tornos SAS 16.6 User manual

SAS 16.6

INSTRUCTION MANUAL

ENGLISH VERSION TRANSLATED FROM THE ORIGINAL VERSION

TORNOS SA CH-2740 MOUTIER

http://www.tornos.ch

Ref. : 300801_en – Printed in Switzerland - Copyright © 1999-2012

Caution!

Before handling the machine,

all users must read the and pay particular attention to the

"SAFETY INSTRUCTIONS" !

Keep this document for future reference.

Instruction manual - SAS 16.6

300801_en - 12/12

I. Identification

I.1. Document

Instruction manual SAS 16.6

No 300801_en

Version manager

Version Date Description

10/12 19/10/2012 First edition

300801_en - 12/12

Instruction manual - SAS 16.6

I.2. Manufacturer

TORNOS SA

Rue Industrielle 111

CH-2740 MOUTIER / SWITZERLAND

Tel. +41 (0)32 494 44 44

Fax +41 (0)32 494 49 03

www.tornos.ch

I.3. Products

SAS 16.6

Instruction manual - SAS 16.6

300801_en - 12/12

Source suvaPro

Behaviour in the event of an emergency

1. Keep calm

2. Think

3. Act Raise the alarm Ambulance

Police

Fire brigade

Poisoning

Doctor

Hospital

Who? Person raising the alarm.

What? What happened?

Where? Place, street, number, access, floor, etc.

How many? Number of people involved.

Other Particular dangers, dangerous materials, etc.

Accident 1. Secure the dangerous area.

2. Raise the alarm.

3. Give first aid.

4. Inform ambulance staff.

Position(s) of first aid box:

Fire 1. Notify the fire brigade.

2. Find shelter for yourself and others.

3. Close window(s) and door(s).

4. Inform the fire brigade staff.

5. Put the fire out.

Evacuation 1. Notify the people in danger and evacuate them.

2. Leave the premises using the stairs.

3. Go to the assembly point.

Assembly point(s):

Person in charge of keeping the emergency numbers, first aid boxes and training up-to-date:

Mandatory!

Apply the regulations in force in your company. If there are no regulations, you can adapt the

above example to your country’s legislation and to the specific needs of your company.

300801_en - 12/12

Instruction manual - SAS 16.6

Instruction manual - SAS 16.6

300801_en - 12/12

TABLE OF CONTENTS

1 Installation conditions.............................................................................. 1-1

1.1 Machine identification....................................................................................1-1

1.2 Machine dimensions.......................................................................................1-2

1.2.1 Technical features and dimensions...................................................................... 1-2

1.2.2 Machine dimensions with the unprotected reel.................................................. 1-3

1.2.3 Machine dimensions with the unprotected with reel and protection............... 1-4

1.2.4 Machine dimensions with the unprotected sediment tank................................ 1-5

1.3 Safety clearance.............................................................................................1-6

1.3.1 Peripheral devices.................................................................................................. 1-6

1.4 Conditions of use.............................................................................................1-7

1.4.1 Respecting the environment ................................................................................. 1-7

1.4.2 Quality of floors....................................................................................................... 1-7

1.4.3 Operating environment.......................................................................................... 1-8

1.4.3.1 Temperature and ambient humidity...............................................................................1-8

1.4.3.2 Noise ..................................................................................................................................1-8

1.4.4 Air extraction specifications.................................................................................. 1-9

1.4.4.1 Minimum room volume....................................................................................................1-9

1.4.4.2 Ventilation of premises.....................................................................................................1-9

1.5 Energy supply connection specifications...................................................1-10

1.5.1 Electrical connection ........................................................................................... 1-10

1.5.2 Installation characteristics................................................................................... 1-11

1.5.3 Pneumatic connection......................................................................................... 1-13

1.6 Guard opening/closing................................................................................1-15

1.7 Consumable filling ........................................................................................1-17

1.7.1 Lubricants .............................................................................................................. 1-17

1.7.1.1 Lubricant equivalence table .........................................................................................1-17

1.7.1.2 Lubricant equivalence table: greases..........................................................................1-17

1.7.1.3 Restrictions.......................................................................................................................1-18

2 Installation................................................................................................. 2-1

2.1 Work environment (specific to the installation)............................................2-2

2.1.1 Order and cleanliness............................................................................................ 2-2

2.2 Unpacking........................................................................................................2-4

2.2.1 Removal of the transport straps............................................................................. 2-4

2.3 Installation........................................................................................................2-5

2.4 Cleaning...........................................................................................................2-5

2.5 Alignment of the bolt-making machine / bar feeder .................................2-6

2.6 Oil recovery tank.............................................................................................2-8

2.7 Connecting the energy supplies ...................................................................2-9

2.7.1 Electrical connection ............................................................................................. 2-9

