TLV SC-F70 User manual

Multicontroller

SC-F70SC-F70

Auto-Tuning PID

and

Heating, Cooling PID

Operating Instructions

Manufacturer

172-65281M-00

2

SC-F70SC-F70

PID Operation Operating Instructions

Table of Contents

Preface....................................................................................................... 4

For Your Safety ........................................................................................ 4

Checking the Model Code and Accessories ............................................ 5

1. Introduction and Installation ................................................................ 6

1.1 How to Use This Book ................................................................. 6

1.2 Setting Feature Jumpers ............................................................... 7

1.3 Attaching to the Panel .................................................................. 9

1.4 Wiring Procedure ........................................................................ 11

2. Using the Panel................................................................................... 17

2.1 Names and Functions on the Panel ............................................ 17

2.2 Guides for Using Keys ............................................................... 19

3. Operation ............................................................................................ 28

3.1 Setting Up the Basic Parameters ................................................ 28

3.2 Test Operation (LOC/MAN Mode) ........................................... 37

3.3 Automatic Operation (LOC/AUT Mode) .................................. 43

3.4 Area Switching Automatic Operation (LOC/AUT Mode) ........ 46

3.5 Compensation for Control Responsiveness ................................. 51

3.6 PID Constants Fine-Tuning Method ........................................... 52

3.7 PID Constants Setting and Control Operation ............................ 53

4. Remote Operation (REM/AUT Mode) .............................................. 55

4.1 Remote Analog Setting Operation ............................................. 55

4.2 Remote Area Switching Operation ............................................ 58

5. Using Other Functions ....................................................................... 62

5.1 Using Alarms. ............................................................................. 62

5.2 Using the Transmission Output.................................................. 65

5.3 Using the Communications Function......................................... 66

5.4 Using Other Convenient Features .............................................. 66

5.5 What Happens When Power Is Lost .......................................... 67

6. Summary of Parameter Groups and Areas ........................................ 68

6.1 Parameters ................................................................................... 68

6.2 Areas ........................................................................................... 81

7. Troubleshooting.................................................................................. 84

7.1 Problem Area .............................................................................. 84

7.2 Error Displayable Controller Problems ..................................... 89

7.3 No Error-Displayable Problems ................................................. 92

7.4 Actuator Control Problems......................................................... 95

7.5 Sensor Problems ......................................................................... 96

7.6 Area Switching External Contact Problems .............................. 99

7.7 External Analog Input Problems .............................................. 100

7.8 Communication Problems ........................................................ 101

3

SC-F70SC-F70

PID Operation Operating Instructions

7.9 Other Problems ......................................................................... 102

8. PID Constants Manual Tuning Method ........................................... 103

8.1 Step Response Method ............................................................. 103

8.2 Ultimate Sensitivity Method .................................................... 105

9. Specifications ................................................................................... 106

9.1 Display Functions ..................................................................... 106

9.2 Measurement Input ................................................................... 106

9.3 Settigns...................................................................................... 107

9.4 Control Operation ..................................................................... 108

9.5 Control Output .......................................................................... 108

9.6 Alarm Ouput ............................................................................. 110

9.7 Transmission Output................................................................. 111

9.8 External Contact Input.............................................................. 111

9.9 Communication Output ............................................................ 112

9.10 Self-Diagnostic Function........................................................ 114

9.11 General Specifications............................................................ 115

9.12 Environmental Conditions (Normal Operation) .................... 115

9.13 Shipping and Storage Conditions........................................... 116

10. Product Warranty.............................................................................. 117

4

SC-F70SC-F70

PID Operation Operating Instructions

Preface

Thank you for choosing the

SC-F70SC-F70

Multicontroller, a

multipurpose, multifunction, easy-to-use controller for your steam system.

About This Book

The multicontroller (hereafter, called the controller) can be used to

control various things, as listed here:

∑Auto-tuning PID operation and heating, cooling PID operation (These

operating instructions)

∑Pressure control

∑Temperature control

We have prepared a book containing operating instructions for each type

of use.

It is important that you use the correct book for your controller.

When the controller was shipped from our factory, the correct book should

have been packed according to your order, but please recheck it now. This

book contains instructions for using the controller for Auto-tuning PID

operation and heating, cooling PID operation.

This book provides, for both inexperienced users and experts, information

for installing and operating your controller, and troubleshooting problems.

It also contains product specifications and warranties.

