Tormax TTXII User manual

Installation and Operating Manual

TTXII Swing Door Operator

T-1132 e 1.09

US801465

V1.4 and up

T-1132 e 2

First edition: 9.02 provisional for 0-Series

Update: 3.03, 8.04, 1.09

We print on environment-friendly paper bleached without chlorine.

The enterprises Landert Motoren AG and Landert GmbH are certified according to

ISO 9001.

Contents

1 Introduction 3

2 Safety 4

2.1 General Safety and Accident Prevention Regulations 4

2.2 Safeguarding Danger Points 5

2.3 Organizational Measures 6

3 Basic Functions 7 - 8

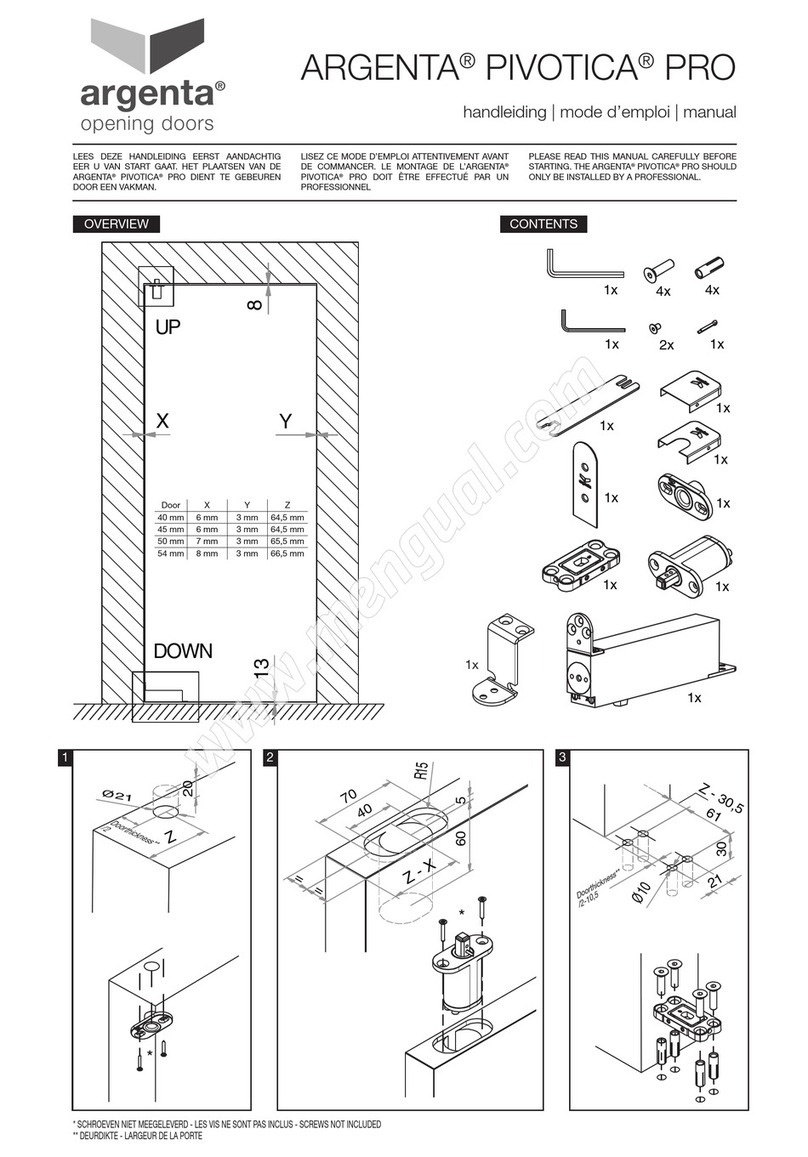

4 Installation

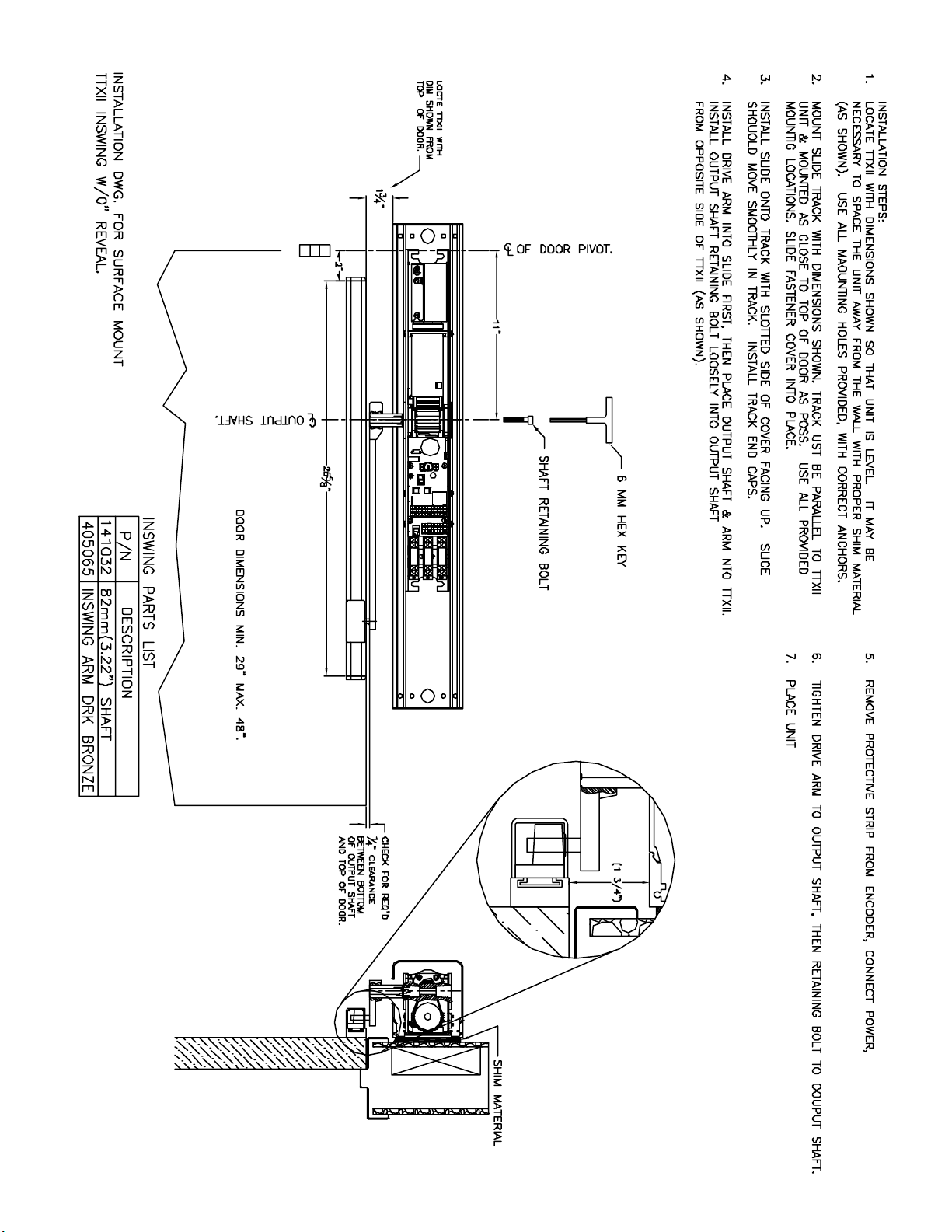

