Tormax 1102 User manual

T-1661 e 11.12.20

Translation of the original

instructions for use

Instructions for Use

For Automatic Swing Doors with Drive

TORMAX 1102 Swing Door Drive

TORMAX 1201 Swing Door Drive

Please follow the safety instructions in chapter 2!

2Instructions for Use TORMAX 1102, 1201 T-1661 e

First edition: 12.14, update 8.15, 11.20

We reserve the right to make technical changes.

Contents

1 General Information 3

1.1 Target Groups 3

1.2 Storage and Forwarding of the Manual 3

1.3 Area of Application 3

1.4 Explanation of the Symbols 4

1.5 Technical Data 4

2 Safety 5

2.1 Responsibilities 5

2.2 Use for the Purpose Intended 5

2.3 Improper use 5

2.4 Pre-conditions for the Operation of the System 6

2.5 Hazards and Risks 6

2.6 Checks 7

2.7 Decommissioning the System in the Event of a Fault 7

2.8 Disposal 7

3 System Overview 8

4 System Functions 11

4.1 Automatic Door Operation with Sensors 11

4.2 Door Leaf Protection 11

4.3 System with Full-Energy Mode 11

4.4 Systems with Low-Energy Mode 11

4.5 Semi-automatic Operation with “Push and Go” 11

4.6 Manual operation with Power Assist 11

4.7 Traffic Control 12

4.8 Automatic System Monitoring 12

4.9 Economy power mode 12

4.10 Electric Lock 12

4.11 Operation in the Event of a Power Failure 12

4.12 Operating Modes 13

5 Operation 14

5.1 Commissioning 14

5.2 Operation with the TORMAX User Interface 14

5.3 Setting Customer Parameters with the TORMAX User Interface 15

5.4 Operation with an Operating Mode Switch 16

5.5 Operation on Power Failure 17

5.6 Resetting the Panic Fitting 17

6 Procedure in the Event of a Fault 17

7 Maintenance 18

7.1 Cleaning 18

7.2 Functional Checks 18

7.3 Maintenance and Testing 18

8 Appendix 19

8.1 Fault Table 19

8.2 Check-List for Functional Checks 21

Declaration of Conformity 23

Instructions for Use TORMAX 1102, 1201 T-1661 e 3

1 General Information

1.1 Target Groups

• Operator of the automatic swing door. The operator is the person responsible for the operation and

maintenance of the system.

• Persons instructed by the operator to carry out certain duties, for example the servicing and main-

tenance of the automatic swing door.

1.2 Storage and Forwarding of the Manual

• Store the instructions for use in the vicinity of the automatic door system.

• If the manual has become illegible due to constant usage, reorder the instructions.

For download and print out see also: www.tormax.com

• When the door system is transferred or resaled to a third party, pass the following documents to

the new owner:

– This instructions for use

– Documentation concerning modification and repair work

– Proof of the regular examinations System test book T-879

1.3 Area of Application

Product name, door system: Automatic swing door (single or double-leaf)

Product name, door drive: TORMAX 1102 Swing Door Drive / TTX 1102

TORMAX 1201 Swing Door Drive

The door drives are defined in more detail by a 4-figure number:

Continuous numbering

Drive for swing door system

Increasing power

1 2 0 1

Door drive identification plate (example) with

the serial number: located on the drive under-

neath the cladding

Door system identification plate

(example): located on the side

panel of the drive.

Initial Commissioning

Swing Door System

Contact

System No.

Manufactured

TORMAX

WT-306 e 2.20

Next Service

DIN 18650-1:2010

4 3 4 0 12

For electrical connection values, please refer to

the operating instructions and the system test book.

000/000/00

MM.YYYY

DD.MM.YYYY

2019

4Instructions for Use TORMAX 1102, 1201 T-1661 e

<

1.4 Explanation of the Symbols

Warning (signal word)

Source of hazard (designates a possibly hazardous situation)

Possible consequences of non-observance

• Measures for averting danger.

Text which is highlighted in grey MUST be observed to ensure that the system operates perfectly.

Failure to observe these sections can cause damage to equipment.

Functions marked with this symbol are the factory setting. However, they can be reprogrammed

by a specialist.

Optional components which are not present in all systems.

