Toro STX-38 EFI User manual

FormNo.3451-484RevA

STX-38EFIStumpGrinderwith

Intelli-Sweep®

ModelNo.23214—SerialNo.410500000andUp

Original Instructions (EN)*3451-484*

www.discount-equipment.com

Go to Discount-Equipment.com to order your parts

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on one of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S.

Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin,

Rice, CH&E, General Equipment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent,

Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air,

APT, Wylie, Ingersoll Rand / Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith

Surface Prep,Small Line, Wanco, Yanmar

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto, Power

Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack, Lull,

Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic, Dynapac,

MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti, Morrison, Contec,

Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S. Curtis, Gehl Pavers, Heli,

Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin, Rice, CH&E, General Equip-

ment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, APT, Wylie, Ingersoll Rand /

Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith Surface Prep,Small Line,

Wanco, Yanmar

Discount-Equipment.com is your online resource for

commercial and industrial quality parts and equipment sales.

561-964-4949

visit us on line @ www.discount-equipment.com

TO PURCHASE THIS PRODUCT PLEASE CONTACT US

Select an option below to find your Equipment

Equipment Financing and

Extended Warranties Available

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisdesignedtogrindandremovetree

stumpsandsurfaceroots.Itisnotintendedtocut

rockoranyothermaterialotherthanwoodandthe

soilaroundastump.Usingthisproductforpurposes

otherthanitsintendedusecouldprovedangerousto

youandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model

and serial numbers of your product ready. Figure 1

illustrates the location of the model and serial

numbers on the product. Write the numbers in the

space provided.

Important: With your mobile device, you can

scan the QR code on the serial number decal (if

equipped) to access warranty, parts, and other

product information.

g247193

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

© 2022—The Toro® Company

2

Printed in the USA

All Rights Reserved

Go to Discount-Equipment.com to order your parts

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................8

CheckingtheFluidLevels...................................8

ChargingtheBattery...........................................8

OpeningtheLiftValve.........................................8

ProductOverview.....................................................8

Controls.............................................................8

Specications..................................................12

Attachments/Accessories.................................12

BeforeOperation.................................................12

BeforeOperationSafety...................................12

AddingFuel......................................................13

PerformingDailyMaintenance..........................13

DuringOperation.................................................14

DuringOperationSafety...................................14

StartingtheEngine...........................................15

DrivingtheMachine..........................................15

ShuttingofftheEngine......................................15

GrindingaStump..............................................16

OperatingTips.................................................16

AfterOperation....................................................16

AfterOperationSafety......................................16

MovingaNon-FunctioningMachine..................17

SecuringtheMachineforTransport..................17

LiftingtheMachine...........................................17

Maintenance...........................................................18

MaintenanceSafety..........................................18

RecommendedMaintenanceSchedule(s)...........18

Pre-MaintenanceProcedures..............................19

RemovingtheFrontCover................................19

RemovingtheBottomShield............................19

Lubrication..........................................................20

GreasingtheMachine.......................................20

EngineMaintenance...........................................21

EngineSafety...................................................21

ServicingtheAirCleaner..................................21

ServicingtheEngineOil....................................22

ServicingtheSparkPlug(s)..............................25

FuelSystemMaintenance...................................26

DrainingtheFuelTank......................................26

ReplacingtheLow-pressureFuelFilter.............26

ServicingtheHigh-PressureFuelFilter.............27

ElectricalSystemMaintenance...........................27

ElectricalSystemSafety...................................27

ServicingtheBattery.........................................27

ReplacingtheFuses.........................................29

DriveSystemMaintenance..................................30

ServicingtheTracks.........................................30

CoolingSystemMaintenance..............................32

CleaningtheEngineScreen.............................32

BeltMaintenance................................................33

ReplacingtheHydrostaticPumpDrive

Belt................................................................33

ControlsSystemMaintenance.............................33

AdjustingtheTraction-Control

Alignment......................................................33

HydraulicSystemMaintenance...........................35

HydraulicSystemSafety...................................35

HydraulicFluidSpecications...........................35

CheckingtheHydraulic-FluidLevel...................36

ReplacingtheHydraulicFilter...........................36

ChangingtheHydraulicFluid............................37

GrinderMaintenance............................................37

ReplacingtheTeeth..........................................37

Cleaning..............................................................38

RemovingDebrisfromtheMachine..................38

Storage...................................................................39

StorageSafety..................................................39

Storage.............................................................39

Troubleshooting......................................................40

3

Go to Discount-Equipment.com to order your parts

Safety

GeneralSafety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•Keepyourhandsandfeetawayfrommovingteeth

orotherparts.