For Your Safety

∑∑

∑∑

∑Safety mark

Every safety notice in this book is shown with a safety mark ( ).

Please read these notices carefully before proceeding.

Danger: Protecting electrical terminals

This product is designed and manufactured to be used mounted on an

instrument panel and the electrical terminals on the back side of the

controller are left exposed.

Therefore, the user must install a protective cover over the terminals to

prevent electrical shock to the user or damage to the multicontroller.

This book will be updated from time to time according to improvements made to

the product. But if you find a discrepancy between the descriptions in this book

and actual operation, and need help, contact TLV.

!

!

!

5

SC-F70SC-F70

PID Operation Operating Instructions

Checking the Model Code and Accessories

Check to make sure you received the correct model of controller and

features, and that the necessary accessories were enclosed.

1. Model code

The model code label is attached to the side of the controller case.

The label should read:

SC-F70-□*□□

ais one of the following numbers:

0: Auto-tuning PID operation

1: Heating, cooling PID operation

bshows the type of external contact:

N: No external contact feature

A: External analog input

D: External area switching contact input

cshows the communication type:

N: No communication feature

1: RS-232C

4: RS-422A

5: RS-485

2. Accessories

The controller package contains:

1. The controller

2. The Operating Instructions (this book)

3. A mounting hardware set (2 brackets)

4. The Operating Instructions for Communications (If the

communication feature is specified)

If the model code differs from your order, or accessories are missing

or damaged, please contact TLV immediately.

a b c

6

SC-F70SC-F70

PID Operation Operating Instructions

1. Introduction and Installation

This chapter describes how the controller should be set up, mounted, and

cabled.

1.1 How to Use This Book

This chart shows an overview of installation flow, with page numbers for

reference.

⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒

Setting feature jumpers

Attaching to the panel

Wiring

Setting up basic parameters

Running in test operation

Running in automatic mode

Running in remote mode

Using other functions

Troubleshooting

Checking model code and

accessories ∑Confirms that you received the correct model and

accessories (see page 5).

∑Customizes the controller with jumpers on a

controller board (see page 7).

∑Mounts the controller on a panel (see page 9).

∑Connects the cable to a control valve, sensor, and

other connectors (see page 11).

∑Turns power on and sets up the basic parameters

(see page 28).

∑Runs the controller in manual mode (see page 37).

∑Runs using areas and parameters in local,

automatic mode (see page 43).

∑Runs using external contacts in remote, automatic

mode (see page 55).

∑Runs using alarms, transmission output, or

communications (see page 62).

∑Resolves problems you may encounter (see page

84).

7

SC-F70SC-F70

PID Operation Operating Instructions

1.2 Setting Feature Jumpers

The following feature jumpers can be set to customize your controller.

∑To select measurement input type

∑To select analog input (used only with the analog input feature).

These jumpers are set at the factory to your order specifications.

If BOTH of the following conditions are met, there is NO need to check

the jumper setting. You can go to "1.3 Attaching to the Panel" directly.

1. The sensor to be used is a pressure transmitter MBS33M (from

Danfoss A/S), KH15 (from Nagano Instrument Corp.), or a

temperature sensor TR1 obtained from TLV.

2. Remote analog setting operation is not used.

Warning:

Do not try to use the controller without setting the jumpers correctly

according to your mode of operation. If you do, an unexpected

malfunction may arise.

Use these steps to set the jumpers

1. Make sure the controller is turned off.

2. Remove the controller body from its

case (see Figure 1).

1. While pushing the stopper tab 1

upward,

2. Pull the body by the frame of the

display panel 2 .

3. To identify the two groups of jumpers,

see Figure 2.

Warning:

To prevent damage, do NOT touch any metal parts on the boards

when you do the next step.

4. Using tweezers, remove and insert the jumpers at the appropriate

positions. Refer to Figure 2 for the jumper positions to select

Measurement Input and Analog Input.

Stopper

PARA

AREA

ENT

A.SEL

DISP

MODE

PV

SETAUTREMAT

AL1AL2AL3AL4

FAIL

SC-F70

[Figure 1]

!

!

2

1

8

SC-F70SC-F70

PID Operation Operating Instructions

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

Voltage Input

Current Input

Analog Input Selection Jumper

Measurement Input Selection Jumper

Voltage Input

(High)

MCU Board

1

2

3

4

5

6

Voltage Input (Low)

[Figure 2. Jumper Setting Guide]

5. Restore the body into the case, and make sure it latches firmly at the

stopper.