1.5 Technical Data

Drive type Electromechanical swing door drive with DC motor

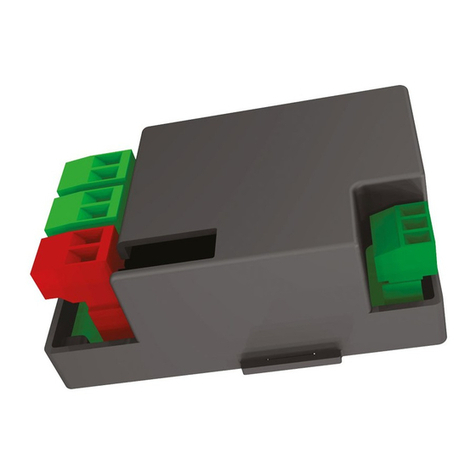

Control system Control unit MCU42

Mains connection 1 × 230 V | 10 – 16 A

1 × 115 V | 15 – 20 A

Power consumption TORMAX 1102: 6 … 210 W

TORMAX 1201: 6 … 235 W

Sensor supply 24V DC 1,5A

Protective class, drive IP20

Ambient temperature –20 °C to +50 °C

Fuse 5 AT

Drive weight

TORMAX 1102 11,2 kg

TORMAX 1201 11,8 kg

Noise emission level < 70 db (A), depending on door and substructure

Service life Tested to 1’000’000 cycles

Instructions for Use TORMAX 1102, 1201 T-1661 e 5

2 Safety

Warning

Important safety instructions

It is important to comply with these Instructions to ensure the safety of persons.

These Instructions must be kept in a safe place.

2.1 Responsibilities

Installation of the system: A specialist from a TORMAX sales partner

For instructing the operator: A specialist from a TORMAX sales partner

For operating the system: The operator or a person instructed by the operator

For maintenance and function control: The operator or a person instructed by the operator

For annual testing and approval: A specialist authorised by the manufacturer

Specialists are persons who have adequate knowledge in the field of power-operated doors as a result

of their specialist training and experience and who are so familiar with the relevant health and safety

regulations, guide-lines and generally recognised codes of practice that they are able to assess the

condition of power-operated doors with regard to the safety of their operation.

Maintenance of electrical parts must be carried out by a trained electrician.

2.2 Use for the Purpose Intended

The product including the associated components is designed for the automation of horizontally mov-

ing swing doors for pedestrian access doors. The drive must only be installed in a dry environment

inside buildings.

• It may only be used on fire protection doors once its suitability has been proven in accordance with

local regulations.

• Assembly, installation, repair and maintenance work and the commissioning of the drive must only

be undertaken my qualified persons.

• The swing door drive may only be operated by properly trained persons who must also follow the

Instructions for Use.

• The door system may be used by persons with impaired physical, mental or sensory capabilities

provided that they are either under the supervision of the person responsible for their safety that the

latter has instructed them on the safe use of the system and its potential risks.

• Children must be supervised to ensure that they do not play close to the system and do not operate

any available operating controls..

2.3 Improper use

The manufacturer will not accept any liability whatsoever for loss or damage caused by improper use,

failure to comply with the maintenance specification (see chapter 7) or unauthorised modification of

the system.

• Any conversion of the system (e.g. other user groups) is not permitted without a new risk assessment

(by a specialist) and the measures derived from it.

• Structural alterations in the danger area around the door system are prohibited without a new risk

assessment (by a specialist) and the measures derived from it.

6Instructions for Use TORMAX 1102, 1201 T-1661 e

• Modifications to the door system (e.g. different, heavier door leaves, different operating equipment

or sensor systems) may only be undertaken by a properly trained person who complies with the

technical limit values.

• Safety facilities (e.g. sensor technology, manual unlocking) must not be removed or disabled.

• User maintenance and cleaning of the system must not be undertaken by children.

Other improper uses (examples)

• Automatic doors with leaves moving vertically.

• Automatic doors with leaves moving in an inclined plane.

• Door systems incorporating a wicket door must not be automated.

• The drive must not be used as a drive for a wicket door.

• Automatic doors and gates located in transport equipment (e.g. motor vehicles or lifts)

• Use in abrasive and corrosive environments or in areas subject to the danger of explosions.

2.4 Pre-conditions for the Operation of the System

The door system was designed, installed and checked for functionality and safety by specialists prior

to hand-over to the operator. The company responsible for the system’s installation instructed the op-

erator on the system’s use and maintenance as well dangers associated with the system operation.

The operator has confirmed this by his signature in the system test book T-879. The provisions imposed

by law, health and safety and occupational health regulations for the avoidance of accidents and the

protection of the environment which are generally applicable in the country in which the system is

operated supplement the instructions for use.

• The staff responsible (see chapter 2.1) must have read and understood these Instructions before

commissioning or using the door system.

• Only use the system when it is in perfect working order. The operating conditions, inspection and

maintenance intervals stipulated by the manufacturer must be observed (chapter 7).

• Arrange to have any faults rectified immediately by a specialist.

2.5 Hazards and Risks

Depending on the system design and equipment,

there is a residual risk of crushing, shearing and

collision with limited force in the movement area of

the door leaf.

Warning

Danger through moving parts:

– in the area of all closing edges (especially hinge)

– in the region of the linkage lever

– when objects such as, for example, display shelves are erected in the direct proximity of

the moving part of the door leaf.

Warning

Hazards can arise due to deliberate damage, incorrect installation, defec-

tive sensors or sensors which are longer properly adjusted, sharp edges,

incorrectly mounted and defective casing or missing covers.

