CARVER ONE

Paintball Marker

Owner’s Manual

WARNING

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS INJURY OR

DEATH. EYE, FACE, AND EAR PROTECTION DESIGNED FOR

PAINTBALL MUST BE WORN BY THE USER AND ANY PERSON

WITHIN RANGE. WE RECOMMEND YOU BE AT LEAST 18

YEARS OLD TO PURCHASE. PERSONS UNDER 18 MUST HAVE

ADULT SUPERVISION WHEN USING THIS PRODUCT. READ THE

OWNER’S MANUAL BEFORE USING THIS PRODUCT.

WARNING

SAFETY IS YOUR RESPONSIBILITY

READ AND FAMILIARIZE YOURSELF AND ANY OTHER USER

OF THIS MARKER WITH THE

SAFETY INSTRUCTIONS

IN THIS

MANUAL. FOLLOW THESE INSTRUCTIONS WHEN USING,

WORKING ON, TRANSPORTING, OR

STORING THIS MARKER.

ALWAYS KEEP THE TRIGGER SAFETY IN SAFE

MODE UNLESS IN A SHOOTING SITUATION, AS

DETAILED IN TRIGGER SAFETY INSTRUCTIONS.

ALWAYS KEEP THE BARREL SLEEVE

INSTALLED WHEN NOT IN A SHOOTING SITUATION,

SEE BARREL SLEEVE INSTRUCTIONS BELOW.

Barrel Sleeve Installation Instructions

1. InserttheBarrelSleeveontotheBarrelandloopthecordoverthetopofthereceiverandposition

atthebackofthegripasshown.

2. Adjustthecordlengthretaineruptothebackofthegripby

pullingthecordthroughituntiltheretainerissnugagainst

thebackofthegrip.Keepingthecordastightaspossible,

leavejustenoughcordelasticitytopullthecord/retainerup

overthetopofthemarkertoremovetheBarrelSleevefor

ring.

3. Afterthecordlengthisproperlyadjusted,lockthecordlengthby

tyingaknotinthecordagainstthebackoftheretainerasshown.

4. Beforeandafterplaying,inspecttheBarrelSleeve.Replacethe

BarrelSleeveifthesleeveorcordisdamaged,orathereisaloss

ofcordelasticity.

5. CleantheBarrelSleevewithplain,warmwaterandstoreoutofsunlightinadryareawhennotin

use.

Introduction

CONGRATULATIONSonyourpurchaseofyourTippmann®paintballmarker.WebelieveourCarver

One™markertobethemostaccurateanddurablepaintballmarkeravailable,anditisproudly

manufacturedbyTippmann.TheTippmann®CarverOnemarkerwillprovideyoumanyyearsof

dependableserviceifcaredforproperly.

PleasetaketimetoreadthismanualthoroughlyandbecomefamiliarwithyourTippmann®CarverOne™

marker’sparts,operation,andsafetyprecautionsbeforeyouattempttoloadorrethismarker.Ifyou

haveamissingorbrokenpart,orneedassistance,pleasecontactTippmannConsumerRelationsat

1-800-533-4831forfast,friendlyservice.

Warning / Liability Statement

ThismarkerisclassiedasadangerousweaponandissurrenderedbyTippmannSports,LLCwiththe

understandingthatthepurchaserassumesallliabilityresultingfromunsafehandlingoranyactionthat

constitutesaviolationofanyapplicablelawsorregulations.TippmannSports,LLCshallnotbeliablefor

personalinjury,lossofpropertyorliferesultingfromtheuseofthisweaponunderanycircumstances,

includingintentional,reckless,negligentoraccidentaldischarges.

Allinformationcontainedinthismanualissubjecttochangewithoutnotice.TippmannSports,LLC

reservestherighttomakechangesandimprovementstoproductswithoutincurringanyobligationto

incorporatesuchimprovementsintoproductspreviouslysold.

Ifyouasauserdonotacceptliability,TippmannSports,LLCrequestsyoudonotuseaTippmannSports,

LLCmarker.ByusingthispaintballmarkeryoureleaseTippmannSports,LLCofanyandallliability

associatedwithitsuse.

Safety Is Your Responsibility!

Trigger Safety

Familiarize Yourself with Safety...

Theownershipofthismarkerplacesuponyouthetotalresponsibilityofitssafeandlawfuluse.Youmust

observethesamesafetyprecautionsasyouwouldanyrearmtoassurethesafetyofnotonlyyourself

buteveryonearoundyou.Outlinedherearesomegeneralprecautionstobeawareof.Theusershouldat

alltimesusecautionandcommonsensewhenusingthismarkerandalwaysrememberthatthegameof

PaintballcanonlysurviveandgrowifitremainsSAFE!