Current Input

RTD

Thermocouple

9

SC-F70SC-F70

PID Operation Operating Instructions

1.3 Attaching to the Panel

Warning: Do not install the multicontroller in the following conditions:

∑Where the ambient temperature is higher than 50˚C (122˚F) or

lower than 0˚C (32˚F).

∑Where the relative humidity is lower than 20% or higher than 80%.

∑Where corrosive gas is generated.

∑Where strong vibrations and the potential for shock exist.

∑Where there is flooding or splashing of oil.

∑Where there is excessive dust.

∑Where there is any inductive disturbance which adversely affects

electrical instruments.

Controller Dimensions and Panel Cut Sizes

These figures show the sizes of the controller and the panel cut

needed to fit the controller in millimeters (in inches).

!

96(3.780")

96(3.780")

91.8(3.614")

(106)(4.173")

30 (1.181") or more

25 (0.984") or more

100(3.937")

12(0.472")

91.8(3.614")

Panel Cut Sizes

92

+0.8

-0

92

+0.8

-0

(3.622)

+0.031"

-0"

(3.622)

+0.031"

-0"

10

SC-F70SC-F70

PID Operation Operating Instructions

Procedure for Attaching to the Panel

1. Referring to the previous figures, cut as many square holes in

the panel as are needed for the number of controllers to be

installed.

Note: The panel thickness must be between 1 to 10 mm ( 0.04

to 0.4 inch).

2. Mount the controller into the cut from the front of the panel.

3. Insert one of the brackets shipped with the controller into the

slot on the top of the controller (see Figure 1).

4. With a Phillips head screwdriver, tighten the screw from the

rear of the bracket (see Figure 2).

When a gap is no longer seen between the panel and the

controller tighten one more full turn.

Be careful not to tighten too much, because the controller

case becomes distorted when overly tightened.

5. Repeat steps 3 and 4 to insert the other bracket on the bottom

of the controller and fasten it in place.

[Figure 2]

!

[Figure 1]

Fastening Screw

Bracket Leg Insert

11

SC-F70SC-F70

PID Operation Operating Instructions

1.4 Wiring Procedure

Refer to the following "Wiring Precautions" and to "Terminal

Configuration" on page 14, to install the cabling.

Warning

Read the following precautions for selecting and wiring cables.

Improper wiring may cause unexpected, intermittent, or difficult-to-

analyze problems.

Wiring Precautions

1. For input and output signal wire (measurement input, analog input,

transmission output, and control output to the valve):

1.) Lay input and output cables as far as possible from power lines to

the controller or other equipment to avoid noise interference,

especially from inverter power lines as they are liable to produce

interference requiring countermeasures be taken on the inverter

side to suppress noise emission.

2.) Use an electrically isolated receiver when transmission outputs

are utilized. If the receiver is not an isolated type, the connection

must be made using an isolation amplifier.

3.) Use shielded cables for input and output signal cables.

4.) When using shielded cables, to prevent noise from being generated

due to floating capacity and the difference in grounding potential

between the cable core and shield, ground the shield as follows:

a. If the signal source is grounded, ground only the side closest

to the signal source.

b. If the signal source is not grounded, ground the controller side.

!

Signal source Controller

Controller

Signal source

12

SC-F70SC-F70

PID Operation Operating Instructions

2. For power lines

Wiring of the controller power source should be done so it will not

be affected by noise from power sources. When a source of noise is

nearby and the controller is affected by the noise, use a noise filter.

1.) Certain types of noise filter may not perform properly. Consider

the line voltage, filter frequency characteristics, and other things

before selecting a filter.

We recommend using the ZCB2203-11S filter, manufactured by

TDK.

2.) Be sure to mount noise filters on grounded panels, and use the

shortest cable possible between the noise filter output and

controller power terminal. A filter mounted on a longer cable may

be ineffective.

3.) When power cables and other cables for the controller are

adversely affected by noise, twist the power supply cables together.

The smaller the pitch, the greater effectiveness against noise.

4.) Do not install fuses, switches, or other such items on the cables

between the noise filter output and the controller power terminals,

because this may adversely affect filter performance.

3. For grounding

1.) Use only power cables that conform to local electrical codes.

To ground the controller, use cables with a nominal cross-

sectional area of 2.0 mm2(0.031 sq.in.) or more, use the same

contact point as the contact ground on the actuator, and ground in

the shortest possible distance.