•Keepbystandersandpetsawayfromthemachine.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard6.Keepbystandersaway

fromthebattery.

2.Nore,opename,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection.9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard

decal93-6686

93-6686

1.Hydraulicuid2.ReadtheOperator's

Manual.

decal93-7321

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,rotating

knives/blades—stayawayfrommovingparts.

4

Go to Discount-Equipment.com to order your parts

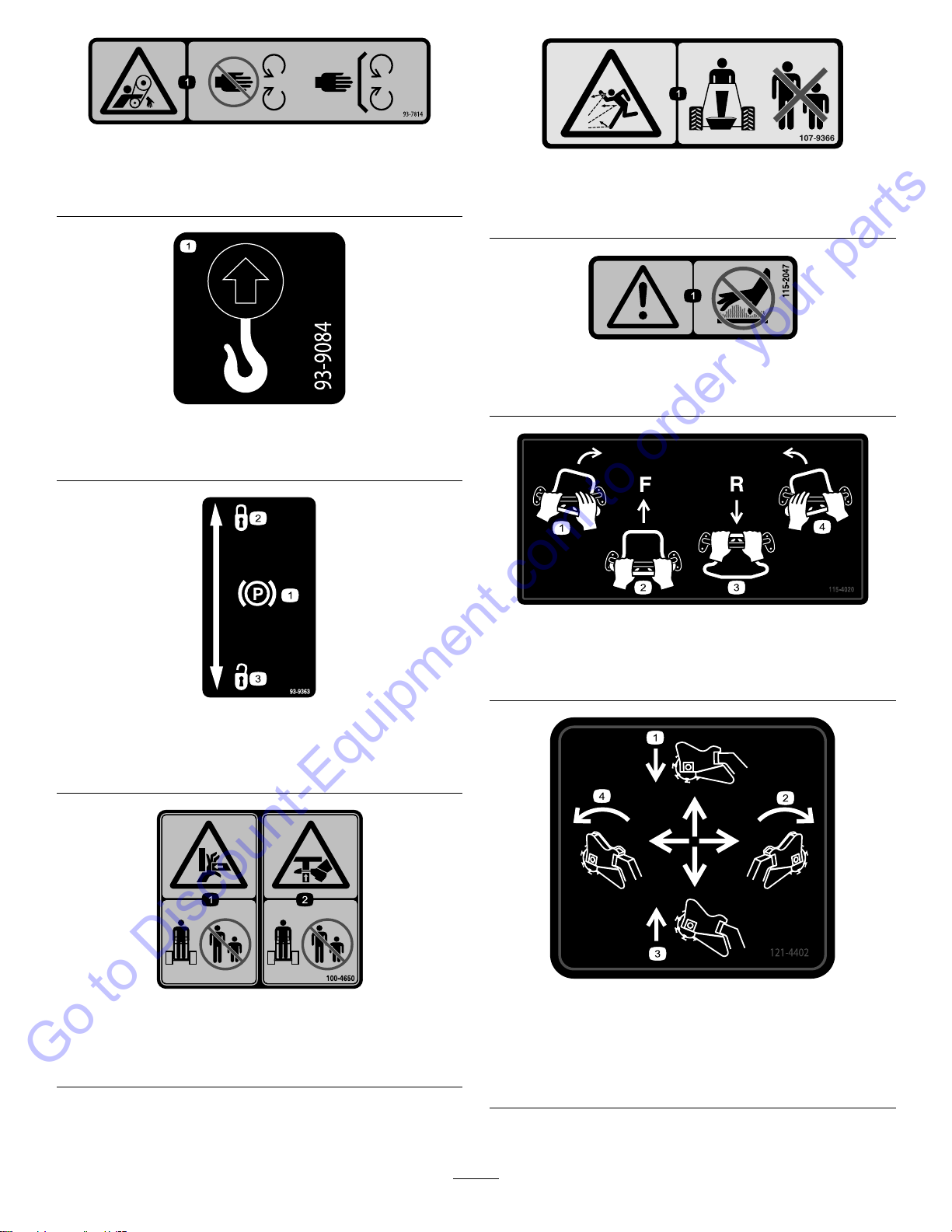

decal93-7814

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal93-9084

93-9084

1.Liftpoint/Tie-downpoint

decal93-9363

93-9363

1.Parkingbrake3.Unlocked

2.Locked

decal100-4650

100-4650

1.Crushinghazardofhand—keepbystandersaway.