• Donotloadorrethismarkeruntilyouhavecompletelyreadthismanualandarefamiliarwith

itssafetyfeatures,mechanicaloperation,andhandlingcharacteristics.

• Handlethisandanymarkerasifitwereloadedatalltimes.

• KeepyourngerofftheTriggeruntilreadytoshoot.

• Donotlookdownthebarrelofapaintballmarker.Accidentaldischargeintotheeyesmaycause

permanentinjuryordeath.

• KeeptheTriggerSafetyintheSafepositionuntilreadytoshoot(seeWarningmessageabove).

• Keepabarrelsleeveinstalledonmarkerwhennotshooting(seeWarningmessageabove).

• Neverpointthemarkeratanythingyoudonotintendtoshoot.

• Neverreyourmarkeratanythingyoudonotintendtoshootbecausetheremaybepaintballs

orforeigndebrislodgedinthechamber,barrel,orthemarker’svalve.

• Donotshootatfragileobjectssuchaswindows.

• Neverreyourmarkeratpersonalpropertyofothers.Thepaintballimpactcancausedamage

andthepaintcanstainthenishofautomobiles,houses,etc.

• Alwayskeepthebarrelpointeddownorinasafedirection,evenifyoustumbleorfall.

• Eye,face,andearprotectiondesignedspecicallytostoppaintballsintheformofgogglesand

fullfacemaskmeetingASTMSpecicationF1776mustbewornbytheuserandanyperson

withinrange.

• Nevershootatapersonwhoisnotprotectedbyeye,face,andearprotectiondesignedfor

paintball.

• Pressurizeandloadamarkeronlywhenthemarkerwillbeimmediatelyused.

• Storethemarkerunloadedanddegassedinasecureplace.

NOTE:Beforestoringordisassembling,besuretoremovepaintballsandair/CO2cylinder(see

Unloading Your MarkerandAir/CO2 Cylinder Warnings),puttheTriggerSafetyintheSafe

positionandinstallthebarrelsleeve.

• Donoteldstriporotherwisedisassemblethismarkerwhileitispressurized.

• Dressappropriatelywhenplayingthegameofpaintball.Avoidexposinganyskinwhenplaying

thegameofpaintball.Evenalightlayerofclothingwillhelpabsorbsomeoftheimpactand

protectyoufromthepaintballs.

• Keepexposedskinawayfromescapinggaswheninstallingorremovingtheair/CO2cylinder,or

ifthemarkerorair/CO2cylinderisleaking.Compressedair,CO2,andnitrogengassesarevery

coldandcancausefrostbiteundercertainconditions.

• Useonly.68caliberpaintballs.Neverloadorreanyforeignobjects.

• Avoidalcoholicbeveragesbeforeandduringtheuseofthismarker.Handlingmarkerswhile

undertheinuenceofdrugsoralcoholisacriminaldisregardforpublicsafety.

• Avoidshootinganopponentatpointblank,6feetorless.

• Familiarizeyourselfwithinstructionslistedontheair/CO2cylinder.Contacttheair/CO2cylinder

manufacturerwithanyquestions.

• Alwaysmeasureyourmarker’svelocitybeforeplayingpaintballandnevershootatvelocitiesin

excessof300feetpersecond(seeVelocity Adjustment instructions).

• AlwayskeepinmindthatthesportofPaintballisviewedandjudgedbyyoursafeand

sportsmanlikeconduct.

Getting Started

• Eyeprotectiondesignedforpaintballusemustbewornbytheuserandanypersonwithin

range.

• Donotdisassemblethismarkerwhileitispressurizedwithair.

• Donotpressurizeapartiallyassembledmarker.

• Readeachstepcompletelybeforeperformingthestep.

NOTE:Carefullyhandstartallthreadedpartswhenassembling,anddonotovertighten,asthis

maypotentiallystripthethreadedparts.

