Toro STX-26 User manual

FormNo.3422-813RevA

STX-26StumpGrinder

ModelNo.23208—SerialNo.402000000andUp

ModelNo.23208G—SerialNo.402000000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3422-813*A

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisdesignedtogrindandremovetree

stumpsandsurfaceroots.Itisnotintendedtocut

rockoranyothermaterialotherthanwoodandthe

soilaroundastump.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure

1illustratesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g242084

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................6

Setup......................................................................10

1InstallingtheGrinderControlLever................10

2CheckingtheFluidLevels..............................10

3ChargingtheBattery......................................10

ProductOverview....................................................11

Controls............................................................11

Specications..................................................14

Attachments/Accessories.................................14

Operation................................................................14

AddingFuel......................................................14

PerformingDailyMaintenance..........................16

StartingtheEngine...........................................16

DrivingtheMachine..........................................17

ShuttingofftheEngine......................................17

GrindingaStump..............................................17

MovingaNon-FunctioningMachine..................18

SecuringtheMachineforTransport..................18

LiftingtheMachine...........................................19

OperatingTips.................................................19

Maintenance...........................................................20

RecommendedMaintenanceSchedule(s)...........20

Pre-MaintenanceProcedures..............................21

RemovingtheCoverPlate................................21

RemovingtheBottomShield............................21

Lubrication..........................................................22

GreasingtheMachine.......................................22

EngineMaintenance...........................................23

ServicingtheAirCleaner..................................23

ServicingtheEngineOil....................................24

ServicingtheSparkPlug(s)..............................26

FuelSystemMaintenance...................................27

DrainingtheFuelT ank......................................27

ReplacingtheFuelFilter...................................28

ElectricalSystemMaintenance...........................28

ServicingtheBattery.........................................28

ReplacingtheFuses.........................................31

DriveSystemMaintenance..................................31

ServicingtheTracks.........................................31

BeltMaintenance................................................34

ReplacingthePump-DriveBelt.........................34

ControlsSystemMaintenance.............................35

AdjustingtheTraction-Control

Alignment......................................................35

HydraulicSystemMaintenance...........................37

HydraulicFluidSpecications...........................37

CheckingtheHydraulic-FluidLevel...................37

ChangingtheHydraulicFluid............................38

GrinderMaintenance............................................39

ReplacingtheTeeth..........................................39

Cleaning..............................................................40

RemovingDebrisfromtheMachine..................40

Storage...................................................................40

Troubleshooting......................................................42

Schematics.............................................................43

3

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol(Figure2),which

meansCaution,Warning,orDanger—personal

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

DANGER

Theremaybeburiedpower,gas,and/or

telephonelinesintheworkarea.Digginginto

themmaycauseashockoranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorlesspoisonthatisfatalifinhaled.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthisinformation,itistheowner'sresponsibility

toexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Beforeusingthemachine,havetheareamarked

forundergroundutilitiesanddonotusethe

machineinmarkedareas.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyand

safelyperformthejob.Useonlytheaccessories

andattachmentsthatareapprovedbythe

manufacturer.

•Wearappropriateclothingincludinggloves,eye

protection,longpants,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Inspecttheareawhereyouwillusetheequipment

andremoveallobjects,suchasrocks,toys,and

wire,thatthemachinecouldthrow.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

FuelSafety

•Useextracarewhenhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Cleandebrisfromthehydrauliclift,drives,

mufers,andengineaftereachusetohelp

preventres.

•Parkthemachineonalevelsurface,lowerthe

hydrauliclift,disengagethehydraulics,engagethe

parkingbrake(ifapplicable),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Neverrunanengineinanenclosedarea.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

4

•Ensurethatallthedrivesareinneutralandthe

parkingbrakeisengaged(ifapplicable)before

startingtheengine.Starttheengineonlyfromthe

operator'sposition.

•Slowdownanduseextracareonhillsides.

Ensuretotravelintherecommendeddirectionon

hillsides.Turfconditionscanaffectthestabilityof

themachine.

•Slowdownandusecautionwhenmakingturns,

crossingroadsandsidewalks,andwhenchanging

directionsonslopes.

•Donotchangetheengine-governorsettingor

overspeedtheengine.

•Keepyourhandsandfeetawayfrommovingparts.

•Lookbehindanddownbeforebackingupto

ensurethatthepathisclear.

•Nevercarrypassengersandkeeppetsand

bystandersaway.

•Donotoperatethemachinewhenyouaretired,ill,

orundertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners.

•Ensurethattheareaisclearofpeoplebefore

operatingthemachine.Stopthemachineif

anyoneentersthearea.

•Neverjerkthecontrols;useasteadymotion.

•Operatethemachineinareaswherethereare

noobstaclesincloseproximitytoyou.Failureto

maintainadequatedistancefromtrees,walls,and

otherbarriersmayresultininjuryasthemachine

backsupduringoperationifyouarenotattentive

tothesurroundings.Operatethemachineonlyin

areaswherethereissufcientclearanceforyou

tosafelymaneuver.

•Locatethepinchpointareasmarkedonthe

machineandkeepyourhandsandfeetawayfrom

theseareas.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

SlopeOperation

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,youmust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Alwaysusecommonsense

andgoodjudgmentwhenperformingthis

evaluation.Changesintheterrain,suchas

moisture,canquicklyaffecttheoperationof

themachineonaslope.

•Operateupanddownslopeswiththefrontof

themachineuphill.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelortrack

goesovertheedgeortheedgecollapses.Keep

asafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

•Avoidstarting,stopping,orturningthemachineon

aslope.Avoidmakingsuddenchangesinspeed

ordirection;turnslowlyandgradually.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Donotoperatethemachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

Beawarethatoperatingthemachineonwetgrass,

acrossslopesordownhillmaycausethemachine

tolosetraction.Lossoftractiontothewheelsor

tracksmayresultinslidingandalossofbraking

andsteering.Themachinecanslideevenifthe

wheelsortracksarestopped.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelortrack

goesovertheedgeortheedgecollapses.Keep

asafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Donotparkthemachineonahillsideorslope

withoutloweringthehydrauliclifttotheground.

MaintenanceandStorage

•Parkthemachineonalevelsurface,lowerthe

hydrauliclift,disengagethehydraulics,engagethe

parkingbrake(ifapplicable),shutofftheengine,

andremovethekey.Waitforallmovingpartsto

stopbeforeadjusting,cleaning,orrepairingthe

machine.

•Cleandebrisfromthehydrauliclift,drives,

mufers,andenginetohelppreventres.Wipe

upanyspilledoilorfuel.

•Allowtheenginetocoolbeforestoringanddonot

storethemachinenearames.

•Neverallowuntrainedpersonneltoservicethe

machine.

5

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Disconnectthebatteryorremovethespark-plug

wiresbeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast;

connectthepositiverstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparkandames.Unplugthe

chargerbeforeconnectingordisconnectingitfrom

thebattery.Wearprotectiveclothinganduse

insulatedtools.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyes,andclothing.Protect

yourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygassescanexplode.Keepcigarettes,

sparks,andamesawayfromthebattery.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Keepallnutsandboltstight.Keeptheequipment

ingoodcondition.

