Tormax iMotion 1301 User manual

T-1305 e 17.2.12

Translation of the original

instructions for use

Instructions for Use

For Automatic Swing Doors with Drive

iMotion®1301 Swing Door Drive

iMotion®1301.S Swing Door Drive

iMotion®1401 Swing Door Drive

2Instructions for Use iMotion 1301/1301.S /1401 T-1305 e

Table of Contents

1 General Information 3

2 Safety 4

2.1 Responsibilities 4

2.2 Use for the Purpose Intended 4

2.3 Pre-Conditions for the Operation of the System 4

2.4 Hazards and Risks 4

2.5 Checks 5

2.6 Decommissioning the System in the Event of a Fault 5

2.7 Disposal 5

3 Product Description 6

3.1 System Overview 6

3.2 System Function 7

3.3 Operating Modes 8

4 Operation 9

4.1 Commissioning 9

4.2 Operation with the TORMAX User Interface 9

4.3 Operation with an Operating Mode Switch 10

4.4 Operation on Power Failure 10

4.5 Resetting the Panic Fitting 10

5 Procedure in the Event of a Fault 11

6 Maintenance 12

6.1 Cleaning 12

6.2 Functional Checks 12

6.3 Maintenance and Testing 12

7 Appendix 13

7.1 Fault Table 13

7.2 Check-List for Functional Checks 14

Declaration of Conformity 15

First edition: 2.12.11, update: 2.12

We reserve the right to make technical changes.

Printed on environmentally friendly paper bleached without the use of chlorine.

Landert Motoren AG and Landert GmbH are certified to ISO 9001.

Instructions for Use iMotion 1301/1301.S /1401 T-1305 e 3

1 General Information

Target Groups

• Operatoroftheautomaticswingdoor.Theoperatoristhepersonresponsiblefortheoperationand

maintenance of the system.

• Personsinstructedbytheoperatortocarryoutcertainduties,forexampletheservicingandmaintenance

of the automatic swing door.

Area of Application

Product name, door system: Automatic swing door

Product name, door drive: iMotion®1301 Swing Door Drive

iMotion®1301.S Swing Door Drive

iMotion®1401 Swing Door Drive

Serial number: ………………………………………

Identification plate

(example)

These Instructions for Use apply to all the above door drives (see the “Technical Data” section for differ-

ences).

Explanation of the Symbols

The warning message warns about possible risk of injury.

Text which is highlighted in grey MUST be observed to ensure that the system operates perfectly.

Failure to observe these sections can cause damage to equipment.

Functions marked with this symbol are the factory setting. However, they can be reprogrammed

by a skilled person.

Optional components which are not present in all systems.

<

The identification plate with the

serial number is placed in the

controlbox(1401)oronthedrive

itself under the casing (1301,

1301.S).

Technical Data iMotion 1301 iMotion 1301.S iMotion 1401

Drive type Electromechanical swing door operator with AC permanent magnet synchronous motor

Control system iMotion MCU32

Mains connection 1x230/1x115VAC,50–60Hz,10A

Power consumption 6 … 250 W 12 … 330 W 4 … 250 W

Power supply 24VDC+0,5/–1,5V,max.18W*/0,75A,

in battery operationmin.16,5V

40VPWM/max.24W*/2A,equivalent

6…24VDC,voltageandfunctionpro-

grammable. Only for inductive or resis-

tive loads without overload protection.

*Totalload30W

24VDC+0,5/–1,5V,max.36W*/1,5A,

n battery operationmin.16,5V

40VPWM/max.24W*/2A,equivalent

6…24VDC,voltageandfunctionprogram-

mable. Only for inductive or resistive loads

without overload protection.

*Totalloadmax.50W

Protective class, drive IP22 IP22 IP 67 (7 days water

up to upper edge of

oorbox)

Protectiveclass,controlbox – – IP 55

Ambient temperature –20°Cto+50°C

Noise emission level <70db(A)

4Instructions for Use iMotion 1301/1301.S /1401 T-1305 e

2 Safety

2.1 Responsibilities

For instructing the operator: A skilled person from a TORMAX sales partner

For operating the system: The operator or a person instructed by the operator

For maintenance and function control: The operator or a person instructed by the operator

For annual testing and approval: A skilled person authorised by the manufacturer

Skilled persons are persons who have adequate knowledge in the field of power-operated doors as a

result of their specialist training and experience and who are so familiar with the relevant health and

safety regulations, guide-lines and generally recognised codes of practice that they are able to assess the

condition of power-operated doors with regard to the safety of their operation.

Maintenance of electrical parts must be carried out by a trained electrician.

2.2 Use for the Purpose Intended

Theautomaticswingdoorisintendedexclusivelyforuseindrypremisesinareasusedasapedestrian

thoroughfare. Special techniques can also be used to attach the drive unit to the building envelope. The

manufacturer will not accept any liability whatsoever for loss or damage caused by improper use, failure

tocomplywiththemaintenancespecication(seesection6)orunauthorisedmodicationofthesystem.

