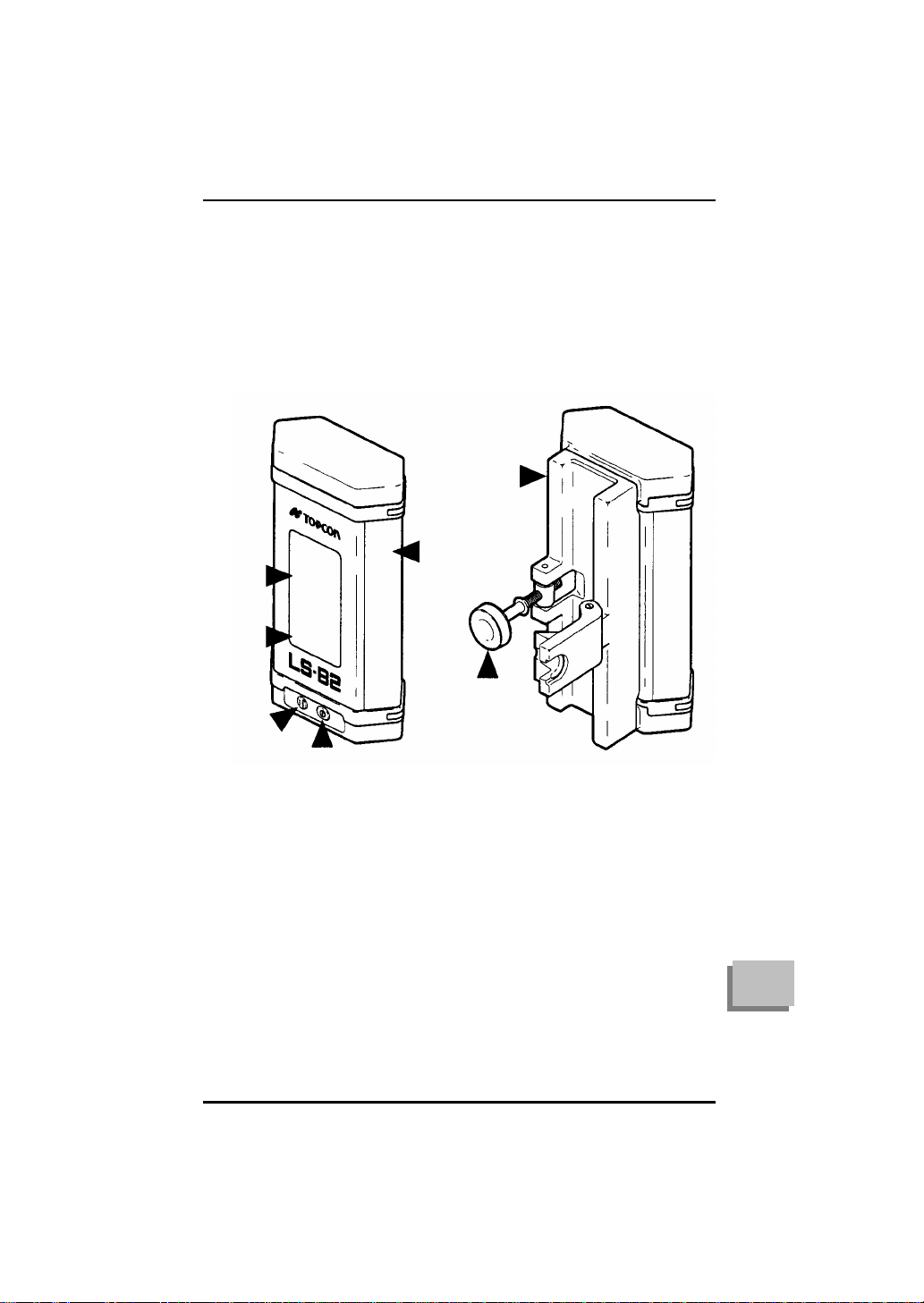

Nomenclature

LS-B2 Operator’s Manual

2

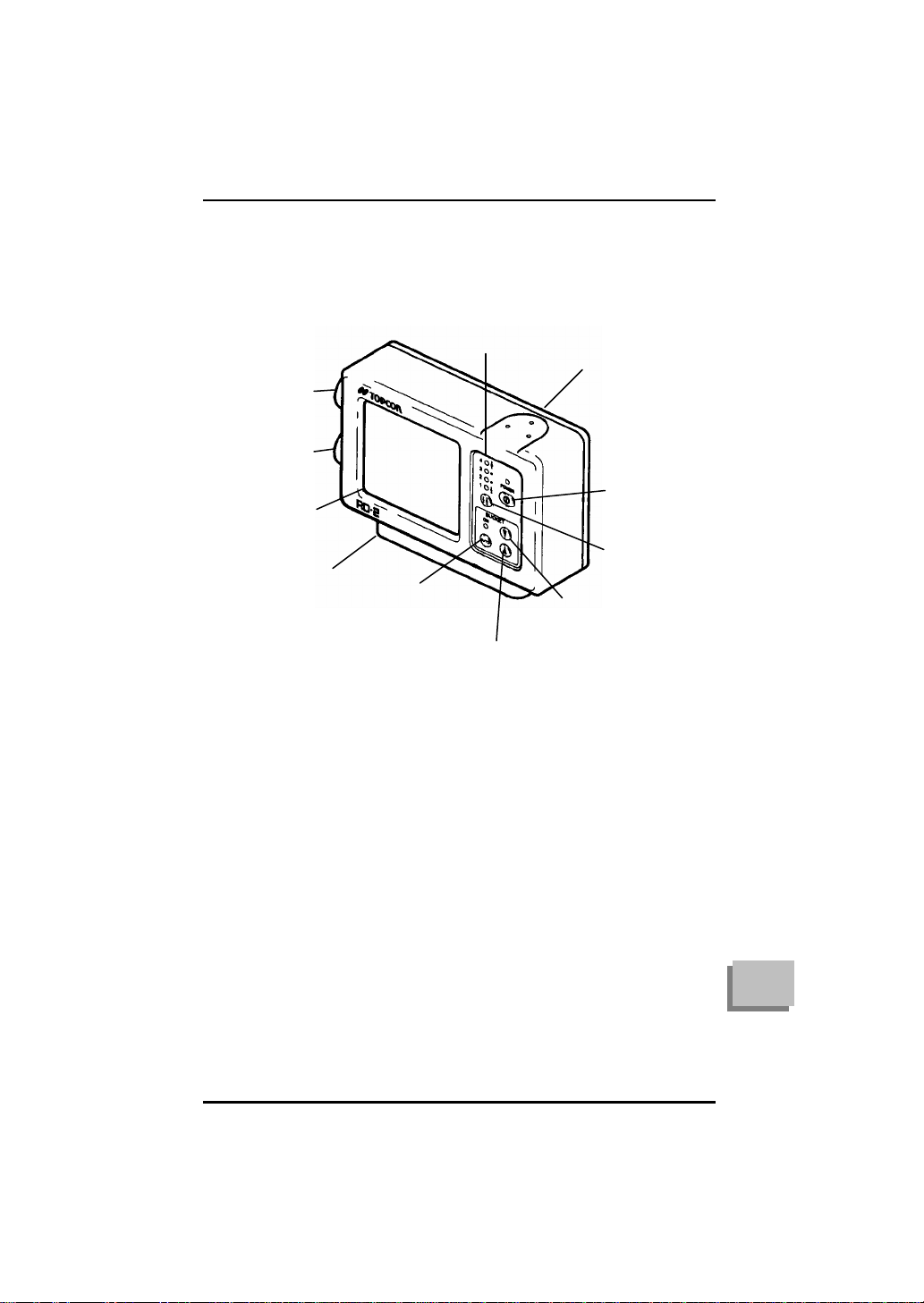

S-B2 Laser Sensor

Introduction

Thank you very much for purchasing this product from Topcon. In

order for it to serve you long and well, we ask that you read and

carefully follow the instructions contained in this manual. If you

have any questions, please contact your local authorized Topcon

dealer for assistance.

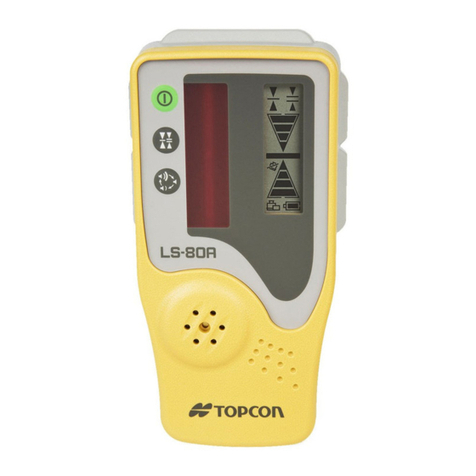

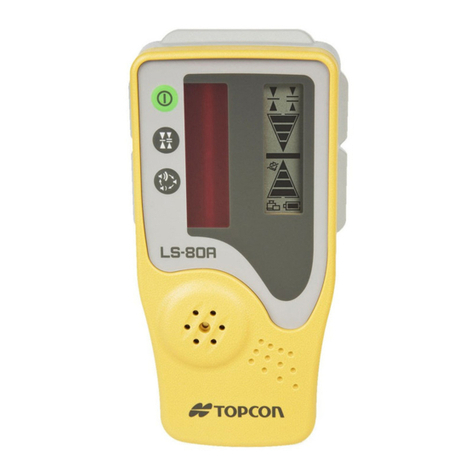

Topcon’s LS-B2 is a machine mounted laser sensor. Used in

conjunction with a rotating laser elevation reference, the LS-B2

helps operators get to grade quickly and accurately.

In manual control, the LS-B2 senses the position of a rotating laser

reference and flashes a clearly visible raise, lower, or on-grade

signal to the operator. The operator then corrects the position of the

cutting edge according to the signal. In automatic control, the LS-

B2 sends the signals directly to the machine’s hydraulics which

make the correction automatically.

The LS-B2 transfers easily from machine to machine and offers the

choice of on-board batteries or machine battery powered operation.

The LS-B2 has a unique infrared communication option called the

IR-2. The IR-2 receives an infrared signal from the LS-B2 and

transfers that signal to the RD-2 remote display mounted in the cab.

Used with the on-board battery pack, the infrared option removes

the need for cables between the LS-B2 and RD-2. This is an

advantage where routing cables from the sensor to the cab or from

the sensor to the battery is difficult and prone to accident.