below.

IN8 Configurable Input (for more details see sections 3.3 and 3.4):

Connected Devices

Parameter Value

Input

IN8 (

P71

)

Input not used

0

√

Primary Air Flow Sensor

1

√

Pellet Level Sensor

2

√

Photo resistance

3

√

IN2, IN3, IN5, IN9 and IN10 Configurable Inputs (for more details see sections 3.3 and 3.4):

Connected Devices

Parameter

Value

Input

IN2

(

P74

)

IN3

(

P75

)

IN5

(

P76

)

IN9

(

P70

)

IN10

(

P73

)

Input not used

0

√

√

√

√

√

Grid Sensor

1

√

√

√

√

√

Door Sensor

2

√

√

√

√

√

Pellet Thermostat

3

√

√

√

√

√

Room Thermostat

4

√

√

√

√

√

Flowswitch

5

√

√

√

√

√

Pellet Level Sensor

6

√

√

√

√

√

External probe

7

√

–

–

–

–

Return Boiler/Flow/DHW probe

8

–

√

–

–

–

Buffer probe /High Buffer Probe

9

–

–

√

–

–

Limit Switch Cleaning Engine

10

√

√

√

√

√

Limit Switch Cleaning Engine 2

11

√

√

√

√

√

Limit Switch Brazier Cleaning Engine

12

√

√

√

√

√

Room Probe

15

√

√

√

–

–

External Chrono

17

√

√

√

√

√

Photo resistance

18

√

√

√

–

–

Bottom Buffer probe

23

√

√

√

–

–

NOTE

If a contact is connected on input IN10, it has to be connect to pins 50 and 53.

F

17

N

19

20

21

22

23

24

AUX 1

FOFF

AUX 2

COM

N.C.

N.O.

18

FON

N

46

47

AUX3

48

49

50

51

IN 9

IN 10-11

S10

GND

S9

54

53

52

COM

N.O.

GND

S11

+V

+CV

Uscita Aux3

Output Aux 2

Output Aux3

Pag. 12 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Keyboards links

The keyboards use the RS485 protocol for connection to the control board. This standard allows connections

to long distances, with high noise immunity, provided that they comply with the directives of the protocol.

It is therefore recommended to use shielded twisted pair wires for connection.

Remote Keyboard

The Remote Keyboard allows remote control of the system. It’s functionality is similar to the Local Keyboard;

on board is inserted a sensor for detecting the ambient temperature and the displayed temperature is

sensed by said sensor.

Links

Below is shown how connect the Remote Keyboard to the SYPlug02 board that leads out of the stove or

boiler the control board’s RS232 and RS485 connectors.

Pag. 13 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Digital Inputs

High Voltage1 (Safety Thermostat)

When the contact is opened in every functioning state, after a delay equal to timer T09, the system goes in

Extinguishing and then in Block; the display visualises error High Voltage 1 Safety (Er01).

This input is suitable to connect a Manually Rearmed Thermostat; if the system does not use this input

short-circuit Pins 11-12 of the connector.

High Voltage 2 (Pressure Switch)

When the contact is opened, after a delay equal to timer T10, the system goes in Extinguishing and then in

Block; the display visualises error High Voltage 2 Safety (Er02). This management can be disabled during

Wood Modality by setting A51=0.

The state of this input is not detected if the Combustion Fan is off.

This input is suitable to connect a Pressure Switch; if the system does not use this input short-circuit Pins

13-14 of the connector.

Encoder Auger

To the connections 40-41-42 you can connect an input to read the encoder signal in order to adjust rounds

number of auger. Connect as showed in the table.

Encoder Combustion Fan

To the connections 40-41-42 or 51-52-54 you can connect an input to read the encoder signal in order to

adjust rounds number of combustion fan. Connect as showed in the table.

Grid Sensor

If the contact is closed and the system is in Pellet modality, the display shows the message Er20; if the

system is in Off state, it isn’t possible the ignition until the contact is opened. If the system is in Combo

modality, at the time of switching to Pellet modality, if the contact is closed, the system goes in Off state

and Pellet modality. In Wood modality the sensor status doesn’t influence the system behavior.

