Tinkerine Studio Ditto User manual

3D Printer + Creative Solution

TINKERINE STUDIO

ASSEMBLY

MANUAL

+

CONTENTS

Safety Instructions

Ditto at a Glance

Bill of Materials

Before You Start

Z-Platform

Ditto Frame pt.1

Ditto Frame pt.2

Gantry pt.1

Gantry pt.2

Gantry pt.3

Extruder

Electronics / Spool Holder

Print Bed

Wiring

Preliminary Run Through

3

4

6

7

8

13

21

27

37

45

49

67

68

71

75

TINKERINE

STUDIO

STUDIO

TINKERINE

STUDIO

STUDIO

IMPORTANT SAFETY INSTRUCTIONS

!WARNING

SHARP EDGES

!WARNING

FIRE

!WARNING

SHOCK

!WARNING

HOT SURFACE

Motor surfaces become hot during operation.

There is a danger of electric shock.

Use only undamaged electrical chords.

DO NOT touch bare wires or receptacles.

DO NOT touch the 3D printer or chords if hands

are wet.

Ensure that all cords are free of damage before

connecting to the power supply.

Ensure that you have a sufcient electrical supply for

supporting the requirements of the motor.

Always use your 3D printer in a well-ventilated and

clean area.

Gas emitted by melting of Polylactide (PLA) or

Acrylonitrile butadiene styrene (ABS) can contain

contaminants that are harmful to breathe.

Never breathe the air that comes directly out of the

hotend. This air is not suitable for breathing.

If you feel ill from breathing while operating your 3D

printer, stop and seek medical attention immediately.

Hotend and heater cartridge become hot during

operation.

DO NOT touch hot surfaces, because they can cause

severe burns.

Allow the hotend to cool before touching it without

proper tools.

Use caution to minimize risk of re.Use caution during assembly and operation of the 3D

printer to ensure no sharp edges will cut you.

Inspect the printer for any damage prior to use. Always operate the printer a safe distance away from

ammable items. Use in well-ventilated areas.

DO NOT place a storage cover on the unit during

operation. Only place a cover on the printer after it has

thoroughly cooled down.

!WARNING

Fragile

Electrical pins and sensors are delicate. Handle with

care.

Unless instructed, DO NOT force components together.

Read the instructions carefully to prevent damaing parts

during assembly or operation.

!WARNING

RISK TO BREATHING

TINKERINE

STUDIO

STUDIO

CARRIAGE

FILAMENT

GUIDE TUBE

Z-AXIS

THREADED ROD

TINKERINE

INTERACTION

MODULE

ELECTRONICS

FAN GRILL

POWER

SWITCH

Y-AXIS

BEARING CAP

PRINT BED

HOTEND

COOLING FAN

X-AXIS

BEARING CAP

Z-AXIS

SMOOTH ROD

DITTO AT A GLANCE

TINKERINE

STUDIO

STUDIO

TINKERINE

INTERACTION

MODULE

EXTRUDER MOTOR

EXTRUDER

HOTEND

Z-AXIS PLATFORM

PRINT BED

PRINT COOLING FAN

SPOOL HOLDER

MOTOR

COMPARTMENT

DITTO AT A GLANCE

TINKERINE

STUDIO

STUDIO

Ditto+ Bill of Material

(30) M3 x 10 screws

(85) M3 x 16 screws

(12) M3 x 20 screws

(8) M3 x 25 screws

(11) M3 x 35 screws

(3) M3 x 50 screws

(3) M3 x 25 athead

(1) M4 x 16 screws

(3) M4 x 20 screws

(10) M3 washers

(100) M3 nuts

(1) M4 washers

(10) M4 nuts

(2) Wires (Arduino to Power)

