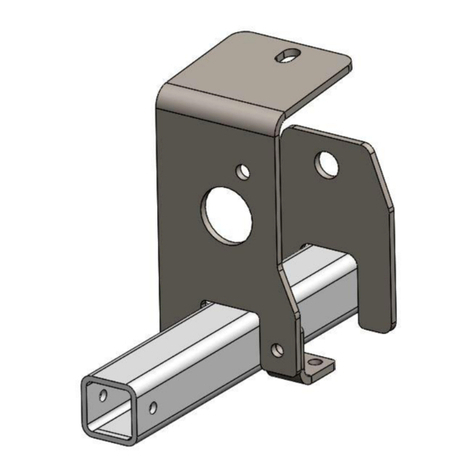

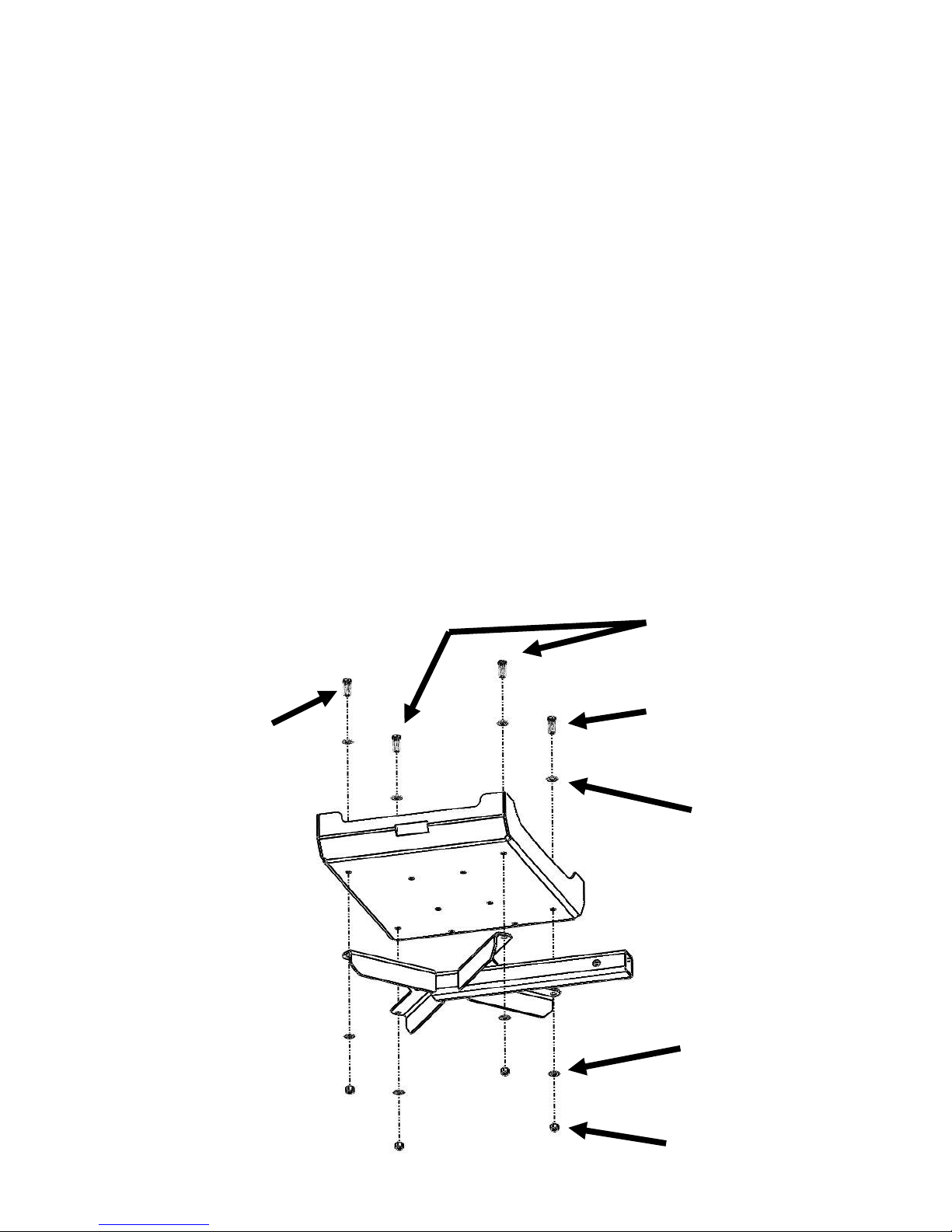

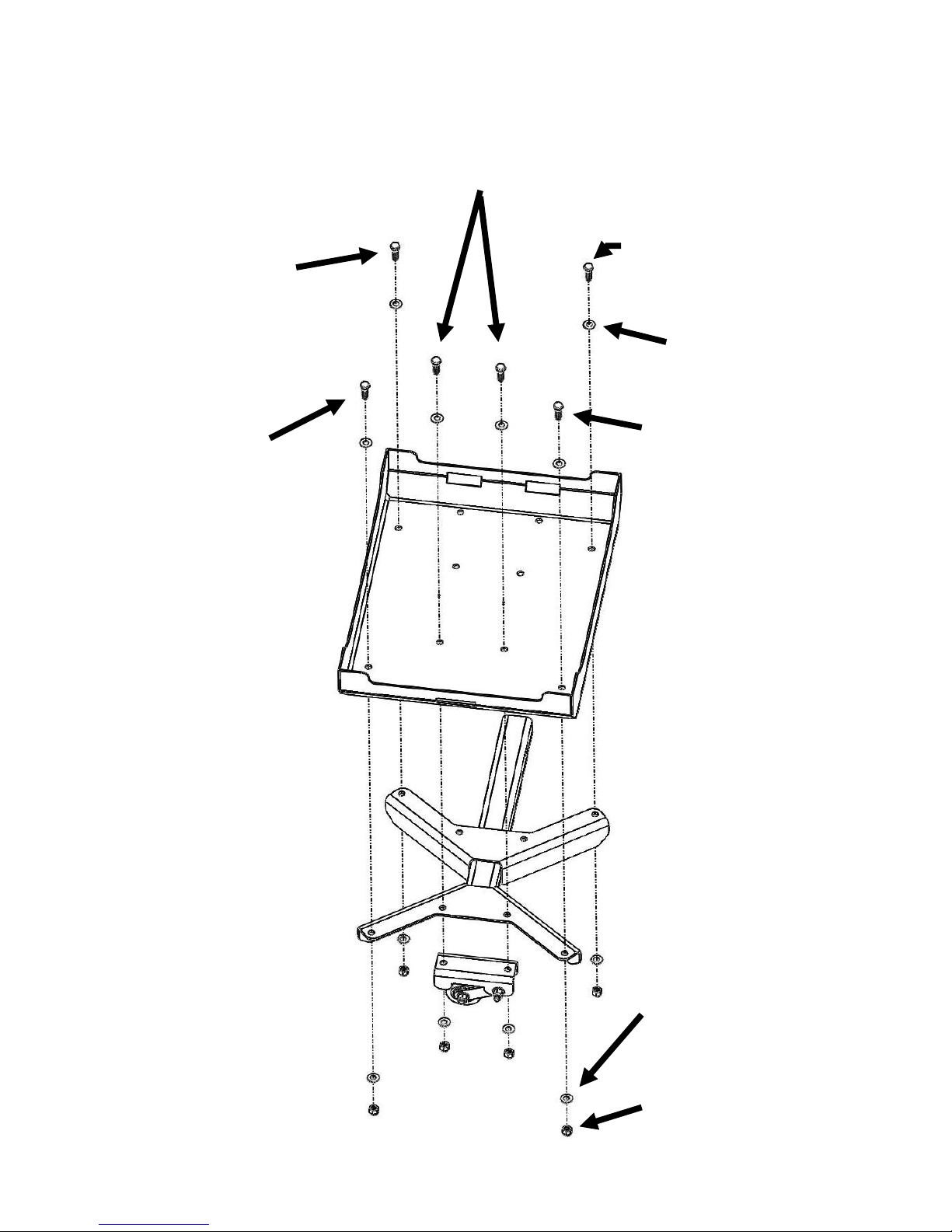

Step 3

Align the outer holes in the Mounting Bracket with the holes in

the Generator Tray. For this installation, the tube on the

Mounting Bracket should be facing toward the side of the

Generator Tray with two rectangular slots.

From the top of the tray, install one 3/8”-16 x 1-1/4” SS Hex Bolt

with one 3/8” SS SAE Flat Washer into one of the outer holes as

well as one diagonal from the bolt you have just installed. Install a

3/8”-16 x 1.25” SS Snake Eye Bolt using the supplied bit with a

3/8” SS SAE Flat Washer into the two remaining outer holes.