2.3 Pre-Conditions for the Operation of the System

The door system was designed, installed and checked for functionality and safety by skilled persons prior

to hand-over to the operator. The company responsible for the system’s installation instructed the operator

on the system’s use and maintenance as well dangers associated with the system operation. The opera-

tor has confirmed this by his signature in the system test book T-879.

The provisions imposed by law, health and safety and occupational health regulations for the avoidance

of accidents and the protection of the environment which are generally applicable in the country in which

the system is operated supplement the Instructions for Use.

• ReadtheInstructionsforUsecarefullybeforecommissioningtheautomaticswingdoor.

• Onlyusethesystemwhenitisinperfectworkingorder.Theoperatingconditions,inspectionand

maintenanceintervalsstipulatedbythemanufacturermustbeobserved(section6).

• Safetyfacilities(e.g.sensortechnology,protectingcovers)mustnotberemovedordisabled.

• Arrangetohaveanyfaultsrectiedimmediatelybyaskilledperson.

2.4 Hazards and Risks

Depending on the system design and equipment, there is a residual risk of crushing, shearing and collision

with limited force in the movement area of the door leaf.

iMotion 1401 iMotion 1301, 1301.S

Instructions for Use iMotion 1301/1301.S /1401 T-1305 e 5

Hazards can arise:

– intheregionofallclosingedges(particularlyclosetothehinge)

– intheregionofthelinkagelever

– if,forexample,salesstandsareerectedindirectproximitytotheoperatingrangeofthedoorleaves

– duetodeliberatedamagebyvandals,defectivesensorsorsensorswhicharenolongerproperlyad-

justed, sharp edges, incorrectly supported and defective casing or missing covers.

2.5 Checks

TheregularchecksandexaminationssetoutinChapter6mustbecarriedoutasinstructedbythemanu-

facturer. The manufacturer recommends that a maintenance contract be concluded in order to operate the

system safely and to maintain its value for as long as possible.

2.6 Decommissioning the System in the Event of a Fault

If there is a fault the automatic swing door may only be taken out of service by a skilled person, the op-

erator or a person who is instructed to do so by the operator. This must be done on all occasions on which

the safety of persons could be compromised.

• Disconnectthesystemfromthepowersupply.

• Selectoperatingmode“P”ifthesystemcontinuestooperateusingtheinternalemergencypowersup-

ply(seesection3.3foroperatingmodes).

• Openthedoormanuallyandsecureintheopenpositionifitisinstalledinanescaperoute.

• Firedoorsmustneverbesecuredintheopenpositioneveninemergencies.

See section 7 for rectification of faults.

2.7 Disposal

This system must be properly dismantled at the end of its working life. Its disposal must comply with na-

tional regulations. We recommend that you contact a skilled person disposal company.

– Aggressiveacids.

– Riskofinjuryifyoudismantlethebatterymodule.

– Disposeofbatteriesproperly.

– Flyingaroundparts.

– Thetensionedspringrepresentsa

hazard when dismantling the drive.

– Beforeopeningthecasing,release

the tension on the spring up to the

stop as indicated in the drawing

(iMotion1301/1301.S:W=0)

– Brokenglass.

– Riskofinjurywhendismantlingthedoorleaves.

– Takecarewhentransportingthedoorleaves.

T1305_2

T1305_1

W

W

6Instructions for Use iMotion 1301/1301.S /1401 T-1305 e

3 Product Description

3.1 System Overview

1 Drive a)Motorandspringunit

b)MCU32controlsystemwithmonitoringsystem,powerlimitationand

permanent diagnosis.

£Controlled closing function of the door in power-off condition

£Controlled opening function in power-off condition

c)Linkage/slidinglever(1301)

c)£Pullarm(1401)

2Drive accessories ua)£Emergency power supply via the battery unit

£Mechanical closing sequence controller for double-leaf doors

£…

3 Door leaves a)Swingleafwithmainclosingedge(HK)andsecondaryclosingedge(NK)

b)£Finger protection to enhance the safety of the secondary closing edge.

4Operating controls a)£iMotion user interface with 6 operating modes and fault display

b)£Operating mode switch with 3 positions.

c)£Lock for the user interface

d)£Remote control of operating modes

5Internal activators a)Withautomaticactivation b)Withmanualactivation

£Radar with/without direction recognition £Push button

£IR motion detector £Contact-free button

£Contact mat £…

6External activators a)Withautomaticactivation b)With manual activation

£Radar with/without direction recognition £Key switch

£IR motion detector £Card reader

£Contact mat £Remote control

£… £…

7Safety sensors a)£Presence sensor safeguarding the swing area when closing

b)£Presence sensor safeguarding the swing area when opening

c)£Presence sensor safeguarding theopposingclosingedge(GK)

d)£Presence sensor: secondary closing edge protection

£…

8Emergency systems a)£Power switch / fuse

b)£Emergency on/off switch

c)£Fire alarm system

9Output message £Bell/gong

£Light

£Door status

10 Lock ua)£Electrical door opener

b)£Door handle

c)£Mechanical door lock

£Depending on the system’s equipment

8c

HK

HK

inside outside

NK GK

GK

5a

7b

6a

6b

1b

1a

2a,

4d

3a

10b,c

4a 4b 4c

5b 8b

4a 4b

10a

8a 7a

7d 7c

3b

3b

T1305_6e

7a

5a

HK

inside

iMotion 1301, 1301.S iMotion 1401

GK

1a,b 2a

3

1c

10b,c

4a 4b 4c

5b 8b

4a

4b

4d

8a 8c 9

1a

1c

Instructions for Use iMotion 1301/1301.S /1401 T-1305 e 7

3.2 System Function

The operator of the door system is responsible for ensur-

ing that the automatic swing door is freely accessible at

all times. The operator must particularly ensure that the

swing area of the door leaves is not obstructed by any

objects.