•Nevertamperwiththesafetydevices.

•Keepthemachinefreeofdebrisbuildup.Wipeup

anyspilledoilorfuel.

•Shutofftheengine,removethekey,andinspect

themachineifyoustrikeanobject.Makeany

necessaryrepairsbeforestarting.

•UseonlygenuineTororeplacementparts.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.Hydraulicuid

escapingunderpressurecanpenetrateskinand

causeinjuryrequiringsurgerywithinafewhours

byaqualiedsurgeon;otherwise,gangrenemay

result.

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard6.Keepbystandersasafe

distancefromthebattery.

2.Nore,opename,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection.9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard

decal93-6686

93-6686

1.Hydraulicuid

2.ReadtheOperator'sManual.

decal93-7321

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,rotating

knives/blades—stayawayfrommovingparts.

6

decal93-7814

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal93-9084

93-9084

1.Liftpoint/Tie-downpoint

decal100-4650

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

awayfromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

awayfromthemachine.

decal107-9366

107-9366

1.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

decal119-4560

119-4560

1.Ignitionkey

2.Engine—start

3.Engine—run

4.Engine—stop

5.Fast

6.Enginespeed

7.Slow

8.On/Closed

9.Choke

10.Off/Open

11.ReadtheOperator'sManualbeforestartingtheengine—1)

EnsurethatthetractioncontrolisintheNEUTRALposition;

2)MovethethrottlelevertotheFASTposition,closethe

choke(ifapplicable),anddonotoperatethejoystick;3)

Turnthekeytostarttheengine.

7

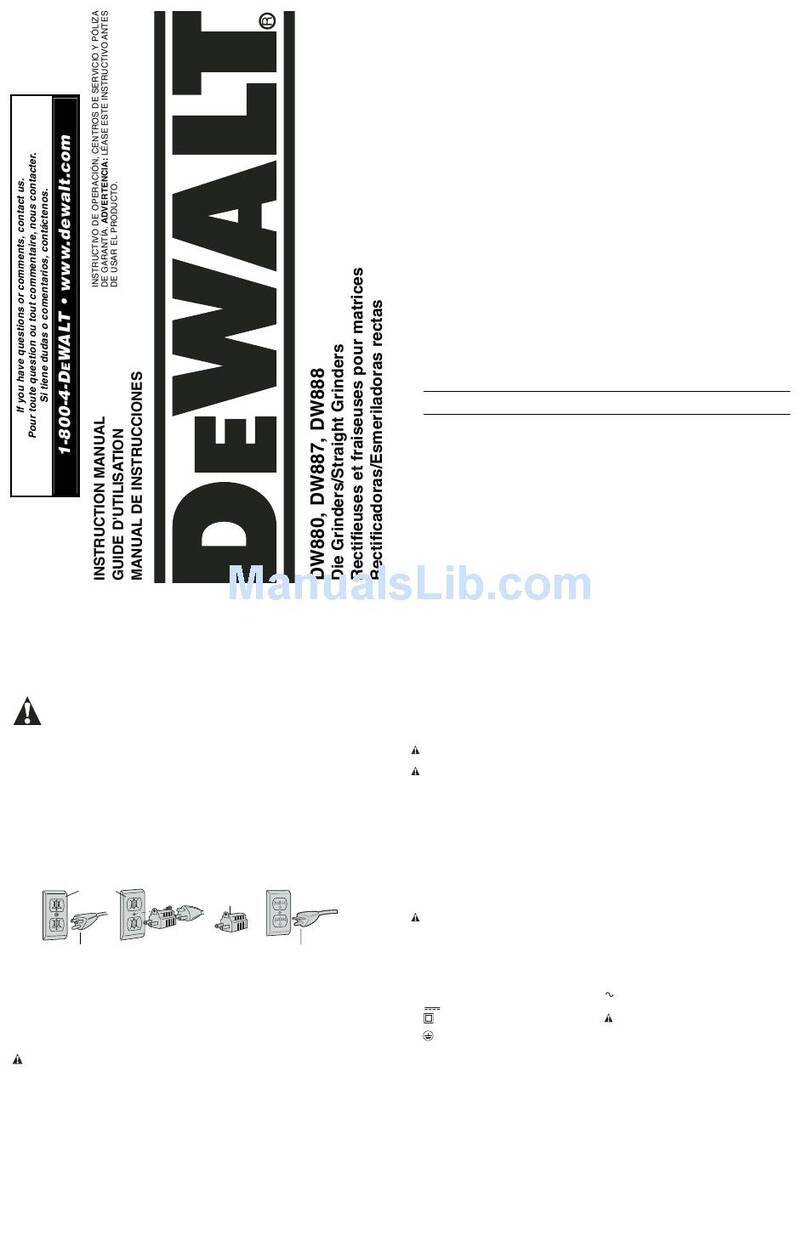

decal119-4561

119-4561

1.Pushforwardtolowerthestumpgrinder.

2.Moverighttomovethestumpgrindertotheright.

3.Pullbacktoraisethestumpgrinder.

4.Movelefttomovethestumpgrindertotheleft.

5.ReadtheOperator'sManualbeforeoperatingthecutter;

engagethesideleverandtopbuttonofthejoystickto

startthecutterblade;continueengagingthesideleverto

maintaincutterrotation.

6.1)T opowerthegrinder,pressthesafetylockandthetrigger

together;2)Tokeepthegrinderrunning,holdthetrigger.

7.1)Grindhorizontallyalongtheedgeofthestump;2)Lower

thegrinderslightlyintothestump;3)Grindhorizontally

downtogroundlevel;4)Movethegrinderforward.

8.Donotstartgrindinginthemiddleofthestump;start

grindingattheedgeofthestump.