2.) It will take about 3 seconds for the controller to prepare for

contact output when the power is turned on. When using the

controller to send a signal to an external interlock circuit or other

circuits, add a delay relay.

IN OUT

Noise filter

Make interval short

Make as short

as possible

Lead Wire

Controller power

source terminals

Lead Wire

Controller Power Source

13

SC-F70SC-F70

PID Operation Operating Instructions

4. Other Precautions

1) Use M3.5 crimp terminals with insulating sleeves.

2) Use a time-lag fuse rated for 250 V, 1 A, if you install an external

fuse.

3) Refer to this wire specification table when selecting cables.

Recommended Wire Specifications

Power line

Grounding wire

In, out signal

Wire Specifications

Type

Cabtyre

Cabtyre

2-wire or 3-wire

shielded

AWG*

16 or larger

14 or larger

18 or larger

Diameter (mm2)

1.25 or larger

2.00 or larger

0.75 or larger

Warning

Do not turn on power supply to the value with which this controller

will be used until instructed to do so in section 3.2 "Test Operation".

!

* American Wire Gage

14

SC-F70SC-F70

PID Operation Operating Instructions

Terminal Configuration and Wiring

The next diagram shows a minimum configuration and its wiring.

This is the simplest configuration in which basic operations can be

performed; using the pressure transmitter MBS33M (from Danfoss

A/S) or the temperature sensor TR1 and the control valve CV10 or

CV16 shipped with the controller from TLV. (Other possible

connections are shown on page16.)

a. An example for auto-tuning PID operation

[Figure 1. Minimum Configuration]

20

21

A

A

B

B

B

B

19

Current Input W/

Power Supply

Remove the cover

1

2

3

4

5

6

7

8

9

10

11

33

34

35

36

37

38

39

40

41

42

43

22

23

24

25

26

27

28

29

30

31

32

12

13

14

15

16

17

18

19

20

21

Power Terminals

Power

GND

POWER

AC100-240V

L

N

1

2

3

Sensor Terminals

Sensor Terminals

RTD

Control Output Terminals

Current output

Wiring Terminals

17

18

[MBS33M Pressure Transmitter]

10

11

2

3

1

Controller

Power

4-20mA

4-20mA+DC24V

[TR1 Temperature Sensor]

MeasurementInputTerminals

15

SC-F70SC-F70

PID Operation Operating Instructions

!

Warning

1. Do not use unused terminals as relay terminals.

2. There are temperature compensating elements at the bottom of

the terminal marked 21. Be careful not to damage these elements

when wiring cables.

b. An example for heating, cooling PID operation

[Figure 2. Minimum Configuration]

CurrentOutput

Power Terminals

Power

GND

POWER

AC100-240V

L

N

1

2

3

1

2

3

4

5

6

7

8

9

10

11

33

34

35

36

37

38

39

40

41

42

43

22

23

24

25

26

27

28

29

30

31

32

12

13

14

15

16

17

18

19

20

21

Heating Control

Output Terminals

CurrentOutput

Wiring Terminals

42

43

10

11

19

20

21

Cooling Control

Output Terminals

Heating Control Valve

Cooling Control Valve

Remove the

cover

Controller

Power

4-20mA

[Temperature Sensor]

Sensor Terminals

ABB

Measurement

Input Terminals

RTD

A

B

B

4-20mA

16

SC-F70SC-F70

PID Operation Operating Instructions

This figure shows all possible connections.

1

2

3

4

5

6

7

8

9

10

11

33

34

35

36

37

38

39

40

41

42

43

22

23

24

25

26

27

28

29

30

31

32

12

13

14

15

16

17

18

19

20

21

No.1 Transmission

Output Terminals

No.1 and 2 Alarm

Terminals

Power Terminals

Power

Relay contact

output

Communication Terminals

RS-422A RS-485 RS-232C

External Remote Input Terminals

Contact input Contact input and

analog input

Sensor Power

Source Terminals

Sensor power

source

Measurement Input Terminals

Current input with

power source

Current input

Voltage input

LOW Voltage input

HIGH

No.4 Alarm Terminals

or Cooling Control

Output (Relay)

Terminals

1

2

3

GND

L

N

POWER

AC100-240V

33

R

(A)

34

R

(B)

35

T

(A)

36

T

(B)

37SG

RS-422A

RD

35

T/R

(A)

36

T/R

(B)

37SG

RS-485

35

SD

36

37SG

RS-232C

12

13

14

15

16

Di1

COM

(-)