(1) M4 Allen Key

(1) M3 Allen Key

(1) 1.5mm Hex Key

(2) Zip Ties

Ditto+ Laser Cut Panels

(1) Hotend

(1) Cartridge heater

(1) Thermistor

(1) NEMA17 Extruder motor

(1) “Tensioning” bearing

(1) Cooling fan ducts

(1) Filament guiding tube

(2) 166mm GT2 belt

(2) 602mm GT2 belts

(2) 545mm GT2 belts

(8) Brass slider bushing

(8) 608ZZ ball bearings

(4) LM8 linear bearings

(8) Pulleys + (8) 3x5mm set screws

(2) 16-tooth pulleys

(8) Steel rods

(1) Bed plate

(3) Calibration springs

(3) Mechanical endstops

(3 Thumb Screw

(2) LED strips

(2) 40mm cooling fans

(1) 50mm cooling fans

(2) NEMA17 stepper motors

(1) NEMA17 stepper motor with threaded rod

(1) Arduino MEGA 2560

(1) RAMPS 1.4

(4) A4988 stepper drivers

(1) Power supply

(1) Power switch

(1) Female power plug

(1) Power cord

(1) USB cable

Included In Kit

Tool List

TINKERINE

STUDIO

STUDIO

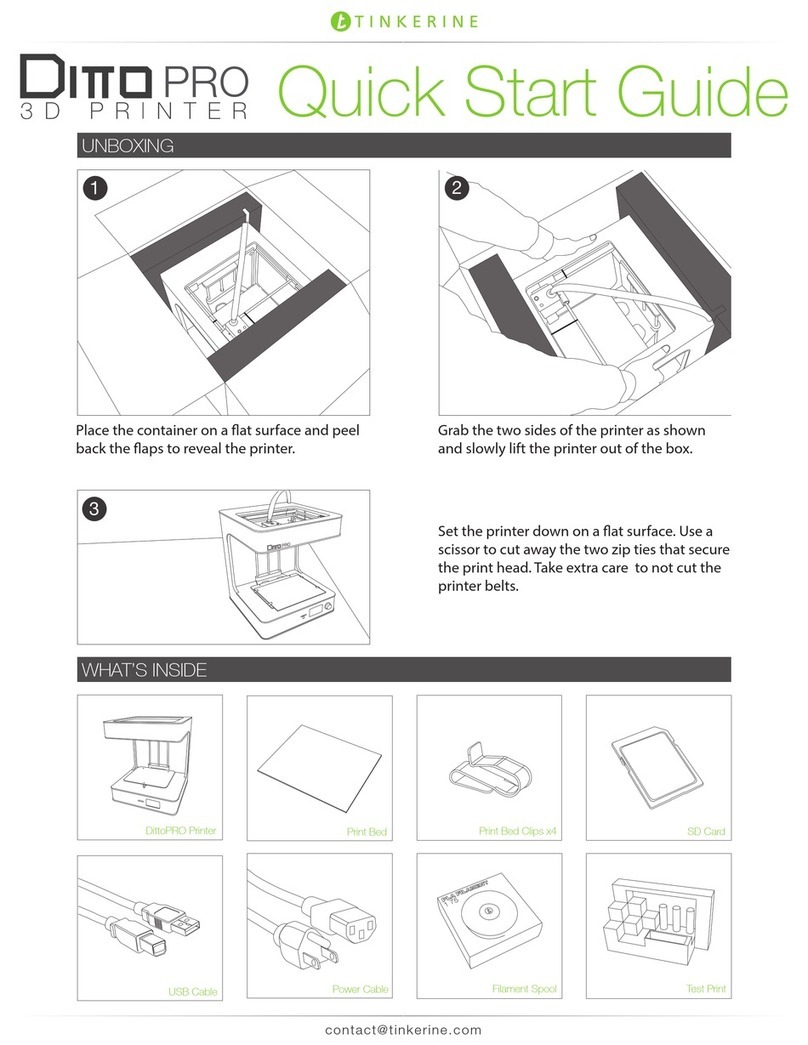

Before you Start

Before you attempt to assemble any of part the Ditto / Litto 3D Printer, it is imperative that you

read the build instructions fully and ensure you understand every part of the instruction.

While Tinkerine Studio provides warranty for all parts of the 3D printer, this does not cover damage

caused by not following the instruction manual or other end-user error.

Go down the BoM (Bill of Material) and tools checklist and ensure that you have all the

required parts to assemble the Ditto 3D Printer. Extra screws have been included into the kit.

Give yourself plenty of room and clean space during the assembly process. This prevents

delicate components like the electronics or bearings from being damage by dust or blunt force.

To ensure proper alignment of the panel and overall rigidity of the printer, it is highly

recommended that the assembly is done on a at surface.

Wipe off any excess grease you nd on the screws with a napkin or an old towel. Screws

are generally greased in order to prevent rusting during production. Cleaning off excess

grease will keep your hands and printer clean during assembly.

Ditto is a rigid and robust 3D printer once assembled, however during the assembly process,

extra care needs to be taken to make sure delicate parts require more precision than force to

come together. If during the assembly process, you are unsure of the instructions, please

contact us for support. Remember, unless instructed, no part in the assembly process should

you need to exert a high amount of force to t pieces together.

Before starting calibration, ensure that all screws and pulley setscrews are properly tightened.

Common calibration issues such as skipping and backlash are usually caused by loose pulleys

and unsecured components.