2.Crushinghazardoffoot—keepbystandersaway.

decal107-9366

107-9366

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

decal115-2047

115-2047

1.Warning—donottouchthehotsurface.

decal115-4020

115-4020

1.Turnright3.Reverse

2.Forward4.Turnleft

decal121-4402

121-4402

1.Pushforwardtolowerthe

stumpgrinder.

3.Pullbacktoraisethe

stumpgrinder.

2.Moverighttomovethe

stumpgrindertotheright.

4.Movelefttomovethe

stumpgrindertotheleft.

5

Go to Discount-Equipment.com to order your parts

decal121-4538

121-4538

1.Attention—readtheOperator’sManual;releasethevalve

tolowerthegrinderheadbeforeusingthemachineforthe

rsttime.

decal130-7580

130-7580

1.Engine—start5.Enginespeed—slow

2.Engine—run6.Engineindicatorlight

3.Engine—stop7.ReadtheOperator's

Manualbeforestartingthe

engine—1)Ensurethat

thetractioncontrolisin

theneutralposition;2)

Movethethrottleleverto

theFastposition,close

thechoke(ifapplicable),

anddonotoperatethe

joystick;3)Turnthekeyto

starttheengine.

4.Enginespeed—fast

decal133-8062

133-8062

decal145-6921

145-6921

1.ReadtheOperator’sManual.