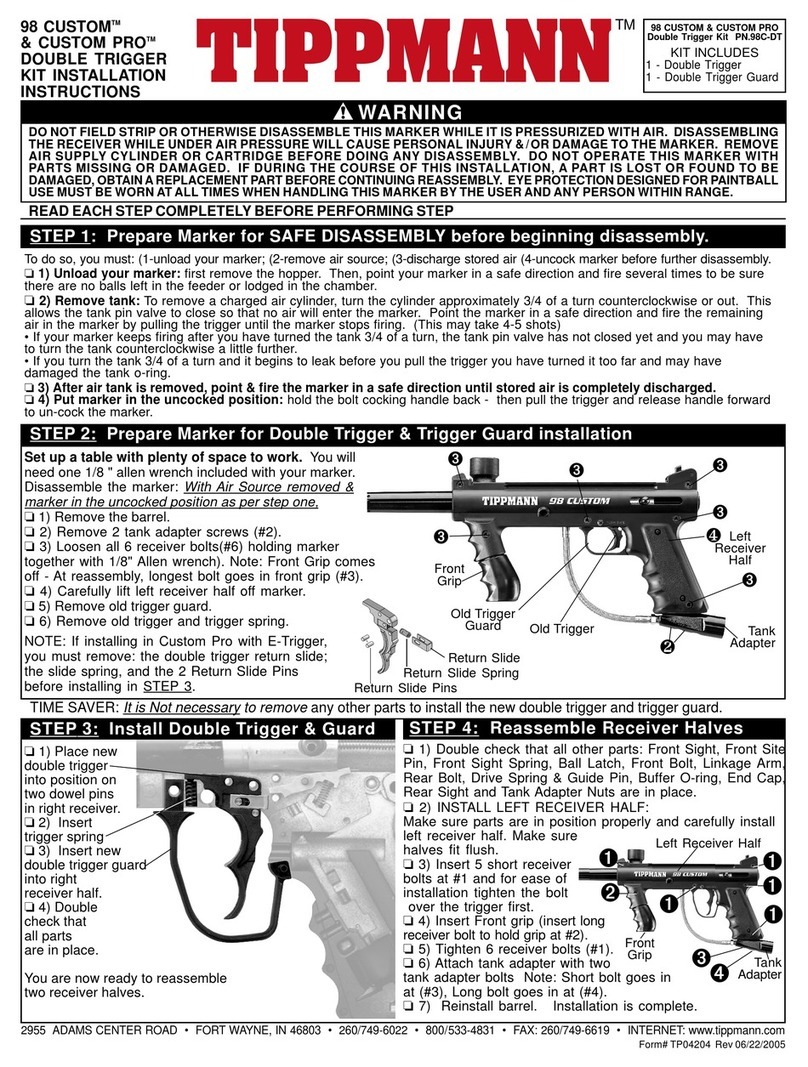

1. Prepare Marker for Air/CO2 Cylinder Installation.

a. ApplyTippmannoiltotheBarrelO-ring.

b. InserttheBarrelintotheReceiver.

c. CarefullyturntheBarrelclockwisebyhanduntiltight.

2. Air/CO2 Cylinder Installation.

ReviewAir/CO2 Cylinder Safety Tips.

a. PuttheTriggerSafetyintheSafepositionandinstalltheBarrelSleeve.

b. Cockthemarkerbyslidingthebolthandlealltheway

backuntilitlocksintoplace.Alwayskeepmarkerinthe

cockedpositionwhenattachingair/CO2cylindertothe

marker.Thishelpspreventanaccidentaldischarge.

c. Lubricatetheair/CO2cylindervalveO-ringwithalittle

Tippmann®oil.

d. Inserttheair/CO2cylindervalveintotheAirSupply

Adapter(ASA)(29)atthebackendofthemarkergrip.

e. Twisttheair/CO2cylinderclockwiseintotheASAuntilit

stops.Usecautionasthemarkerisnowcapableofring

afteryouputtheTriggerSafetyintheFireposition.

(Ifyoudonothearthefullair/CO2cylinderengage,the

pinvalvecouldbetooshortorthepinvalvesealisdamaged,followtheAir/CO2 Cylinder

Removalinstructionsandtakeyourair/CO2cylindertoa“C5”CertiedAirsmithforinspection

orcontactthecylindermanufacturer).

3. Loading the Hopper

TheBarrelSleevemustbeinstalledandtheTriggerSafetyintheSafeposition.

a. MakesurethattheFeedElbow(9)andHopperarecleanandfreeofsharpedgesordebris.

Thiskeepspaintballsfrombreakingprematurely,andallowspaintballstofeedtothemarker’s

chambersmoothly.

b. InstalltheHopperneckintotheFeedElbow.

c. TightentheFeedElbowBolt(11)usingtheincluded3/16”allenwrench.

d. WiththeBarrelSleeveinstalled,andtheTriggerSafetyintheSafeposition,youarenowready

toloadthehopperwith.68caliberpaintballs.Donotforceexcessivenumbersofpaintballsinto

thehopper.

4. Fire the Marker

a. RemovetheBarrelSleevefromthemarker.

b. Pointthemarkerinasafedirection.

c. PuttheTriggerSafetyintheFireposition.

d. Pullthetriggertorethemarker.