If the input is set but not used, leave the pins unconnected.

Door Sensor

In case of opening the door, on the panel appears the message 'Port', the Augers turn off and the

functioning of the Combustion Fans depends from the parameter P96 value.

P96=0: both Fans are blocked if the exhaust temperature is higher than the thermostat Th01 in

Pellet modality or Th13 in Wood modality, in Block State or, if in a different state, independently

from Th01/Th13.

P96=1: Combustion Fan 1 goes to maximum speed and Combustion Fan 2 is blocked if the exhaust

temperature is higher than the thermostat Th01 in Pellet modality or Th13 in Wood modality, in

Block state or, if in a different State, independently from Th01/Th13.

P96=2: Combustion Fan 1 is blocked and Combustion Fan 2 goes to maximum speed if the exhaust

temperature is higher than the thermostat Th01 in Pellet modality or Th13 in Wood modality, in

Block state or, if in a different State, independently from Th01/Th13.

P96=3: both fans go to maximum speed if the exhaust temperature is higher than the thermostat

Th01 in Pellet modality or Th13 in Wood modality, in Block state or, if in a different State,

independently from Th01/Th13.

P96=4:both fans go to a speed set by parameters PA46 and PA47 if the exhaust temperature is

higher than the thermostat Th01 in Pellet modality or Th13 in Wood modality, in Block state or, if

in a different State, independently from Th01/Th13.

In case of use of the Photoresistance and while the system is in OFF, while the door is open the reading of

the light will be ignored.

If the door is open, the Timer T21 resets.

In case in which the sensor is selected but not used, short circuit the corresponding pins of the board.

Pellet Thermostat

Pag. 14 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

When the contact switches on there is return of flame and until the contact is open, the display shows Er06

and:

if P44, P36 or P48 are equal to sixteen or seventeen (product with two Auger), the Auger is Off,

the Auger 2 and fan combustion are always On.

if P44, P36 and P48 are equal to one (product with Auger and Safety Valve), the Auger is Off, the

combustion fan is off and the Safety Valve closes.

if P44, P36 and P48 are different from one, sixteen and seventeen (product with one Auger), the

Combustion Fan is always On, the Auger is On if A44=0, is Off if A44=1.

If the contact is opened in Ignition, the output heating resistance is turned off.

If the input is set but not used short circuit the relative pins.

Flow Switch

To use a Flow Switch input set the parameter (P26=0, 1, 5, 6). Leave unconnected the pins if it is set but

not used.

Room Thermostat

Setting the parameter Enables A01 it is possible to:

if A01 = 0

contact closed

: the system goes in Ignition

contact open

: the system goes in Extinguishing

This functioning is available only in Pellet or Combo modality, and P11 = 4 (Combi 2)

if A01 = 1

contact closed

: the system goes in Run Mode

contact open

: the system goes in Modulation

if A01 = 2

contact closed

: the system goes in Run Mode

contact open

: the system goes in Standby

if A01= 3

contact closed

: the system reactivates the Pump

contact open

: if the temperature of the water exceeds the value of the Thermostat for the

Activation of the System Pump (Th19 or Th59), the system blocks the Pump until the

temperature reaches the Th21 or Th78 Thermostat

if A01= 4

contact closed

: the system reactivates the Pump and goes in Run Mode

contact open

: the system goes in Standby and blocks the Pump as in case 2 and 3

if A01= 5

contact closed

: the system goes in Run Mode

contact open

: the system goes in Standby with Pellet, and in Modulation with Wood.

if A01= 6

contact closed

: the system reactivates the Pump

contact open

: the system with Wood passes to Modulation, with Pellet if the temperature of the

water exceeds the value of the Thermostat for the Activation of the System Pump (Th19 or

Th59), the system blocks the Pump until the temperature reaches the Th21 or Th78

Thermostat

if A01= 7

contact closed

: the system reactivates the Pump and goes in Run Mode

contact open

: the system goes in Standby and blocks the Pump as in case 2 and 3 with Pellets,

goes to Modulation with Wood.