Danger for body and life, danger of injury

• Have system repaired by a qualified person

T1661_3

1

1

1

2

3

Instructions for Use TORMAX 1102, 1201 T-1661 e 7

2.6 Checks

The regular checks and examinations set out in Chapter 7 must be carried out as instructed by the

manufacturer.

2.7 Decommissioning the System in the Event of a Fault

If there is a fault the automatic swing door may only be taken out of service by a skilled person, the

operator or a person who is instructed to do so by the operator. This must be done on all occasions on

which the safety of persons could be compromised.

• Disconnect the door system from the power supply. All the poles are disconnected using a 3-pole

IEC-plug or another all-pole disconnection device (e.g. in the fuse box).

• If another power source (e.g. battery u) is available, it must be disconnected from the system by a

specialist.

• If the door is classified as an escape route or fire door according to local standards:

– Open the door manually and secure in the open position if it is installed in an escape route.

– Fire doors must never be secured in the open position even in emergencies.

See section 6 for rectification of faults.

2.8 Disposal

This system must be properly dismantled at the end of its working life. Its disposal must comply with

national regulations. We recommend that you contact a skilled person disposal company.

Warning

Electric voltage

Risk of injury by electric shock

• Disconnect the mains power supply to the installation before dismantling.

Warning

Aggressive acids

Risk of injury if you dismantle the battery module.

• Dispose of batteries properly.

Warning

Flying around parts

The tensioned spring represents a hazard when dismantling the drive.

• Before opening the casing, release the tension on the spring up to the stop.

Warning

Broken glass

Risk of injury when dismantling the door leaves.

• Take care when transporting the door leaves.

8Instructions for Use TORMAX 1102, 1201 T-1661 e

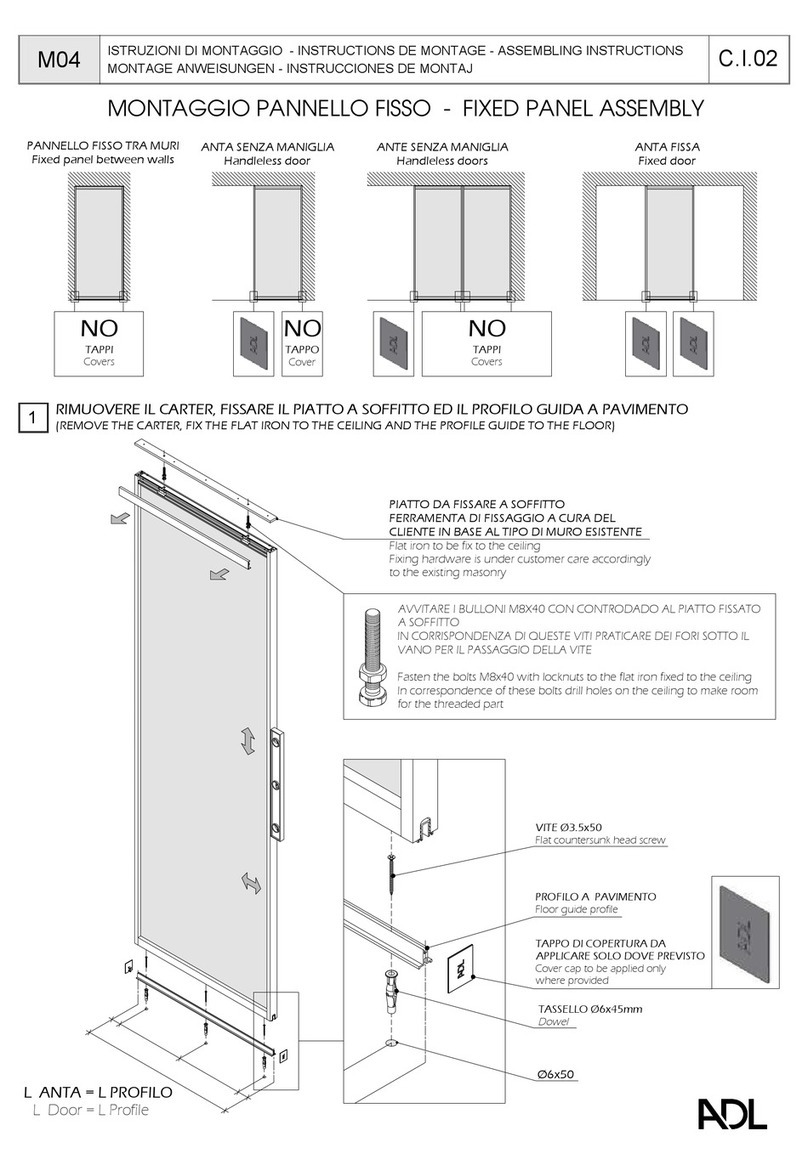

3 System Overview

System with standard linkage (1c) System with sliding lever (1c)