Automatic Door Operation with Sensors

Whenoperatingautomatically(AUTOMATICoperatingmode)thedoorisautomaticallyopenedfromboth

sides by sensors when a person approaches.

A key switch uor card reader unormally allows access from outside when the door is in operating mode

EXIT or OFF. The door unlocks, opens and closes again as soon as no further sensors are activated after

a hold-open time which is set separately.

The sensors for the door opening and the maintained opening of the door are arranged and adjusted in

such a way that the door opens promptly and remains open as long as a person is within the operating

rangeofthedoorleaf.Thedoorcancloseneverthelessbutonlyafteratimeofapprox.>1minute.

The reduced closing speed which is set by the installer and is adjusted in line with the door weight, com-

bined with a force of < 150 N prevents the impact of the moving leaves on a person from being too severe.

The obstruction is also detected by the control system and the door automatically reverses.

Safety sensors are necessary and depend on the design of the door system (distances, speeds, forces

appliedbythedoor).When a person moves into the danger area, the door leaf stops or slows down to a

very low speed depending upon the settings performed by the fitter at the time of commissioning.

Semi-automatic Operation with “Push-and-Go”

Instead of having sensors the door can be manually pushed open. After being detected by the control

system, the door opens automatically and closes again.

Traffic Control

Movement throughthedoorcanbeallowedin only onedirectionifdesired(operating mode EXIT) or

completelyblocked(operatingmodeOFF).

If there is a high level of pedestrian traffic or if the door is to be used by infirm or frail persons, the door

can be switched to operate in operating mode AUTOMAT 2 with a longer hold-open time.

Automatic System Monitoring

The control system monitors the safety sensors by a cycle of active tests. The control system also conducts

continuous internal system tests. If a safety-related component should fail, the system automatically

switches into a safe condition. At the same time the fault number is displayed on the user interface. You

can find further information on this subject in section 5 “Procedure in the Event of a Fault”.

Electric Lock u

The system can be locked in the closed position by means of an electric lock u.

Operation in the Event of a Power Failure

Depending on the equipment installed, the following functions are possible:

– Controlled closing using the integral spring. The door can be opened manually by means of the door

handle(unlocking).

The door then closes again in a controlled manner using the integral spring.

– Controlledopeningusingtheintegralspring.Thedoorremainsopen.

T1540_12

8Instructions for Use iMotion 1301/1301.S /1401 T-1305 e

– Continuedoperationforacertainperiodinthecurrentoperatingmodebymeansofabatteryunitu.

– Unlockingandopeningof thedoorfromoutsidebymeansofakeyswitchandthebatteryunitu.

3.3 Operating Modes

The automatic door system can be operated with the TORMAX user interface u(6 operating modes and

statusdisplay)orwithanoperatingmodeswitchu(3operatingmodes).

Operating Mode OFF

Theinternalandexternalsensorsaredisregarded.Thedoorismechanicallyheldintheclosedposition

and locked using an electric lock u. Access is only possible using the key switch or if the door is manu-

ally unlocked using a key or the door handle is used to open the door manually.

<The door can still be used for 5 seconds after selecting operating mode OFF. The door then locks at

the end of this period as soon as it is closed. The transition is signalled on the user interface by the flash-

ing display of operating mode OFF.

Operating Mode AUTOMATIC 1

The operating mode AUTOMATIC 1 is normally used during the day. The door opens automatically through

the inside and outside sensors. The door can behave differently depending on the settings programmed

during commissioning:

“Push-and-Go”

If the door is manually pushed in the opening direction, it reacts as if to a command to open: it opens

automatically, waits for the hold-open time and then closes.

Systems with an Electric Door Lock u

The lock unlocks on every valid opening impulse. The door lock must be manually unlocked with the door

handle before it is possible to open the door with the “Push- and-Go” system. In this operating mode the

door lock can also be permanently unlocked depending on the setting programmed at the time of com-

missioning.

Operating Mode AUTOMATIC 2

Corresponds to operating mode AUTOMATIC 1 but a different motional sequence can be set during com-

missioning(e.g.asloweropeningmovement,differentopenpositionsandalongerhold-opentime).

Operating Mode EXIT

Operating mode EXIT is normally used for the period before the shop or office closes. The door will only

openautomaticallywhenactivatedbytheinternalsensor.Whenthedooropenstheexternalsensoris

also monitored for safety reasons. The open position is determined by the preceding selection of the op-

erating mode AUTOMATIC 1 or AUTOMATIC 2. Additionally the door can be locked automatically by the

door lock u.The door lock can be permanently unlocked in this operating mode in case of need.