Di2

Di3

Di4

12

13

14

15

16

Di1

COM

(-)

0-5V,1-5V

0-10V,0-20mA

4-20mA

17

21

18

19

20

4

5

6

AL1

AL2

COM

NO

NO

38

39 4-20mA 17

18

4-20mA+DC24V 18

19

0-20mA

4-20mA 20

21

0-10mV

0-100mV

0-1V

20

21

18

19

0-5V

1-5V

0-10V 20

21

DC24V

Current output

Thermocouple RTD

20

21

19

20

21

A

B

B

Control Output

(Current) Terminals, or

Heating Control

Output (Current)

Terminals, or No.3

Transmission Output

Terminals

No.3 Alarm Terminals,

or Control Output (Relay)

Terminals, or Heating

Control Output (Relay)

Terminals

7

8

9

NO

NC

COM

Relay contact

output

Current output

10

11 4-20mA

40

41 NO

Relay contact

output

No.2 Transmission

Output Terminals or

Cooling Control Output

(Current) Terminals

4-20mA

42

43

Current output

[Figure 2. Full Configuration]

*When you use a

thermocouple or

an RTD for

measurement

input, the sensor

power source

becomes

unavailable.

17

SC-F70SC-F70

PID Operation Operating Instructions

2. Using the Panel

To run the controller, data must be entered into some areas and parameters in

advance. This chapter shows how to use the keys and how to read messages

displayed on the LEDs, and explains how to enter the necessary data.

2.1 Names and Functions on the Panel

PARAAREA

ENT

A.SELDISP

MODE

SFT AUT

PV

REM AT

AL1 AL2 AL3 AL4

FAIL

SC-F70

: LED Display

: Keys

1

5

4

2

1

8

76

2

3

3

4

5

18

SC-F70SC-F70

PID Operation Operating Instructions

LED Display

No.

1

2

3

4

5

Functions

∑Calls up and scrolls through operational displays

∑Selects an area number

∑Refers to or sets an area group

∑Refers to or sets a parameter group

∑Registers the new setting

∑Increments a setting value

∑Decrements a setting value

∑Changes operation modes

Keys

Name

Display key

Area Select key

Area key

Parameter key

Enter key

Up key

Down key

Mode key

No.

1

2

3

4

5

6

7

8

<

<

A.SEL

AREA

DISP

PARA

MODE

ENT

Functions

∑Shows measured values

∑Shows symbols while setting areas or parameters

∑Shows set values

∑Shows changed values while setting areas or parameters

∑Shows the status of the controller

∑

On during control when set values SoFT start through time

∑On during AUTo mode

∑On during REMote mode

∑Blinks during auto-tuning

∑On when a CPU FAILure is detected

∑On when an ALarm condition exists

∑Shows symbol code to indicate what is shown on

Set Value display

∑Shows status of deviation between set value (SV)

and measured value (PV)

∑On when PV is greater than SV

∑On when PV is less than SV

Name

Measured Value (PV)

Set Value (SV)

Indicator Lamp

SFT

AUT

REM

AT

FAIL

AL1

AL2

AL3

AL4

Symbol Display

Deviation Display

△

▽

19

SC-F70SC-F70

PID Operation Operating Instructions

2.2 Guide for Using keys

This section explains how to use keys to accomplish your specific tasks:

1) If you want to know the controller's target set value, soft start time, or

valve control output during normal controller operation, or you want

to end any of the following 2), 3), 4), or 5) key operations:

Go to " Key Operation Flow" on page 20.

2) If you want to select an area number for an operation:

Go to " Key Operation Flow" on page 22.

3) If you want to know or change the values set in a specific area:

Go to " Key Operation Flow" on page 23.

4) If you want to know or change the values set in a specific parameter:

Go to " Key Operation Flow" on page 24.

5) If you want to know or change the mode of operation:

Go to " Key Operation Flow" on page 25.

DISP

A.SEL

AREA

MODE

PARA

20

SC-F70SC-F70

PID Operation Operating Instructions

DISP

The value set for the soft start time is displayed for the

first 2 seconds; then the remaining hours for the soft start

is displayed.

<

<

This panel appears only when a soft start time has been

set. Ramp value is the transient target value in the

process of ramp operation.

The first digit indicates the area number.

DISP

DISP

DISP

DISP

In MAN mode, you can set a new value to control the valve.

