Do not modify or alter the instrument

or any parts of the instrument.

●Failure to do so may cause serious

accident or malfunction.

Do not use accessories or parts

other than those specified by the

manufacturer.

●Failure to do so may cause serious

accident or malfunction.

Do not touch the power plug with a wet

hand.

●

It may cause a serious or deadly electrical

shock.

Do not use any damaged power cord,

plug or loose outlet.

●

It may cause an accidental fire, short

circuit or malfunction.

When leaving the instrument out of use

for a long period of time, be sure to

remove the power plug from the wall

outlet for safety.

●

Failure to do so may allow insulation to

deteriorate, thereby causing an electrical

shock, short circuit or fire.

Do not install the instrument in facilities

that store chemicals which could

generate flammable gases or fumes.

●

Electrical components can corrode and

may cause a short circuit, electrical shock

or fire.

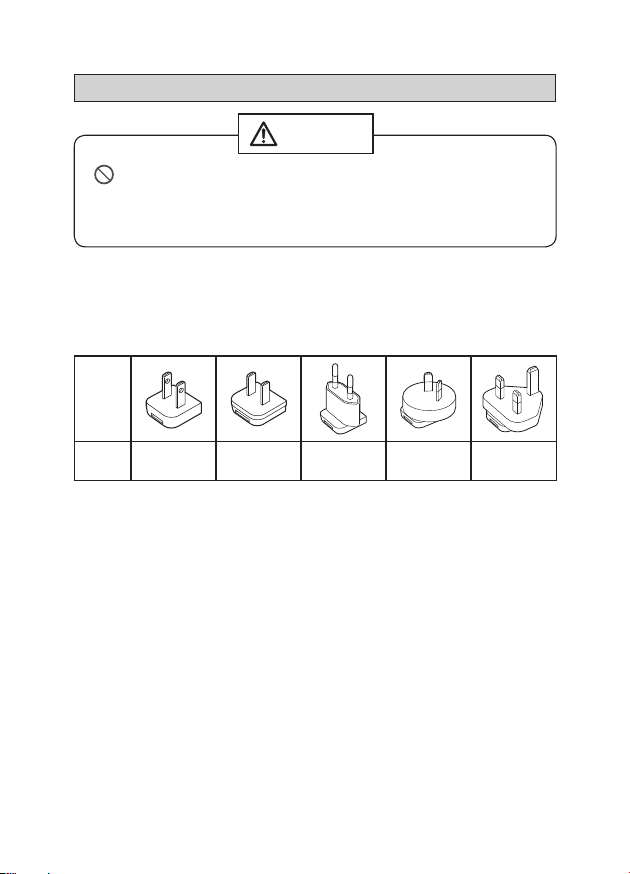

Be sure to use only the AC adapter that

comes provided with this product.

●

Failure to do so may cause a fire or

electrical shock.

Be sure to unplug the instrument before

performing maintenance procedures.

●

Failure to do so may cause a serious

electrical shock.

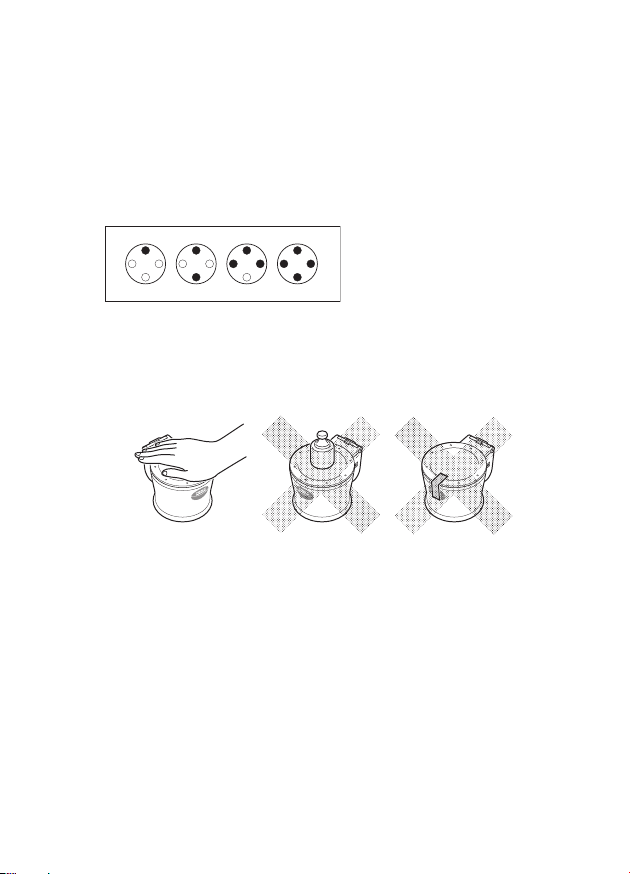

Do not use the instrument to centrifuge

explosive samples.

●

Failure to do so may cause fatal or

serious accidents. The instrument is not

an explosion-proof model.

Do not centrifuge explosive or flammable

materials or substances which could

react violently with one another.

Do not use the instrument to centrifuge

infectious samples.

●

Failure to do so may cause a serious hazard

to laboratory personnel. The instrument is

not a biohazard safety model.

If there is the need of handling any

potentially infectious or radioactive

samples, or other hazardous materials,

implement appropriate safety measures.

When returning the instrument or any

parts of the instrument for replacement or

repair, the instrument or the parts must be

appropriately decontaminated before

shipping it in any of the following cases:

1:In cases where the instrument or any

parts of the instrument has been

exposed to infectious and hazardous or

radioactive substances.

2:In cases where the instrument or any

parts of the instrument has any residue

of blood or other chemicals and has

been identified as hazardous.

When disposing or transferring the

instrumentor its parts, the instrument or the

parts must be appropriately decontaminated

before shipping it in any of the following cases:

1:In cases where the instrument or any

parts of the instrument has been

exposed to infectious and hazardous or

radioactive substances.

2:In cases where the instrument or any

parts of the instrument has any residue

of blood or other chemicals and has

been identified as hazardous.

1-2. Warnings and Cautions

3