Operating Mode OPEN

The door opens and remains open. The open position is determined by the preceding selection of the

operatingmodeAUTOMATIC1orAUTOMATIC2.Thedooropensagainonreceivingthenextopenimpulse

or when changing the operating mode to OFF and back again to OPEN.

Operating Mode Manual Operation

The door leaf can be freely moved. This operating mode can be used for cleaning the door leaf or for

temporarily shutting down the door. The system is reset after leaving this operating mode.

In this operating mode the door lock can also be permanently unlocked depending on the setting pro-

grammed at the time of commissioning.

P

Instructions for Use iMotion 1301/1301.S /1401 T-1305 e 9

4 Operation

The automatic swing door may only be operated by a skilled person, the operator or a person instructed

by the operator.

4.1 Commissioning

Beforeswitchingonthemainspowersupply:

• Unlocktheoptionalmechanicaldoorlock.

• Checkthatthemovementareaof thedoorleavesisfreefromobstructionssuchasracks,plantcontain-

ers, umbrella stands etc.

• SwitchonthemainspowersupplyandselectoperatingmodeAUTOMATIC1,forexample.

The first movement after switching the power on for the first time is slow and H62 and H67 are dis-

played.Thecontrolsystemisdeningtheclosedpositionof thedoorleaf (H62)andischeckingthe

doorleaftraveldistance(H67).

The door is now ready for operation.

4.2 Operation with the TORMAX User Interface u

TORMAX User Interface uLock ufor User Interface

Selection of Operating Modes

• Releaselockufor user interface.

• Pressselectorkeys1or2briey.Thecorrespondingoperatingmodesymbolisilluminated.

Fault Display

E.g. H91 or E42 See section 7 for the meaning of the display.

• Resetbypressingtheselectorkey2briey.

Resetting the System

• Presstheselectorkey2foratleast5seconds.

The software is restarted. The control system then conducts a calibration run, checks the travel distance

and looks for the closed position. Displayed as H62 and H67.

www.tormax.com

1

2

3

4

1

1

0

T1427_4

T1321_1e

OFF

AUTOMATIC 1

AUTOMATIC 2

OPEN

EXIT

Operating mode

symbols

Manual operation

Door electrically

locked

Selector key 2,

downwards

Selector key 1,

upwards

10 Instructions for Use iMotion 1301/1301.S /1401 T-1305 e

4.3 Operation with an Operating Mode Switch u

Selection of Operating Modes

The switch position defines the operating mode.

T1305_4

OFF

AUTOMATIC 1

OPEN

Resetting the system

– Changetheoperatingmodeintheeventof afault

or

– Cutoffpowersupplytothesystemforatleast5seconds.

4.4 Operation on Power Failure

Opening a Door using a Key Switch uwith aBattery Unit u

• Turnthekeyswitchtothe“on”positionandholdinplaceforatleast5seconds,thenturnthekeyto

the original position.

The battery is activated using the “wake up” function.

The key switch must not remain permanently in the “on” opposition.

The door is unlocked and opened.

The battery switches off again after the time programmed <by the installation engineer or

when the battery is fully discharged.

If required, the operating mode can be changed on the user interface during the wake-up.

4.5 Resetting the Panic Fitting u

• SelectoperatingmodeOFF(operatingmodeswitch, user interface )ordisconnecttheoperator

frommains(installationswitch,mainsplug).

• Pushthedoorleafbackintotheinitialposition.

• ChooseoperatingmodeAUTOMATIC1orswitchonoperator.

Instructions for Use iMotion 1301/1301.S /1401 T-1305 e 11

5 Procedure in the Event of a Fault

Faults are evident from abnormal door behaviour and/or as a fault display on the user interface. Fault

displays on the user interface take the form of a flashing “E” or “H” followed by two figures.

H=notication>thesystemcancontinuetobeused.

E=fault>thesystemisstationary.

Some faults or notifications can be rectified by restarting the door drive with a software reset and/or

briefly disconnecting the system from the power supply.

Fault Display and Reset Using the TORMAX User Interface

See the table in section 7.1 for an overview of the fault displays.

Browsethroughthefaultdisplayusingselectorkey1upwards

(todisplayseveralfaults).

1. Reset the faultdisplay,pressselectorkey2(downwards)briey.

2. Software reset: press the key for 5 seconds.

Reset of the Fault with the Operating Mode Switch

Software reset in the event of a fault: change the operating mode.

Reset of the Fault by Disconnecting the Power Supply

If the system does not have a battery unit, disconnect from the power supply for about 10 seconds.

If this does not reset the fault or if it re-occurs after a short time, you must arrange for the fault to be rec-

tified by a skilled person from your TORMAX dealer. In this case note the fault number and inform the

dealer. See the last page or the service tag on the system for the dealer’s address.