Outswing Surface Mount With 0” to 9 -7/8” Reveal 9

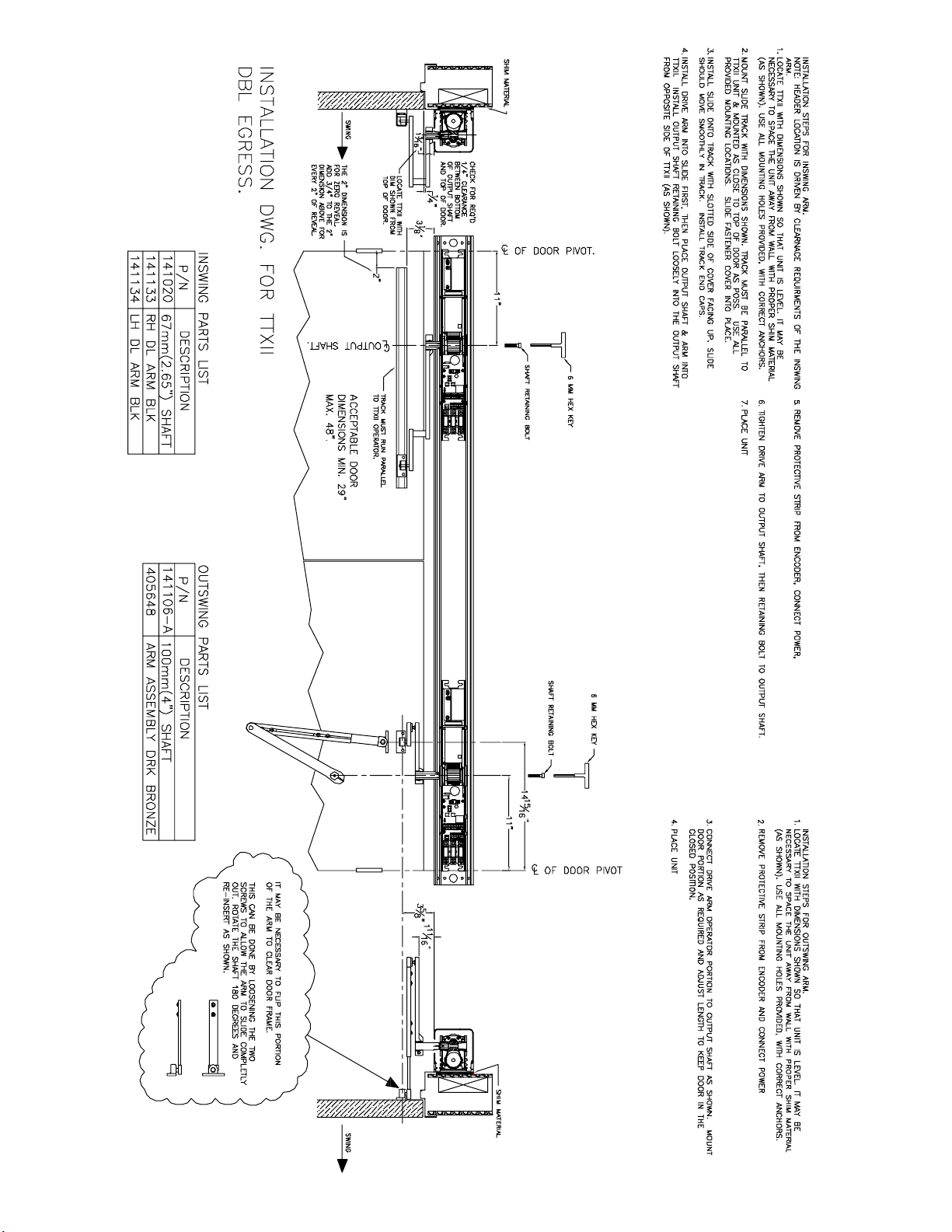

Double Egress with Surface Mount

5 Mechanical Adjustments

6 Electrical Connections and Wiring Diagrams 14 - 14g

7 Commissioning and Adjustments

7.1 Commissioning with “Teach-In General” 15

7.2 Programming Examples 16

7.3 Programming Table 17

7.4 Programming Functions

18 - 19

7.5

Simultaneous or Double Egress Programming 20 - 21

8 Trouble Shooting 22

Inswing Surface Mount With 0” Reveal 10

12

Inswing Surface Mount With Deep Reveal 11

13

3

T-1132 e

Adressee

Area of Application

1 Introduction

These instructions are addressed to AAADM Certified installation and service

technicians.