6

Go to Discount-Equipment.com to order your parts

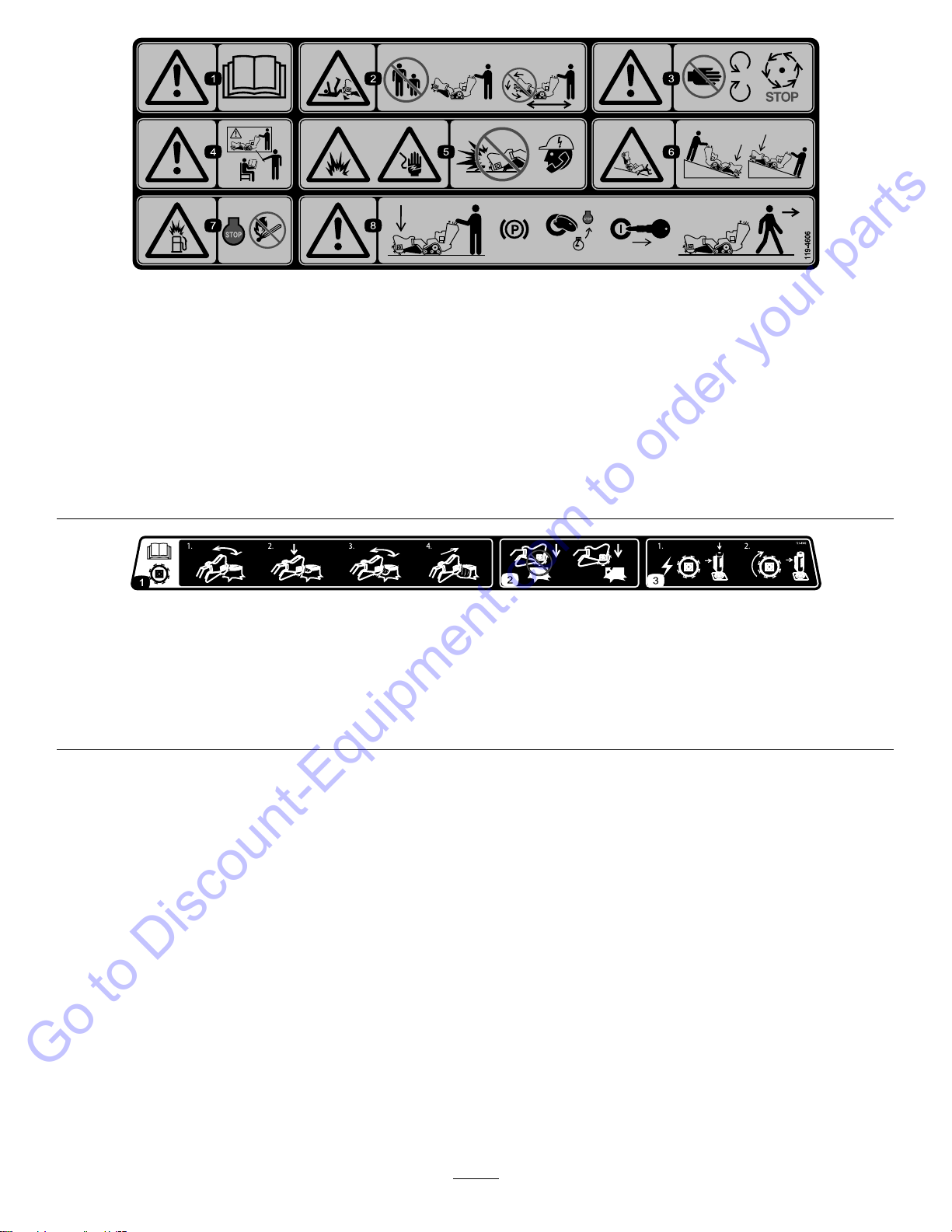

decal119-4606

119-4606

1.Warning—readtheOperator'sManual.5.Explosionandelectricshockhazard—donotdiginareaswith

buriedutilitylines;contactlocalpowerorganizationsbefore

digging.

2.Cutting/dismembermenthazard;grinder—keepbystanders

awayfromthemachine;donotoperatethegrinderheadwhile

transportingthemachine.

6.Tipping/crushinghazard—lowerthecutterheadwhen

operatingonslopes.

3.Warning—stayawayfrommovingparts;waitforallmoving

partstostop.

7.Explosionhazard,fueling—shutofftheengineandextinguish

allameswhenfueling.

4.Warning—donotoperatethismachineunlessyouaretrained.8.Warning—lowerthegrinderhead,engagetheparkingbrake

(ifapplicable),shutofftheengine,andremovethekeybefore

leavingthemachine.

decal121-4382

121-4382

1.ReadtheOperator’sManualforinformationonoperatingthe

grinder—1)Grindhorizontallyalongtheedgeofthestump;2)

Lowerthegrinderslightlyintothestump;3)Grindhorizontally

downtogroundlevel;4)Movethegrinderforward.

3.1)T opowerthegrinder,pressthesafetylockandthetrigger

together;2)T okeepthegrinderrunning,holdthetrigger.

2.Donotstartgrindinginthemiddleofthestump;startgrinding

attheedgeofthestump.

7

Go to Discount-Equipment.com to order your parts

Setup

CheckingtheFluidLevels

Beforestartingtheengineforthersttime,check

theengine-oilandhydraulic-uidlevels.Refertothe

followingsectionsformoreinformation:

•CheckingtheEngine-OilLevel(page22)

•CheckingtheHydraulic-FluidLevel(page36)

ChargingtheBattery

Chargethebattery;refertoChargingtheBattery

(page28)formoreinformation.

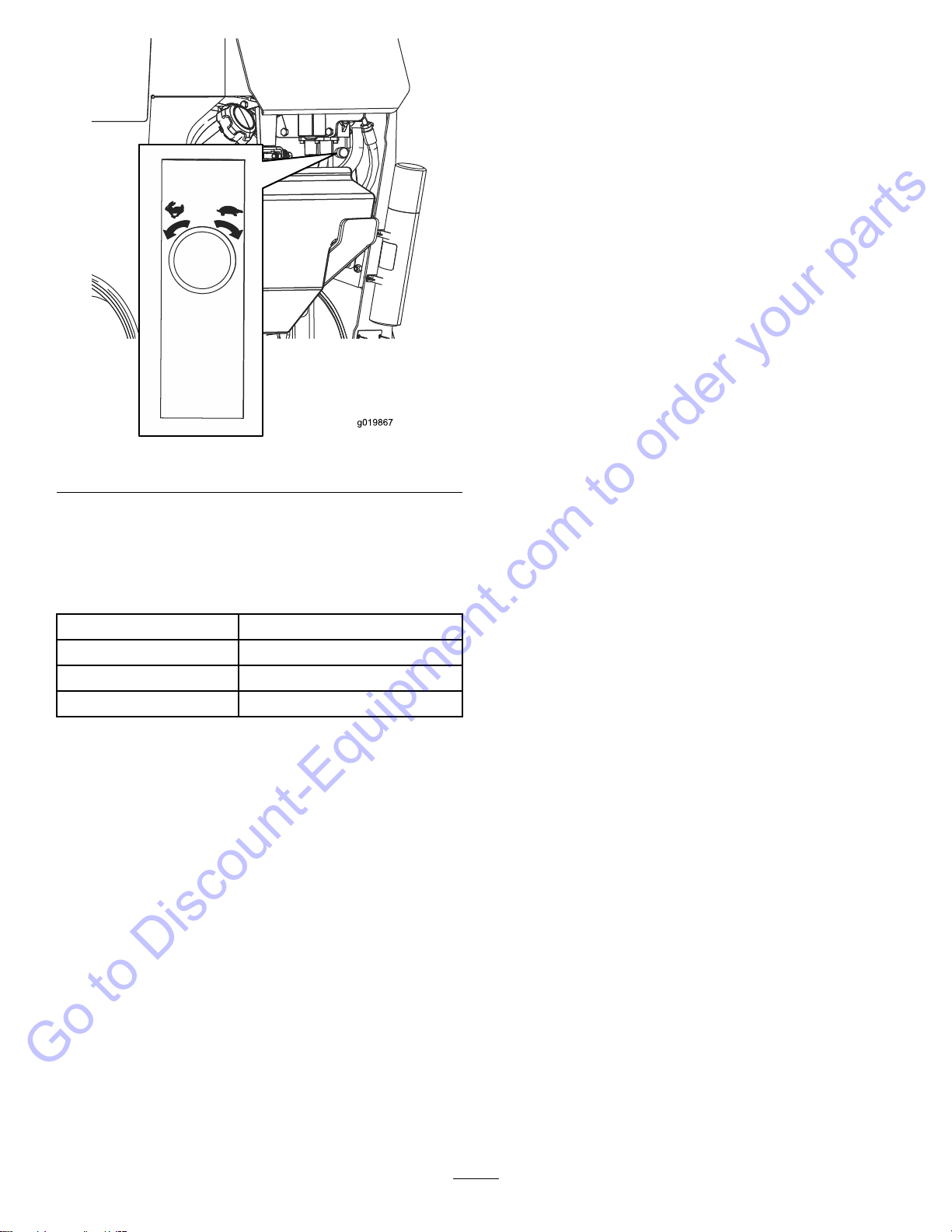

OpeningtheLiftValve

Beforeyoucanraisethegrinderandmovethe

machine,youmustopentheliftvalvelocatedunder

thecontrolpanel(Figure3).Turntheknobcounter

clockwisetoallowyoutoliftthegrinder.Thefarther

youturntheknob,thefastertheheadraisesand

lowerswhenactivated.

g019867

Figure3

ProductOverview

g319366

Figure4

1.Control

panel

3.Engine5.Tie-down

loop

7.Battery

2.Chip

shield

4.Grinder6.Track

Controls

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

ControlPanel

g024907

Figure5

1.Keyswitch6.Referencebar

2.Throttlelever7.Reversesafetyplate

3.Engineindicatorlight8.Grindercontrollever

4.Hourmeter9.Handle

5.Tractioncontrol

8

Go to Discount-Equipment.com to order your parts

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTAR

T.Referto

StartingtheEngine(page15).

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasetheenginespeed.

HourMeter

Thehourmeterdisplaysthenumberofhoursof

operationthathavebeenloggedonthemachine.

ReferenceBar

Whendrivingthemachine,usethereferencebar

asahandleandaleveragepointforcontrollingthe

machine.T oensuresmooth,controlledoperation,

donottakebothhandsoffthereferencebarwhile

operatingthemachine.

Engine-IndicatorLight

Theengine-indicatorlightilluminateswhenthereisa

faultintheengineelectronic-controlunit.

Ifthelightilluminates,contactaKohlerenginedealer

fordiagnosisandservice.