NOTE:

If there is a sanitary water demand in Wood Mode, the Room Thermostat does not block the Pump and, if it

was previously blocked by the Thermostat, it is reactivated. In plants 4 and 10 the Pump is blocked in Wood

mode too.

If A13=2, on Summer all operations of Room Thermostat are disabled except for A01=0.

If A01=1,2, 3, 4, 5, 6, 7 and the input is not used short circuit the relative pins.

Pellet Level

Setting the parameters P36, P44 and P48 in the Technical Menu it is possible to:

P44, P48 and P36 different from 2

Pag. 15 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

If the level falls below the threshold, the system signals the lack of fuel for a time equal to the

T24, then it goes in Extinguishing with error (Er18). If the tank is filled the system stops every

signalling and it is possible to restart it.

This control is done only in Pellet modality.

P44=2 or P48=2 or P36=2

If the level falls below the predetermined threshold, the output that controls the Load Pellet

Connection:

Level

Pellet

Sensor

+Vc

Sx

GND

+V

-GND

Out

+V of sensor to the pin 43 or 53

-GND of sensor to the relative GND pin of the

input set as Pellet Level

Out of sensor to the relative pin Sx of the

input set as Pellet Level

If a Pellet Level Sensor is connected with output in DC and the voltage is greater than 5v, connect it to the

IN8 or IN9 input. These inputs can support voltage until 12V. Sensors with maximum output 5V, can be

connected to every input. The temperature controller can support only Pellet Level sensors PNP type.

Limit Switch Cleaning Engine

Use the contact only if an output is set as Cleaning Engine.

Limit Switch Cleaning Engine 2

Use the contact only if an output is set as Cleaning Engine 2.

Limit Switch Brazier Cleaning Engine

Use the contact only if an output is set as Brazier Cleaning Engine.

External Chrono

At the closure of contact, the system goes in Ignition, at the opening it goes in Extinguishing.

Analog Inputs

Exhaust Probe (Thermocouple)

To the connections 25-26 is available the Exhaust Probe. With this probe, it is possible to read the exhaust

temperature.

This probe is a Thermocouple K sensor. The sensor can read from 0 to 500°C with a precision of 1 °C. If you

don’t connect the probe to the system you’ll read 900 °C.

NOTE: even if the sensor can read temperatures in the range 0 ÷ 500 °C the entire sensor wiring can work

only in the range 0 ÷ 500 °C.

TiEmme elettronica is not responsible of any damage or bad functioning of the probe due to a wrong use of

it (i.e. thermic and mechanical stresses to the probe).

Boiler Probe

To the connections 31-32 is available the Boiler Probe. With this probe, it is possible to read the water

temperature of the boiler. If you don’t connect the probe to the system you’ll read -50 °C, in case of short-

circuit you’ll read the maximum value.

Buffer Probe / Top Buffer Probe

To use this input as a Probe set the parameter P26=4, 8, 10, 11 and P74, P75 or P76=9.

This probe is a NTC 10K sensor; it can read from -50 to 110°C with a precision of 1 °C. If you don’t connect

the probe to the system you’ll read -50 °C. In case of short-circuit you’ll read 110 °C.

Bottom Buffer Probe

To use this input as a Probe set the parameter P26=4, 8, 10, 11 and P74, P75 or P76=23.

If you don’t connect the probe to the system you’ll read -50 °C. In case of short-circuit you’ll read 110 °C.

Boiler Return Probe / Flow

To use this input as a Probe set the parameter P26=7, 8, 9 and P74, P75 or P76=8.

This probe is an NTC 10K sensor and its range is -50÷110 °C with a precision of 1 °C. If you don’t connect

the probe to the system you’ll read -50 °C, in case of short-circuit you’ll read 110°C.

