TH8400 Series Operation Manual

Contents

Chapter 1 Overview......................................................................................................................3

1.1 Introduction..................................................................................................................3

1.2 Condition of Use..........................................................................................................3

1.3 Weight and Dimension.................................................................................................4

1.4 Safety Requirement......................................................................................................4

1.5 Electromagnetic Compatibility ....................................................................................5

Chapter 2 Panels...........................................................................................................................2

2.1 Introduction to front panel ...........................................................................................2

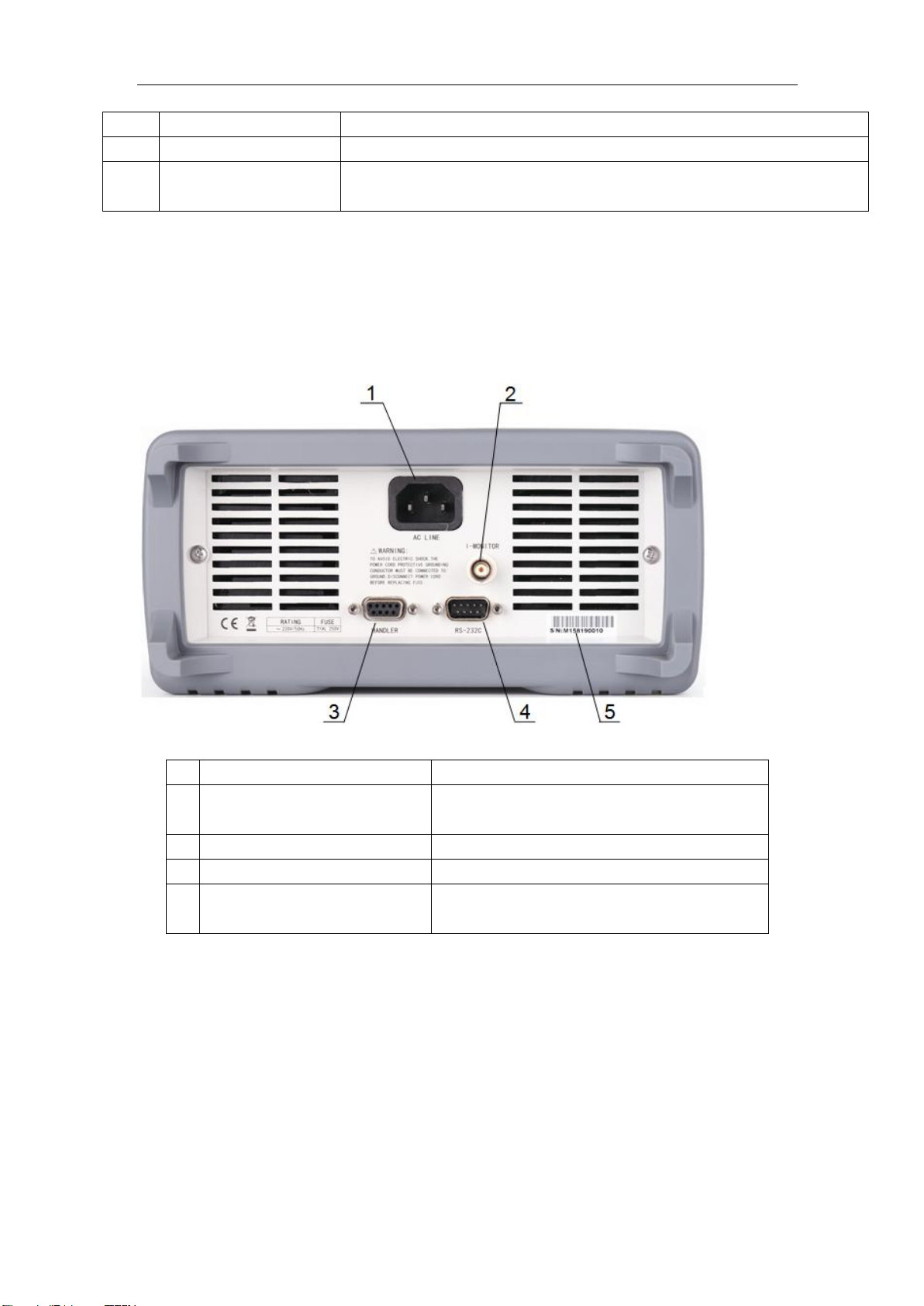

2.2 Introduction to rear panel.............................................................................................3

2.3 Introduction to display zone.........................................................................................3

2.4 Summary of the Displayed Page..................................................................................4

2.4.1 DISP (Function Display Page) .....................................................................4

2.4.2 SETUP (System Settings Page)....................................................................5

Chapter 3 Function Setting and Use.............................................................................................6

3.1 Static Mode (Static)......................................................................................................6

3.1.1 Constant Current(CC) ..................................................................................7

3.1.2 Constant Voltage(CV)..................................................................................7

3.1.3 Constant Resistance(CR)..............................................................................8

3.1.4 Constant Power(CP).....................................................................................8

3.2 Dynamic Mode (Dynamic) ..........................................................................................8

3.3 Sequential Operation (List)..........................................................................................9

3.4 CR-LED .....................................................................................................................10

3.5 Battery Test (Battery).................................................................................................11

3.6 Time Test(Timing)......................................................................................................12

3.7 Overcurrent Protection Test(OCPT)...........................................................................13

3.8 Over Voltage Protection Test(OVPT).........................................................................14

3.9 OPPT..........................................................................................................................15

3.10 Load Effect.................................................................................................................15

3.11 Sweep.........................................................................................................................17

3.12 Automatic Test (AUTO).............................................................................................18

Chapter 4 System Setup..............................................................................................................20

4.1 SYSTEM Setup (System) ..........................................................................................20

4.1.1 Language....................................................................................................20

4.1.2 Key Sound..................................................................................................20

4.1.3 Remote Compensation...............................................................................20

4.1.4 Start-up Parameters ....................................................................................21

4.1.5 Display Mode.............................................................................................21

4.1.6 Source under Test.......................................................................................22

4.1.7 External Analog..........................................................................................22

4.2 Load Unload (Von/Voff).............................................................................................22

4.3 Security Setting (Protect)...........................................................................................23

4.4 File Store....................................................................................................................24