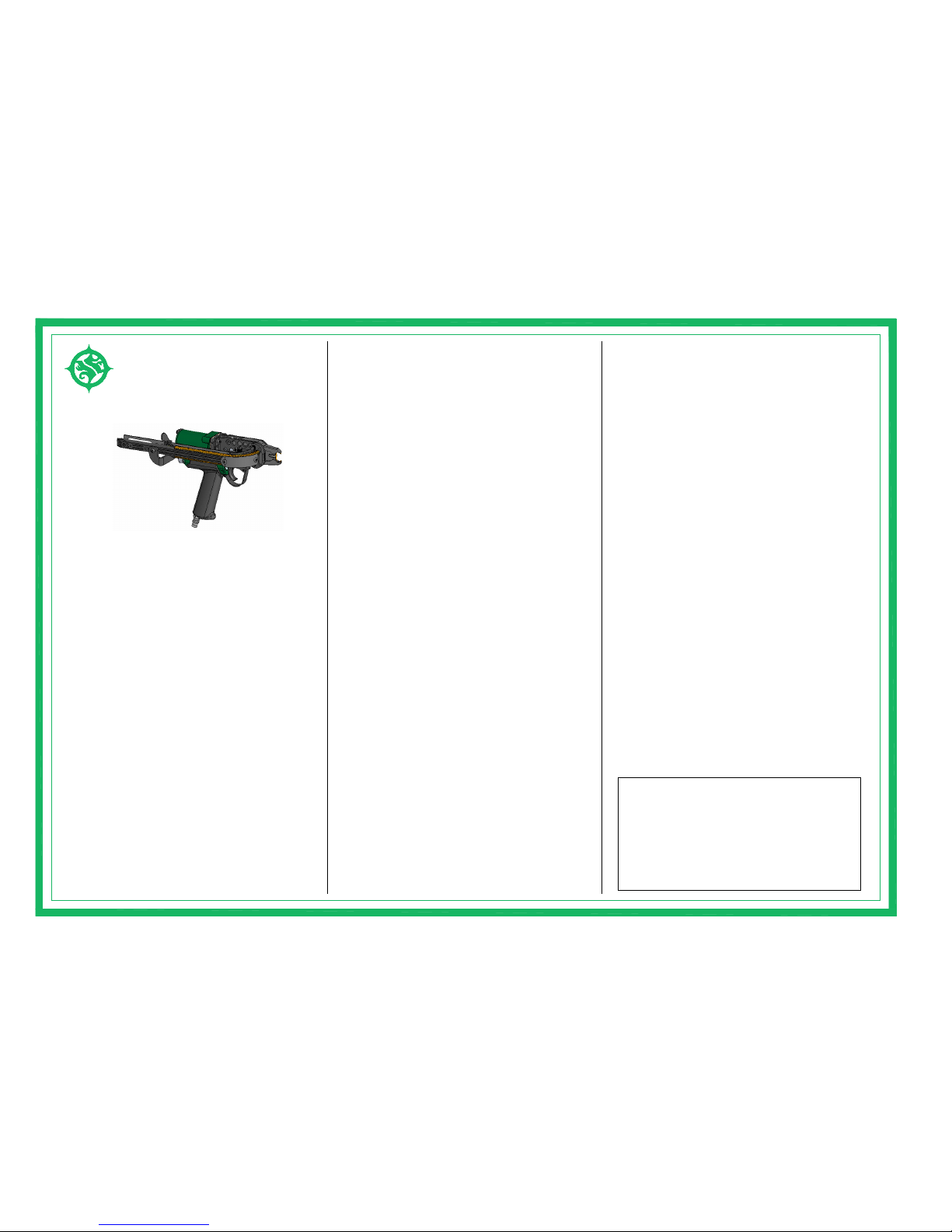

Toolex 594102 User manual

INSTRUCTION MANUAL

594102

AIR HOG RING STAPLER

1

1

2

1

47,48,49

Assembly

NO.202 NO.203 NO.200

NO.201

NO.205

Pusher Assembly

68,69

12,29,30,31,32,47,48,49,89

Assembly Frame Assembly

20,35R,35L,36,37,86 23,27,28

Housing Assembly

39 Socket Head Cap Screw AC01039 4

80 Guard

83 Screw

82 Clip Anti-Backup

86 Plate Screw

89 Flexloc Nut

204 Feeder Guid Rail

78A Magazine Shim

79 Washer

81 Guard Screw

67 Nut

70 Pusher Spring

74 Jaw Bolt

71 Button Head Screw

75 Magazine Spring

73 Magazine Body

78 Magazine Shim

77 Roll Pin

76 Magazine Shoe

64 Socket Head Cap Screw

68 Pusher

69 Extruded Rivet

59 Inlet Bushing

AC0178A

AC02082

1

AC02083

1

AC01089 3

AC01086

1

AC02080

AC02081

1

AC01079

2

AC02204

AC01059

1

AC02068

1

AC01069

1

AC02073

AC02074

2

AC02077

1

AC01078

1

AC02076

1

AC02075

2

AC01071

1

AC01070

1

AC01064

1

AC01067

1

57 Nut

47 Feeder Blade

49 Roller Pin

48 Piston Rod

56 Washer

51 Feeder Arm

58 Screw

50 Lower Jaw

45 Latch

41 Jaw Bushing

43 Latch Pin Clip

44 Latch Spring

46 Roller

40 Upper Jaw

AC02048

AC04050

AC03050

AC02050

1

1

AC01056 2

AC01057 4

AC01058 2

AC01051 1

AC03048

1AC03048

AC01049

AC03047

AC03047 1

AC02

AC02

AC03

AC04

AC03

AC04

AC04

AC03

1

AC02047

AC02046

AC01046

4

AC01046

AC03045

AC03045 1

AC04040

AC01041

1

AC01045

1

AC01043

AC01044

2

AC03040

AC02040

AC02

AC04

AC03

AC02

AC04

AC03

AC02

AC04

AC03

AC02

1

AC01007

7 Throttle Spring

23 Stud

30 Piston

28 Set Screw

29 O-Ring