T1305_5

T1305_4

12 Instructions for Use iMotion 1301/1301.S /1401 T-1305 e

6 Maintenance

The system was tested and approved by a skilled person before initial commissioning. The manufacturer

recommends that you conclude a service contract in order to maintain the value of your system for as long

as possible as well as to ensure the system operates reliably and safely for a long time.

Only genuine TORMAX spare part should be used. The manufacturer accepts no liability if you fail to

observe this requirement.

The following maintenance work must be carried out:

6.1 Cleaning

– Closingdoorscancrush–danger!

– Trappedlimbscanleadtoseriousinjury.

– ThesystemmustonlybecleanedinoperatingmodeOFF,OPENorManualOperation.

• Cleanthecontrolbox,userinterface,thecoversanddoorleaveswithadampclothandacommercial

cleaning agent.

6.2 Functional Checks

The operator must check the function and safety devices of the automatic swing door at least every

three months. This will ensure that faults or hazardous changes in the system are detected at an

early stage. See section 7.2 “Check-list for Functional Checks” for items to be checked.

You should arrange for any defects detected during the routine checks to be rectified immediately by a

TORMAXdealer(seethelastpageofthisManualfortheaddress).

– Possiblemalfunctionof theautomaticswingdoor.

– Potentialhazards–injurycausedbyimpactorcrushing.

– Donotuseanypartofyourbodyforfunctionalchecks.Useasuitableobject(e.g.styro-

foamorcardboard)instead.

6.3 Maintenance and Testing

Maintenance and testing should only be carried out by a trained skilled person following the manufacturer’s

instructions.

Maintenance Interval

The maintenance interval depends on the frequency of use but the system must be maintained at least

once per year.

Scope of the Maintenance Work

The content of the maintenance work is specified by the manufacturer in an inspection list.

System Test Book

The test findings are recorded after the test in the system test book. The operator must keep it in a safe

place.

Instructions for Use iMotion 1301/1301.S /1401 T-1305 e 13

7 Appendix

7.1 Fault Table

System Behaviour No. Cause Remedy/ Rectification

The door stops when

opening.

H91 Electronic obstacle recognition

caused by persons, wind pressure

and ventilation when opening.

Remove the obstruction.

Avoid drafts.

Door reverses when

closing.

H92 Electronic obstacle recognition

caused by persons, wind pressure

and ventilation when closing.

Remove the obstruction.

Avoid drafts.

The door stops repeat-

edly when opening.

H93 Electronic obstacle recognition on

opening in the same position by sta-

tionary obstacle.

Remove the obstruction.

The door stops repeat-

edly when closing.

H94 Electronic obstacle recognition on

closing in the same position by sta-

tionary obstacle.

Remove the obstruction.

Search run notified. H62

H67

Search run of the door after a reset or

after power recovery.

Allow the search run to travel its full

course.

Door operates at a re-

duced speed.

H71 Batteryoperation Wait for power recovery

Switch on mains supply.

Door remains closed. – Operating mode for example OFF,

EXIT or P. The door is prevented from

moving by the lock.

E.g. select operating mode AUTO-

MATIC 1. Unlock the lock. Push the

door closed briefly.

Door remains open. – OperatingmodeforexampleOPENor

P. The door is prevented from moving

by the lock.

E.g. select operating mode AUTO-

MATIC 1. Remove the obstruction.

The door remains

closed.

E31 The safety facility in the opening direc-

tionispermanentlyactive(>1minute)

or defective.

Remove objects from within the

rangeofthesensor(s).

The door remains open E32 The safety facility in the closing direc-

tionispermanentlyactive(>1minute)

or defective.

Remove objects from within the

rangeofthesensor(s).

The door does not open

or does not close.

E33 The safety facility for the swing area is

permanentlyactive(>1minute)orde-

fective.

Remove objects from within the

rangeofthesensor(s).

The door does not open

or does not close.

E34 The stop safety facility is permanently

active(>1minute)ordefective.

Remove objects from within the

rangeofthesensor(s).

The door remains open. E41

E42

E43

Activatorinsideisactive>1min.

Activatoroutsideisactive>1min.

Keyswitchisactive>1min.

Get sensor adjusted by a skilled

person.

Reset the key switch.

The door stands still E5.. Anomaly in the travel distance.

Solid obstruction in the movement

area.

Remove firm obstacle in the travel-

ling range of the door.

Perform a software-reset.

The door stands still E61

E62

Power supply is overloaded or voltage

too low.

Get the power supply and connec-

tions checked by a skilled person.

The door stands still E64

E65

Drive/control system is overheated. Wait for the automatic reset after

the door/control system has

cooled.

Protect from direct sunlight.

The door stands still. E..

E8..

Control system shut down for safety

reasons.

Perform a software-reset.

The door collides with

people.

–Safety device or setting inadequate. Shut down the system.

(seesection2.6).

14 Instructions for Use iMotion 1301/1301.S /1401 T-1305 e

7.2 Check-List for Functional Checks

Item To Be Checked Procedure Result

Sensors

T1540_5

• Walkthroughthedoordirectlyfrom

the front and from different direc-

tions at normal speed, starting both

from the inside and outside.

The door opens at the right time

and with sufficient speed so that

passage through the door Is not

hindered.

Safety Sensors

T1540_6

• Walkthroughthedoordirectlyfrom

the front and from different direc-

tions at a slow speed like an infirm

person, starting both from the inside

and outside.

The door opens and remains

open until you are completely

through the door.

Swing Leaf, Door Frame

T1540_10

• Checktheglassdoorllings,door

edges and rubber profiles for dam-

age.

The door fillings have no sharp

edges and splintered glass.

The side parts and the door seals

are in place and undamaged.

Panic Fitting u

T1540_9

• Isolatethedrivefromthepowersup-

ply(mainsystemswitch,mainsplug)

or select operating mode OFF. Then

push the door in the direction opposite

to the opening direction until the pan-

ic fitting releases the door leaf. Now

push the door leaf back to the initial

position.

The panic fitting can be released

and returned to the initial position.

Drive, Lever and Hinges

T1540_8

iMotion 1401 iMotion 1301, 1301.S

• Checkthenoisesmadewhilethe

door moves.

No unusual and noticeable noise

can be heard from the drive, the

lever or in the region of the hinges.

No significant wear is visible.

Operating components, lettering and marking

3

• Check the function and marking of

operating controls. Check all lettering

and marking for their condition.

The operating controls are func-

tioning correctly; the markings are

visible and legible.

System Vicinity

T1540_7

• Check access to the door and the

movement area of the door leaves.

Access to the door is free from

objects and items likely to cause

the user to trip. There are no ob-

jects such as shelves, plant con-

tainers and umbrella stands

within a radius of 50 cm of the

movement area.

Instructions for Use iMotion 1301/1301.S /1401 T-1305 e 15

Declaration of Conformity

In the sense of the guideline for machines 2006/42/EG, appendix II A

Product: Automatic Swing Door

Type designation: ❏iMotion 1301 ❏iMotion 1301.S ❏iMotion 1401

Serial number: .

Manufacturer’s address : .

Base documents: Declaration of incorporation by TORMAX | Landert Motoren AG with

the document number: T-1542

Additionally to the standards listed in the declaration of incorporation

this door installation is in conformity with the regulations listed

below:

DIN 18650-2

We declare in sole responsibility, that the above mentioned product, which is referred to by this

declaration, is in conformity with the guideline for machines 2006/42/EG (Declaration of

incorporation T-1542).

Furthermore, the guideline 2006 /95 / EG (low tension) and 2004 /108 / EG (electro-magnetic-

compatibility) must also be adhered to. This product is in conformity with the base documents

and standards listed above (Declaration of Conformity T-1309).

Place:

Date:

CE authorized person:

the passion to drive doors

TORMAX Sliding Door Drives

TORMAX Swing Door Drives

TORMAX Folding Door Drives

TORMAX Revolving Door Drives

Manufacturer: Advice, sales, installation,

repairs and service:

TORMAX |CH-8180Bülach-Zürich

Phone +41(0)448635111

Fax +41(0)448611474

Homepage www.tormax.com

E-Mail [email protected]

TORMAX is a Division and a registered trademark of Landert Motoren AG

415793

This manual suits for next models

2

Table of contents

Other Tormax Door Opening System manuals

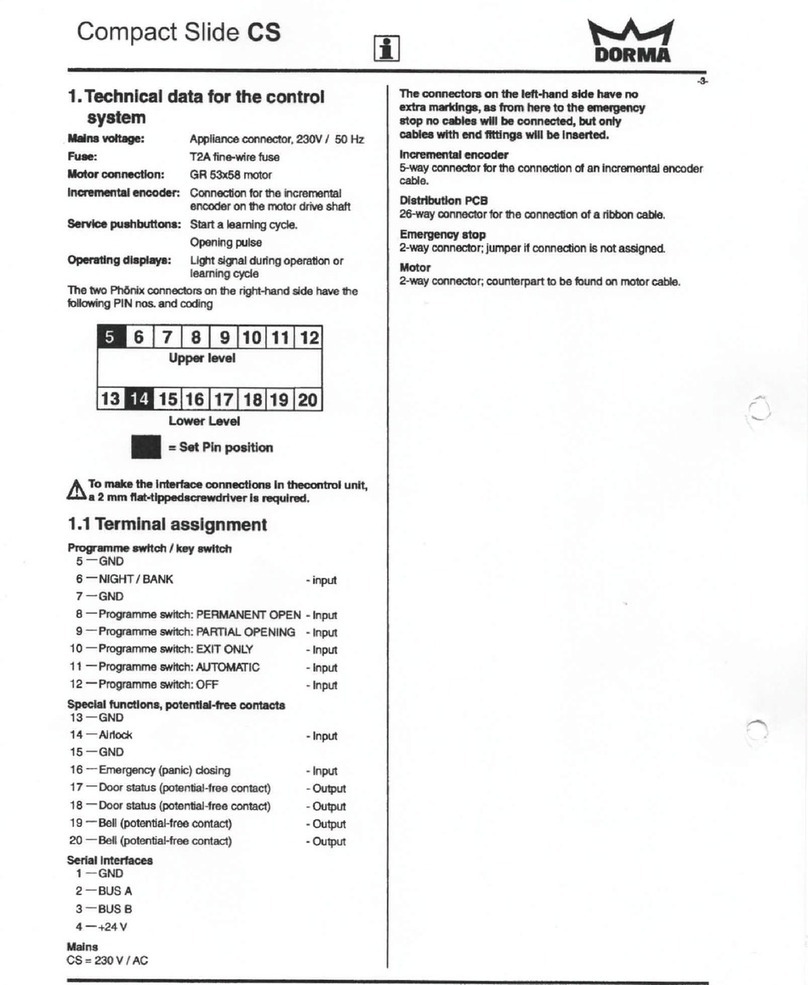

Popular Door Opening System manuals by other brands

Dr. Hahn

Dr. Hahn Turband 3 installation instructions

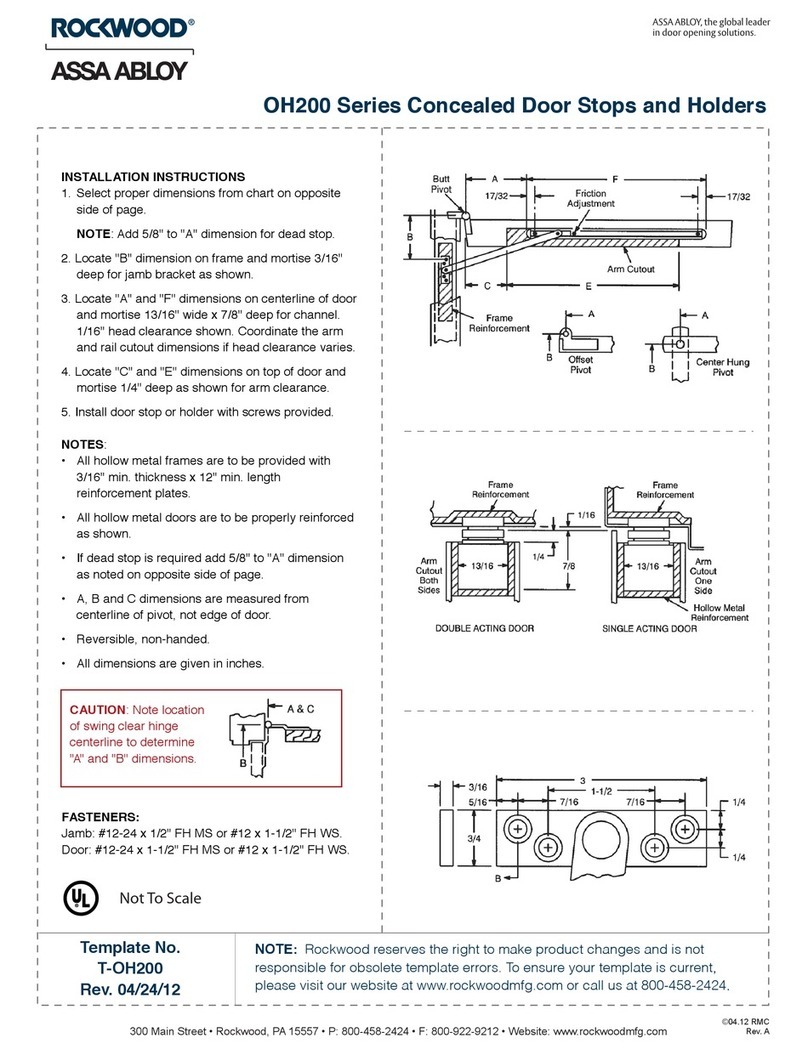

Assa Abloy

Assa Abloy Rockwood OH200 Series installation instructions

Woelm

Woelm HELM GT-L 80 installation instructions

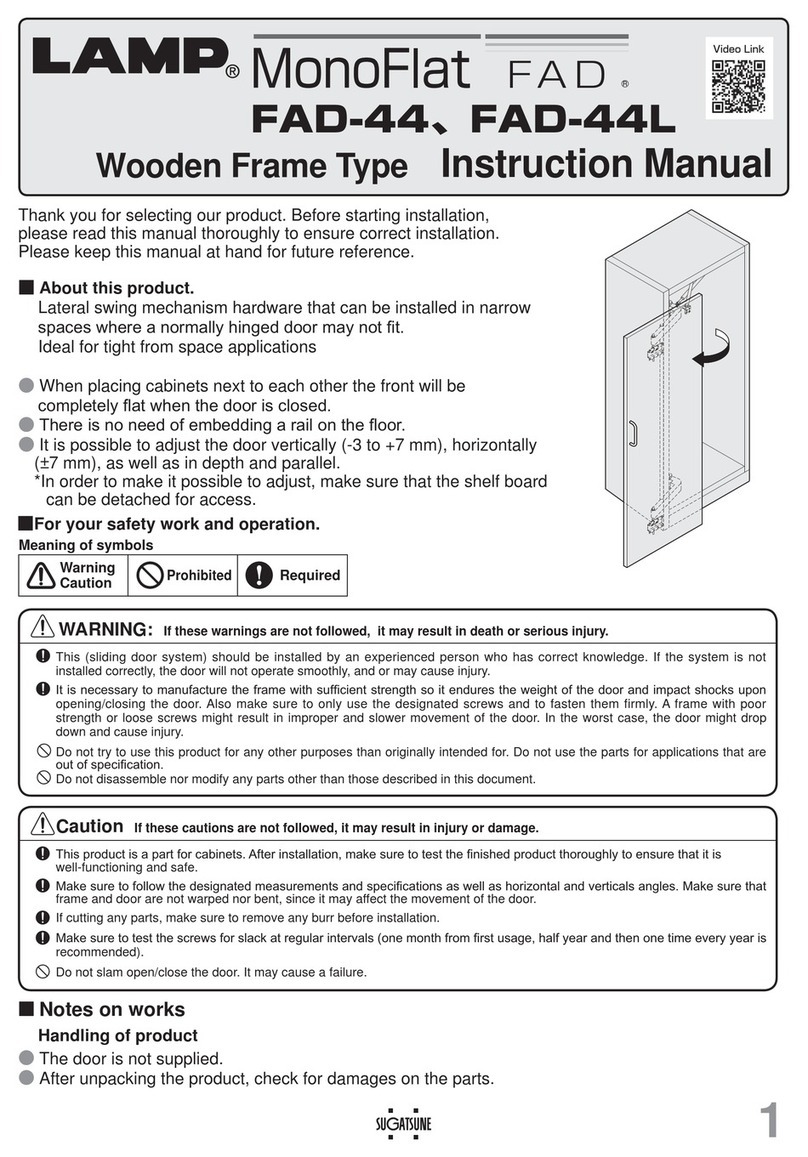

SUGATSUNE