This document is applicable to the Tormax TTXII swing door operator with SW 1.4

and up.

Non-compliance endangers the safety of the installation personnel, the system op-

erator or the user.

Warning of electrical voltage.

Passages with text on grey background must be absolutely observed for reliable

performance of the system! Neglect can cause material damages.

Explanation of Symbols

T-1132 e 4

2 Safety

2.1 General Safety and Accident Prevention

Regulations

Prior to installation or commissioning, read and follow this information that is being

described on this page—especially the following notes relating to safety—and adhere

to them at all times! Damage to the unit and personal injury may result if these instruc-

tions were not carefully followed.

Pay particular attention to the specially marked notes in this manual (for an explanation

of the symbols please refer to chapter 1)!

These products are Underwriters Laboratories, Inc. (UL) listed and cUL certified

for the Canadian marketplace, and therefore comply with the requirements of

the National Electrical Code (NEC) and the Canadian Electrical Code (CEC).

Installations intended to meet UL and cUL requirements must be followed as

described in the instruction provided herein. These are minimum standard re -

quirements. Where local codes exceed these requirements, they must be fol -

lowed as well.

Warnings of Dangerous Electrical Voltages or Current

Be sure the electrical power is disconnected and locked-out when working on the

operator unit.

Install the electrical cables and power only after the mechanical installation to the

unit is done.

Turn on the power to the operator unit only after all internal cables are connected.

Do not connect cables while the unit is powered.

Always use appropriate tools for installation and repair.

Prior to commissioning or performing any work on the door system, the operating in-

structions for the TORMAX operator and the following safety directions should be

studied with great care and must be observed!

General safety Instructions

Proper grounding methods has to employed to reduce magnitude of transient

over Voltage, To Simplify ground fault location,To improve system and equipment

fault protection,To reduce maintainence time and expense and greater safety

for personnel.

Installer should do permanent wiring as required by the local codes.

Preventing General Hazards and Possible Damage to This Equipment

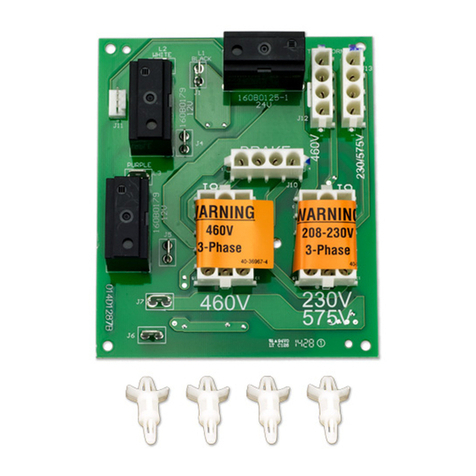

Verify that the power selection switch is set to the correct voltage before start-up.

to the input power supply plug. It should not be routed through doorways, window

not be attached or otherwise secured to the building structure. It should not also be

concealed behind walls, etc.

parts of the operator, door, or system.

The power receptacle must be of the grounding-type. It is very important that the

unit will be properly grounded.

5

T-1132 e

TheTORMAXoperatorisdesignedaccordingtothecurrentstateoftechnologyas

well as the recognized safety-relevant regulations and is intended exclusively for the

deployment in conjunction with automatic interior and exterior doors (without wind

loads) used by people e.g. in hospitals, homes for the elderly, shopping centres, of¿ce

buildings and large-scale enterprises. The operator corresponds to protective class

IP 22. Without additional safety precautions, it may only be installed within, i.e. at the

inside,ofbuildings.

Anyotheruseoranyuseexceedingthisaimisdeterminedtobenotforitsintended

purposeandmayleadtopersonalinjurytotheuserorathirdparty.Furthermore,the

system or other material assets can be damaged. The manufacturer will not be respon-

sible for any damage resulting from this; the risk is carried entirely by the operator of

thedoorsystem.

The operating, service and maintenance conditions speci¿ed by the manufacturer are

to be maintained. The persons entrusted with the service and maintenance must be

acquainted with the matter and informed about any possible danger.

Toensureareliablefunctionofthedoorthemomentoffrictioncausedbye.g.bad

aligning of door leaves or wind charge may not exceed 5 Nm.

In addition to the operating instructions, the legal and other obligatory regulations for

accident prevention and environmental protection, in the respective country where the

door system is operated, shall be applicable. The special directives for automatic doors

(e.g. of the European committee for standardization CEN) must be adhered to.

Furthermore, the operational/national regulations apply.

Arbitrary changes to the system will exempt the manufacturer from any liability for

damages resulting from this.

2.2 Safeguarding Danger Points

General

Automaticdoorsystemsaretoconstructedinsuchamannerthatonopeningand

closing motions endangerments through jamming, shearing and drawing-in are

avoided or safeguarded against, for example through:

– Safety separations

– Limitation of the door-leaf forces

– Monitored safety facilities

–S

eparating protective facilities

DIN V 18650-2: 2003

ANSI Compliance - Always inspect your adjustments to be ANSI A156.10 or A156.19 compliant before

handing over to the enduser.

Maximum Door Leaf

Weights

Intended Purpose

0

50

100

200

220

320

400

36 42 48

Door leaf width

Door leaf weight

lb

In

T1132_40e

T-1132 e 6

2.3 Organizational Measures

The installation or service should be made by an AAADM Certified technician

in accordance with the latest ANSI A156.10 or A156.19 standard.

Contact Tormax for training classes conducted at our facility if you wish to

attend a factory training class.

Use the system only in a technically sound state. Eliminate faults immediately that

mayimpairsafety.

the drive lever, the linkage and the secondary closing edges of the hinges.

Use exclusively tools that are suitable for the respective work procedure. Pay atten-

tion to good condition of the tools.