31 Cylinder Gasket

27 Housing

35L Side Plate (Left)

35R Side Plate (Right)

37 Trigger

36 Roll Pin

32 Piston Stop Spacer

11 O-Ring Support

12 O-Ring

17 Throttle Stem

16 Front Valve Seat

10 Valve Screw Washer

20 Trigger Guard

21 Flexloc Nut

18 Button Head Cap Screw

8 Throttle Spring Locator

9 Throttle Valve Screw

13 O-Ring Center Support

14 Throttle Valve Spacer

2

AC01023

AC01028

AC01032

AC01032

AC02032

1

AC01036 3

AC01037 1

AC0135R

AC0135L

1

1

2

1

1

1

AC01029

AC01030

AC01031

1AC01027

AC04

AC03

AC02

1AC01008

4

1

5

2

1

1

1

2

2

AC01011

AC01014

AC01012

AC01013

AC01018

AC01017

AC01016

AC01009

AC01010

1

2

AC01020

AC01021

ITEM DESCRIPTION

1 Set Screw

5 Rear Valve Seat

4 Air Deflector

3 Shakeproof lock Washer

6 O-Ring

NO.

TOOL

7

1

1

1

PART

AC01003

NUMBER

AC01001

AC01005

AC01004

2AC01006

Q'TY

NO.206

73,75,76,77,80,81,82,83

Magazine Assembly

AC02 & AC03 & AC04

clearance; then, after tightening the Cap Screws (#74 x 2 pcs),

Remove Cap Screws (#18 & #39 x 4 pcs) and Frame Assy. (203)

which to do it .Obviously, the less the tool is abused, the better.The

to remove Valve units. One Valve will stay on Spacer (#14) and can

complete Valve Assembly (should then have free motion of about

second Valve mounted on Screw (#9) in from other side and

Assemble one Valve on Spacer (#14). Holding Allen wrench, bring

#16). Using two Allen wrenches, unscrew Throttle Valve Screw (#9)

Loosen Set Screws (#28) and remove Adjustable Valve Seats (#5 &

Rollers (#46 x 4 pcs) can be taken out the front end of the Frame.