decal133-8056

133-8056

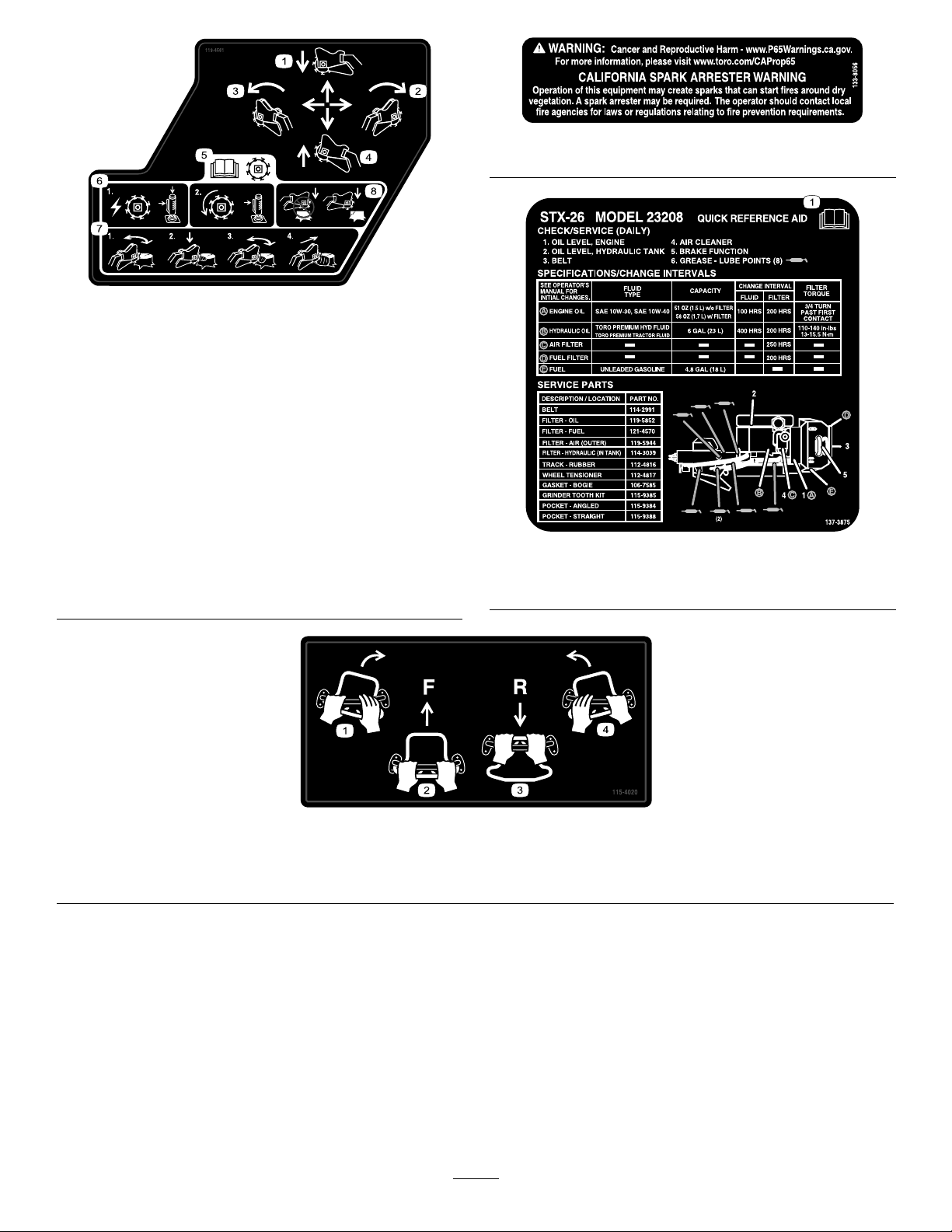

decal137-3875

137-3875

1.ReadtheOperator’sManual.

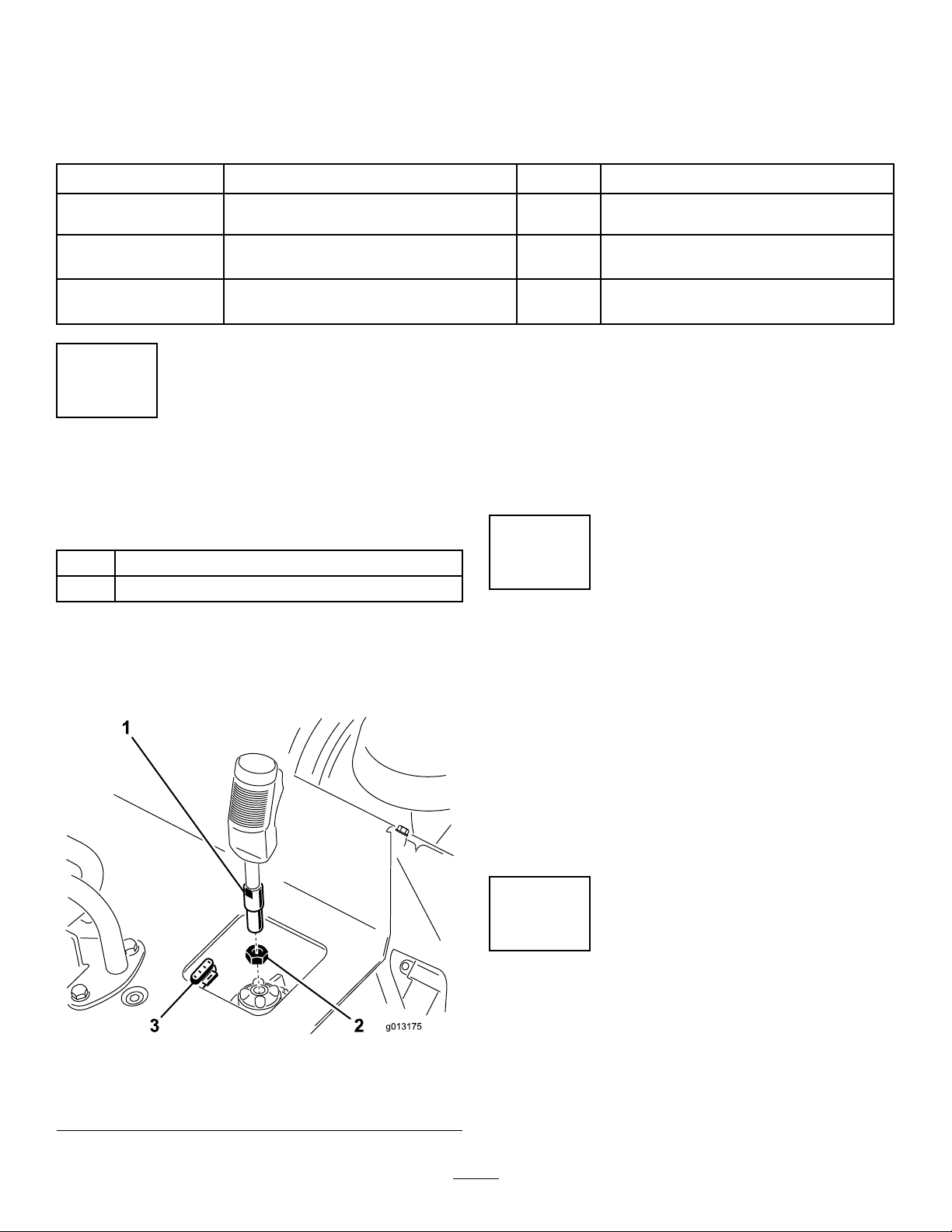

decal115-4020

115-4020

1.Turnright3.Reverse

2.Forward4.Turnleft

8

decal119-4606

119-4606

1.Warning—readtheOperator'sManual.5.Explosionandelectricshockhazard—donotdiginareaswith

buriedutilitylines;contactlocalpowerorganizationsbefore

digging.

2.Cutting/dismembermenthazard;grinder—keepbystanders

asafedistanceawayfromthemachine;donotoperatethe

grinderheadwhiletransportingthemachine.

6.Tipping/crushinghazard—lowerthecutterheadwhen

operatingonslopes.

3.Warning—stayawayfrommovingparts;waitforallmoving

partstostop.

7.Explosionhazard,fueling—shutofftheengineandextinguish

allameswhenfueling.