Ex. Installation on lintel Ex. Installation on door leaf Ex. Installation on lintel

Single-leaf door system (fig. with standard linkage)

Double-leaf door system (fig. with standard linkage)

T1661_16

1c 1c

1c

1c

1c

1c

T1661_16

1c 1c 1c

1c

1c

1c

T1661_16

1c 1c

1c

1c

1c

1c

10b

4a/4b

7b7b 6a

6b

3b3b

HKHK

outside

3b

3b

T1661_7e

7a 7a

5a

10a

NK NK

1a,b,d

3a 3a

1c 1c

inside

2b

2c 4a 4b 4c 4d

5b 8b

8a

8c

9

1a,b,e

2a

2a

10c,d

7b

6a

6b

10a 3b

3b

HK

GK HK

GK

T1661_1e

7a

5a

1a,b

3

1c

10b

10c,d

4a 4b 4c

5b 8b

4a/4b

8a

8c

9

inside outside

2a

HK: Main closing edge

NK: Secondary closing edge

GK: Counter closing edge

Instructions for Use TORMAX 1102, 1201 T-1661 e 9

1 Drive a) Motor and spring unit

b) MCU42 control system with monitoring system, power limitation and

permanent diagnosis.

£Controlled closing function of the door in power-off condition

£Controlled opening function in power-off condition

c) Linkage / sliding lever

d) Primary drive

e) Secondary drive

2Drive accessories a) £Emergency power supply via the battery unit

b) £Mechanical door coordinator for double-leaf doors

c) £Driver flap to the mechanical door coordinator

3 Door leaves a) Swing leaf with main closing edge (HK) and secondary closing edge (NK) *

b) £Finger protection to enhance the safety of the secondary closing edge *

4Operating controls a) £User interface with 5 operating modes and fault display

b) £Operating mode switch with 3 positions.

c) £Lock for the user interface

d) £Switch for 1-leaf operation *

5Internal activators a) With automatic activation b) With manual activation

£Radar with/without direction recognition * £Push button *

£IR motion detector * £Contact-free button *

£Contact mat * £Button for passage with bed *

6External activators a) With automatic activation b) With manual activation

£Radar with/without direction recognition * £Key switch

£IR motion detector * £Card reader *

£Contact mat * £Remote control *

£Button for passage with bed *

7Safety sensors a) £Presence sensor safeguarding the swing area when closing

b) £Presence sensor safeguarding the swing area when opening

8Emergency systems a) £Power switch / fuse *

b) £Emergency-off *

c) £Fire alarm system *

9Output message £Bell / gong *

£Door status *

10 Lock a) £Electrical door opener *

b) £Door handle *

c) £Mechanical door lock *

d) £Electical lock *

£Depending on the system’s equipment

* Provided by the installation company.

The company installing the system must select and install suitable components in accordance with the

product standard EN16005.

10 Instructions for Use TORMAX 1102, 1201 T-1661 e

Block Diagram

All work on the mains power supply cable and the system's cabling must only be undertaken by an

authorised and properly trained person who must refer to all necessary documents.

Single-leaf door system

Double-leaf door system

Drive unit with control system

T1661_12e

230 VAC

115 VAC

User interface

5 operating modes

Operating mode switch

3 operating modes

Battery unit

Key switch

Electric door opener/

Electric lock

Building management

system

Lock user interface

Combined sensor

inside

Opening activator

inside

Sensor safeguarding

second. closing edge

Combined sensor

outside

Opening activator

outside

or

Drive unit with control system

Secondary drive

230 VAC

115 VAC

Battery unit

Switch single leaf

operation

Sensor safeguarding

second. closing edge

Drive unit with control system

Primary drive

T1661_15e

230 VAC

115 VAC

User interface

5 operating modes

Operating mode switch

3 operating modes

Battery unit

Key switch

Button for passage

with bed

Lock user interface

Combined sensor

inside

Opening activator

inside

Sensor safeguarding

second. closing edge

Combined sensor

outside

Opening activator

outside

or

Building management

system

Combined sensor

inside

Combined sensor

outside

Electric door opener/

Electric lock

Electric door opener/

Electric lock

Instructions for Use TORMAX 1102, 1201 T-1661 e 11

4 System Functions

The operator of the door system is responsible for ensur-

ing that the automatic swing door is freely accessible at all

times. The operator must particularly ensure that the swing

area of the door leaves is not obstructed by any objects.

4.1 Automatic Door Operation with Sensors

When operating automatically (operating mode AUTOMATIC) the door is automatically opened from

both sides by sensors when a person approaches. A key switch uor card reader unormally allows

access from outside when the door is in operating mode EXIT or OFF. The door unlocks u, opens and

closes again as soon as no further sensors are activated after a hold-open time which is set sepa-

rately.

Double-leaf doors open at the same time or, in the case of overlapping door leaves, in sequence. Clos-

ing must be in the correct closing sequence and, for reasons of safety, one after the other.