2.7.1.1 Connections between the basic machine and the electric cabinet........................2-10

2.7.1.2 Connection to the local mains......................................................................................2-11

2.7.1.3 Connection via an autotransformer..............................................................................2-12

2.7.2 Peripheral options device connection............................................................... 2-13

2.7.3 Pneumatic connection......................................................................................... 2-14

300801_en - 12/12

0. - Instruction manual - SAS 16.6

0-6

2.8 Topping up liquids......................................................................................... 2-15

2.8.1 Cutting liquid tank ................................................................................................ 2-15

2.8.2 Oil tank................................................................................................................... 2-16

2.9 Preparation of the machine for movement................................................ 2-17

2.9.1 Disconnecting power sources............................................................................. 2-17

2.9.1.1 Electrical power supply .................................................................................................2-17

2.9.1.2 Pneumatic power supply...............................................................................................2-18

2.9.2 Emptying liquids.................................................................................................... 2-18

2.9.2.1 Cutting liquid...................................................................................................................2-18

2.9.2.2 Greasing liquid ...............................................................................................................2-18

2.9.2.3 Machine cleaning..........................................................................................................2-18

2.10 Moving the machine .................................................................................... 2-19

2.10.1 Lifting the machine............................................................................................... 2-19

Instruction manual - SAS 16.6 - 1. Installation conditions

300801_en - 12/12 1-1

1. Installation conditions

For unpacking and moving the machine, see the document Transport sheet.

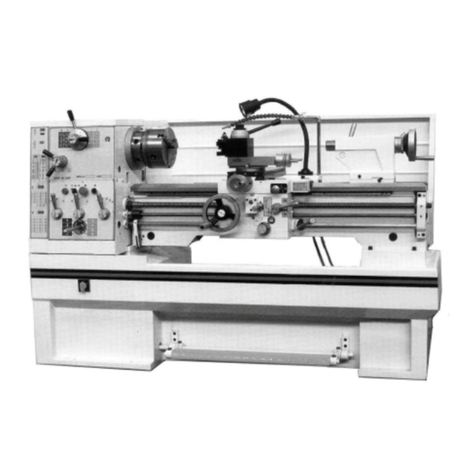

1.1. Machine identification

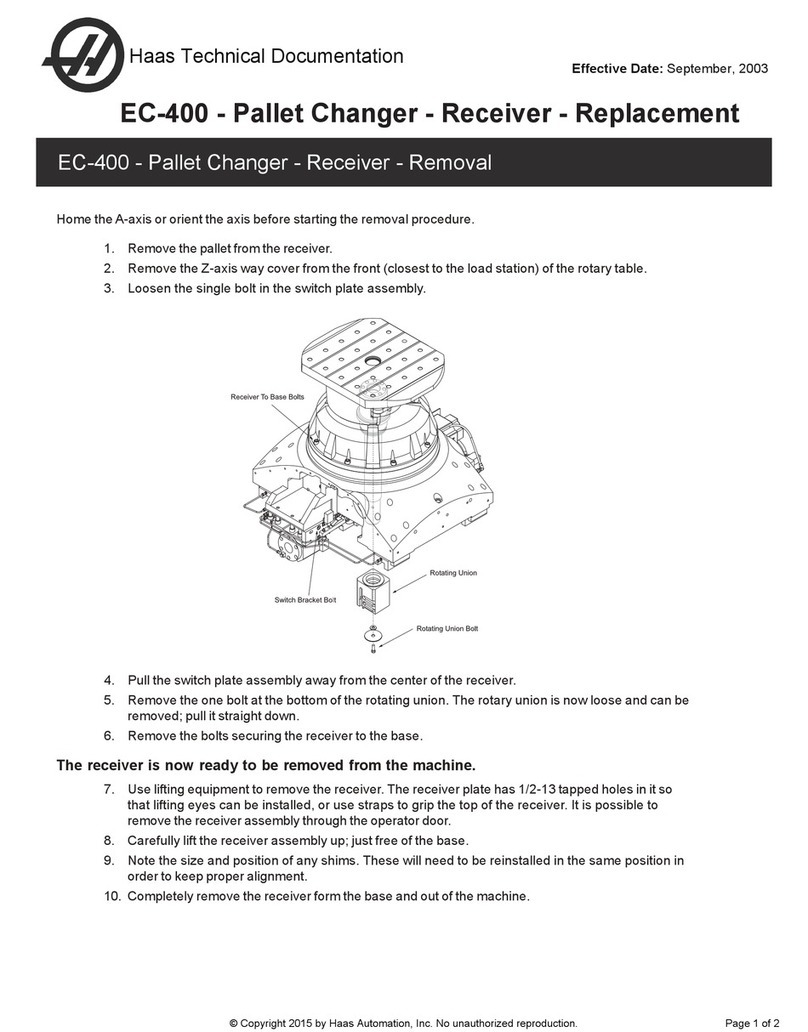

Fig. 1

The warning plate contains the following information:

Location of parts

Rep. Description

(1) Machine type

(2) Serial number

(3) Machine identification number

(4) Year of manufacture

Mandatory!