4.Warning—donotoperatethismachineunlessyouaretrained.8.Warning—lowerthegrinderhead,engagetheparkingbrake

(ifapplicable),shutofftheengine,andremovethekeybefore

leavingthemachine.

9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

Grindercontrollever1

1Jamnut1Installthegrindercontrollever.

2Nopartsrequired–Checktheuidlevels.

3Nopartsrequired–Chargethebattery.

1

InstallingtheGrinder

ControlLever

Partsneededforthisprocedure:

1Grindercontrollever

1Jamnut

Procedure

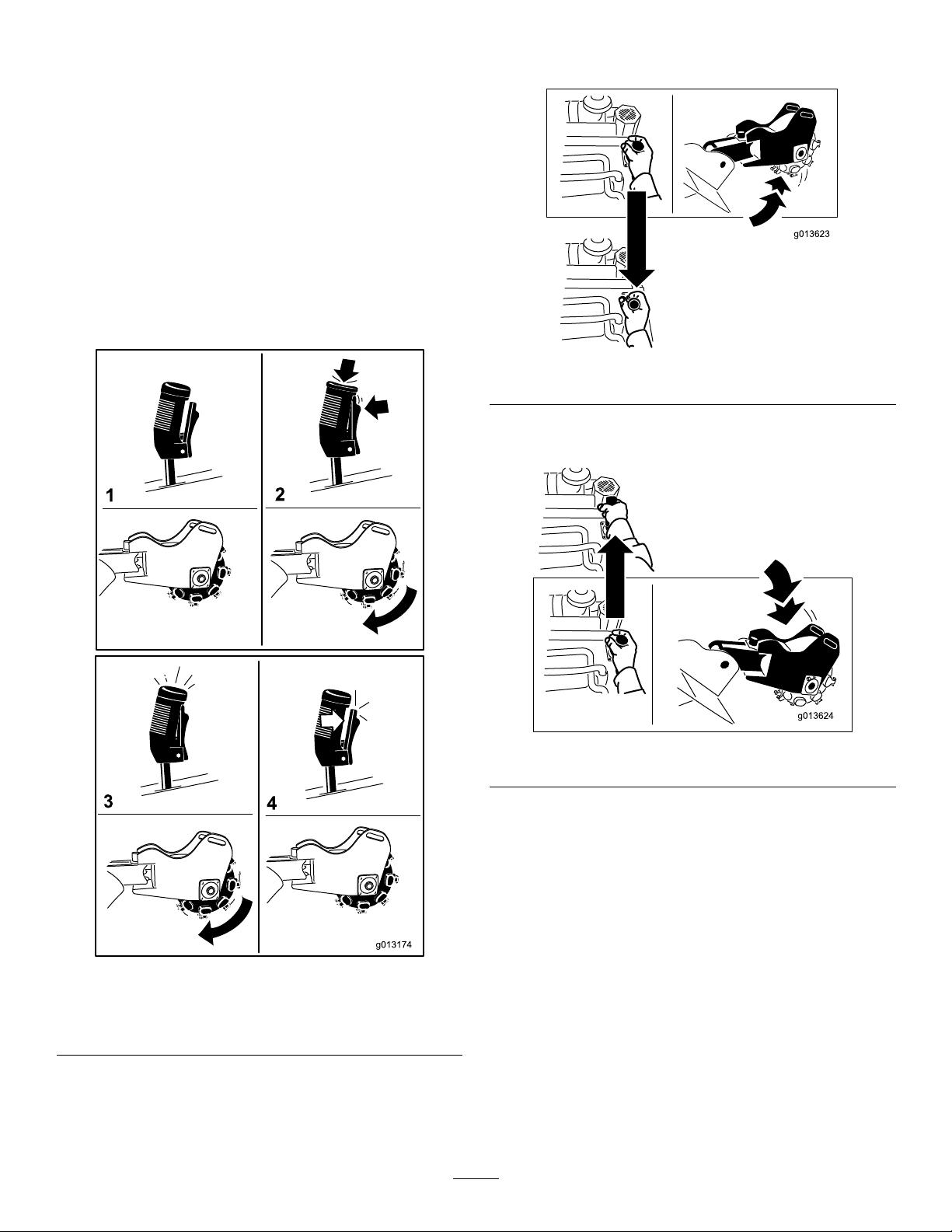

1.Threadthejamnutontothegrindercontrollever

(Figure3).

g013175

Figure3

1.Grindercontrollever3.4-pinconnector

2.Jamnut

2.Threadthegrindercontrolleverintothe

receptacleonthecontrolpanel(Figure3).

3.Withthetriggerorientedforward,tightenthejam

nutagainstthereceptacletosecuretheleverin

place(Figure3).

4.Connectthewireonthelevertothe4-pin

connectorunderthecontrolpanel(Figure3).

2

CheckingtheFluidLevels

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,check

theengine-oilandhydraulic-uidlevels.Refertothe

followingsectionsformoreinformation:

•CheckingtheEngine-OilLevel(page24)

•CheckingtheHydraulic-FluidLevel(page37)

3

ChargingtheBattery

NoPartsRequired

Procedure

Chargethebattery;refertoChargingtheBattery

(page29)formoreinformation.