Pag. 16 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

DHW Probe

To use this input as a Probe set the parameter P74, P75 or P76=8 and P26=2, 3, 10, 11.

This probe is an NTC 10K sensor and its range is 0 ÷ 110° C with a precision of 1 °C.

If you don’t connect the probe to the system you’ll read -50 °C, in case of short-circuit you’ll read 110°C.

External Probe

To use this input as a Probe set the parameter P74, P75 or P76=7.

This probe is an NTC 10K sensor and its range is -50÷110 °C with a precision of 1 °C. If you don’t connect

the probe to the system you’ll read -50 °C, in case of short-circuit you’ll read 110°C.

Water Pressure Sensor

To the connections 37-38-39 is available the Pressure Sensor to read the boiler’s pressure. It can read from

0 to 3000 mbar. To activate the alarms due over/under pressure of the boiler, set the parameter A14=1. In

this case, set the minimum and maximum pressure levels (SP01 and SP08 parameters).

Photo Resistance

The probe detects the flame brightness of the brazier. The brightness range goes from 0 to 100. If not

connected the read value is 0. In case of use on input IN8 connect it to pin 44 (signal) and 33 (+5V).

The photo resistance is enabled only in Pellets modality. If the system provides a Wood

modality it is necessary to use also the thermocouple.

Primary Air Flow or Vacuum Sensor

Setting the parameter P71 it is possible to choice the sensor to connect to the Input IN8.

If P71=1 it is possible to connect an Air Primary sensor or a Vacuum sensor; the sensor works on the

combustion parameters (Auger and Combustion Fan). The range is 0÷2000.

In the case of disconnected probe the system will read a speed value of 0. In case of failure adjustment it

shows the message Er17, in case of broken sensor or not connected properly, will appear the message

Er39.

If an Air Primary sensor is used:

Connections:

43=+12V (red wire)

44=SEG (brown wire)

45=GND (black wire)

If a Vacuum sensor is used:

has to be placed horizontally through the bracket supplied

the connections for the pressure reading (see Figure 1 and 2) should be directed downward.

Connections:

43=+12V (red wire)

44=SEG (yellow wire)

45=GND (black wire)

Caption:

1 Connection pressure P1 (high pressure)

2 Connection pressure P2 (low pressure)

3. Electrical connections

Pag. 17 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Room Probe

To use this input as a Probe set the parameter P74, P75 or P76=15.

This probe is an NTC 10K sensor and its range is -50÷110 °C with a precision of 1 °C. If you don’t connect

the probe to the system you’ll read -50 °C, in case of short-circuit you’ll read 110°C.

Setting the parameter A01 it is possible to:

thermostat not reached

: the system goes in Ignition

thermostat reached

: the system goes in Extinguishing

This functioning is available only in Pellet or Combo modality, and P11 = 4 (Combi 2)

if A01 = 1

thermostat not reached

: the system goes in Run Mode

thermostat reached

: the system goes in Modulation

if A01 = 2

thermostat not reached

: the system goes in Run Mode

thermostat reached

: the system goes in Standby

if A01= 3

thermostat not reached

: the system reactivates the Pump

thermostat reached

: if the temperature of the water exceeds the value of the Thermostat for the

Activation of the System Pump (Th19 or Th59), the system blocks the Pump until the

temperature reaches the Th21 or Th78 Thermostat

if A01= 4

thermostat not reached

: the system reactivates the Pump and goes in Run Mode

thermostat reached

: the system goes in Standby and blocks the Pump as in case 2 and 3

if A01= 5

thermostat not reached

: the system goes in Run Mode

thermostat reached

: the system goes in Standby with Pellet, and in Modulation with Wood.

if A01= 6

thermostat not reached

: the system reactivates the Pump

thermostat reached

: the system in Wood modality passes to Modulation, in Pellet modality, if

the temperature of the water exceeds the value of the thermostat for the activation of the

System Pump (Th19 or Th59), the system blocks the Pump until the temperature reaches the

Th21 or Th78 Thermostat

if A01= 7

thermostat not reached

: the system reactivates the Pump and goes in Run Mode

thermostat reached

: the system goes in Standby and blocks the Pump as in case 2 and 3 with

Pellets, goes to Modulation with Wood.