Electricvoltage/current:Theoperatoristobedisconnectedfromelectricalmains

beforeanyworkisperformedonelectricalparts.

Install cabling only after the installation is complete.

Plug in the power plug only after all internal cables are connected.

Requirements for Installa -

tion or Service Technicians

Fundamental Safety Mea -

sures – Appropriate Behav -

iour

7

T-1132 e

3 Basic Functions

Motion Control – General

The door opens motor-driven in accordance with the stored speed pro¿le (see section

7.1) against the installed spring. If the motor torque decreases the door is braked down

by the spring. The door is held in the open position by a reduced motor torque. The

closing action is performed through spring force only. Thereby, the motor adjusts the

speed. At the completion of the closing motion, deceleration occurs with adjustable

homing in speed over an adjustable angle (see section 7.4.2). The motor is switched

off when the door is closed.

Functionalityoftheunit

OpensthedoorinoperatingmodeAUTOinaccordancewith“Teach-InGeneral”.

Opens the door in operating mode AUTO and in operating mode OFF in accordance

with “Teach-In General”, or with “Teach-In Key Switch” if this was performed after

“Teach-In General”.

Opens the door in AUTOMATIC mode according to the “Teach-In General ” instructions

when the door is manually pushed open to an adjustable angle. “Push-and-Go” can

be switched off.

Whentheopendoor(operatingmodeOPEN,duringhold-opentime,stepcontrol)is

movedmanuallyandconsiderably(16°)inclosingdirection,itwillcloseautomati-

cally.

This prevents the door from opening if closed, cancells the opening cycle or

If both the safety device in opening direction and the safety device in closing direction,

respond at the same time during a motion, the door stops in place. Through “Teach-In

General”, the safety sensor is disabled automatically – if necessary – over a predeter-

mined door swing range. If this function is not used, a jumper is inserted between

14–15.

Standard function:

Safety device in closing direction reactivates the door if the sensor becomes active.

If the door reaches the full closed position the input is inhibited and can be used manually

w/o activation. The input becomes active after another activation command is given.

Optional functions:

Safety device for the swing area

The input keeps a closed door closed and an open door open.

Safety Device Bodyguard

This function is only in use with the safety device “Bodyguard” of BEA.

The door remains open or closed. A commenced motion is completed.

Using this function automatically changes the settings of Feedback Door State to “door

opening or door open” data for the LO21 / LO21P lock out relay.

If these safety functions are not used, a jumper is inserted between 18–19.

Outputforactivetestingofthesafetydeviceinopeningdirectionandsafetydevicein

closing direction (i.e. BEA Superscan or Bircher Topscan).

An opening can only be initiated through the key switch. Switching to operating mode

OFFinterruptsanycurrenthold-opentime.

Activator (4 - 5)

Key Switch (7 - 8)

Safety device in closing

direction/safety device for

the swing area.

(18 - 19 NC)

Safety Device on

Pull / Swing side

(14 - 15 NC)

Test of safety devices

Operating Mode OFF

“Push / Pull”

“Push-and-Close”

T-1132 e 8

Feedback Door State

(door position)

Anopeningcanbeinitiatedbyanactivator,akeyswitchandalsoby“PushandGo”

depending upon con¿guration.

The door opens and stops in open position. It opens according to the settings of “Teach-

In General”.

Unlocks on each opening command. On completion of the opening time delay, the door

starts opening. When the door has moved somewhat in opening direction, the door

lockdropsoffagain.Thedoorlockisactivatedonlyinproximityofthe“doorclosed”

position.

The feedback “door closed” (or “door open” if recon¿gured)between11–12isonlyvalid

as long as mains supply is available. This message is established as soon as the

processor considers the driving function as complete. Connection for 24 VDC relay or

signal light. Transistor output short circuit proof in relation to internal supply voltage

24 VDC / 0.75 A.

Ifasecondopeningwidthhasbeencon¿gured(“Teach-Inkeyswitch”)thefeedback

“door open” is as follows:

Triggering of opening Feedback defined by

Activator “Teach-In General”

Key-switch “Teach-In key-switch”

“Push-and-Go” “Teach-In General”

Manual operation the smaller of both opening widths

The control provides .75 amps total to the sensors and the lock output. If the control

is over loaded the led point may start to flicker, go dim or completley turn off. If this

occurs install an aux power supply to power up your accessories.

Ifthedoorhitsa¿rm obstacle during opening, the motor driven opening procedure is

terminated immediately. If the door hits an obstacle during closing, it opens again waits

forthesafetytimetoelapseandtriestocloseagain.Thenextopeningcommandopens

thedooragainasusual.Ifreversingisswitchedoff,thedoorstaysontheobstacle

whenclosed.Onopeningafter60seconds,thepoweredopeningprocedurestops.

The door opens when an impulse is received (key-switch, activator or “Push-and-Go”),

remainsinthevalidopenpositionduringthevalidhold-opentime,andclosesthere-

after again.

The door opens when an impulse is received (from the key switch, activator or “Push-

and-Go”) and remains in the open position. The door closes immediately after the next

impulse or “Push-and-Close”. The motional sequence depends on the settings of the

respective “Teach-In”.

The motorisswitchedoffimmediatelywhenthedoorisblocked.

Motor and transformer contain thermal relays that interrupt the current supply to the

control system at 230 °F. The system operates as during a power failure until the

temperature drops to 185 °F.

Thedoorcanbemanuallyopenedifthedoorlockcanbeunlockedwiththedoorhan-

dle. The door closes through spring force. The motor, which is controlled short-circuited,

controls the closing action with constant braking power. After return of power, the

system is immediately ready for use again.