10

ProductOverview

g013171

Figure4

1.Reverse

safety

plate

3.Engine5.Tie-down/lift

point

7.Chip

shield

2.Control

panel

4.Battery6.Track8.Grinder

Controls

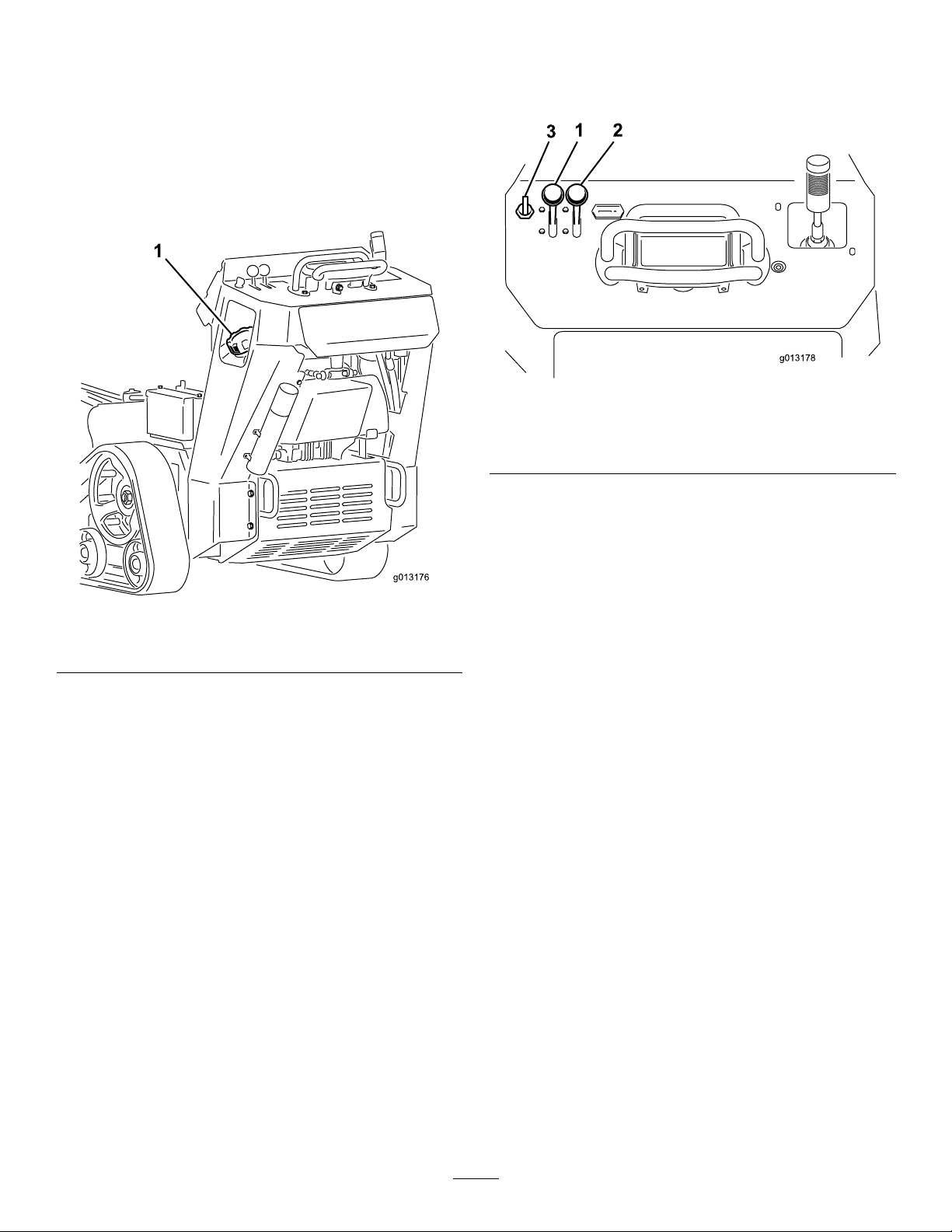

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

ControlPanel

g025098

Figure5

1.Keyswitch5.Tractioncontrol

2.Throttlelever6.Referencebar

3.Chokelever7.Grinder

control/hydraulic-liftlever

4.Hourmeter

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.Referto

StartingtheEngine(page16).

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasetheenginespeed.

ChokeLever

Beforestartingacoldengine,movethechokelever

forward.Aftertheenginestarts,regulatethechoke

tokeeptheenginerunningsmoothly.Assoonas

possible,movethechokeleverallthewayrearward.

Note:Awarmenginerequireslittleornochoking.

HourMeter

Whentheengineisoff,thehourmeterdisplaysthe

numberofhoursofoperationthathavebeenlogged

onthemachine.

11

ReferenceBar

Whendrivingthemachine,usethereferencebar

asahandleandaleveragepointforcontrollingthe

machine.T oensuresmooth,controlledoperation,

donottakebothhandsoffthereferencebarwhile

operatingthemachine.

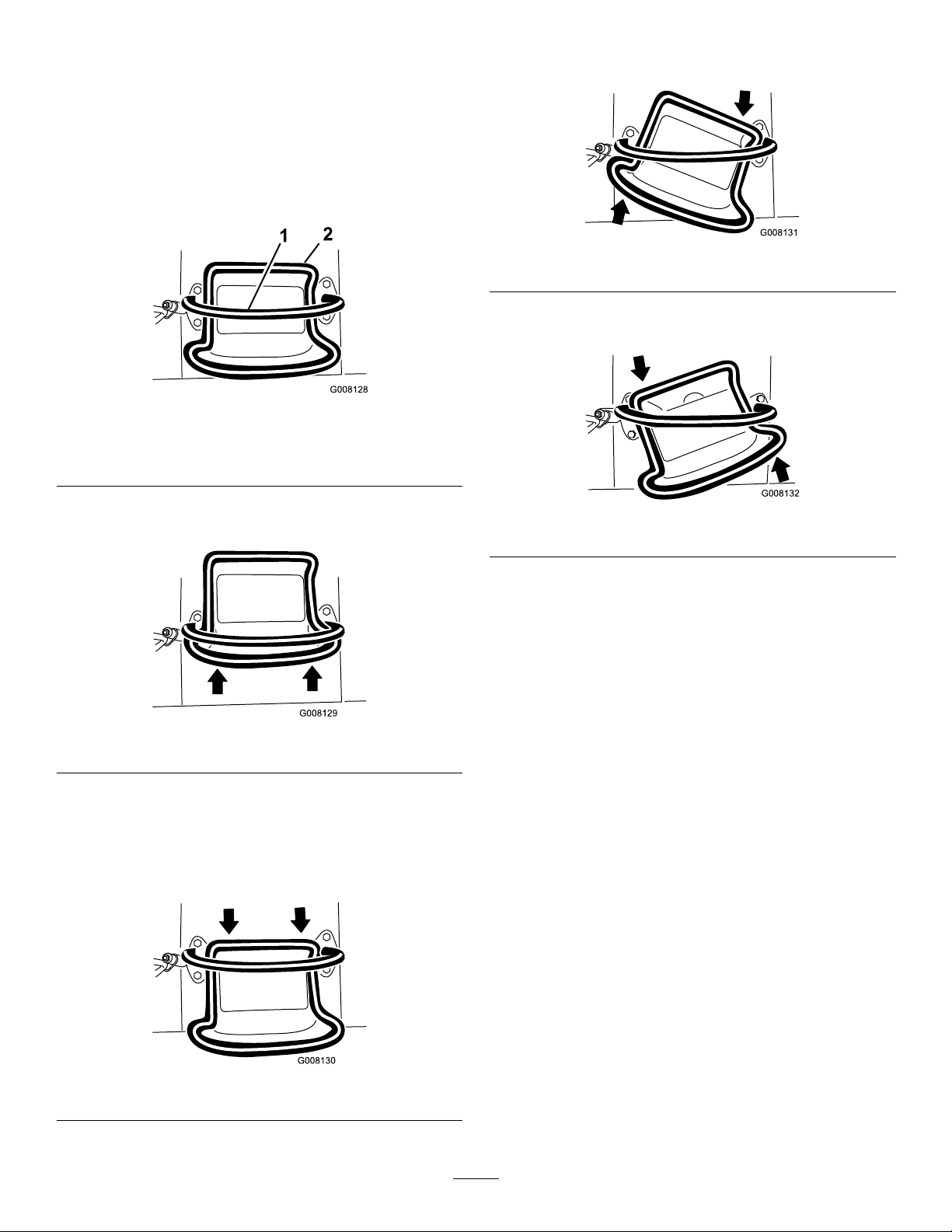

TractionControl

g008128

Figure6

1.Referencebar

2.Tractioncontrol

•Tomoveforward,movethetractioncontrolforward

(Figure7).

g008129

Figure7

•Tomoverearward,movethetractioncontrol

rearward(Figure8).