Secure the bottom of each bolt with one 3/8” SS SAE Flat Washer

and one 3/8”-16 Grade 8 Nylock Nut. See Figure 3.1

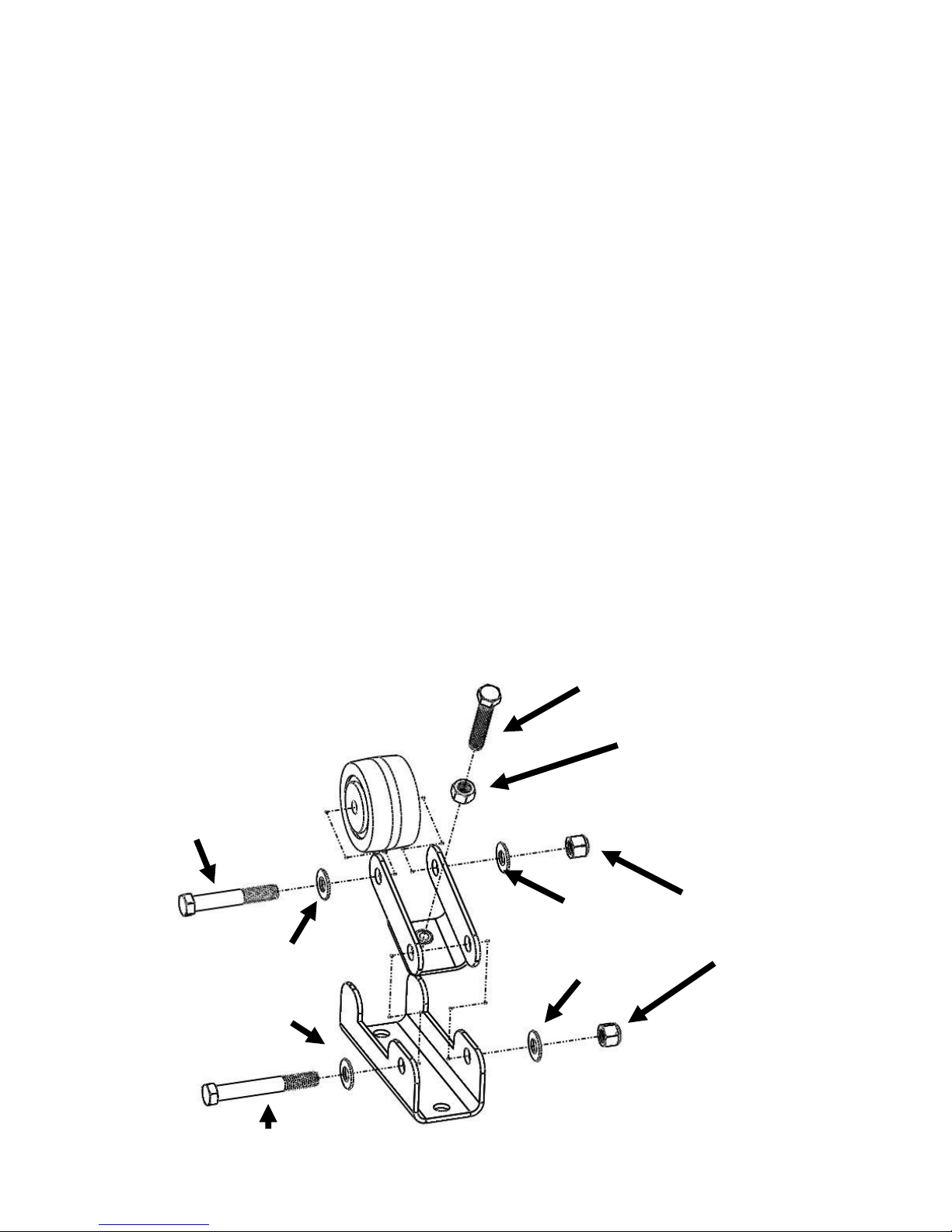

Align the two holes in the wheel bracket assembly with the two

holes in the Mounting Bracket. Figure 3.1 shows the wheel

bracket assembly positioned for a driver side space dock

installation. For passenger side installations, reverse the direction

of the wheel bracket from what is shown.

Install one 3/8”-16 x 1-1/4” SS Hex Bolt into each of the two holes

in the top of the Generator Tray and out through the Wheel

Bracket and Mounting Bracket. Secure each bolt with one 3/8”

SS SAE Flat Washer and one 3/8”-16 Grade 8 Nylock Nut.