Power Supply 24 VDC

Reversing Motion

(Reverse on Obstruction)

Time Control

Step Control

Internal Protective Devices

Power Failure

Operating Mode OPEN

Door Lock

Operating Mode AUTO

4 Installation

3/8”

14 - 15/16”

)ROTAREPOII-XTTEHTGNINOISIMMOC(7NOITCESEESDNAOTUAOTNI

9

TINUECALP

,

T

F

A

HSTUPTUOLLATS

NIGE

D

02

.XORPPADETATOR

SAHROTOMECNO.NEPODLOHOTNI

TFAHSTUPTUOEUQROTDNAREH

TOHCAE

HTIW

LELLRAPGNINNURB&ASECAFRUSHTIW

.SBL-.TF03OT

)ROTAREP

OII-X

TTEHTGNINOISIMMOC(

7NOITCESEESDNAO

T

UAO

TN

I

10

OTNITINUECALP

GNIDAOLERPROFNEPODLOH

)ROTAREPOII-XTT

EHTGNINOISIMMOC(7NOITCESEESDNAOTUAOTNI

11

OTNITINU

ECALP

GNIDAOLERPROFNEPODLOH

)ROT

AREPOII-

XTTEHTGNINO

ISIMMOC(7NOITCESEESDNAOTUAOTNI

)ROTAREPOII-XTTEHTGN

INOISIMMOC(7NO

ITCESEES

DNAOTUAOTNI

12

GNIDAOL

E

R

P

ROFNEPODL

OH

OTNITINUE

CALP

,PLACE UNIT

INTO HOLD OPEN. ONCE MOTOR HAS ROTATED APPROX . 20 DEG, INSTALL

OUTPUT SHAFT AS SHOWN WITH SURFACES A & B RUNNING PARALLEL

WITH EACH OTHER AND TORQUE OUTPUT SHAFT TO 30 FT. -LBS.

T-1132 e 13

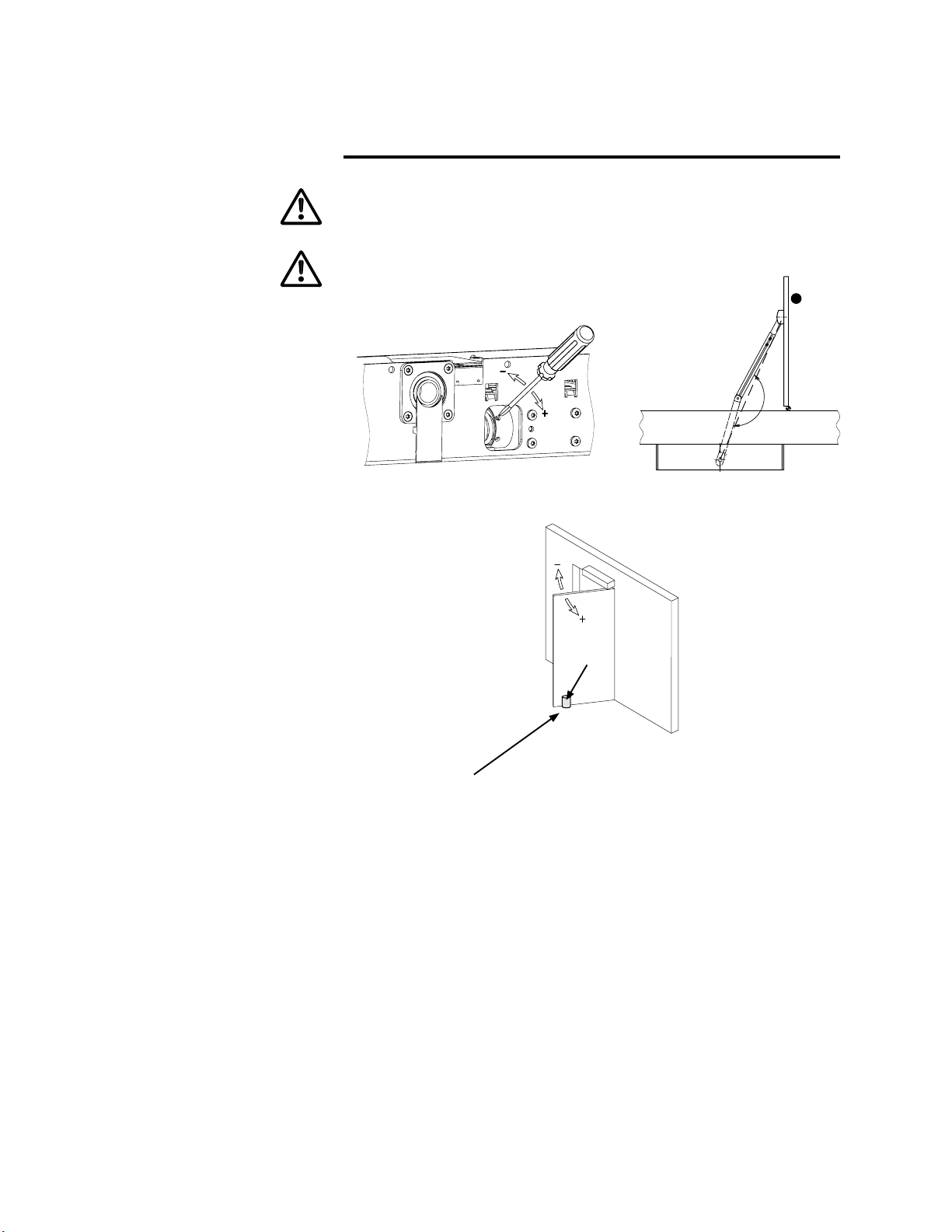

5 Mechanical Adjustments

An external door stop may be installed as shown but you must leave a 3/8” space

between the door and any physical stop.

The door should only be opened so far that the standard linkage cannot tip over and

the sliding lever does not leave the rail.

90°

!

External door stop.

14

T-1132 e

6 Electrical Connections

Before beginning the work described here check that the mains supply is switched

off.

If possible, route the mains connection along the side of the power supply to the op-

erator.