Important:Whenreversing,lookbehindyou

forobstructionsandkeepyourhandsonthe

referencebar.

g008130

Figure8

•Toturnright,rotatethetractioncontrolclockwise

(Figure9).

g008131

Figure9

•Toturnleft,rotatethetractioncontrol

counterclockwise(Figure10).

g008132

Figure10

•Tostopthemachine,releasethetractioncontrol

(Figure6).

Note:Thefartheryoumovethetractioncontrolin

anydirection,thefasterthemachinemovesinthat

direction.

12

GrinderControl/Hydraulic-Lift

Lever

Operatethegrinderusingthegrindercontrollever

asfollows:

•Tostartthegrinder(Figure11),squeezethe

triggerandthenpresstheredbuttononthetopof

thelever.Oncethegrinderhasstarted,youcan

releasetheredbutton.

•Tostopthegrinder(Figure11),releasethetrigger

formorethanahalfsecond.

Note:Ifyouareoperatingthegrinderand

momentarilyreleasethetrigger(i.e.,lessthana

halfsecond),thegrindercontinuestooperate.

g013174

Figure11

1.Neutral3.Runthegrinder

2.Startthegrinder4.Stopthegrinder

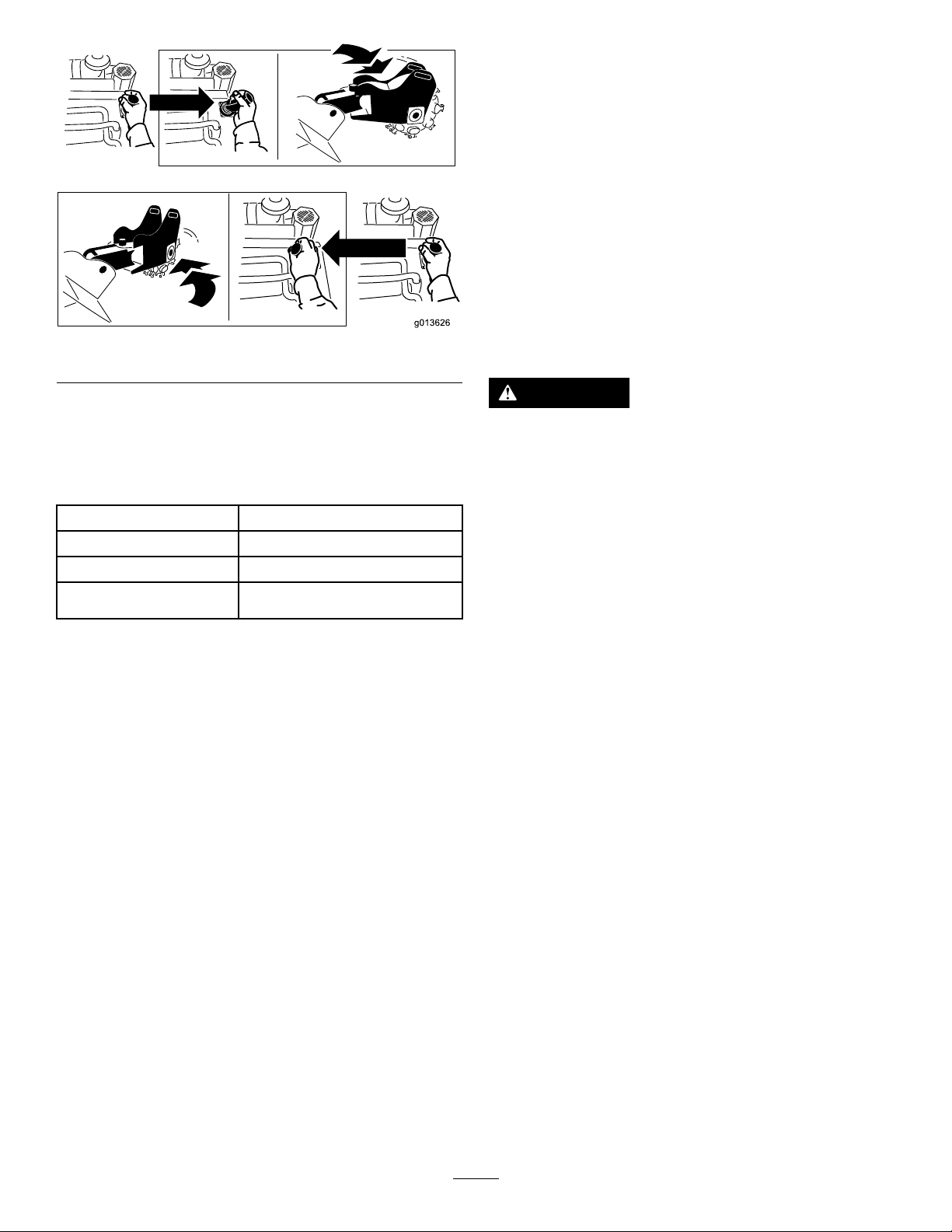

•Toraisethegrinder,pulltheleverrearward(Figure

12).

g013623

Figure12

•Tolowerthegrinder,pushtheleverforward(Figure

13).

g013624

Figure13

•Torotatethegrindertotherightorleft,movethe

leverinthedesireddirection(Figure14).

13

g243266

g013626

Figure14

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width84cm(33inches)

Length198.5cm(78inches)

Height113cm(44.5inches)

Weight544Kg(1,200lb)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Beforeoperating,checkthefueland

oillevel,andremovedebrisfromthemachine.

Also,ensurethattheareaisclearofpeopleand

debris.Youshouldalsoknowandhavemarked

thelocationsofallutilitylines.

Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatorposition.

AddingFuel

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltanksoutdoors,inanopen

area,whentheengineiscold.Wipeupany

fuelthatspills.

•Neverllthefueltanksinsideanenclosed

trailer.

•Neversmokewhenhandlingfuelandstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

14

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark

thatcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbed,becauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfrom

thetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankopening.

•Keepfuelawayfromyoureyesandskin.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachineatall

timestokeepthefuelfreshlongerwhenusedas

directedbythefuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

15

FillingtheFuelTank

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure15).

g013176

Figure15

1.Fuel-tankcap

4.Fillthetankwithfueltoabout6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

5.Installthefuel-tankcapsecurely.

6.Wipeupanyspilledfuel.

PerformingDaily

Maintenance

Beforestartingthemachineeachday,performthe

EachUse/DailyprocedureslistedinMaintenance

(page20).

StartingtheEngine

1.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions(Figure16).

g013178

Figure16

1.Throttlelever3.Key

2.Chokelever

2.MovethechokelevertotheONposition(Figure

16).

Note:Awarmorhotenginemaynotrequire

choking.

3.TurnthekeytotheONposition(Figure16).

Whentheenginestarts,releasethekey.

Important:Donotengagethestarterfor

morethan10secondsatatime.Iftheengine

failstostart,allowa30-secondcooldown

periodbetweenattempts.Failuretofollow

theseinstructionscanburnoutthestarter

motor.

4.GraduallymovethechokelevertotheOFF

position(Figure16).Iftheenginestallsor

hesitates,engagethechokeagainuntilthe

enginewarmsup.

5.Movethethrottlelevertothedesiredsetting

(Figure16).