Velocity Adjustment

Eachtimeyouplaypaintball,checkthevelocityofyourpaintballmarkerwithachronograph(an

instrumentformeasuringvelocity)priortoplayingpaintball.Verifythatthemarker’svelocityissetbelow

300feetpersecond(orlessifrequiredbytheplayingeld).

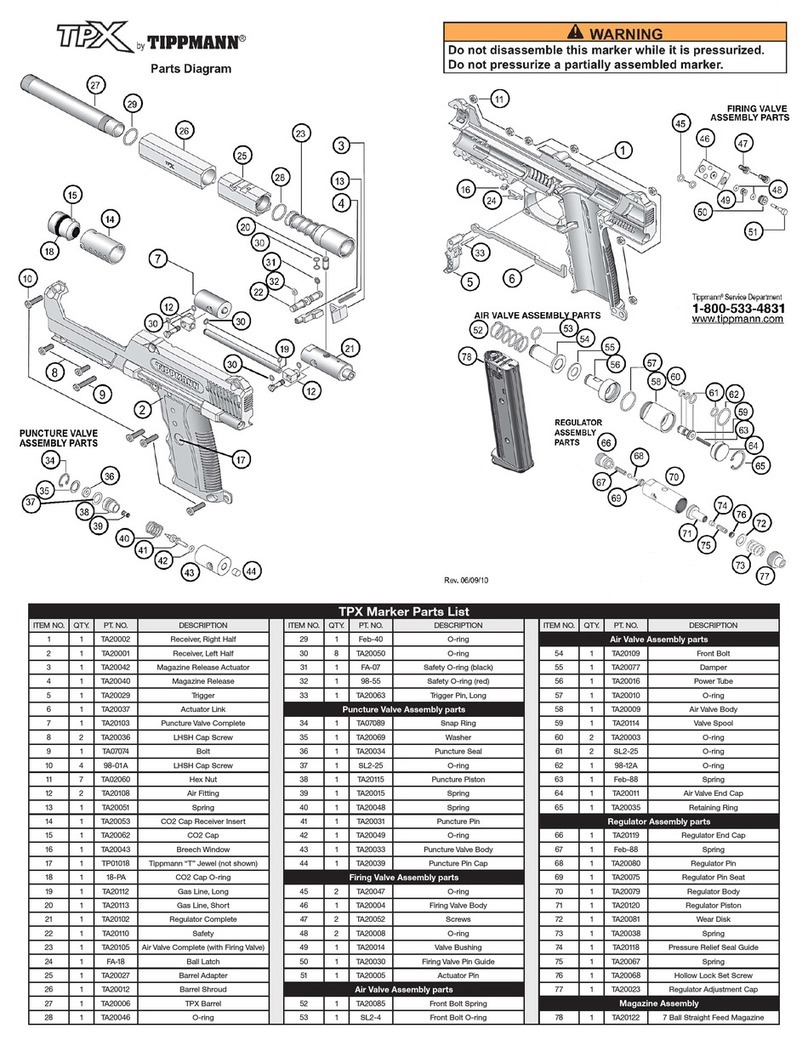

Toadjustthevelocity,usethe3/16”allenwrenchincludedwithyourmarker.TheVelocityAdjustment

Screw(#51inPartsDiagramandshowninFigure3)islocatedonleftsidereceiver.Toreducethe

velocity,turnthescrewinwardorclockwise.Toincreasethevelocity,turnthescrewcounterclockwise.Do

notremovethevelocityscrew.

Unloading Your Marker

1. Eyeprotectiondesignedforpaintballusemustbewornbytheuserandanypersonwithinrange.

2. InstallthebarrelsleeveandputtheTriggerSafetyintheSafeposition.

3. EmptyandremovetheHopper.

4. Gotoadesignatedringarea,removetheBarrelSleeve,andputtheTriggerSafetyintheFire

position.

5. Pointyourmarkerinasafedirectionandreseveraltimestobesuretherearenoremaining

paintballslodgedinthechamberorbarrel.IMPORTANT:Donotuncockyourmarkerasuncocking

yourmarkermaypushaballintothechamberordownintothebarrel,makingithiddenfromview.

6. ReturntheTriggerSafetytotheSafepositionandreinstalltheBarrelSleeve.

7. Visuallyinspectthechamberforpaintballs.

8. ReadthefollowingAir/CO2 Cylinder WarningsandSafety Tipsbeforeremovingtheair/CO2

cylinderfromyourmarker.

