6

Table of contents

Masthead ........................................................................................................................................................................................5

Table of contents.............................................................................................................................................................................6

Safety alerts, visual presentation, and layout..................................................................................................................................8

1. Safety instructions.......................................................................................................................................................................9

General safety instructions.....................................................................................................................................................9

General electrical safety instructions .....................................................................................................................................9

General behaviour when handling the product.......................................................................................................................9

Intended use ..........................................................................................................................................................................9

Persons authorized to use the product ................................................................................................................................10

Foreseeable misuse.............................................................................................................................................................10

Referenced documents........................................................................................................................................................10

Prohibition of certain activities..............................................................................................................................................10

Painting plastic components and seals................................................................................................................................10

Safety markings on the product .........................................................................................................................................10

Notes on the type plate ......................................................................................................................................................11

Note on Low Voltage Directive...........................................................................................................................................11

Note on Pressure Equipment Directive ..............................................................................................................................11

Notes related to the TüV approval mark ............................................................................................................................11

Notes on CE marking.........................................................................................................................................................11

Notes related to the UKCA marking ...................................................................................................................................12

Note on EAC marking ........................................................................................................................................................12

Note on China RoHS mark.................................................................................................................................................12

Emergency shutdown ........................................................................................................................................................12

Assembly, maintenance, fault, repair .................................................................................................................................12

First start-up, daily start-up ................................................................................................................................................12

Residual risks.....................................................................................................................................................................13

2. Lubricants .................................................................................................................................................................................14

General information .............................................................................................................................................................14

Material compatibility ...........................................................................................................................................................14

Temperature properties .......................................................................................................................................................14

Aging of lubricants ...............................................................................................................................................................14

Avoidance of faults and hazards ..........................................................................................................................................14

Solid lubricants.....................................................................................................................................................................15

3. General description...................................................................................................................................................................16

Maxilube pumping centre.....................................................................................................................................................16

SKF Maxilube changeover valve unit...................................................................................................................................17

4. Operation ..................................................................................................................................................................................18

Operation of the pumping centre..........................................................................................................................................18

Commissioning ....................................................................................................................................................................18

4.2.1 Connections...............................................................................................................................................................19

4.2.2 Commissioning with Maxilube ECOlid set and MPB pump ........................................................................................20

4.2.3 Commissioning with Maxilube STAlid set and MPB pump.........................................................................................22

Replacing the lubricant barrel ..............................................................................................................................................23

4.3.1 Maxilube ECO with lid set and MPB pump ................................................................................................................23

4.3.2 Maxilube STA with lid set and MPB pump .................................................................................................................24

Manual operation .................................................................................................................................................................25

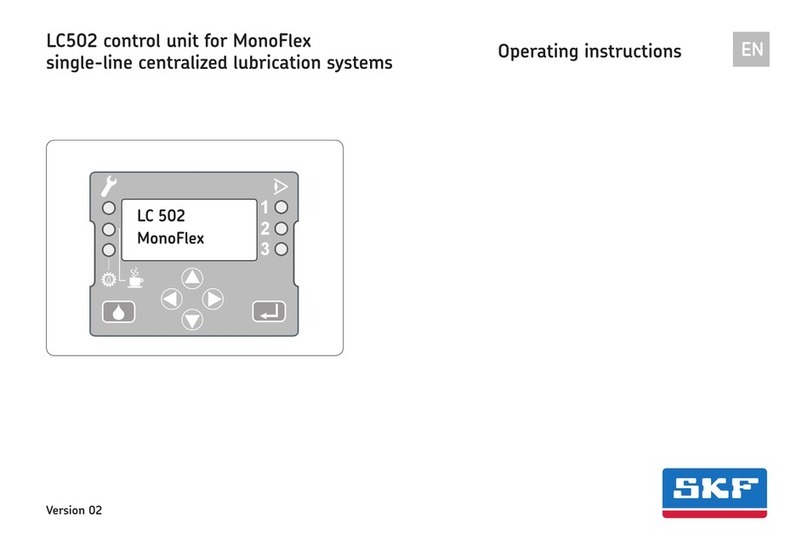

5. IF-105 user interface .................................................................................................................................................................26

General description..............................................................................................................................................................26

Main components.................................................................................................................................................................26

Channel LEDs......................................................................................................................................................................27

Function LEDs .....................................................................................................................................................................27

Buttons.................................................................................................................................................................................28

Display .................................................................................................................................................................................28

Operation of IF-105..............................................................................................................................................................29

5.7.1 Normal mode .............................................................................................................................................................29

5.7.2 Phase codes for normal mode and alarm mode ........................................................................................................30

5.7.3 Normal mode displays, single and dual line lubrication systems ...............................................................................31

5.7.4 Normal mode displays, progressive lubrication system .............................................................................................32