Spacer (#32). Piston Rod Assembly with Feeder Blade (#47) and

from Cylinder Housing. After taking off Piston(#30) and Piston Stop

the operating speed of the tool and may cause damage to it.

using 1/4" (6.35mm) ID air hose. Higher pressures will not increase

Air pressure should be maintained at 85-96 PSI (5.98-6.68 kg/cm2)

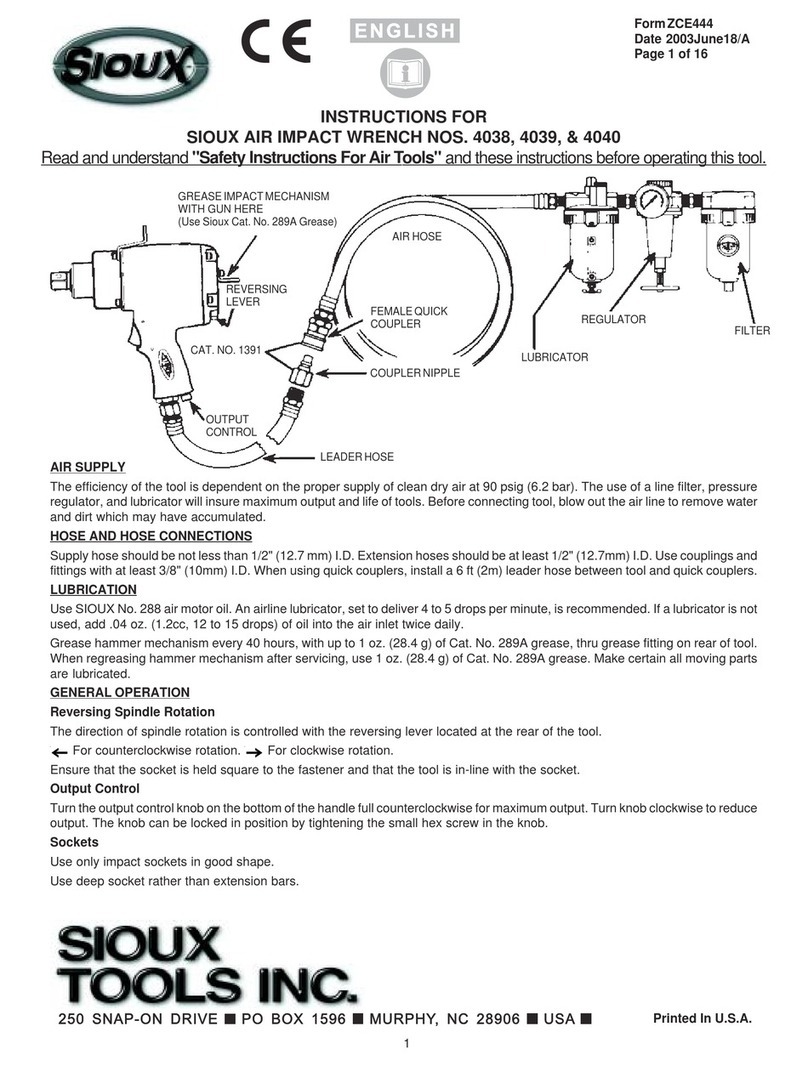

AIR PRESSURE

tool for a long and useful work life.

Please take care in handling, operation and maintenance of your

matter that is inside the tool will reduce its Operational efficiency.

cycling completely. Obviously, moisture, dirt or any other foreign

check to make sure that the application is correct and that the tool is

fastener. If for any reason you are not getting complete closure,

also note that the tool should make a complete closure of the

Far when you use it in the direction of your application. Please

tool should be handled firmly in your hand and don't stretch too

TO ASSEMBLE

1/16").

be disassembled after removal from Housing.

THROTTLE

PRECAUTIONS MAY RESULT IN SERIOUS

MAY RESULT. FAILURETO FOLLOW THESE

AWAY FROM ALL MOVING PARTS. INJURY

THE FRONT OF JAWS OF THE TOOL AND

KEEP HANDS AND CLOTHING AWAY FROM

DO NOT POINT THE TOOL AT ANY PERSON.

INJURY.

clearance should be rechecked.

promptly from stock. PLEASE SEE C-RING STYLES CHART

and #50). Remove Magazine Assembly(#73) and Feeder Guide Rail

Remove Flexlock Nuts(21) and Jaw Bolts (#74).Take out Jaws(#40

request. Use only parts that are specifically fabricated for the AC

replacement parts for repairs. Parts price lists are available upon

and have it checked for proper operation. ANN-CHAIN will ship

If any tool is not operating properly, remove it from service at once

for further details regarding materials, points and size of C-RING.

These rings are available from ANN-CHAIN and will be shipped

oiled, periodic oiling in small amounts may increase the serviceable

Although the jaws and other moving parts of the tool do need to be

A good grade of oil that emulsifies in water is recommended for air

Lubricators and Filter Units for proper lubrication and clean, dry air.