Air/CO2 Cylinder Warnings

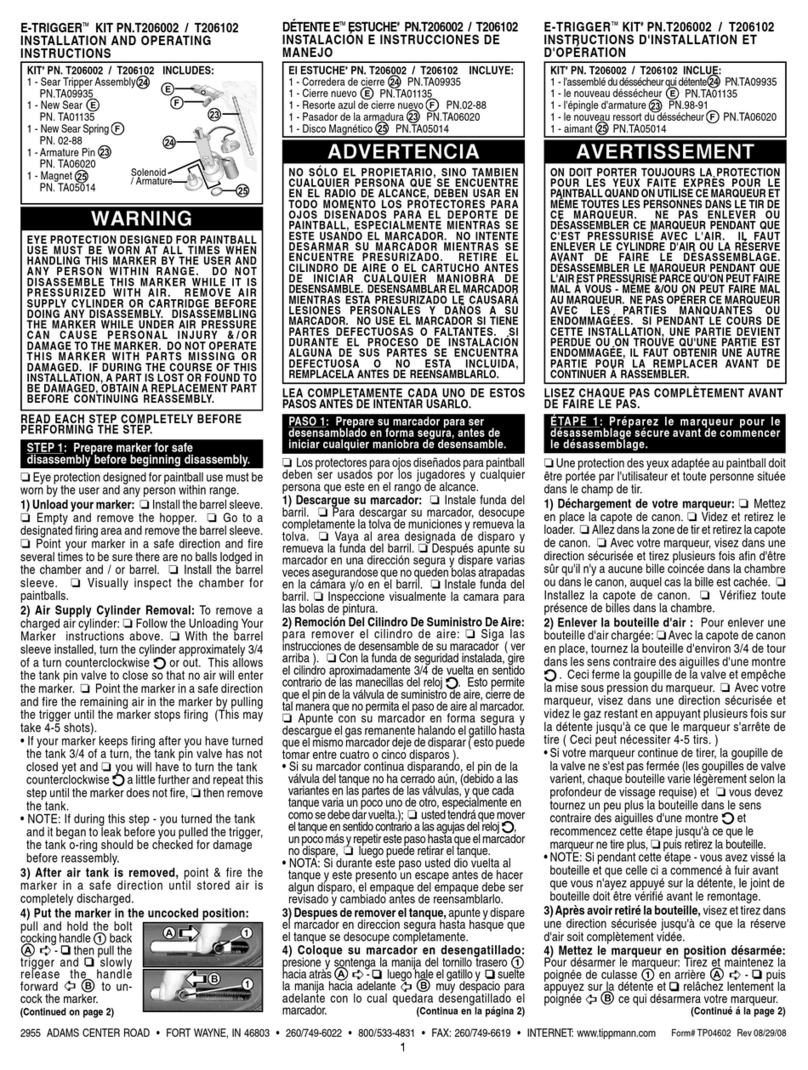

RefertoFigure4.Therehavebeenreportedincidentscausedby

playersunknowinglyunscrewingthecylinder(2)fromthecylinder

valve(1).Thisoccurswhentheplayerthinkstheentirevalve-cylinder

assemblyisbeingunscrewedfromtheairsupplyadaptor(ASA)ofthe

paintballmarker,wheninfacttheyareunscrewingthecylinderfromthe

cylindervalve.

Toavoidthisdanger,itisrecommended(ifyourcylinderisnotalready

marked)thatyouusepaintornailpolishtoplaceamark(3)onthe

cylindervalve,andplaceanothermark(4)onthecylinder,inlinewith

the#3markasshown.

Wheneveryouturnthecylinderduringremoval,watchthemarkson

thecylinderandthecylindervalvetobesurethattheyrotatetogether.

IfatanytimethesemarksstarttoseparateasshowninFigure5,the

cylinderisstartingtounscrewfromthecylindervalveandyoumust

STOPandtaketheentireunittoa“C5”certiedairsmithforsafe

removaland/orrepair.

NOTE:Thecylindervalveshouldunscrewfromthepaintballmarkerin

about3or4fullturns.Ifyounishthe4thfullturnandthecylindervalve

isnotunscrewedfromthepaintballmarker,STOP!Taketheentireunit

toa“C5”certiedairsmithforsaferemovaland/orrepair.

Locatea“C5”CertiedAirsmithatwww.paintball-pti.com/search.asp.

Whetheryouhaveaneworusedrellableair/CO2cylinder,youareatriskifanyofthefollowinghas

occurred:

• Thevalveunitwasreplacedoralteredafterpurchase.

• Ananti-siphondevicewasinstalled.

• Thevalveunitwasremovedfromthecylinderforanyreason.

• Anymodicationwasdonetotherellableair/CO2cylinder.