4.2 Door Leaf Protection

The safety devices are selected and installed by the installation company in line with general and

country-specific standards, guide-lines and requirements.

4.3 System with Full-Energy Mode

The door leaves are equipped with safety sensors on the leaves. The safety sensors prevent a person

in the operating radius of the leaf from being hit by the leaf. If one of the safety sensors should fail, the

system switches to safety mode. The door can still be opened but only manually. In the case of low risk

systems, the system switches to emergency mode. The door leaf still moves but only slowly and in

Low-Energy mode. If the safety device fails in the closing direction, the door remains open for 30 sec-

onds.

4.4 Systems with Low-Energy Mode

Hazards due to impact and crushing are minimised by restrictions on speed and force. Thus the system

provides a high degree of safety.

The system offers maximum ease of use and safety if it is equipped with additional safety sensors.

4.5 Semi-automatic Operation with “Push and Go”

Instead of having sensors the door can be manually pushed open. After being detected by the control

system, the door opens automatically and closes again.

4.6 Manual Operation with Power Assist

In operating mode P “Manual operation” or depending on the exact setting in AUTOMAT, the door can

be easily opened manually with “Power Assist”. After opening, the door remains in the hold open posi-

tion before it closes automatically using little force.

Depending on the configuration, “Power Assist” can be activated in advance for a limited period using

a button, door trap sensor or a motion detector. In this case the door can be easily opened with very

little effort.

T1540_12

12 Instructions for Use TORMAX 1102, 1201 T-1661 e

4.7 Traffic Control

Movement through the door can be allowed in only one direction if desired (operating mode EXIT) or

completely blocked (operating mode OFF).

Double-leaf door systems can also be operated as single leaf doors by means of the single leaf op-

eration switch. In this case both doors can only be opened by means of the key switch or the “bed

movement” switch.

4.8 Automatic System Monitoring

The control system monitors the safety sensors by a cycle of active tests. The control system also

conducts continuous internal system tests. If a safety-related component should fail, the system auto-

matically switches into a safe condition. At the same time the fault number is displayed on the user

interface. The operating mode currently displayed also flashes. You can find further information on this

subject in section 6 “Procedure in the Event of a Fault”.

4.9 Economy Power Mode

Economy power mode is activated as standard. This mode consumes less power in the non-operative

state. The illumination on the user interface and most sensors are automatically switched off when not

in use.

4.10 Electric Lock u

The system can be locked in the closed position by means of an electric lock u.

4.11 Operation in the Event of a Power Failure

Depending on the equipment installed, the following functions are possible:

– Controlled closing using the integral spring. The door can be opened manually by means of the

door handle (unlocking).

The door then closes again in a controlled manner using the integral spring.

– Continued operation for a certain period in the current operating mode by means of a battery unit u.

– Unlocking and opening of the door from outside by means of a key switch and the battery unit u.

The closing sequence is maintained in double-leaf door systems by the use of a mechanical door

coordinator.

Instructions for Use TORMAX 1102, 1201 T-1661 e 13

4.12 Operating Modes

The automatic door system can be operated with the TORMAX user interface u(5 operating modes

and status display) or with an operating mode switch u(3 operating modes).

Operating Mode OFF

The internal and external sensors are disregarded. The door is mechanically held in the closed position

and locked using an electric lock u. Access is only possible using the key switch or if the door is

manually unlocked using a key or the door handle is used to open the door manually. The door can still

be used for 5 seconds after selecting operating mode OFF. The door then locks at the end of this pe-

riod as soon as it is closed. The transition is signalled on the user interface by the flashing display of

operating mode OFF.

Operating Mode AUTOMATIC

The operating mode AUTOMATIC is normally used during the day. The door opens automatically through

the inside and outside sensors. The door can behave differently depending on the settings programmed

during commissioning:

“Push-and-Go”

If the door is manually pushed in the opening direction, it reacts as if to a command to open: it opens

automatically, waits for the hold-open time and then closes.

Systems with an electric door lock u

The lock unlocks on every opening impulse. For opening by “push-and-go”, the door lock must be un-

locked manually with the lever handle. In this operating mode the door lock can also be permanently

unlocked depending on the setting programmed at the time of commissioning.

Operating Mode EXIT

Operating mode EXIT is normally used for the period before the shop or office closes. The door will

only open automatically when activated by the internal sensor. When the door opens the external sen-

sor is also monitored for safety reasons. The open position is determined by the preceding selection

of the operating mode AUTOMATIC. Additionally the door can be locked automatically by the door

lock u.The door lock can be permanently unlocked in this operating mode in case of need.

Operating Mode OPEN

The door opens and remains open. The open position is determined by the preceding selection of the

operating mode AUTOMATIC. The door opens again on receiving the next open impulse or when

changing the operating mode to OFF and back again to OPEN.