The serial number must be quoted for all contacts with TORNOS SA departments.

300801_en - 12/12

1. Installation conditions - Instruction manual - SAS 16.6

1-2

1.2. Machine dimensions

1.2.1. Technical features and dimensions

Name Unit Value

Number of spindles - 6

Maximum round bar release (diameter) mm 16

Maximum hexagonal bar release (s/flat) mm 13

Maximum square bar release mm 11

Spindle speed (3 ranges according to stress)

Range 1 – Ratio R1 rpm 800 to 2000

Range 2 – Ratio R2 rpm 800 to 4000

Range 3 – Ratio R3 rpm 800 to 8000

Production range p/min 3 to 75

Accelerated run programmable up to rpm 65

Maximum length feeder with standard cams mm 63

Maximum length parts with standard cams mm 52

Maximum length feeder with LP* cams mm 85

Maximum length parts with LP* cams mm 75

*The use of LP cams limits production to 60 p/min and

spindle speed to 6000 rpm

Number of transverse sliders - 6

Run of transverse sliders mm 20

Number of available independent feeders - 4

Normal run for independent feeders mm 45

Central slider run mm 50

Drive motor for spindles

Constant torque up to 4,000 rpm) Nm 47.7

Constant power from 1500 rpm (50 % ED) kW 7.5

Camshaft drive motor

Rated torque Nm 5.9

Maximum speed rpm 3,000

Coolant pump motor (50Hz)

Speed rpm 1500

Power kW 2.2

Coolant pump capacity (to 50Hz) l/min 95

Outer dimensions (see figures 2 to 7)

Machine and command cabinet, leng. mm 2962

Machine with 3 m long guidebars. mm 5049

Width (at guard) mm 1100

Height on the spraying guard mm 1615

Height at signal lamp mm 1962

Weight of the machine alone, approx. kg 2,700

Weight of electrical command cabinet, approx. kg 270

Instruction manual - SAS 16.6 - 1. Installation conditions

300801_en - 12/12 1-3

1.2.2. Machine dimensions with the unprotected reel

Fig. 2

L l l1 B

3m bars 5049 2377 2469 152

4 m bars 6049 3377 3469 493

300801_en - 12/12

1. Installation conditions - Instruction manual - SAS 16.6

1-4

1.2.3. Machine dimensions with the unprotected with reel and protection

Fig. 3

L l l1 A

3 m bars 5049 2377 2517 2101.5

4 m bars 6049 3377 3517 2760.5

Instruction manual - SAS 16.6 - 1. Installation conditions

300801_en - 12/12 1-5

1.2.4. Machine dimensions with the unprotected sediment tank

Fig. 4

L l l1 B

3m bars 5049 2377 2469 152

4 m bars 6049 3377 3469 493

300801_en - 12/12

1. Installation conditions - Instruction manual - SAS 16.6

1-6

1.3. Safety clearance

Fig. 5

1.3.1. Peripheral devices

Mandatory!

A clearance of at least 1 metre must be left for access all around the machine and its periphery

This clearance space is reserved and authorised only to those people working on the machine

for production or maintenance purposes.

Specifications

Name Unit Value

Minimum safety clearance all around the machine m 1

Warning!

The clearance space of 1 metre around the machine must consider the dimensions of the

optional peripherals.

Instruction manual - SAS 16.6 - 1. Installation conditions

300801_en - 12/12 1-7

1.4. Conditions of use

1.4.1. Respecting the environment

The use of the machine and of the different elements surrounding it must be made in observance

of the environmental regulations in force in the country of installation.

Waste resulting from production must be disposed of in accordance with the regulations in force

in the country of installation.

Machine use

- Take the necessary precautions in the plants, so as not to pollute the environment.

- The use of the machine and of the different elements surrounding it must be made in observance

of the environmental regulations in force in the country of installation.

- Waste resulting from production must be disposed of in accordance with the regulations in force

in the country of installation.

Scrapping

Scrapping the machine, its components and the elements connected to it must be performed in

observance of the environmental regulations in force in the country of installation.

Special attention must be paid to:

- lubricant oils,

- batteries,

- electronic parts.

which must be handed over to a recycling plant.

Regulations in force

The user should find out more from the relevant authority in the country of installation.