Ifanyoftheseconditionshasoccurred,takeyourair/CO2cylindertoa“C5”CertiedAirsmithfor

inspectionorcontactthecylindermanufacturer.

Air/CO2 Cylinder Safety Tips

SAFETYTIPStoensurethatyourairorCO2cylinderissafeforplay:

• Improperuse,lling,storage,ordisposalofair/CO2cylindermayresultinpropertydamage,

seriouspersonalinjuryordeath.

• Makesurethatanymaintenanceormodicationtoanyair/CO2cylinderisdonebyaqualied

professional,suchasa“C5”certiedairsmith.

• Theuseofanti-siphondevicesisnotrecommended.However,ifoneisalreadyinstalledon

yourair/CO2cylinder,orsuchdeviceisdesired,itiscriticalthatyourcylinderbecheckedbya

qualiedprofessional,andyouhavethedeviceinstalledbyaqualiedprofessional.

• Allair/CO2cylindersmustbelledonlybyproperlytrainedpersonnel.

• Cylindervalvesmustbeinstalledonlybyproperlytrainedpersonnel.

• Donotoverllacylinder!Neverexceedtheair/CO2cylinder’scapacity.

• Donotexposepressurizedair/CO2cylindertotemperaturesexceeding130degreesFahrenheit

(55degreesCelsius).

• Donotusecausticcleanersorstrippersontheair/CO2cylinderorcylindervalve,anddonot

exposethemtocorrosivematerials.

• Donotmodifytheair/CO2cylinderinanyway.Nevertrytodisassemblethecylindervalvefrom

theair/CO2cylinder.

• Anyair/CO2cylinderthathasbeenexposedtore,orheatedtoatemperatureof250degrees

Fahrenheit(121degreesCelsius)ormoremustbedestroyedbyproperlytrainedpersonnel.

• Useappropriategasforyourcylinder.OnlyuseCO2inaCO2cylinder,andonlyuse

compressedairinacompressedaircylinder.

• Keepallcylindersoutofthereachofchildren.

• Theair/CO2cylindershouldbeinspectedandhydrostaticallyretestedatleastevery5yearsby

aDOTlicensedagency.

• Keepexposedskinawayfromescapinggaswheninstallingorremovingtheair/CO2cylinder,

orifthemarkerorcylinderisleaking.CompressedairandCO2gassesareverycold,andcan

causefrostbiteundercertainconditions.

NOTE:Locatea“C5”certiedairsmithatwww.paintball-pti.com/search.asp.

Air/CO2 Cylinder Removal

1. ReadAir/CO2 Cylinder WarningsandAir/CO2 Cylinder Safety Tipsbeforebeginningthe

cylinderremovalprocess.

2. Eyeprotectiondesignedforpaintballusemustbewornbytheuserandanypersonwithinrange.

3. FollowtheUnloading Your Markerinstructions.

4. Watchthemarksonthecylinderandcylindervalve(asshowninFigure4)asyouturnthecylinder

approximately¾turncounterclockwise.Thisallowstheair/CO2cylinder’spinvalvetoclosesothat

nogasentersthemarker.

5. RemovetheBarrelSleeve.SettheTriggerSafetytotheFireposition.Pointthemarkerinasafe

direction,anddischargetheremaininggasinthemarkerbyrepeatedlypullingthetriggeruntil

themarkerstopsring(thismaytake4-5shots).Ifyourmarkercontinuestore,thecylinder’s

pinvalvehasnotclosedyet(thecylinderpinvalvecouldbelongerthanusual.Becauseofthe

variancesincylinderpinvalveparts,eachcylindervariesslightlyonexactlyhowfarithastobe

turned).Turnthecylindercounterclockwisealittlefurtherandrepeatthisstepuntilthemarkerdoes

notre.Onlythenremovetheair/CO2cylinder.

NOTE:Ifduringthisstep,youturnedtheair/CO2cylinderanditbegantoleakbeforeyoupulled

thetrigger,thecylinder’sO-ringshouldbecheckedfordamagebeforeanyre-assembly(see

Repairing Air/CO2 Cylinder Leaksbelow).

6. Aftertheair/CO2cylinderisremoved,againpointandrethemarkerinasafedirectiontoverifythe

markeriscompletelydischargedofgas.

7. MovetheTriggerSafetytotheSafepositionandinstalltheBarrelSleeve.

Repairing Air/CO2 Cylinder Leaks

Themostcommonleakoccursfromabadair/CO2cylindervalveO-ring.ToreplaceavalveO-ringyou

mustrstremovethebadO-ringandtheninstallanewone.ThisO-ringislocatedonthetipofyourair/

CO2cylindervalve.ThebestvalveO-ringsaremadeofurethane.UrethaneO-ringsarenotaffectedby

highair/CO2pressures.ThesemaybepurchasedfromTippmann®oryourlocalpaintballdealer.

