4.0 Specifications

Model number.................................................................................................................................................................................PBD-2870

Stock number…………………………………………………………………….......................................................................................................... PBD-2870

Motor and electricals:

Motor type…………………………………………………….................................................................................................................Induction motor

Motor power....................................................................................................................................................................................1.1 kW

Power supply..................................................................................................................................................................1~230V, PE, 50 Hz

Protection class................................................................................................................................................................................... IP 54

Listed load amps................................................................................................................................................................................. 6.4 A

Machine lamp......................................................................................................................................................Halogen lamp 24V, 35 W

Coolant pump..................................................................................................................................................................................... 40 W

Capacities:

Centre height................................................................................................................................................................................. 140 mm

Swing over bed...............................................................................................................................................................................280 mm

Swing over cross slide.................................................................................................................................................................... 170 mm

Distance between Centres.............................................................................................................................................................700 mm

Spindle:

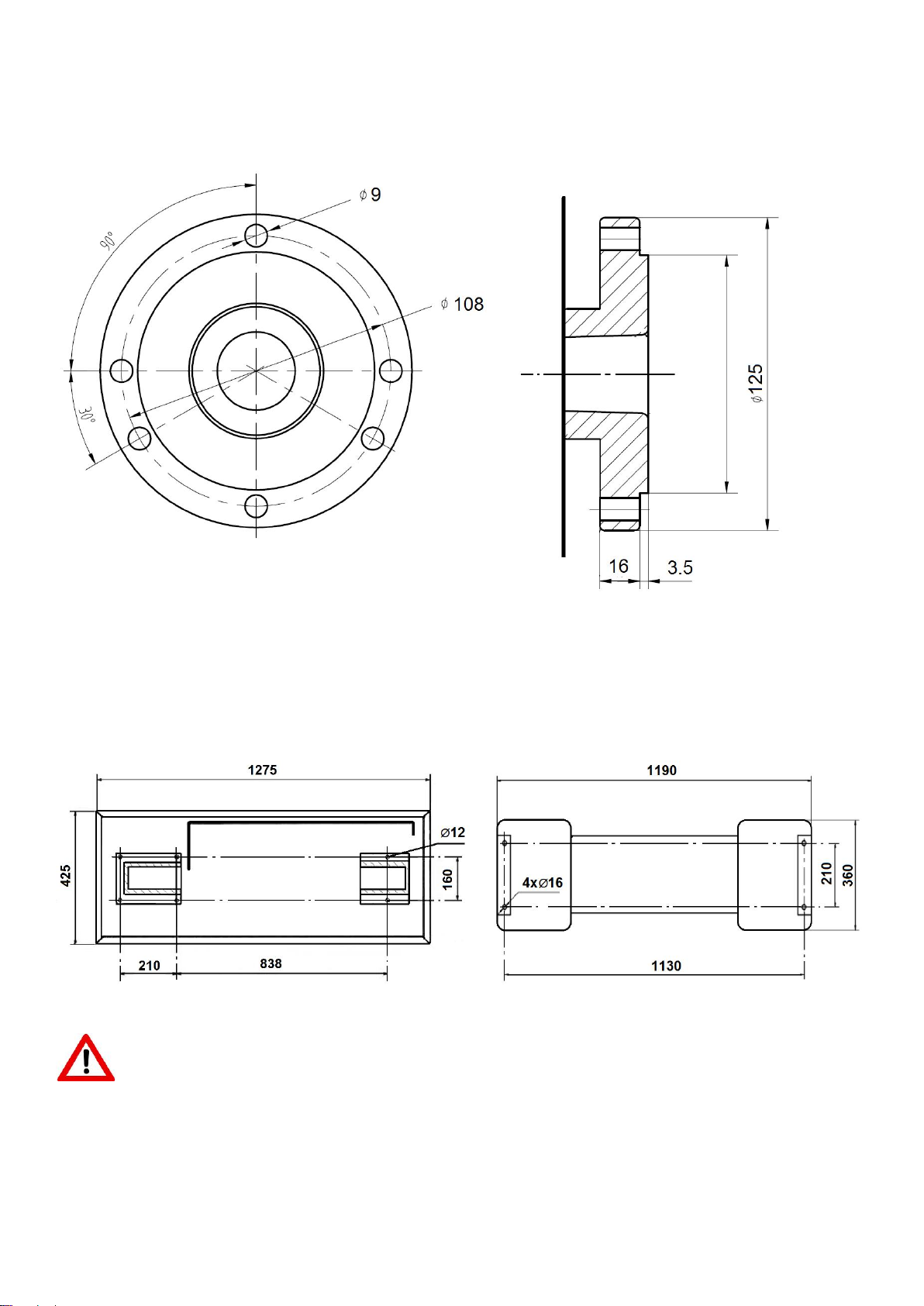

Spindle nose mounting.................................................................................cylindrical mount (Ø125mm, Ø96mm, Ø108-3xØ9 & 4xØ9)

Spindle bore..................................................................................................................................................................................... 26 mm

Spindle taper........................................................................................................................................................................................MT4

Number of spindle speeds........................................................................................................................................................................ 6

Range of spindle speeds................................................................................................................................................... 150 ~ 2000 /min

Tailstock:

Tailstock ram travel..........................................................................................................................................................................85 mm

Tailstock taper......................................................................................................................................................................................MT2

Bed and Slides:

Bed width.......................................................................................................................................................................................180 mm

Cross slide travel............................................................................................................................................................................ 160 mm

Top slide travel.................................................................................................................................................................................60 mm

Tool size max..............................................................................................................................................................................12x12 mm

Lead screw pitch................................................................................................................................................................................ 3 mm

Longitudinal feeds.........................................................................................................(6x) 0.07 / 0.1 / 0.14 / 0.2 / 0.28 / 0.40 mm/rev

Metric threads........................................................................................................................................................(21x) 0.2~4.0 mm/rev

Inch threads........................................................................................................................................................................(21x) 8 ~ 56 TPI

Materials:

Machine Bed............................................................................................................ Cast iron, induction hardened and precision ground

Headstock, tailstock, slides........................................................................................................................................................... Cast iron

Spindle bearings..............................................................................................................................Taper roller bearings, quality level P5

Sound emission in idle 1........................................................................................................................................................ 73.4 dB (LpA)

Sound emission during cutting 1............................................................................................................................................78.3 dB (LpA)

1Sound emission measured according to EN ISO 11202, in 1m distance, 1.6m above ground. The specified values are emission levels

and are not necessarily to be seen as safe operating levels. As workplace conditions vary, this information is intended to allow the user

to make a better estimation of the hazards and risks involved only.

Dimensions and Weights:

Overall dimensions, assembled (W x D x H)..................................................................................................1380 x 700 x 650 (1285) mm

Shipping dimensions (W x D x H) (Separate packing).......................................................... 1320 x 700 x 690mm & 820 x 680 x 430 mm

Shipping dimensions (W x D x H) (Whole packing)................................................................................................. 1400 x 700 x 1470mm

Net weight (approximate)................................................................................................................................................................. 280kg

Shipping weight (approximate)........................................................................................................................................................ 320 kg

L = length; W = width; H= height; D= depth

The specifications in this manual were current at time of publication, but because of our policy of continuous improvement, JET reserves

the right to change specifications at any time and without prior notice, without incurring obligations.