1.4.2. Quality of floors

Information!

The floor needs to be sufficiently resistant to support the weight of the machine and all its

components. TORNOS SA recommends a non-slip surface. We do not recommend the use of

non-slip mats in other places. This could cause people to trip and fall.

Specifications

Name Unit Value

Quality of the floor - Hard, stable, free

from vibrations

and perfectly

level

Allowable surface load daN/cm² 12

300801_en - 12/12

1. Installation conditions - Instruction manual - SAS 16.6

1-8

1.4.3. Operating environment

1.4.3.1. Temperature and ambient humidity

Caution!

All devices are used within the tolerances not reaching and not exceeding the limits of their

operating specifications.

1.4.3.2. Noise

The purpose of the noise measurements is to determine the average sound levels where an

operator works most of the time.

The measurements take account of the following:

- a) sound power level,

- b) sound surface pressure level,

- c) Sound pressure level at the operator's workstation.

Attention!

If due to special reasons, the work station noise level (Leq) is 85 dB(A) or higher, the employer shall

provide useful information on the noise as well as hearing protection devices at work stations;

wearing these is recommended.

Specifications

Name Unit Value

Maximum ambient humidity % 79

Room temperature of the workplace °C 5 - 35

Relative temperature °C +/- 15

Note!

The parameters which influence the real exposure levels include the duration of the operator's

exposure to noise, the shop characteristics, the other sources of noise, etc.

The values measured in the given conditions are those of the actual emission levels and make no

claim to conform to the safety-at-work levels.

Even though correlations between the noise emission and exposure levels exist, this noise

declaration report cannot serve as a basis for determining whether additional precautions are

required.

Any measurement results obtained on a particular production site, will obviously differ from those

measured by TORNOS SA at its plants.

Instruction manual - SAS 16.6 - 1. Installation conditions

300801_en - 12/12 1-9

1.4.4. Air extraction specifications

1.4.4.1. Minimum room volume

1.4.4.2. Ventilation of premises

Information!

According to DIN 14497, the minimum room volume per machine must be 10m3 per kilogram of

CO2in order to allow use of the fire-fighting equipment (reference 5483).

Warning!

If the room volume is too small, there is a risk of death from asphyxiation when using the fire-

fighting device.

Minimum shop volume per machine

Name Unit Value

SAS 16.6 m3100

Information!

The premises where the machine is installed must be adequately ventilated.

Mandatory!

Observe the regulations in force in the country of installation.

300801_en - 12/12

1. Installation conditions - Instruction manual - SAS 16.6

1-10

1.5. Energy supply connection specifications

1.5.1. Electrical connection

Setting the machine with the electric cabinet, see figure 6.

Connecting the electric cabinet to the mains

If the machine is powered by another network than 380 V / 50 Hz, 400 V / 50 Hz, 420 V / 50 Hz,

440 V / 60 Hz, 460 V / 60 Hz, 480 V / 60 Hz, you need to connect the TM2 transformer (see also

chapter XX) referring to the diagram SAS–16.6, no. 300197.

Note!

When the machine is installed, it is important to replace the 4 lifting rings for the electric cabinet

(see figure 6) by the 4 screws with special washers.

This is to weatherproof the electric cabinet. These screws can be found in a packet attached to

one of the 4 lifting rings.

Instruction manual - SAS 16.6 - 1. Installation conditions

300801_en - 12/12 1-11

1.5.2. Installation characteristics

Main power connection

The connection system for the machine to the mains is provided by the cable to the bottom of

the electric cabinet (see figure 7).

The machine SAS 16.6 is protected from short circuits and power surges by an FR2 circuit breaker of

the electromagnetic and thermal type.

Connect the power according to the real network measurements. The tolerances indicated in the

table must not be surpassed in any event.

Specifications

Name Unit Value

Power active kW 9

Installed power kVA 15

Specifications

Network power foreseen (V) Previously

delayed fuse (A) Frequency

foreseen (Hz) Entrance

section

(mm2)

200 – 20 Nm 40 50 / 60 – 10

230 +/– 5% – 40 50 / 60 – 10

380 +/– 5% – 32 50 / 60 – 4

400 +/– 5% – 32 50 / 60 – 4

420 +/– 5% – 32 50 / 60 – 4

440 +/– 5% – 20 50 / 60 – 4

460 +/– 5% – 20 50 / 60 – 2.5

480 +/– 5% – 20 50 / 60 – 2.5

500 +/– 5% – 20 50 / 60 – 2.5

300801_en - 12/12

1. Installation conditions - Instruction manual - SAS 16.6

1-12

Fig. 6

Fig. 7

Network entrance inlet

Table of contents

Other tornos Lathe manuals