TINKERINE

STUDIO

STUDIO

Z - Platform Assembly

Parts Required

x2

x2

x4

x4

M3x35 Screw M3 Nuts

x10 x14

M3x10 Screw

x4

M3x16 Screw

x4

M4x20 Screw

x1

45mm Bearing

x2

Lead Screw Nut

x1

Bed Plate

Bearing Holder

(Attached to Z-Axis Motor)

UNSCREW TO DETACH

Z-Base

Z-Bridge

1.

M3x10 (x4)

Screw nut comes attached to the

lead screw motor. Remove from

screw and insert it into the

Tools Required

M3 Allen Key

M4 Allen Key

TINKERINE

STUDIO

STUDIO

2.

3.

4.

x2

45mm Linear Bearing

Arm A

Arm B

Take a 45mm linear bearing and place a

bearing holder on both ends. You will need

two sets.

Add the side arm panels to the existing

assembly, note the different panels + orienta-

tion of the arms (A + B) shown in the picture.

Swapping the position of the A+B pieces will

allow us to create the mirrored version of

Arm A

A

A

B

B

TINKERINE

STUDIO

STUDIO

5.

6.

Arm A

M3x35 (x5)

M3 Nut (x5)

One by one, insert the M3 Nut into the

T-slots shown in the picture. Screw the four

M3x35 screws in but do not tighten them all

the way.

After Steps 3 and 4, you should

have two sets of the Z-axis arm

that have the outer panel that

mirror each other.

TINKERINE

STUDIO

STUDIO

7.

8.

Arm B

Arm A

M3x35 (x5)

M3 Nut (x5)

During this point, double check to make sure

all panels are properly aligned and the top

side of the bed is leveled with the arms.

Tighten all screws evenly.

TINKERINE

STUDIO

STUDIO

Ditto Frame Assembly pt.1

M3 Nuts

x39

Tools Required

M3 Allen Key

Left Side Panel

Adhesive LED Strips

Right Side Panel

Parts Required

M3x16 Screw

x39

Central Back Panel

Base Panel

Z-Constraint BZ-Constraint A

Z-Constraint C

Bottom Front Panel

Bottom Bracket

Top Front Panel

Motor Bracket

Top Ring Panel

+

TINKERINE

STUDIO

STUDIO

1.

M3x16 (x4)

M3 Nut (x4)

Z-Constraint C

Install the two Z-Constraints C as shown

in the picture. Make sure to face the back

panel in the correct direction. Insert the

constraint into the corrent tabs, place the

M3 nuts in position and screw in the

M3x16 screws from the other side.

TINKERINE

STUDIO

STUDIO

2.

M3x16 (x2)

M3x10 (x4)

A

B

M3 Nut (x2)

Install Constraint A to the back panel and lightly secure with the two M3x16 screw +

nut. Insert Constraint B underneath Constraint A and secure with four M3x10 screws.

Tighten all screws once everything is aligned and in place.

TINKERINE

STUDIO

STUDIO

Top Ring Panel

FRONT

BACK

LED Strip (x2)

Using the two LED light strip supplied in your kit, one-by-one peel off the backing to reveal the adhesive strip

and stick the LED strip in the area shown in the picture. Make sure the LED is applied inbetween the T-Slot

and edge of the inner ring. The front and back side of the ring panel will be wider.

TINKERINE

STUDIO

STUDIO

M3x16 (x4)

M3 Nut (x4)

LED Side Facing Down

3.

Insert the top ring and and bottom plate into the back plate, then secure with M3x16 and nuts in the T-Slots.

For the top ring, the side with the led should be facing downward. Thread the LED wires into the hole shown

in the picture.

TINKERINE

STUDIO

STUDIO

4.

Install the two side panels into the main body. Secure each side with ve M3x16 screws and nut. Make sure

the panel with the power switch and fan grill cutout is on the right side.

M3x16 (x10)

M3 Nut (x10)

TINKERINE

STUDIO

STUDIO

5.

Install the top front and top bottom panels. At this point, you will want to make sure all the panels are properly

aligned and leveled to a at surface. Due to the natural property of wood you wooden frame may not be perfectly

tapered to the surface, however we can correct this later on once the other components are installed.

M3x16 (x12)

M3 Nut (x12)

TINKERINE

STUDIO

STUDIO

6.

Install the top and bottom brackets into the main body. You will need to insert some screws from the front of the

machine.

M3x16 (x7)

M3 Nut (x7)

This manual suits for next models

1

Table of contents

Other Tinkerine Studio 3D Printer manuals

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual

Tinkerine Studio

Tinkerine Studio Ditto Pro Parts list manual

Tinkerine Studio

Tinkerine Studio DittoPro-R Parts list manual

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual

Tinkerine Studio

Tinkerine Studio LITTO User manual

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual