7

E

N

G

L

I

S

H

Getting Started (continued from page 6)

6

Safety Is Your Responsibility (continued from page 5)

E

N

G

L

I

S

H

Getting Started

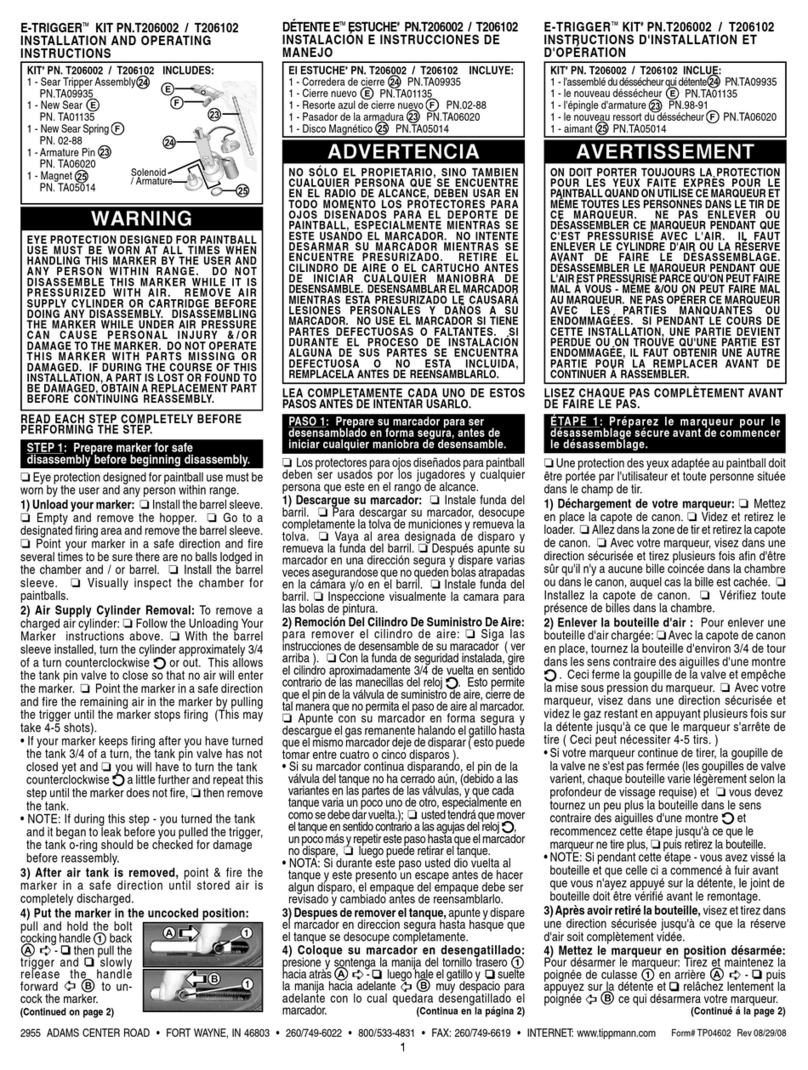

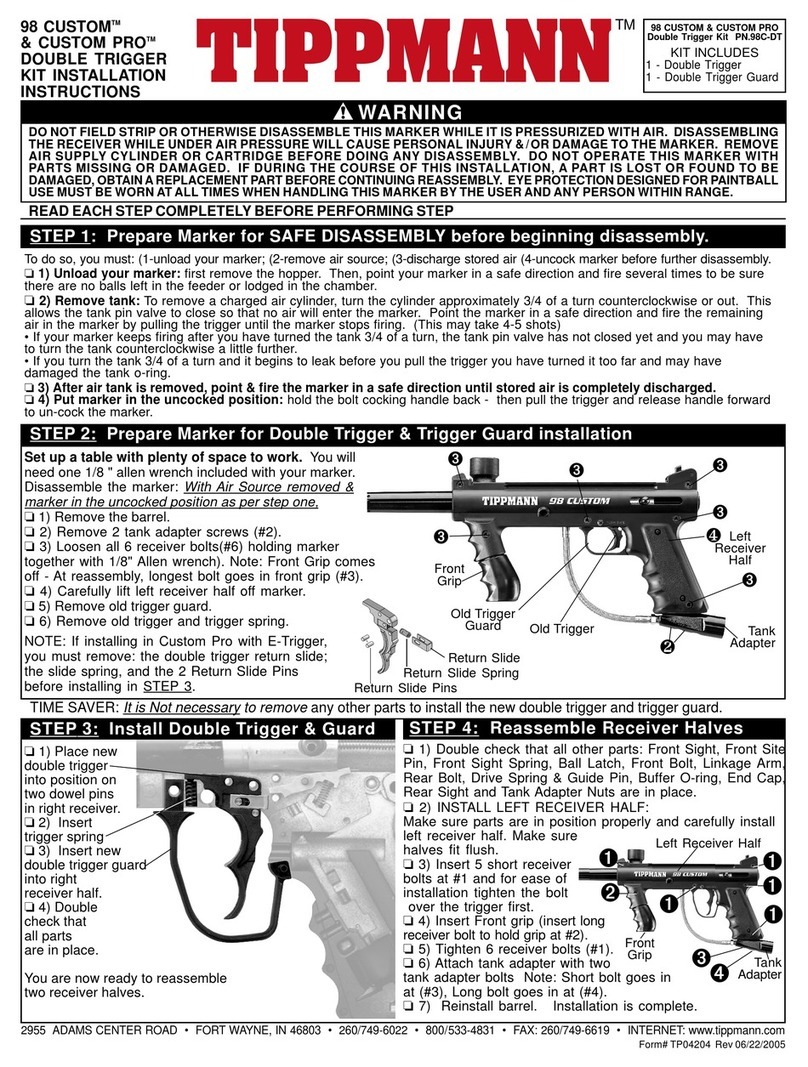

STEP 1) Prepare Marker for Air Supply Cylinder

Installation

• Model: A-5TM WITH E-GRIPTM - You must first install battery

(see instructions on page 8) before performing STEP 2.

• Models: A-5TM,A-5TM RESPONSETM,A-5TM STEALTHTM

andA-5TM STEALTHTM CR-15TM - Go to STEP 2.

STEP 2) Air Supply Cylinder Installation

• Do not pressurize a partially assembled paintball marker.

• First install barrel sleeve (see instructions on page 2).

• Next put trigger safety in Safe Mode (see instructions on page 4).

• Next you need to cock the marker by sliding the bolt handle

all the way back until it clicks. Then release cocking handle.

Cockinghandlewillslideforward. Markerisnowcocked. Always

keepmarker in the cocked position when airsupply is attached

to marker. This will help prevent an accidental discharge.

• To install the air supply cylinder, lubricate the cylinder valve

o-ring with a little gun oil then insert the cylinder valve end

into the air supply adapter at the back end of the marker

grip (or remote coil onA-5TM STEALTHTM). Twist the cylinder

clockwiseinto the adapter until it stops. Your marker is ready

tofireonceyouswitchtoFireModefromSafe Mode. Ifthe tank

is full and you do not hear the air supply engage, the pin valve

could be too short or the pin valve seal is damaged.

Getting Started (continued on page 7)

STEP 3) Hopper and CycloneTM Feeder

Barrel Sleeve must be installed (see page 2) and safety in

Safe Mode (see page 4) before filling the hopper.

• Make sure that the CycloneTM feeder housing is clean, free of

debris,andthe CycloneTM feedersturn freely when the manual

advance lever knob is pushed.

• Makesurethatthehopperisclean,freeofsharpedgesor debris.

Thiswillkeepthe paintballsfrombreakingand feed the marker

smoothly.

• Install the hopper neck into the CycloneTM feeder housing

aligning the hopper neck tab to fit into the cutout in the

CycloneTM feeder housing. With the barrel sleeve installed

and safety in Safe Mode, you are now ready to load your

hopper with paintballs. After filling the hopper with paintballs

the chamber will still be empty. You need to push the feeder

manual advance lever to chamber a paintball. Only remove

barrel sleeve and turn off the safety when ready to shoot.

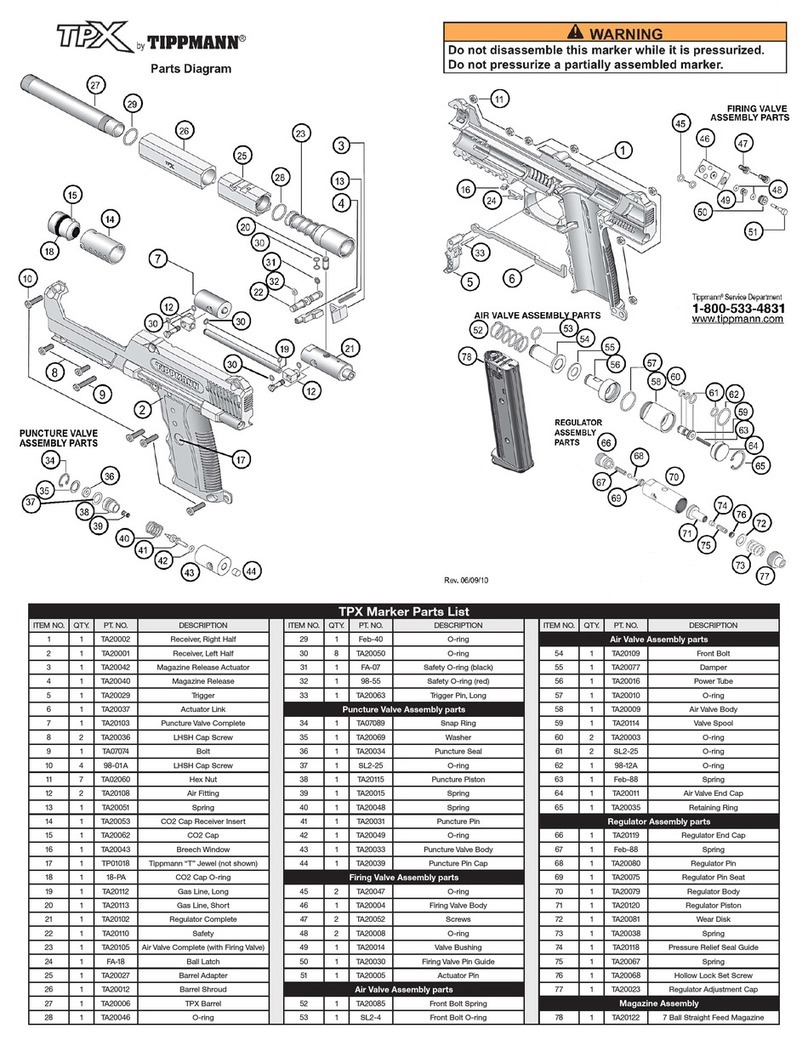

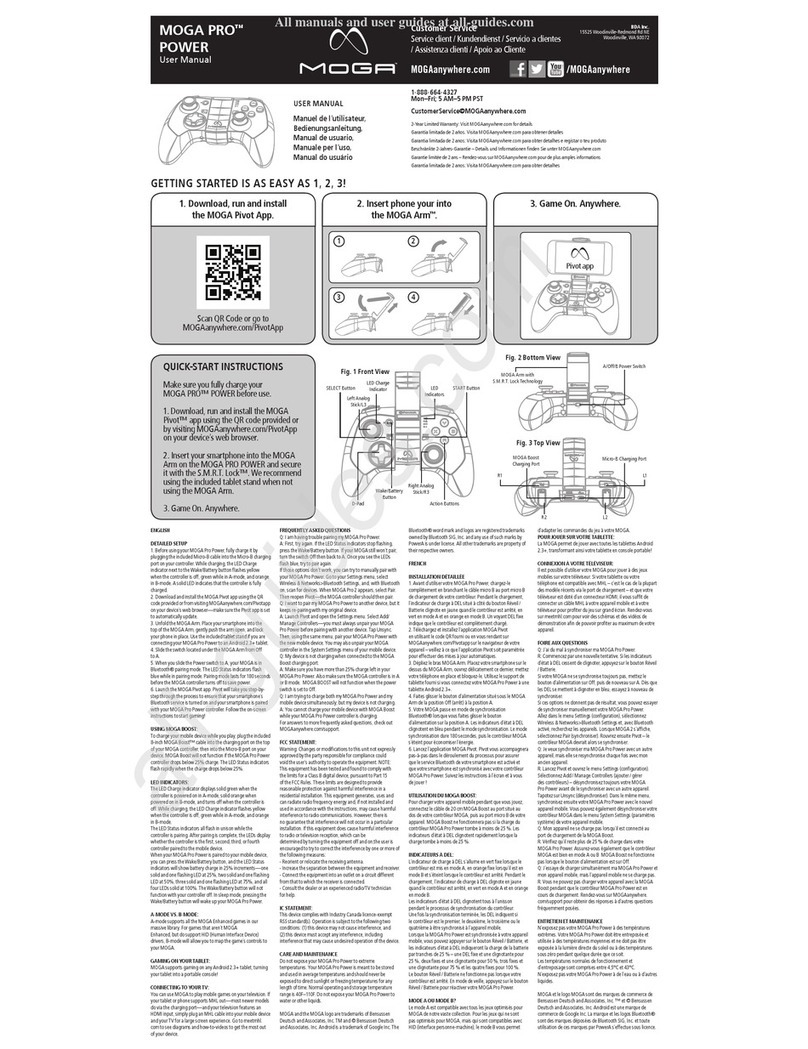

Allen Wrench

Velocity

Adjustment

Screw

To adjust the velocity use the small (5/32”) allen wrench

included with your marker. The velocity adjustment screw is

located on the right side of the receiver. To adjust the velocity

down, turn the screw inward or clockwise. To turn the velocity

up, turn the screw out or counterclockwise. Do not remove

velocity screw. NOTE: You must turn the velocity screw all

the way in before doing any disassembly.

Even a light layer will absorb some of the impact and protect

you from the paintballs.

• Keep exposed skin away from escaping gas when installing

or removing air supply cylinder or if the marker orair supply

is leaking. Compressed air, CO2, and nitrogen gasses are

very cold and can cause frostbite under certain conditions.

• Use only .68 caliber paintballs, never load or fire any foreign

objects.

• Avoid alcoholic beverages before and during the use of this

marker. Handling markers while under theinfluence of drugs

or alcohol is a criminal disregard for public safety.

• Avoid shooting an opponent at point blank, 6 feet or less.

• Familiarize yourself with instructions listed on air supply

cylinder or adaptor. Contact the air supply cylinder or

adaptor manufacturer with any questions.

• Always measure your marker’s velocity before playing

paintball and never shoot at velocities in excess of 300 feet

per second (see instructions on page 7).

STEP 5) Velocity Adjustment

Eachtime you play paintball, thevelocity

of your paintball marker should be

checked with a chronograph, an

instrument for measuring velocity, prior

to playing paintball to verify that the

marker’svelocityissetbelow300feet per

secondorlessif required by playing field.

STEP 6) Rear Sight Adjustment

Rotate the rear sight to preferred width to allow easy sighting.

For markers with FlatlineTM barrel system, 260-275 feet per

second is recommended for best performance.

Feeder Manual

Advance Lever

STEP 4) Rate of Fire Adjustments and Troubleshooting

• Marker:A-5TM WITH E-GRIPTM - Go to page 10 and follow

E-GRIPTM Tuning and Operating Instructions.

• Markers: A-5TM ResponseTM andA-5TM STEALTHTM CR-15TM- Go

to page 12 and follow Tuning The Response Trigger Rate of

Fire instructions.

• Markers: A-5TM andA-5TM STEALTHTM - Go to STEP 5.