Operating Mode Manual Operation

The door leaf can be freely moved. This operating mode can be used for temporarily shutting down the

door. On each opening command In this operating mode the door lock is unlocked during 10 s. After a

single leaf of a double-leaf door system has been opened manually, the closing sequence is maintained

mechanically by means of a mechanical door coordinator. If there is no mechanical door coordinator,

the door leaves can be opened manually independently of each other without regard to the overlap on

the door leaves.

Single-Leaf Operation Switch

– Secondary leaf ON: If an opening command is given or in the event of Push & Go, both leaves always

open.

– Secondary leaf OFF: If an opening command is given via the internal or external sensors or by Push

& Go, only the primary leaf. If an opening command is given by the “passage for beds” button or the

key switch, both doors are opened.

P

14 Instructions for Use TORMAX 1102, 1201 T-1661 e

5 Operation

The automatic swing door may only be operated by a skilled person, the operator or a person in-

structed by the operator.

5.1 Commissioning

Before switching on the mains power supply:

• Unlock the optional mechanical door lock.

• Check that the movement area of the door leaves is free from obstructions such as racks, plant

containers, umbrella stands ect.

• Switch on the mains power supply and select operating mode AUTOMATIC 1, for example.

The first movement after switching the power on for the first time is slow and H67/ H62 is dis-

played. The control system is checking the door leaf’s travel distance and defining the end position.

The door is now ready for operation.

5.2 Operation with the TORMAX User Interface u

TORMAX User Interface Lock ufor User Interface

www.tormax.com

1

2

3

4

1

1

0

T1427_4

T1661_2e

OFF

AUTOMATIC

not assigned

OPEN

EXIT

Operating mode

symbols

Manual operation

Door electrically

locked

Selector key 2

Selector key 1

Unlocking of Operating Unit

The operating unit can be protected against unauthorized access by way of the lock uor the code lock.

• Unlock lock = position 0

or

• Enter code … / … / … using operating unit. The code can be determined by the engineer.

Example with code 3 / 3 / 3. Press upper selection button 3 times, then press the lower selection but-

ton 3 times and the upper selection button within 15 s . In case of entering wrong code: Wait at least

5 s . After successfully entering the code, the operating unit will be released within 60 s. The type of

operation can be adjusted. Access will be automatically blocked again for 60 s after the button has

been pressed for the last time.

Selection of Operating Modes

• Press selector keys 1 or 2 briefly. The corresponding operating mode symbol is illuminated.

Instructions for Use TORMAX 1102, 1201 T-1661 e 15

Fault Display

E.g. H31 or E42 See section 8 for the meaning of the display.

Resetting the System

• Press the selector key 2 for at least 5 seconds.

The software is restarted. On double-leaf door systems the software is restarted automatically on both

drives.

5.3 Setting Customer Parameters with the TORMAX User Interface

The company undertaking the installation reserves the right to restrict access to all or some of the

customer parameter settings. If the user interface is in an area accessible to the public it must be

protected against third party access by a “code lock” or a “lock for the user interface”.

Access level “U” for customer parameters

Enter the three digit code for parameters

• Similarly, select and confirm the second and the third characters of the code.

If “C” appears, access is blocked. Parameters cannot be re-set in this case.

T1661_10e

Uappears, ready for programming

Confirm with

key 2

P

T1661_11e

Zero appears as first digit of code

P

Enter first code

digit with key 1

Confirm with

key 2

T1661_9e

Indication of operating mode

Press keys 1 and 2

simultaneously until

«U» appears

P

16 Instructions for Use TORMAX 1102, 1201 T-1661 e

Parameters for displays

01 Drive type (1 = 1102, 2 = 1201)

042 Firmware version

043 Number of cycles

044 Number of operating hours

046 Control address for network

Parameters for settings

10 0…E Hold open time for activator inside/ outside

0 / 1/ 2 / 3 /4 / 5 / 6 / 8 /10 /12.5 /15 /17.5 /20/40/ 60 s11 0…E Hold-open time button e.g. for beds

12 0…E Hold-open time for key switch

13 0…9 Delay for operating mode OFF (selection via

user interface)

1/ 3 /5 / 7.5 /10 /15 /20 /30 /45 / 60 s

14 0…9 Bell active time 0 / 0.5 / 1 / 2 / 3 / 4 / 5 / 6 / 8 / 10 s

15 0…E Hold open time for Power Assist 0/1/2/3/4/5/6/8/10/12,5 /15 /17,5 /20 /40 / 60 s

16 0…E Hold open time for Push and Go

20 0…6 Opening speed 10 … 100 %

21 0…6 Closing speed

301…3/6 Power limit when opening

Maximum depends on the drive type

311…3/6 Power limit when closing

321…3/6 Power limit when closing before the door is

closed

38 0…6 Starting angle for Push & Go / Power Assist 1/ 2 / 3 / 5 / 8 / 12 / 16 degrees

39 0…5 Starting angle for Push & Close Maximum / 8 / 10 / 12 / 14 / 16 degrees

80 0…2 Bell trigger Activator outside / activator inside / key switch

81 0…4 Button press time (detection delay for activator) 0/1/2/3/5

91 0…4 Code lock for user interface Switched off / code 111/... 222 /… 333 /…123

Command

040 Software reset

5.4 Operation with an Operating Mode Switch u

Resetting the System

– Change the operating mode in the event of a fault with code E31 – E38 or E51

or

– Cut off power supply to the system for at least 5 seconds (systems without battery unit only).