NOTE:

If there is a sanitary water demand in Wood Mode, the Room Thermostat does not block the Pump and, if it

was previously blocked by the Thermostat, it is reactivated. In plants 4 and 10 the Pump is blocked in Wood

mode too.

If A13=2, on Summer all operations of Room Thermostat are disabled except for A01=0.

If A01=1,2, 3, 4, 5, 6, 7 and the input is not used short circuit the relative pins.

Pag. 18 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

4Keyboards

The keyboards of the system can be local (mounted on the machine) or remote (mounted outside of the

machine), type of touch screen or LCD. The recognition by the baseboard of a keyboard, is via the

communication address of the same keyboard. Program: address 16 for local key, address 17 for remote key

LCD100

The main frame shows:

time and date, chrono activation,

combustion power, combustion recipe,

system operating state, error code, main

temperature, main thermostat,

summer/winter modality, combi

functioning

Button

Function

P1

Exit menu and submenu

P2

Ignition and extinguishing (push for 3 seconds), Reset errors (push for 3 seconds), Enable/disable

chrono

P3

Enter in User Menu 1/submenu, Enter in User Menu 2 (push for 3 seconds), Save data

P4

Enter in Visualizations Menu, Increase

P5

Enable chrono program, Change the operation mode of the system if P11=2, 3, 4 (only in Off

state)

P6

Enter in Visualizations Menu, Decrease

Led

Function

Led

Function

D1

Heating Resistance On

D7

Output Aux3 On

D2

Auger On

D8

-

D3

Pump On

D9

External Chrono reached

D4

Valve On

D10

Pellet Sensor signaling lack of material

D5

Output V2 On

D11

Room Thermostat reached

D6

Output Aux2 On

D12

DHW demand

Display K100

The main frame shows:

time and date, chrono

activation, combustion power,

heating power, system operating

state, error code, main

temperature, main thermostat

Button

Function

K1

Exit Menu/Submenu

K2

Ignition and extinguishing (push for 3 seconds), Reset errors (push for 3 seconds), Enable/disable

chrono

K3

Enter in User Menu 1/submenu, Enter in User Menu 2 (push for 3 seconds), Save data

K4

Enter in Visualizations Menu, Increase

K5

Enter in Visualizations Menu, Decrease

Led

Function

Led

Function

Room Thermostat reached

External Chrono reached

Winter

Summer

Pellet Modality/Wood Modality

Combi Modality On

Pag. 19 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Display K400

The K400 control panel allows to move between screens with the horizontal or vertical swipe. The symbols

near the following pictures point out the possibility to move with the swipe in that screen.

Home Page 1

The home page is

composed of two pages:

Date and time, main

temperature, main

thermostat, warning alarms

tool

Home page buttons

System ignition and unblock

Access to Visualizations menu

Access to User menu 1

Access to chrono function

Access to User menu 2

Access to the error list (64 errors recorded)

Main Led

The arrow in the main screen allows to access the toolbar where the system special led are located. The

followings are available:

combustion power set

Chrono state

Winter

Summer

Wood

Pellet

System functioning

Climatic function

Pag. 20 / 70 DMAN802000093-Manual MB250 Hydro Wood-Pellet STD11

Home Page 2

System functioning

Led

System functioning Led

Auger On

Igniter On

Pump On

Valve ON

Output V2 ON

Aux2 output On

Aux3 output On

External Chrono reached

Lack of material

Room thermostat

reached

DHW request

Error messages and views

Both the keyboard touch screen and LCD you can view the messages on the main screen such as error

messages.

-Errors:

All errors make the security system block except errors Er04 and Er05 to wood.

Er01

Security Error High Voltage 1. It may also intervene with the system off.