The connecting cables must be of the type “PVC cable H05VV-F” or “rubber hose

cable H05RR-F”.

Round the edges and remove burrs from all conduits used for the mains connection.

Remove mains supply cover (1).

Connect the mains cable to terminal (11)

in accordance with gure.

Route the mains cable either through the

prepared holes of the side cover or through

the slots in the mounting plate.

Use only cable bushings made from syn-

thetic materials. Metallic bushings are to

be earthed.

Check correct adjustment of the voltage

selector (12) and reinstall the mains supply

cover (1).

Mains Connection

10AT

L1 3mm

N

230/115V~

50/60 Hz

T1132/1

L1

N

12

11

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

To Reduce the risk of electric shock, it is critical that all wiring ........

1) Be properly Grounded

2) Be permanently Fastened

3) Satisfy local code requirements.

SW D61-070809 / V1.4 Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 14 a

Terminal Connections

Legend:

*programmable

A57.0.xamlatot,)CDV42…12(CDV42V42+

IN Input (contact load 24 VDC / 4 mA)

edoidevitcetorpdetargetni)A57,0/CDV42daol.xam(NPNtuptuOTUO

** Applying an impulse on operating mode OFF (min 0.6 s) interrupts the

current hold-open time.

1 2 3 4 5 6 7 8 9 10 11 12

IN

GND

IN

GND

IN

+24 V

GND

IN

OUT

+24 V

OUT

+24 V

Activator

Status indication

door closed/*open

** OFF

AUTO

OPEN

Key switch

Door lock 24 VDC

locked currentless

* unlocked currentless

–

+

No protective

circuit necessary

13 14 15 16 17 18 19 20

–

+

GND

IN

OUT

24 V

GND

IN

OUT

24 V

+

+

–

+

Safety devices without

monitoring

Safety device

in opening

direction

Safety device in

closing direction/

*Swing area

Title:

TTXII WITH LARCO 433 WIRELESS

RECEIVER AND TRANSMITTER

Dwg.

by:

Date:

DWG NO:

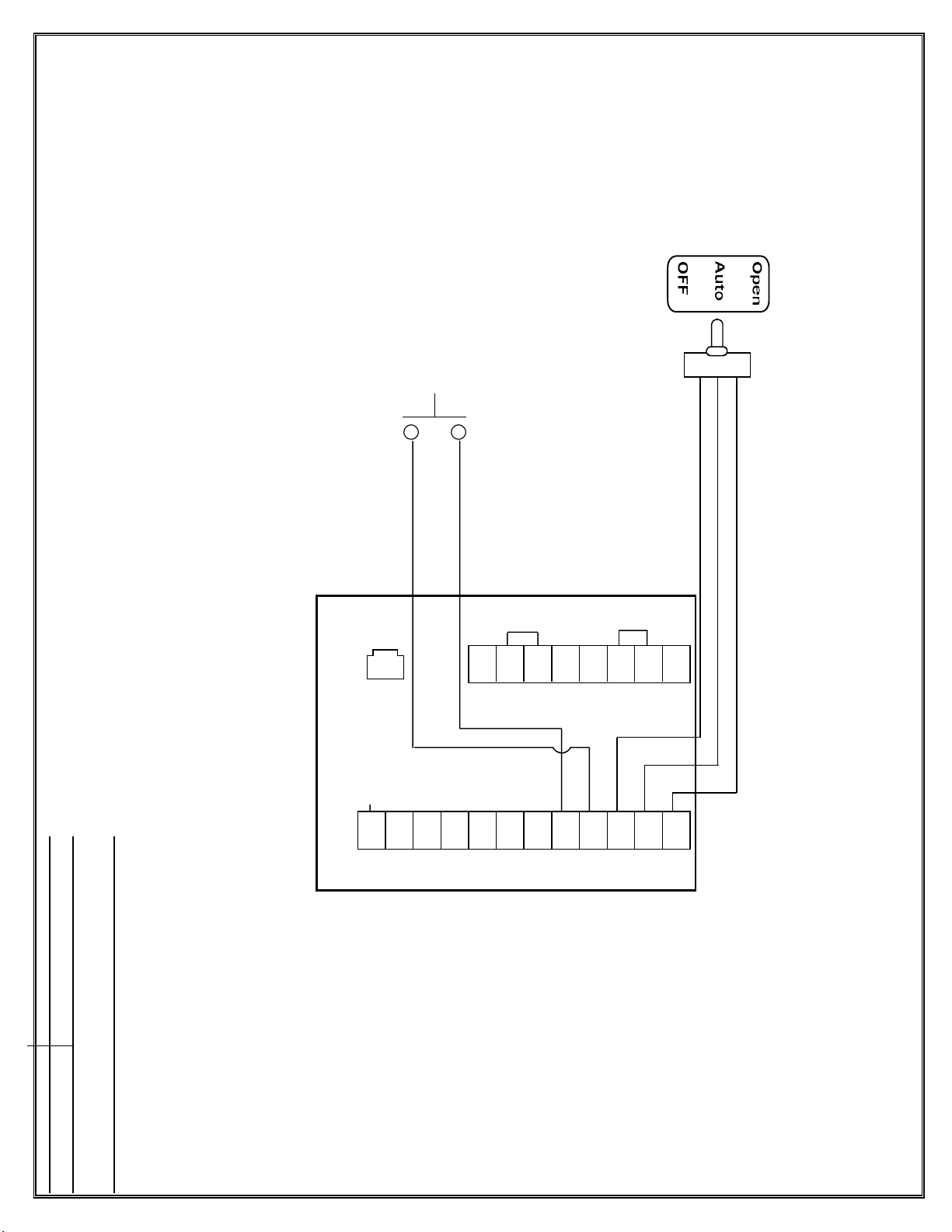

OFF/AUTO/HOLD OPEN

Red

White

Blue

Beto Rendon

4-3-06

22d

Note:

Please see programming matrix on page 25 for setup.