SUGATSUNE LAMP MonoFlat FAD Series instruction manual

Chamberlain

Chamberlain DDO8900W manual

Assa Abloy

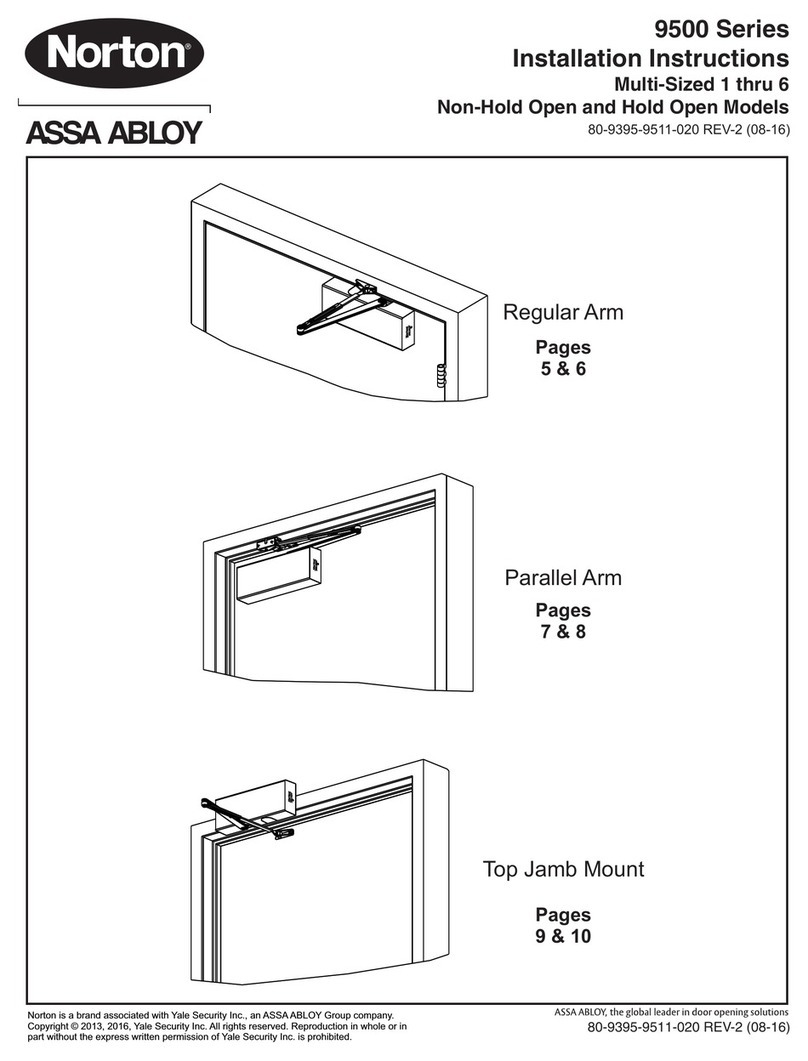

Assa Abloy Norton 9500 Series installation instructions

Dorex

Dorex 1701 Series installation instructions

Norton

Norton tri-style 1603BC installation instructions

MFZ Ovitor

MFZ Ovitor CS 110 operating instructions

Beninca

Beninca JM.3 Operating instructions and spare parts catalogue

Dormakaba

Dormakaba ITS 96 Fixing instructions

Chamberlain

Chamberlain 9747E Series Installation