NOTE:Ifanewair/CO2cylindervalveO-ringdoesnotresolvealeak,donotattempttorepairtheair/

CO2cylinder.ContactTippmannSports,LLC,yourlocalpaintballdealer,ora“C5”CertiedAirsmith.

Cleaning and Maintenance

• Eyeprotectionmustbewornbytheuser.

• Toreducethechanceofanaccidentaldischarge,followtheUnloading Your Markerand

Air/CO2 Cylinder Removalinstructions.

• Donotdisassembleamarkerwhileitispressurizedwithair.

• Donotpressurizeapartiallyassembledmarker.

• Followwarningslistedontheair/CO2cylinderforhandlingandstorage.

• Familiarizeyourselfwithinstructionslistedonair/CO2cylinder.

• Contacttheair/CO2cylindermanufacturerwithanyquestions.

• Donotuseanypetroleumbasedcleaningsolvents.

• Donotuseanycleaningsolventsthatcomeinaerosolcans.

NOTE:Petroleumbasedproductsandaerosolproductscandamageyourmarker’sO-rings.

Tocleanyourpaintballmarkerexterior,useadamptoweltowipeoffpaint,oil,anddebris.

Tocleaninsidethebarrel:

1. RemovetheHopper.

2. CompletelyloosentheFeedElbowThumbNut(10)fromtheReceiverandremovetheFeed

Elbow(9)fromthemarker.

3. InsertthetabofthecleaningsqueegeeintotheFeedElbowopeningtothebarrelandpushthe

squeegeeintothebarreluntilthetabisaccessibleatthemuzzleendofthebarrel.

4. Pullthesqueegeethroughthebarreltoremovedebris.

5. Repeatifnecessary.

6. ReplacetheFeedElbowbackontothemarker.

7. TightentheFeedElbowThumbNuttosecuretheFeedElbowtothemarkerandreinstallthe

Hopper.

Tomaintainyourmarkeringoodworkingcondition,inspect,clean,andreplaceanydamagedparts.

LubricateasinstructedintheMarker Disassembly/Re-assemblysectionbelow.Thebestvalve

O-ringsaremadeofurethane.UrethaneO-ringsarenotaffectedbyhighgaspressures.Thesemay

bepurchasedfromTippmann®oryourlocalpaintballdealer.UseTippmann®oiltolightlylubricatethe

O-rings,springs,andotherareasindicatedinMarker Disassembly/Re-assemblyinstructions.This

maintainsyourmarkeringoodworkingcondition.

Storage

PuttheTriggerSafetyintheSafeposition.Unloadthemarkerandremovetheair/CO2cylinder.Putthe

boltintheforward(uncocked)position.Cleanandoilthemarkersothatitdoesnotrust.InstalltheBarrel

Sleeve,andstoreyourmarkerinadryarea.

Whenremovingyourmarkeroutofstorage,makesuretheTriggerSafetyisintheSafepositionandthe

BarrelSleeveisinstalled.Youshouldre-oiltherearboltO-ringandthefrontboltO-ringbeforeuse.