Parking-BrakeLever

Toengagetheparkingbrake,lifttheleverupward.

Todisengagetheparkingbrake,pushthelever

downward.

g019832

Figure6

1.Parking-brakelever

TractionControl

g008128

Figure7

1.Referencebar

2.Tractioncontrol

•Tomoveforward,movethetractioncontrolforward

(Figure8).

g008129

Figure8

•Tomoverearward,movethetractioncontrol

rearward(Figure9).

Important:Whenreversing,lookbehindyou

forobstructionsandkeepyourhandsonthe

referencebar.

g008130

Figure9

9

Go to Discount-Equipment.com to order your parts

•Toturnright,rotatethetractioncontrolclockwise

(Figure10).

g008131

Figure10

•Toturnleft,rotatethetractioncontrol

counterclockwise(Figure11).

g008132

Figure11

•Tostopthemachine,releasethetractioncontrol

(Figure7).

Note:Thefartheryoumovethetractioncontrolin

anydirection,thefasterthemachinemovesinthat

direction.

GrinderControl

Operatethegrinderusingthegrindercontrollever

asfollows:

•Tostartthegrinder(Figure12),squeezethe

triggerandthenpresstheredbuttononthetopof

thelever.Oncethegrinderhasstarted,youcan

releasetheredbutton.

•Tostopthegrinder(Figure12),releasethetrigger

formorethanahalfsecond.

Note:Ifyouareoperatingthegrinderand

momentarilyreleasethetrigger(i.e.,lessthana

halfsecond),thegrindercontinuestooperate.

g019833

Figure12

1.Neutral3.Runthegrinder

2.Startthegrinder4.Stopthegrinder

10

Go to Discount-Equipment.com to order your parts

•Toraisethegrinder,pulltheleverrearward(Figure

13).

g019834

Figure13

•Tolowerthegrinder,pushtheleverforward(Figure

14).

g019835

Figure14

•Torotatethegrindertotherightorleft,movethe

leverinthedesireddirection(Figure15).

g019836

g019837

Figure15

Lift/LowerSpeedControl

Youcanchangehowquicklythegrinderheadraises

andlowersusingthelift/lowerspeedcontrol,located

undertherightsideofthecontrolpanel(Figure16).

Rotatethedialcounterclockwisetoincreasethe

speedorrotateitclockwisetoreducethespeed.

Ifyoumuststopthemachinewiththegrinderhead

raised,turnthecontroldialallthewayclockwiseto

lockthegrinderheadbeforeleavingthemachineor

performinganymaintenance

CAUTION

Ifyouleavethegrinderheadintheraised

positionwithoutturningthelift/lowerspeed

controldialallthewayclockwise,thegrinder

couldlower,crushingyouorbystanders.

Wheneverpossible,lowerthegrindertothe

groundbeforeshuttingofftheengine.If

youmustkeepthegrinderheadraised,turn

thelift/lowerspeedcontroldialalltheway

clockwisetolockthegrinder.

11

Go to Discount-Equipment.com to order your parts

g019867

Figure16

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width86cm(34inches)

Length241cm(95inches)

Height130cm(51inches)

Weight794kg(1,750lb)

Attachments/Accessories

To ensure optimum performance and continued safety

certication of the machine, use only genuine Toro

replacement parts and accessories. Replacement

parts and accessories made by other manufacturers

could be dangerous, and such use could void the

product warranty.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas;notethelocationofunmarkedobjectsand

structures,suchasundergroundstoragetanks,

wells,andsepticsystems.

•Inspecttheareawhereyouwillusetheequipment.

–Evaluatetheterraintodeterminewhat

accessoriesandattachmentsyouneedto

properlyandsafelyperformthejob.

–Removealldebris.

–Ensurethattheareaisclearofbystanders

beforeoperatingthemachine.

–Stopthemachineifanyoneentersthearea.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetydecals.

–Theownerisresponsiblefortrainingall

operatorsandmechanics.

–Neverallowchildrenoruntrainedpeople

tooperateorservicethemachine.Local

regulationsmayrestricttheageorrequire

certiedtrainingoftheoperator.

–Knowhowtostopthemachineandshutoffthe

enginequickly.