DISP

DISP

®®

®®

®Key Operation Flow

At any time, pressing the key displays the following

controller values:

a. Auto-tuning PID operation

DISP

Note: When you press the key the first time in MAN mode, the current

control value is displayed.

Control output value

DISP

PARAAREA

ENT

A.SELDISP

MODE

測定値

目標値

PV

SC-F70

PARAAREA

ENT

A.SELDISP

MODE

測定値

ランプ値

PV

SC-F70

PARAAREA

ENT

A.SELDISP

MODE

測定値

ソフト時間

PV

SC-F70

PARAAREA

ENT

A.SELDISP

MODE

測定値

制御出力値

PV

SC-F70

PARAAREA

ENT

A.SELDISP

MODE

測定値

新制御出力値

PV

SC-F70

Other than

status

Measurement value

Target value

Measurement value

Ramp value

Measurement value

Soft time

Measurement value

Value control output Value control output

Measurement value

DISP

Other manuals for SC-F70

2

Table of contents

Other TLV Controllers manuals

Popular Controllers manuals by other brands

Müller

Müller MDR-057 Operating and assembly instructions

Siemens

Siemens SINAMICS V20 Inverter operating manual

HaiLin Controls

HaiLin Controls LAKEplus installation guide

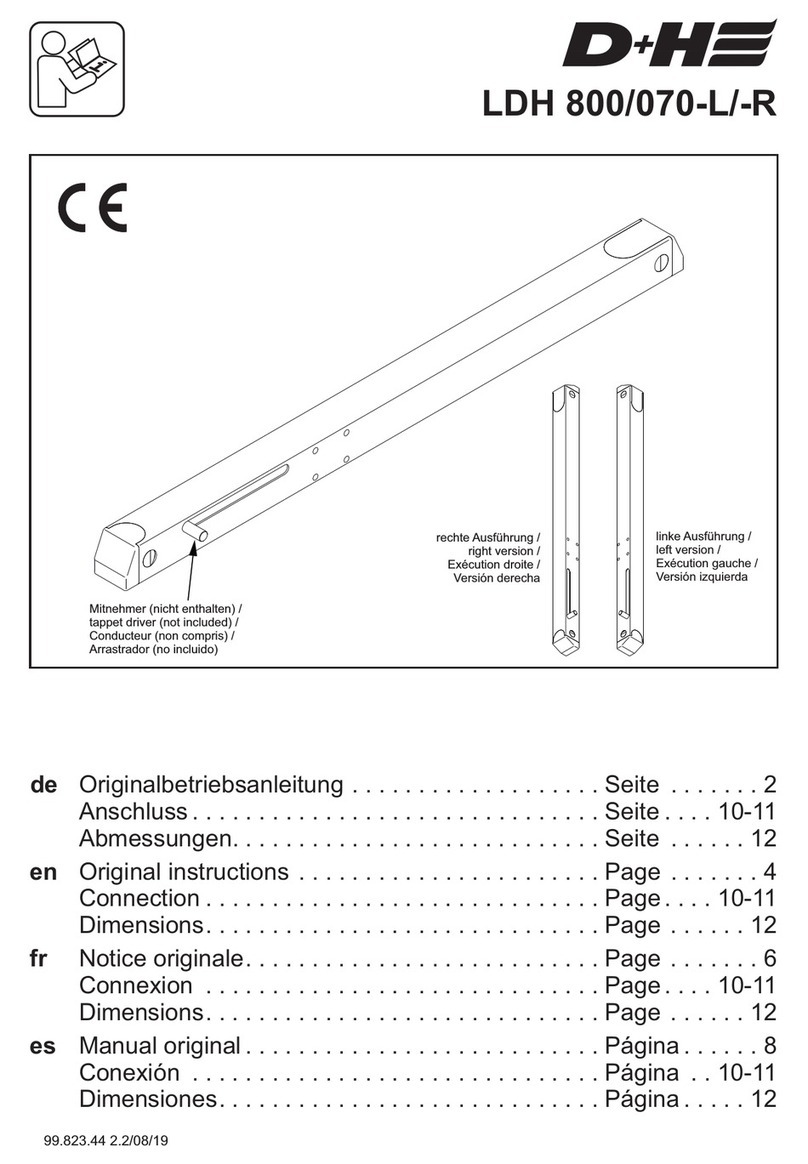

D+H

D+H LDH 800-L Original instructions

Manson Engineering Industrial

Manson Engineering Industrial PVC-7830 user manual

Swegon

Swegon DETECT IAQ a Instructions for use