©2019 CDI Meters, Inc. 10.19

Installing the Meter

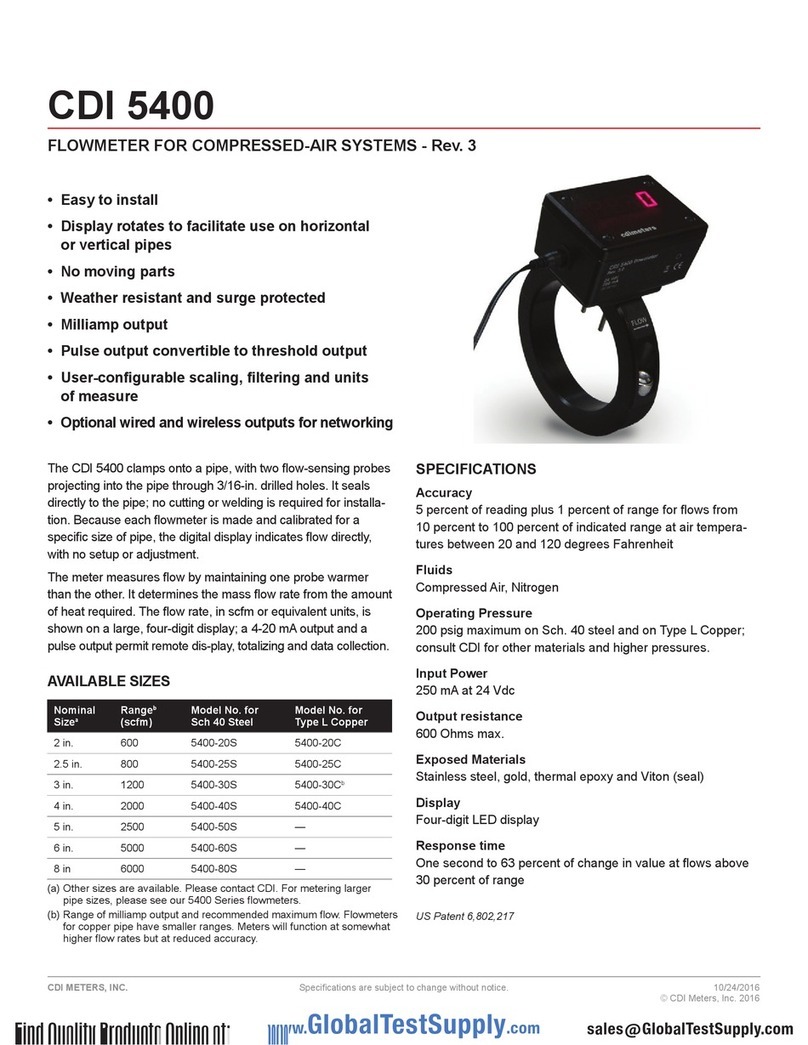

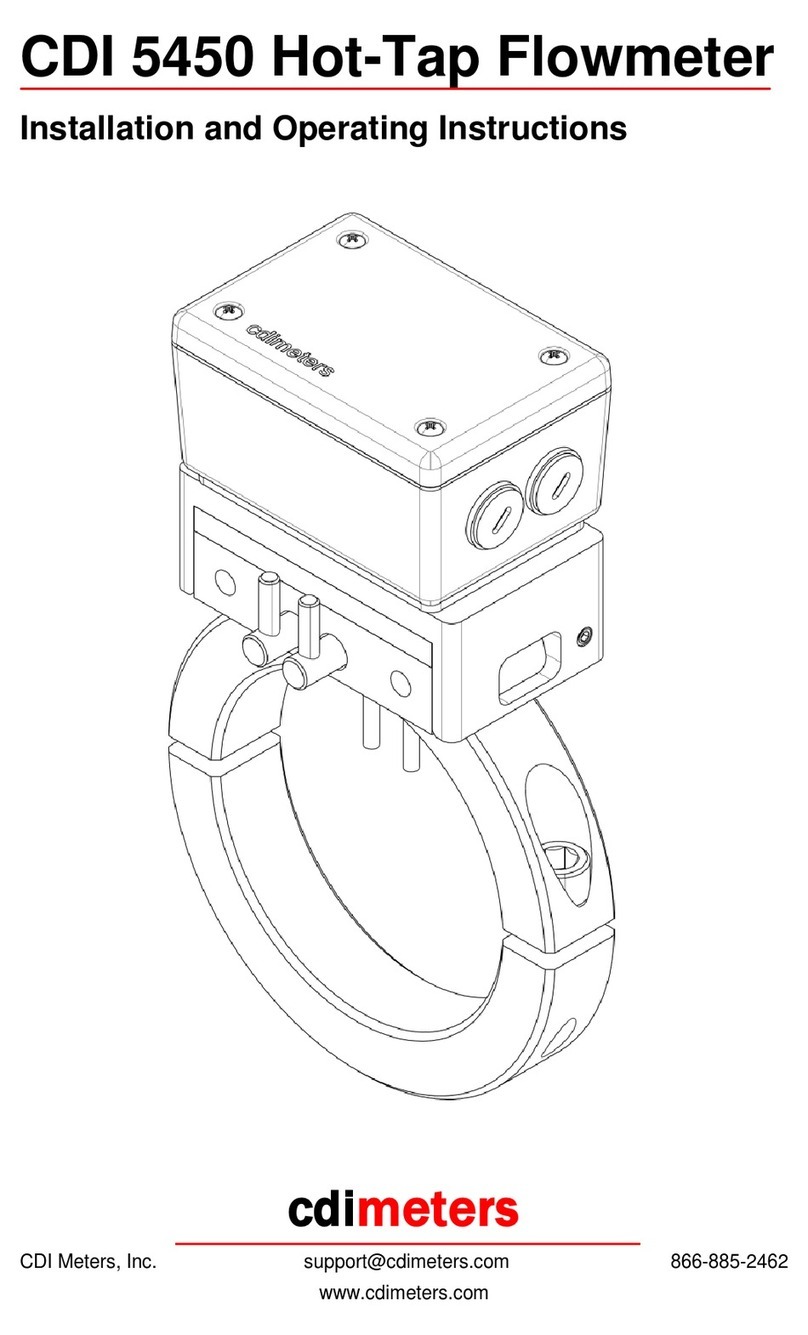

Make sure the probes are clean. If there is any oil or dirt on them, clean them

with alcohol or a similar degreaser. Insert the band clamps into the slots provided

for them and then insert the probes into the holes in the pipe, with the flow arrow

pointing in the proper direction. Engage and tighten the band clamps.

Wiring the Meter

The meter requires 24 Volt dc power. Insert the power-supply cable through the

grommet at the bottom of the meter. Connect the positive lead to the dc+

terminal, the negative lead to the dc- terminal and the shield, if one is present, to

the gnd terminal. If you are using the wall-plug supply and adaptor cable

provided by CDI, the band-marked lead (not the printed lead) is positive.

Programming the Monitoring Functions

The meter has four display modes: rate, minimum, average and total. The display

is controlled by a button on the underside of the meter. Pressing the button

repeatedly will cycle the display through the four modes; LEDs above the digital

display indicate which mode is active; when no LED is lit, the meter is in the rate

mode.

Minimum and Average Modes

The minimum and average functions look back over periods of time specified by

the user. Each is based on 360 samples taken over the specified period of time.

Minima and averages are calculated and stored for groups of 36 samples, so the

displayed results are updated at an interval of one tenth of the period specified

by the user. Thus, if the average is computed over 0.1 hour (six minutes), the

flow will be sampled every second and the display will update every 36 seconds.

Please note that, since the minimum and average are based on data stored in

memory, they will not be meaningful until the specified period has elapsed.

Total Mode

Cumulative air usage is displayed in thousands of cubic feet, or in cubic meters.

The total is not resettable.

Filter

A simple digital filter is provided for situations in which flow is continuously

varying and a steady, filtered display is useful. If the filter factor is programmed to

zero (see below) there is no filtering. If it is one, the current value is averaged in

equal parts with the previous filtered value. If it is two, one quarter of the present

value is added to three quarters of the previous filtered value, and so on, with

factors available up to six. Filtered values are used in calculating minima and