–Checkthattheoperator'spresencecontrols,

safetyswitches,andshieldsareattached

andfunctioningproperly.Donotoperatethe

machineunlesstheyarefunctioningproperly.

–Locatethepinch-pointareasmarkedonthe

machineandattachments;keepyourhands

andfeetawayfromtheseareas.

–Stopthemachine,shutofftheengine,and

removethekeybeforeleavingtheoperating

position.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

12

Go to Discount-Equipment.com to order your parts

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachinetokeep

thefuelfreshlongerwhenusedasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

grinder.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure17).

g020516

Figure17

1.Fuel-tankcap

2.Fuelgauge

4.Addfueltothetankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

5.Installthefuel-tankcapsecurely,turningituntil

itclicks.

6.Wipeupanyspilledfuel.

PerformingDaily

Maintenance

Beforestartingthemachineeachday,performthe

EachUse/DailyprocedureslistedinMaintenance

(page18).

13

Go to Discount-Equipment.com to order your parts

DuringOperation

DuringOperationSafety

GeneralSafety

•Keepyourhandsandfeetawayfrommovingteeth

orotherparts.

–Keepbystandersandpetsawayfromthe

machineandnevercarrypassengers.

–Wearappropriateclothing,includingeye

protection,longpants,substantialslip-resistant

footwear,andhearingprotection.

–Tiebacklonghairanddonotwearloose

clothingorloosejewelry.

–Stopgrindingifanyoneentersthearea.

•Operatethemachineonlyinareaswherethereis

sufcientclearanceforyoutosafelymaneuver.

•Beawareofobstaclesincloseproximitytoyou.

Failuretomaintainadequatedistancefromtrees,

walls,andotherbarriersmayresultininjuryasthe

machinebacksupduringoperationifyouarenot

attentivetothesurroundings.

•Lookbehindanddownbeforebackingupto

ensurethatthepathisclear.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverjerkthecontrols;useasteadymotion.

•Theowner/usercanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Donotoperatethemachinewhenyouaretired,ill,

orundertheinuenceofalcoholordrugs.

•Operatethemachineonlyingoodlight.

•Ensurethatallthedrivesareinneutralandengage

theparkingbrakebeforestartingtheengine.Start

theengineonlyfromtheoperator'sposition.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Stopthegrinderwhenyouarenotgrinding.

•Stopthemachine,shutofftheengine,remove

thekey,andinspectthemachineifyoustrike

anobject.Makeanynecessaryrepairsbefore

resumingoperation.

•Neverrunanengineinanenclosedarea.

•Neverleavearunningmachineunattended.

Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowerthegrindertotheground.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

•Checkforoverheadclearance(i.e.,electrical

wires,branches,anddoorways)beforedriving

underanyobjectsanddonotcontactthem.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•UseonlyT oro-approvedattachmentsand

accessories.

SlopeSafety

•Operateupanddownslopeswiththefrontofthe

machineuphill.

•Raisingthegrinderonaslopeaffectsthestability

ofthemachine.Keepthegrinderinthelowered

positionwhenonslopes.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingthemachineonaslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

14

Go to Discount-Equipment.com to order your parts

asafedistancebetweenthemachineandany

hazard.

•Ifthemachinestartstotip,letgoofthecontrols

andstepawayfromthemachine.

•Donotparkthemachineonahillsideorslope.

StartingtheEngine

1.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions(Figure18).

g024908

Figure18

1.Key2.Throttlelever

2.TurnthekeytotheONposition(Figure18).

Whentheenginestarts,releasethekey.

Important:Donotengagethestarterfor

morethan10secondsatatime.Iftheengine

failstostart,allowa30-secondcooldown

periodbetweenattempts.Failuretofollow

theseinstructionscanburnoutthestarter

motor.

3.Movethethrottlelevertothedesiredsetting

(Figure18).

Important:Iftheengineisrunathigh

speedswhenthehydraulicsystemiscold

(i.e.,whentheambientairtemperatureis

nearfreezingorlower),hydraulicsystem

damagecouldoccur.Whenstartingthe

engineincoldconditions,allowtheengine

toruninthemiddlethrottlepositionfor

2to5minutesbeforemovingthethrottle

tofast(rabbit).Atnormaltohighambient

temperatures,runthemachineatfullthrottle

forthebestperformanceandcooling.