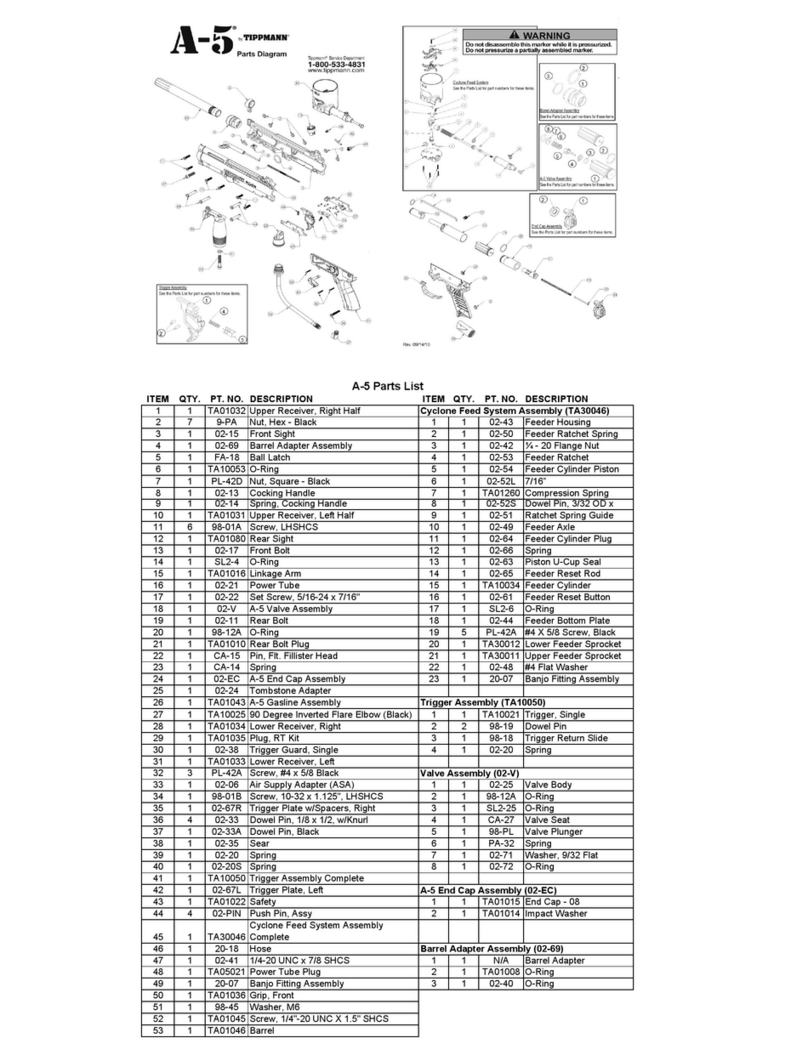

Marker Disassembly/Re-assembly

Alwaysweareyeprotectionwhenperforminganymarkerdisassemblyorre-assembly.RefertotheParts

Diagramfortheseinstructions(itemnumbersareinparentheses).Disassemblyinstructionsarelisted

here.Tore-assemble,justdothestepsinthereverseorder.

1. Pullthebolthandleback(seeFigure2)andkeepholdingontoit.Thenpullthetriggerandallowthe

bolthandletomoveslowlyforward.Thisuncocksthemarker.

2. ToremovetheBarrel(item54,seeFigure1),simplyunscrewtheBarrelfromtheReceiver,andto

reinstallit,justturnitclockwisetothreaditintotheReceiver.

3. ToremovetheLeft Grip(22)ortheRight Grip(18),removetwoScrews(14)fromeachgrip.

ReassemblebyusingtheScrewstofastentheGripstotheReceiver.

4. ToremovetheFeed Elbow(9)fromthereceiver,unscrewtheThumbnut(10)fromtherightside

ofthereceiver.TheC-Clip(16)keepstheThumbnutfromcomingloose

fromtheFeedElbow.TheFeedElbowhingesdownwardandthebottom

tabscomeoutoftheslotsintheRightReceiverHalf(1).TheScrew(11),

Flat Washer(17)andNut(12)areusedtoholdtheHopperintheFeed

Elbow.Replaceonlyifnecessary.Doallreassemblyinthereverseorder.

Cord Length

Retainer

WARNING

The brass or nickel plated cylinder valve (Figure 4, #1) is intended to be

permanently attached to the air/CO2 cylinder (2).

An air/CO2 cylinder can y off with enough force to cause serious injury or

death if the cylinder (2) unscrews from the cylinder valve (1).

Figure 4: Properly marked

Valve and Cylinder

12

34

Figure 5: Misaligned Valve and

Cylinder

3

4

Figure 6: The Feed Elbow.

16

10

9

11

17

12

WARNING

EXCEPT WHEN YOUR MARKER IS IN USE, ALWAYS MAKE SURE THAT THE

TRIGGER SAFETY IS IN THE SAFE POSITION,

(WHICH DISABLES THE TRIGGER) AND THAT THE

BARREL SLEEVE IS PROPERLY INSTALLED

(SEE BARREL SLEEVE INSTALLATION ABOVE).

TO LOCK THE TRIGGER (SAFE POSITION):

PUSH THE TRIGGER SAFETY IN FROM THE MARKER SIDE SHOWN ABOVE

TO THE SAFE POSITION.

TO UNLOCK THE TRIGGER (FIRE POSITION): PUSH THE TRIGGER SAFETY

FROM THE OPPOSITE SIDE OF THE MARKER TO ENABLE FIRING.

TIPPMANN®

2955AdamsCenterRoad,FortWayne,IN46803USA

P)260-749-6022•F)260-749-6619

www.tippmann.com

Figure 2: Pull the Bolt Handle back

until it locks into place.

Figure 3: Velocity Adjustment Screw

Location

Figure 1: Barrel and O-ring

Barrel Sleeve