Safety

2.1 Safe Operation Guide

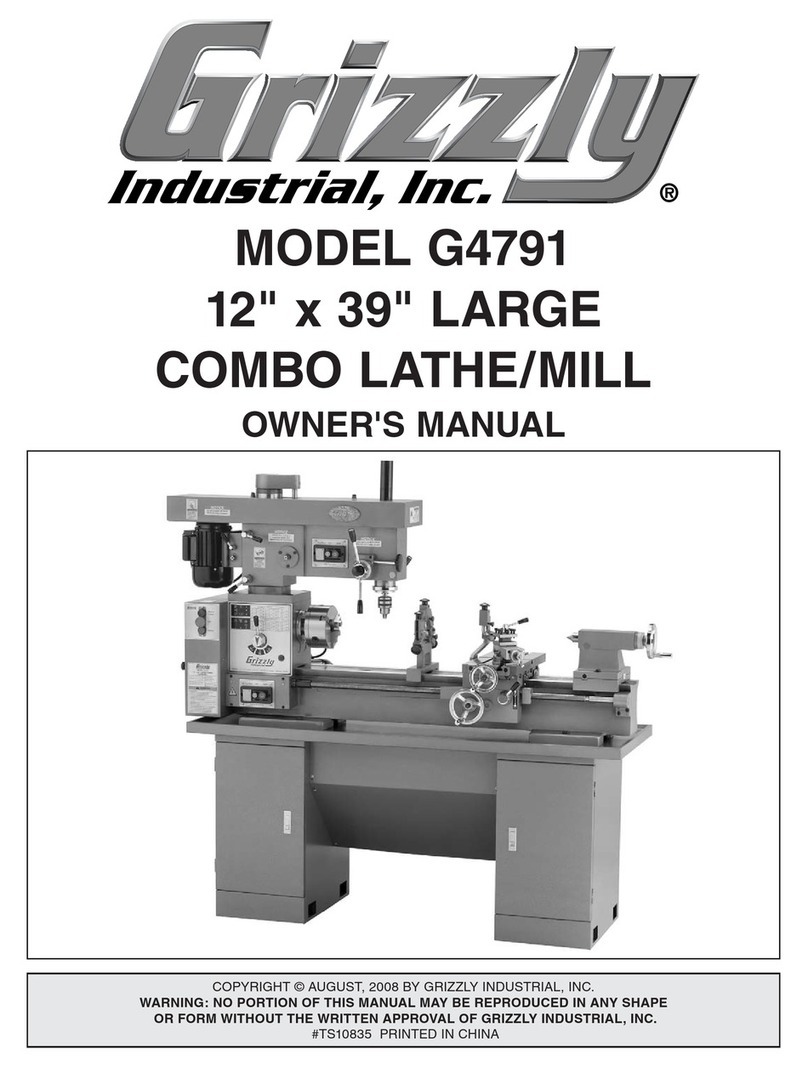

This machine tool is a high speed and powerful cutting machine tool, which, if used improperly, will lead to danger.

Operators are requested to read the Safe Operation Guide described below before operating the

Machine. Care should be taken to observe and maintain the lathe in a normal use environment during subsequent use,

so as to avoid any danger from occurring.

Important

Only professional persons who have referred to the operating manual and safe operation machine training, can operate

the machine.

Be sure to read the Safe Operation Guide carefully described below before operating the machine:

• Keep the machine tool and the working area clean and orderly.

• All the protective devices and the cover plates should be in place and the side covers should be closed.

• Take care not to place any objects within the machining area, as there may be the risk of collisions with the

rotating parts or moving parts of the machine tool.

• Do not touch or step across the moving or rotating parts of the machine.

• Before starting up the machine, you must be aware of to shut down the machine properly.

• Do not operate the machine under the overload.

• In case of any unforeseen circumstances occurring, the operation of the machine should be stopped immediately.

• Before installing a chuck or any other accessories on the spindle, the machine power should be cut off, so as to

prevent the spindle from rotation.

• In the absence of checks and assertions of whether your fixtures are compatible with the machine, your fixtures

should not be installed.

• Check the load capacity of the centers used to ensure that they meet the requirements.

• When leaving the machine, be sure to switch the power off.

• The maximum weight of the workpiece on the machine tool is 40kg.

• The chuck should be correctly and securely mounted on the spindle of the machine.

• Care should be taken to ensure that the workpiece is clamped firmly, and the spindle speed should not exceed

the safe speed of the chuck.

• As there may be contact with the human body, especially when using materials of small diameters, under no

circumstances should the bar materials extend beyond the end of the spindle of the headstock that has no

special protection or corresponding support shall be used.

• There is a marked speed limit for the chuck, and no shift of speed during running posted on the lower right corner

of the headstock. Alongside an electric warning sign posted on the electrical cabinet and a warning sign for no

touching on the workpiece (or chuck) with hand is allowed when the workpiece is rotating posted on the

protective cover of the chuck in this machine tool, to remind you to take care during your operation.

• The Emergency Stop button is a red button displayed on the control panel. When this is pressed down, the motor

will stop its rotation immediately, which should be used in an emergency situation to prevent the machine tool

from collision.

• Do not process toxic or flammable materials, which will emit deadly fumes. Before processing, consult your

material suppliers, so as to obtain safe materials.

• Do not carry out any maintenance on the machine when it is charged. Check the control components and the

operating elements of the machine tool regularly, to ensure that the machine works normally. When carrying out

an overhaul of the machine tool, qualified parts & components shall be used for replacement.

• Do not carry out any modifications or change of the equipment presumptuously, which, if necessary, shall be

treated by this company. Any personal injury or mechanical damage to the machine tool caused by any

modification or change shall not be within the scope of the responsibility of this company.

• Keep children far away from the machine tool.