OFF

AUTOMATIC

OPEN

T1305_4

Instructions for Use TORMAX 1102, 1201 T-1661 e 17

5.5 Operation on Power Failure

Opening a Door using a Key Switch uwith aBattery Unit u

• Activate the key switch and hold in place for at least 5 seconds, then turn back the key.

The battery is activated using the “wake up” function.

The key switch must not remain permanently in the “on” opposition.

The door is unlocked and opened.

The battery switches off again after the time programmed by the installation engineer or

when the battery is fully discharged.

If required, the operating mode can be changed on the user interface during the wake-up.

5.6 Resetting the Panic Fitting u

• Select operating mode OFF (operating mode switch , user interface ) or disconnect the drive from

mains (installation switch, mains plug).

• Push the door leaf back into the initial position.

• Choose operating mode AUTOMATIC or switch on drive respectively.

6 Procedure in the Event of a Fault

The automatic swing door drive may only be operated by a specialist, by the operator or by a person

instructed by the operator.

Faults are evident from abnormal door behaviour and/or as a fault display on the user interface. Fault

displays on the user interface take the form of a flashing “E” or “H” followed by two figures.

H = notification > the system can continue to be used.

E = fault > the system is stationary.

Some faults or notifications can be rectified by restarting the door drive with a software reset and/or

briefly (> 10 s) disconnecting the system from the power supply.

Fault Display and Reset Using the TORMAX User Interface

See the table in section 8.1 for an overview of the fault displays.

Browse through the fault display using selector key 1

(to display several faults).

1. Reset the fault display, press selector key 2 (downwards) briefly.

2. Software reset: press the key for 5 seconds.

Reset of the Fault with the Operating Mode Switch

Software reset in the event of a fault: change the operating mode.

Reset of the Fault by Disconnecting the Power Supply

If the system does not have a battery unit, disconnect from the power supply for about 10 seconds.

If this does not reset the fault or if it re-occurs after a short time, you must arrange for the fault to be

rectified by a skilled person from your TORMAX dealer. In this case note the fault number and inform

the dealer. See the last page or the service tag on the system for the dealer’s address.

T1305_5

T1305_4

18 Instructions for Use TORMAX 1102, 1201 T-1661 e

7 Maintenance

The system was tested and approved by a skilled person before initial commissioning. The manufac-

turer recommends that you conclude a service contract in order to maintain the value of your system

for as long as possible as well as to ensure the system operates reliably and safely for a long time.

Only genuine TORMAX spare part should be used. The manufacturer accepts no liability if you fail

to observe this requirement. Original spare parts and original accessories guarantee the safety of

use in accordance with norm EN 16005.

Warning

Possible risk of injury!

Entrapment of limbs can lead to serious injury.

• The drive must be disconnected from all power sources, including batteries during clean-

ing maintenance and replacement of parts.

7.1 Cleaning

• Clean casing parts, the user interface and door leaves with a damp cloth and a commercial cleaner.

7.2 Functional Checks

• Check the door system's function and safety devices at least every 3 months.

This will ensure that faults or hazardous changes in the system are detected at an early stage. See

chapter 8.2 “Check-list for Functional Checks” for items to be checked.

• You should arrange for any defects detected during the routine checks to be rectified immediately by

a TORMAX dealer (see the last page of this Manual for the address).

Warning

Potential switching malfunction in the automatic swing door.

Potential hazards – injury caused by impact or crushing.

• Secure the area around the door while checking the door's functions.

7.3 Maintenance and Testing

Maintenance and testing should only be carried out by a trained specialist following the manufacturer’s

instructions.

Maintenance Interval

The maintenance interval depends on the frequency of use but the system must be maintained

at least once per year.

Scope of the Maintenance Work

The content of the maintenance work is specified by the manufacturer in an inspection list.

System Test Book

The test findings are recorded after the test in the system test book. The operator must keep it in a safe

place.

Instructions for Use TORMAX 1102, 1201 T-1661 e 19

8 Appendix

8.1 Fault Table

For the procedure in the event of a fault, see chapter 6.

System Behaviour No. Cause Remedy/ Rectification

The door stops when

opening.

H31 Electronic obstacle recognition

caused by persons, wind pressure

and ventilation when opening.

Remove the obstruction.

Avoid drafts.