Important:Runningtheengineathigh

speedswhenthehydraulicsystemiscold

(i.e.,whentheairtemperatureisator

belowfreezing)coulddamagethehydraulic

system.Whenstartingtheengineincold

conditions,allowittoruninthemiddle

throttlepositionfor2to5minutesbefore

movingthethrottletotheFASTposition.

Note:Iftheoutdoortemperatureisbelow

freezing,storethemachineinagaragetokeep

itwarmerandaidinstarting.

16

DrivingtheMachine

Usethetractioncontrolstomovethemachine.The

fartheryoumovethetractioncontrolsinanydirection,

thefasterthemachinemovesinthatdirection.

Releasethetractioncontrolstostopthemachine.

CAUTION

Whenreversing,youmaybackintostationary

objectsoroverbystandersandcauseserious

personalinjuryordeath.

Lookbehindyouforobstructionsor

bystandersandkeepyourhandsonthe

referencebar.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placethe

throttleleverintheFASTpositionforbestperformance.

Youcan,however,usethethrottlepositiontooperate

atslowerspeeds.

ShuttingofftheEngine

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.MovethethrottlelevertotheSLOWposition

(Figure16).

3.Iftheenginehasbeenworkinghardorishot,let

itidleforaminutebeforeturningthekeyswitch

totheOFFposition.

Note:Thishelpstocooltheenginebeforeyou

shutitoff.Inanemergency,youcanshutoff

theengineimmediately.

4.TurnthekeyswitchtotheOFFpositionand

removethekey.

CAUTION

Achildoruntrainedbystandercould

attempttooperatethemachineandbe

injured.

Removethekeyfromtheswitchwhen

leavingthemachine,evenifjustforafew

seconds.

GrindingaStump

DANGER

Thismachineiscapableofamputatinghands

andfeet.

•Alwayswearsubstantial,slip-resistant

footwear.

•Stayintheoperatingpositionwhilethe

machineisrunning,andkeepawayfrom

movingparts.

•Keepallbystandersasafedistanceaway

fromthemachine.

•Stopthemachineimmediatelyifany

peopleoranimalsentertheworkarea.

WARNING

Grindingastumpthrowswoodchips,soil,

andotherdebrisintotheair,whichcould

injureyouorbystanders.

•Alwaysweareyeprotectionandlongpants

whenusingthegrinder.

•Keepallbystandersasafedistanceaway

fromthegrinder.

WARNING

Thegrinderisveryloudwhencuttingastump

andcandamageyourears.

Alwayswearhearingprotectionwhenusing

thegrinder.

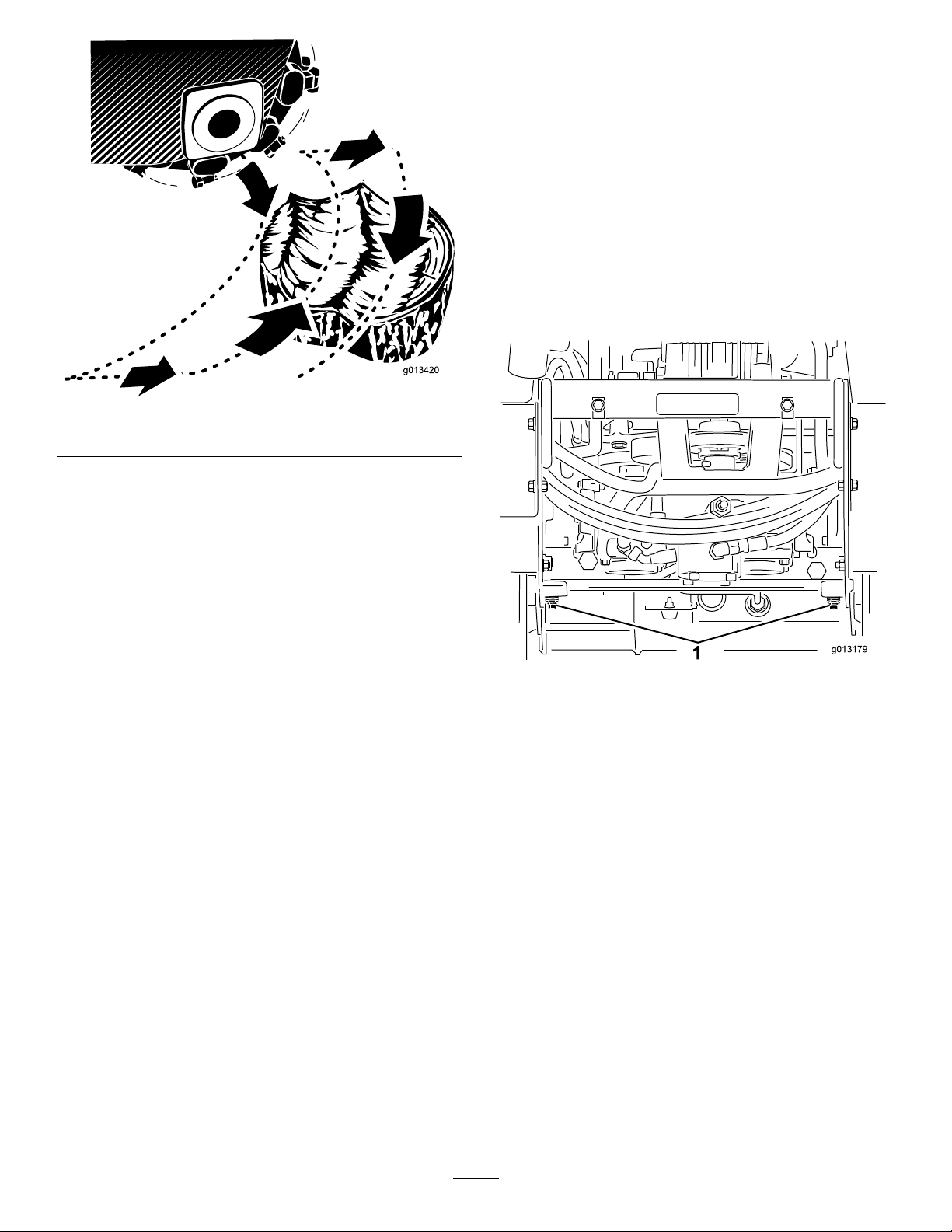

1.Starttheengine,raisethegrinder,setthe

throttlelevertotheFASTposition,andmovethe

machinetothestumptobeground.

2.Usethegrindercontrolleverandthetraction

controltopositionthegrindertothesideofthe

frontofthestump,about2cm(1inch)below

thesurface(Figure17).

3.Startthegrinderandwaitforittogetuptofull

speed.

4.Usethegrindercontrollevertoswingthegrinder

slowlyacrossthefaceofthestump,cutting

awayaswathofchips(Figure17).

Important:Thegrinderautomaticallyslows

downthespeedatwhichitswingsintothe

stumptomaintaintheoptimumywheel

speedandnotbogdowninthewood.

17

g013420

Figure17

5.Movethemachineforwardafewcentimeters

(inches)andrepeatstep4(Figure17).

6.Repeatsteps4through5untilyouhaveground

offtheentirefaceofthestump(Figure17).

7.Backupthemachine,positionthegrindertothe

sideofthefrontofthestump,andloweritto

about2cm(1inch)belowthesurface.

8.Repeatsteps4through7untilthestumpis

groundaway.

9.Ifthereareanylargerootstobeground,position

thegrinderovereachrootandusethetraction

controlandgrindercontroltomovethegrinder

alongtheroot,grindingitaway.

10.Cleandebrisfromthehydrauliclift,drives,

mufers,andengineaftereachuse;referto

RemovingDebrisfromtheMachine(page40).

MovingaNon-Functioning

Machine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,oryouwill

damagethehydraulicsystem.

1.Engagetheparkingbrakeandlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Removethebottomshield.

4.Usingawrench,turnthetowvalvesonthe

hydraulicpumpstwicecounter-clockwise(Figure

18).

g013179

Figure18

1.Towvalves

5.Installthebottomshieldandtowthemachine

asrequired.

6.Afterrepairingthemachine,closethetowvalves

beforeoperatingit.

SecuringtheMachinefor

Transport

Important:Donotoperateordrivethemachine

onroadways.Usecarewhenloadingorunloading

themachineintoatrailerortruck.

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Securethemachinetoatrailerwithchainsor

strapsusingthetie-down/liftloopsatthefront

andrearofthemachine(Figure19andFigure

18

20).Refertoyourlocalordinancesfortrailerand

tie-downrequirements.

g013180

Figure19

1.Fronttie-downloop

g013181

Figure20

1.Reartie-downloops

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloops

asliftpoints(Figure19andFigure20).

OperatingTips

•Cleantheareaoftrash,branches,androcks

beforeoperatingtopreventequipmentdamage.

•Alwaysusefullthrottle(maximumenginespeed)

whengrinding.

•Cuttheedgesofthestumpformoreefcient

grinding.Onceyourcuttingswathiscloseto1/4

ofthewheeldiameter,lowerthegrinderandbegin

cuttingontheedgeagain.

g013671

Figure21

•Listentotheengineandwatchthegrinderwheel

speedtomaintainthespeedofthewheel.Slow

downtheheadsweepbyfeatheringthejoystickas

cuttingbecomesdifcult.

•Asyougrindfromlefttoright,mostofthedebris

goestotheleftofthegrinderwheel.Whenyou

grindfromtherighttoleft,thedebrisgoestothe

right.

•Youmayalsogrindastumpfromthesidetolessen

turfdamage.

19

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst8hours•Changetheengineoil.

Aftertherst50hours•Checkandadjustthetracktension.

Beforeeachuseordaily

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheengine-oillevel.

•Checktheconditionofandcleanthetracks.

•Checktheconditionoftheteeth;rotateorreplaceanythatarewornordamaged

andtorquethenutsforallteeth.

•Checkforloosefasteners.

Aftereachuse•Removedebrisfromthemachine.

Every25hours•Checkthebatteryelectrolytelevel.

•Checkthehydraulic-uidlevel.

Every100hours

•Changetheengineoil.

•Replaceorcleanandgapthesparkplug(s).

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

Every200hours•Changetheengine-oillter.

•Replacethefuellter.

Every250hours

•Replacetheprimaryairlterandchecktheconditionofthesafetylter(moreoften

indirtyordustyconditions).

•Checkandgreasetheroadwheels.

Every400hours•Changethehydraulicuid.

Every500hours•Replacethesafetyairlter(moreoftenindirtyordustyconditions).

Every1,500hours•Replaceallmovinghydraulichoses.

Yearlyorbeforestorage•Checkandadjustthetracktension.

•Touchupchippedpaint.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyinthekeyswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromthekeyswitchanddisconnectthewiresfromthesparkplugsbefore

youdoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthe

sparkplugs.

20

Other manuals for STX-26

2

Table of contents

Other Toro Grinder manuals

Popular Grinder manuals by other brands

Caravaggi

Caravaggi SP 20 User & maintenance manual

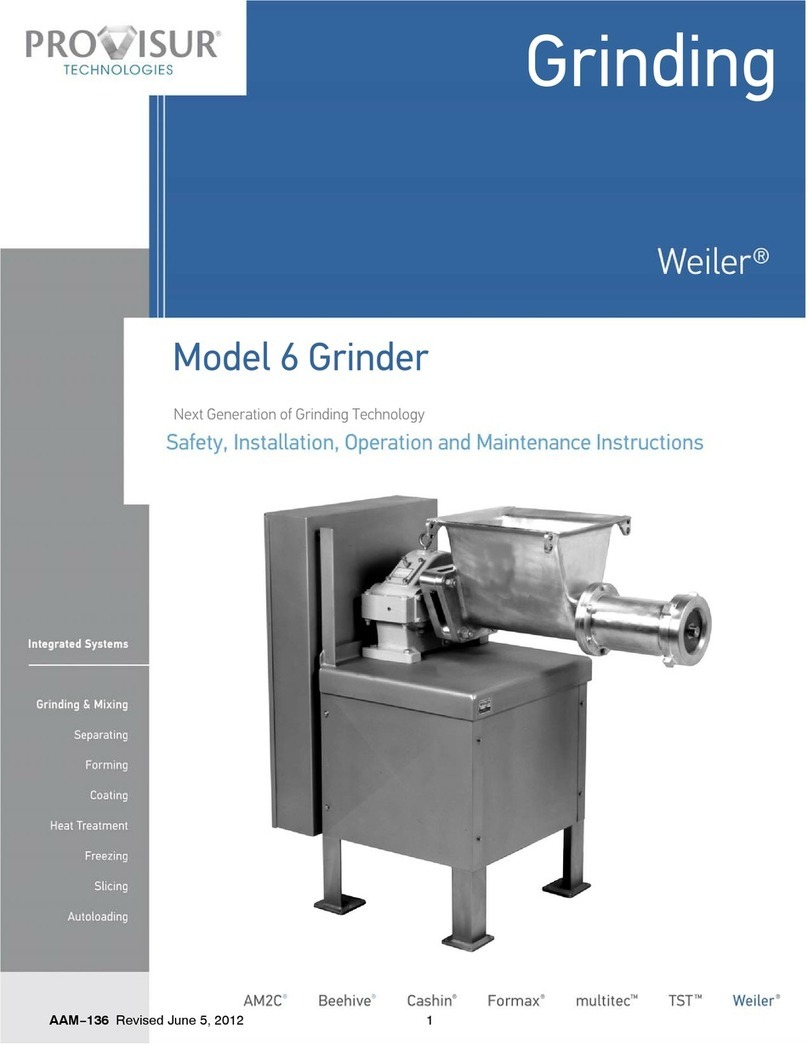

Provisur

Provisur Weiler 6 SAFETY, INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

EINHELL

EINHELL TE-RS 18 Li Original operating instructions

Climax

Climax VM2150 Series operating manual

Makita

Makita 9556HP instruction manual

DeWalt

DeWalt XR LI-ION DCG412 user guide