Er02

Security Error High Voltage 2. It can only intervene if the fan Combustive is active.

Er03

Extinguishing for low exhaust temperature or missing light in the brazier

Er04

Shutdown over temperature water

Er05

Extinguishing due to high exhaust temperature

Er07

Encoder Error. The error may occur due to lack signal Encoder

Er08

Encoder Error. The error can occur due to problems of adjustment of the number of

revolutions

Er09

Water pressure low

Er10

Water pressure high

Er11

Clock Error. The error occurs due to problems with the internal clock.

Er12

Extinguishing for ignition failure.

Er15

Extinguishing due to power failure for more than T89 minutes

Er16

RS485 communication error

Er17

Adjusting the Air Flow Failed

Er18

Exhaustion Pellet

Er23

Boiler probe or Back boiler probe or probe Buffer open

Er25

Engine cleaning brazier broken

Er26

Engine cleaning broken

Er27

Engine cleaning 2 broken

Er39

Sensor Flowmeter broken

Er41

Minimum air flow in Check Up is not reached

Er42

Maximum air flow exceeded (F40)

Er47

Error Encoder Auger: missing signal Encoder (if P81=1 or 2)

Er48

Error Encoder Auger: Auger regulation speed not achieved (if P81=1 or 2)

Table of contents

Other TiEmme Controllers manuals

Popular Controllers manuals by other brands

Zennio

Zennio MAXinBOX 8 Technical documentation

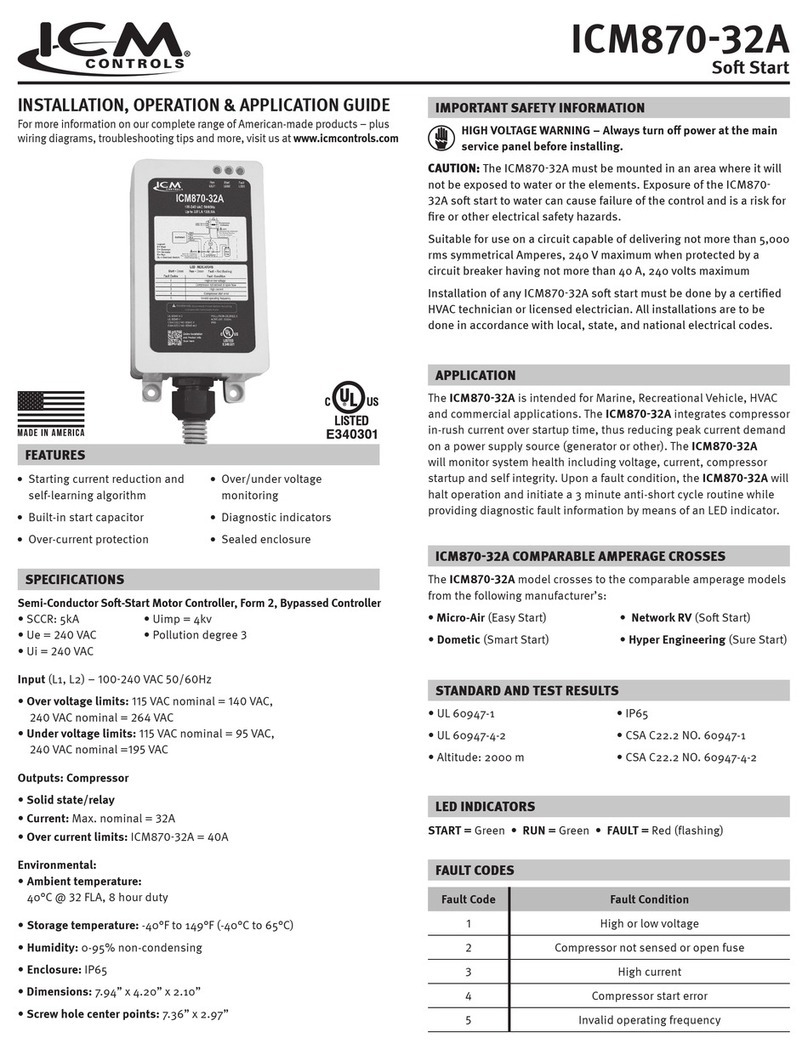

ICM Controls

ICM Controls ICM870-32A Installation, operation & application guide

RADEMACHER

RADEMACHER HomePilot Translation of the commissioning instruction manual

ABB

ABB i-bus KNX FCL/S 1.6.1.1 product manual

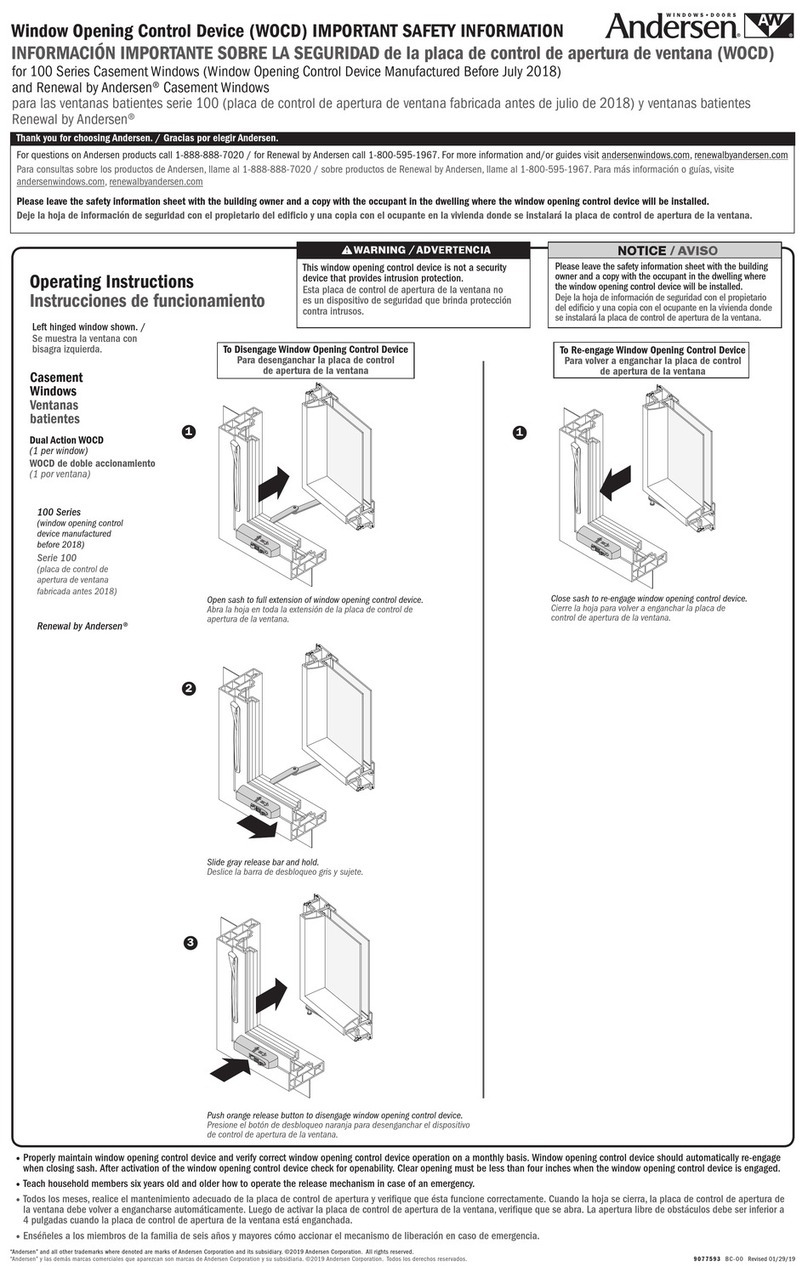

Andersen

Andersen 100 Series Important safety information

Siemens

Siemens GLB111.9E/MO manual