Door reverses when clos-

ing.

H32 Electronic obstacle recognition

caused by persons, wind pressure

and ventilation when closing.

Remove the obstruction.

Avoid drafts.

The door stops repeat-

edly when opening.

The door stands still.

H33 Electronic obstacle recognition on

opening in the same position by

stationary obstacle.

Remove the obstruction.

The door stops repeat-

edly when closing.

The door stands still.

H34 Electronic obstacle recognition on

closing in the same position by sta-

tionary obstacle.

Remove the obstruction.

Search run notified. H62

H67

Search run of the door after a reset

or after power recovery.

Allow the search run to travel its full

course.

Door remains open or is in

operation again.

H71 System is in battery operation. Pause / ensure mains power supply

is connected.

Note in the event of el-

evated motor load.

H74 Drive is heavily loaded in the open

position by a soft stop or wind

load.

Remove the obstruction in the re-

gion of the open stop. Avoid wind

load.

The door remains open

or closed. The door

moves slowly.

H...

H0..

H1..

H2..

H4..

Problem with commissiong data. Have commissioning / repair car-

ried out by a specialist.

Door remains closed. –

E11

E12

Operating mode for example OFF,

EXIT or P. The door is prevented

from moving by the lock.

Motor lock will not unlock

will not lock

E.g. select operating mode AUTO-

MATIC. Unlock the lock. Push the

door closed briefly.

Prevent wind load on the door leaf.

Remove obstruction in the closed

position area.

The door remains open. – Operating mode OPEN or the door

is obstructed in the open position.

E.g. select operating mode AUTO-

MATIC. Remove the obstruction.

The door remains closed.

The door moves slowly.

E31 The safety facility in the opening

direction is permanently active

(>1 minute) or defective.

Remove objects from within the

range of the sensor(s).

The door remains open

or closed. The door

moves slowly.

E32 The safety facility in the closing di-

rection is permanently active

(>1 minute) or defective.

Remove objects from within the

range of the sensor(s).

The door does not open

or does not close.

E33 The safety facility for the swing area

is permanently active (>1 minute) or

defective.

Remove objects from within the

range of the sensor(s).

The door does not open

or does not close.

E34 The stop safety facility is perma-

nently active (>1 minute) or defec-

tive.

Remove objects from within the

range of the sensor(s).

The door opens slowly. E35 The safety facility in the opening

direction is permanently active

(> 1 minute) or defective.

Remove objects from the sensor

area.

20 Instructions for Use TORMAX 1102, 1201 T-1661 e

System Behaviour No. Cause Remedy/ Rectification

The door closes slowly. E36 The safety facility in the closing di-

rection is permanently active

(>1 minute) or defective.

Remove objects from within the

range of the sensor(s) and/or per-

form reset.

Tür öffnet mit Niederen-

ergie (evtl. langsamer)

E37 The safety facility in the opening

direction is permanently active

(>1 minute) or defective.

Remove objects from within the

range of the sensor(s) and/or per-

form reset.

Tür schliesst mit Nieder-

energie (evtl. langsamer)

E38 The safety facility in the closing di-

rection is permanently active

(>1 minute) or defective.

Remove objects from within the

range of the sensor(s) and/or per-

form reset.

The door remains open. E41

E42

E43

Activator inside > 1 min. active

Activator outside > 1 min. active

Key switch > 1 min. active

Reset key switch

Get sensor adjusted by an expert.

The door remains open. E45 Emergency opening is active for

> 1 minute

Reset the command from the higher

ranking system.

The door remains closed. E46 Emergency closing is active for

> 1 minute

Reset the command from the higher

ranking system.

The door remains closed. E47 Blocking switch active for

> 1 minute

Reset the command from the higher

ranking system.

The door remains open. E48 ”Beds“ sensor active for > 1 minute. Reset the switch for “passage with

beds”.

The door stands still. E49 Power Assist Pre-release >1 min.

active

Reset switch for “Pre-release”.

The door stands still. E51 Encoder/motor defective. Have the system repaired by a

specialist.

The door stands still. E61

E62

E63

Power supply is overloaded or volt-

age too low.

Get the power supply and connec-

tions checked by a skilled person.

The door stands still. E64 Drive/control system is overheated. Wait for the automatic reset after

the door/control system has

cooled.

Protect from direct sunlight.

The door stands still. E66 Motor or output stage defective. Wedge the door open in the open

position or disengage the linkage.

Switch off the power supply.

Arrange for the system to be re-

paired by a specialist.

The secondary door leaf

remains motionless.

E99 Fault on the secondary drive. Arrange for the system to be

checked by a specialist.

The door stands still. E..

E0..

E2..

Control system shut down for

safety reasons.

Perform a software-reset.

Arrange for the system to be re-

paired by a specialist.

Other manuals for 1102

2

This manual suits for next models

1

Table of contents

Other Tormax Door Opening System manuals