LARCO ULTRA SMALL

433 REC

LARCO 433

TRANSMITTER

BLACK

BROWN/WHITE

RED

ORANGE

IN

GND

IN

GND

IN

IN

GND

1

2

3

4

5

6

7

8

9

10

11

12

+24v

OUT

+24v

OUT

+24v

GND

GND

IN

OUT

+24V

IN

OUT

+24V

13

14

15

16

17

18

19

20

TTX II

14 b

Title:

Dwg.

by:

Date:

DWG NO:

OFF/AUTO/HOLD OPEN

Red

White

Blue

Beto Rendon

11/14/06

22e

Note:

1) Please see programming matrix on page 25 for proper programming and setup for operators (Safety Device Bodyguard).

2) Bodyguard relay must be changed to 2 NC.

Bodyguard III

Red

Black

White

Green

Brown

Blue

LO21

Orange

Brown

Red/White

White

Red

Black

ACTIVATION

TTX II WITH BODYGUARD AND LO21

IN

GND

IN

GND

IN

IN

GND

1

2

3

4

5

6

7

8

9

10

11

12

+24v

OUT

+24v

OUT

+24v

GND

GND

IN

OUT

+24V

IN

OUT

+24V

13

14

15

16

17

18

19

20

TTX II

14 C

Title:

TTXII Btm Load

Dwg.

by:

Beto Rendon

Date:

2/15/08

DWG NO:

Green

White

Red

ACTIVATION

IN

GND

IN

GND

IN

IN

GND

1

2

3

4

5

6

7

8

9

10

11

12

+24v

OUT

+24v

OUT

+24v

GND

GND

IN

OUT

+24V

IN

OUT

+24V

13

14

15

16

17

18

19

20

TTX II

14 d

22 L

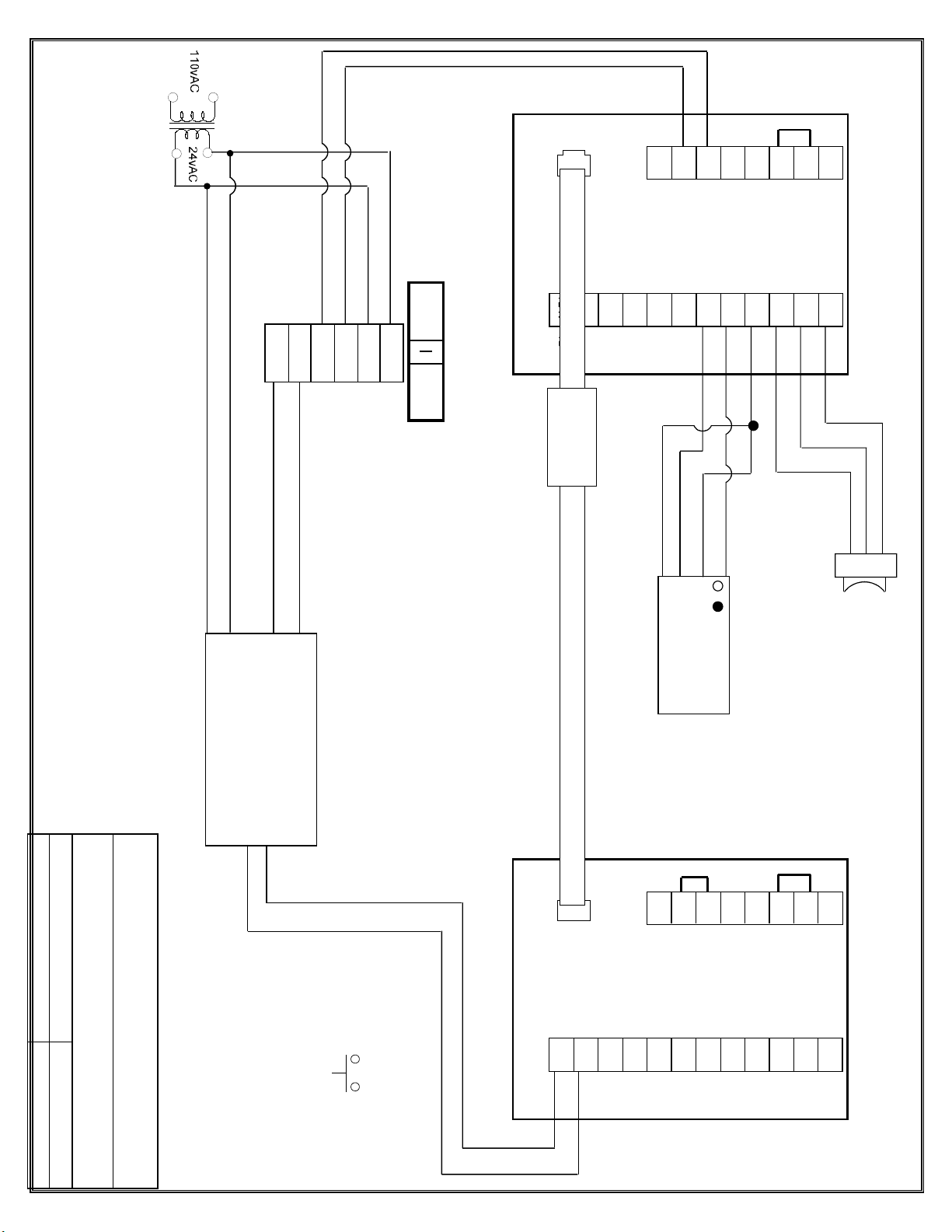

Title:

TTXII PAIR WITH LARCO 433 WIRELESS

RECEIVER AND TRANSMITTER

Dwg.

by:

Beto Rendon

Date:

2-12-09

DWG NO:

22N

OFF/AUTO/HOLD OPEN

Red

White

Blue

Note:

See programming matrix on page 25 and programming procedure on page 30.