To insure long, trouble-free service, we recommend Air Line

moisture in the air line will adversely affect the smooth operation

sufficient to provide a constant and even flow of clean, dry air. The

The air line should have an attached air line filter and regulator

filter should be installed as close as possible to the tool. Dirt or

PNEUMATIC CLIP RING TOOL AC02, AC03,AC04

to take a long, hard look at your work and choose the best way in

a variety of other things. The most important point to remember is

a group of wire, the tool is frequently used as a pusher puller and/or

into foam, it should be cleaned occasionally. Also, when"grabbing"

area of maintenance to be conscious of is when pushing the tool

this is like any other tool and should be properly maintained. One

It should be kept in mind that in using the air powered clip ring tool,

in most operations the tool is used 90 degrees to the work performed.

The air powered clip ring tool should be held firmly in the hand and

OPERATION

and shorten its useful life.

proper operational precautions may result in damage to your tool

is of high quality and made to exacting standards, failure to follow

pressures above 100 PSI (7.03 kg/c

dirt and other foreign matter and do not operate the tool at air

working order, do not drop the tool, keep the mechanism free from

For best operating results and long life, maintain the tool in good

OPERATING INSTRUCTIONS & PARTS LIST

). Although your clip ring tool

Feeder Blade, Rollers and Piston Rod

Jaws, Magazine, Feeder Guide Rail

TO DISASSEMBLE

model tool which you own.

(#204).

REPAIR AND SERVICE PARTS

C-RINGS

TEL: 886-4-7521297 FAX: 886-4-7521293

CHANG HUA CITY, TAIWAN, R.O.C.

NO.65-5, LANE 540, YOAN-FONG RD.,

ANN-CHAIN ENTERPRISE CO., LTD.

LUBRICATION

life of the tool that receives heavy use.

MANUAL OILING

tools.

of the tool and decrease its serviceable life.

AIR FILTER AND REGULATOR

Spacer (#32), Piston (#30) and Flexloc Stop Nut (#21). Insert

Magazine must be held tight against Side Plate while checking this

clearance between Magazine Shoe (#76) and Feeder Blade (47).

between Magazine (#73) and Side Plate (#35R) to produce a

Before tightening Cap Screws (#74), insert enough Shims (#78)

ADJUSTMENT OF MAGAZINE

(#41 x 2 pcs) into Jaws (#40 & #50), side jaws into place and

Assembly Latch(#45) and Latch Pin Clip (#43).Insert Jaw Bushings

(#64) tight. Continue turning to desired Pusher Spring tension and

Pusher spring (#70), slide into Bracket and insert lower Cap Screw

With Feeder Arm (#51) in place, assemble Feeder Guide Rail(#204).

Throttle Stem (#17) and then assemble Frame to Housing.

MAGAZINE

complete assembly.

FEEDER GUIDE RAIL

lock with Nut (#67).

2pcs) and Rollers (#46 x 4 pcs). Put in Frame. Mount Piston Stop

Onto Piston Rod (#48) mount Feeder blade (#47), Roller Pins(#49 x

FEEDER BLADE, ROLLERS, PISTON ROD

Piston (#30) and Piston O-Ring (#29).

off Adjustable Valve Seat until leak stops. If leaks do not stop, check

be raised from its Bushing Seat, causing air leakage. To correct back

If an Adjustable Valve Seat is turned too far, the opposite Valve will

TO LOCATE AND CORRECT AIR LEAKS

Handle. After finer adjustment, lock Valve Seats in place with Set

Front Valve Seat (#16), turning until air stops exhausting through

leaking through Valve. Using Throttle Stem (#17) to turn, install

front Valve closed with a 3/8" dia. turn Valve Seat in until air stops

Adjustable Valve Seat (#5). With air partly turned on and holding

With Throttle Spring Locator (#7 & #8) in place, partially screw in

THROTTLE VALVE ADJUSTMENT

Screws (#28) in Housing casing.

Table of contents

Other Toolex Power Tools manuals

Popular Power Tools manuals by other brands

ABB

ABB T&B Tools TBM12PCR-LI operating instructions

Parkside

Parkside PES 200 B1 Operation and safety notes

Metabo HPT

Metabo HPT WR 18DBDL2 Safety instructions and instruction manual

DeWalt

DeWalt XR DCH614X2 Original instructions

DeWalt

DeWalt DCF503E Original instructions

Craftsman

Craftsman 875.199320 owner's manual