LARCO ULTRA SMALL

433 REC

BLACK

BROWN/WHITE

RED

ORANGE

Master

LARCO 433

TRANSMITTER

IN

GND

IN

GND

IN

IN

GND

1

2

3

4

5

6

7

8

9

10

11

12

+24v

OUT

+24v

OUT

+24v

GND

GND

IN

OUT

+24V

IN

OUT

+24V

13

14

15

16

17

18

19

20

TTX II

IN

GND

IN

GND

IN

IN

GND

1

2

3

4

5

6

7

8

9

10

11

12

+24v

OUT

+24v

OUT

+24v

GND

GND

IN

OUT

+24V

IN

OUT

+24V

13

14

15

16

17

18

19

20

TTX II

406079

Primary Secondary

14 e

Title:

TTXII PAIR WITH LO21, BODYGUARD AND

433 WIRELESS RECEIVER.

Dwg.

by:

Beto Rendon

Date:

2-13-09

DWG NO:

22O

Note:

See programming matrix on page 25 and programming procedure on page 30.

Set Bodyguard to relay 2 - NC.

LARCO 433

TRANSMITTER

LO21

Orange

Brown

Red/White

White

Red

Black

Black

White

Green

Blue

Red

Brown

Bodyguard II

I

OFF/AUTO/HOLD OPEN

Red

White

Blue

LARCO ULTRA SMALL

433 REC

BLACK

BROWN/WHITE

RED

ORANGE

Primary Secondary

IN

GND

IN

GND

IN

IN

GND

1

2

3

4

5

6

7

8

9

10

11

12

+24v

OUT

+24v

OUT

+24v

GND

GND

IN

OUT

+24V

IN

OUT

+24V

13

14

15

16

17

18

19

20

TTX II

IN

GND

IN

GND

IN

IN

GND

1

2

3

4

5

6

7

8

9

10

11

12

+24v

OUT

+24v

OUT

+24v

GND

GND

IN

OUT

+24V

IN

OUT

+24V

13

14

15

16

17

18

19

20

TTX II

406079

14 f

Table of contents

Other Tormax Door Opening System manuals

Popular Door Opening System manuals by other brands

Simons Voss Technologies

Simons Voss Technologies SmartHandle Series manual

Dormakaba

Dormakaba CLPKT90 installation instructions

Frisco

Frisco Eclipse 73 Series installation guide

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

ADL

ADL LIGHT Assembling instructions

Record

Record DFA 127 user manual

Dormakaba

Dormakaba HSW EASY SAFE installation instructions

Automatic Technology

Automatic Technology Syncro ATS-3 Quick operation guide

Bohle

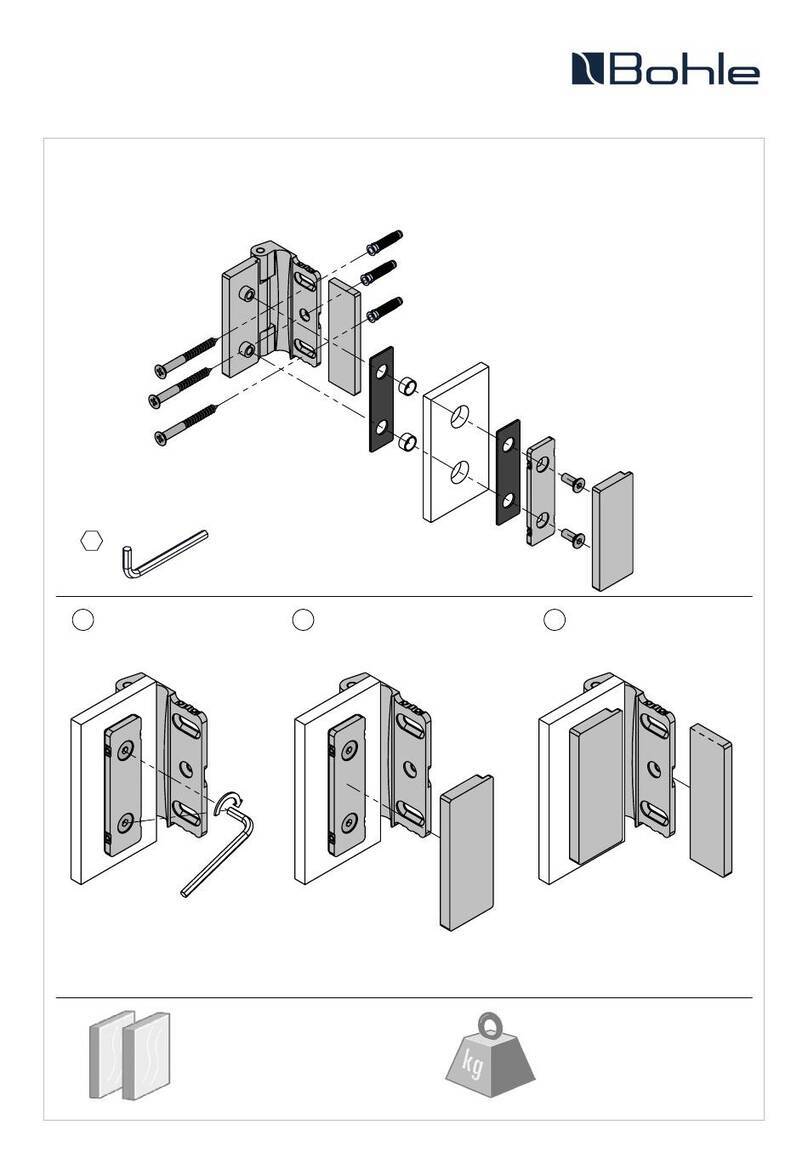

Bohle BO 5215430H instruction manual

DDS

DDS 2300CA Series Operation and maintenance manual

Genie

Genie GCL OPGSX Series installation manual

Cal-Royal

Cal-Royal CR801 Series installation instructions