Note:Iftheoutdoortemperatureisbelow

freezing,storethemachineinagaragetokeep

itwarmerandaidinstarting.

DrivingtheMachine

Usethetractioncontrolstomovethemachine.The

fartheryoumovethetractioncontrolsinanydirection,

thefasterthemachinemovesinthatdirection.

Releasethetractioncontrolstostopthemachine.

CAUTION

Whenreversing,youmaybackintostationary

objectsoroverbystandersandcauseserious

personalinjuryordeath.

Lookbehindyouforobstructionsor

bystandersandkeepyourhandsonthe

referencebar.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placethe

throttleleverintheFASTpositionforbestperformance.

Youcan,however,usethethrottlepositiontooperate

atslowerspeeds.

ShuttingofftheEngine

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

grinder.

2.MovethethrottlelevertotheSLOWposition.

3.Iftheenginehasbeenworkinghardorishot,let

itidleforaminutebeforeturningthekeyswitch

totheOFFposition.

Note:Thishelpstocooltheenginebeforeyou

shutitoff.Inanemergency,youcanshutoff

theengineimmediately.

4.TurnthekeyswitchtotheOFFpositionand

removethekey.

CAUTION

Achildoruntrainedbystandercould

attempttooperatethemachineandbe

injured.

Removethekeyfromtheswitchwhen

leavingthemachine,evenifjustforafew

seconds.

15

Go to Discount-Equipment.com to order your parts

GrindingaStump

1.Starttheengine,raisethegrinder,setthe

throttlelevertotheFASTposition,andmovethe

machinetothestumptobeground.

2.Usethegrindercontrolleverandthetraction

controltopositionthegrindertothesideofthe

frontofthestump,about2cm(1inch)below

thesurface(Figure19).

3.Startthegrinderandwaitforittogetuptofull

speed.

4.Usethegrindercontrollevertoswingthegrinder

slowlyacrossthefaceofthestump,cutting

awayaswathofchips(Figure19).

Important:Thegrinderautomaticallyslows

downthespeedatwhichitswingsintothe

stumptomaintaintheoptimumywheel

speedandnotbogdowninthewood.

g019845

Figure19

5.Lowerthegrinderaboutaninchandswingit

backoverthestump.

6.Repeatsteps4and5untilyouhavereached

groundlevel.

7.Raisethegrindersothatitisabout2.5cm(1

inch)belowthetopoftheremainingstump,

movethemachineforwardafewcentimeters

(inches),andrepeatsteps4through6untilyou

havegroundawaytheentirestump.

8.Ifthereareanylargerootstobeground,position

thegrinderovereachrootandusethetraction

controlandgrindercontroltomovethegrinder

alongtheroot,grindingitaway.

9.Cleandebrisfromthegrinder,drives,mufers,

andengineaftereachuse.

OperatingTips

•Cleantheareaoftrash,branches,androcks

beforeoperatingtopreventequipmentdamage.

•Alwaysusefullthrottle(maximumenginespeed)

whengrinding.

•Cuttheedgesofthestumpformoreefcient

grinding.Onceyourcuttingswathiscloseto1/4

ofthewheeldiameter,lowerthegrinderandbegin

cuttingontheedgeagain.

g019845

Figure20

•Listentotheengineandwatchthegrinderwheel

speedtomaintainthespeedofthewheel.Slow

downtheheadsweepbyfeatheringthejoystickas

cuttingbecomesdifcult.

•Asyougrindfromlefttoright,mostofthedebris

goestotheleftofthegrinderwheel.Whenyou

grindfromtherighttoleft,thedebrisgoestothe

right.

•Youmayalsogrindastumpfromthesidetolessen

turfdamage.

AfterOperation

AfterOperationSafety

GeneralSafety

•Parkthemachineonalevelsurface,disengage

thegrinderhydraulics,lowerthegrinder,engage

theparkingbrake,shutofftheengine,andremove

thekey.Waitforallmovementtostopandallow

themachinetocoolbeforeadjusting,servicing,

cleaning,orstoringit.

•Cleandebrisfromthedrives,mufers,andengine

tohelppreventres.Cleanupoilorfuelspills.

16

Go to Discount-Equipment.com to order your parts

•Keepallpartsingoodworkingconditionandall

hardwaretightened.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

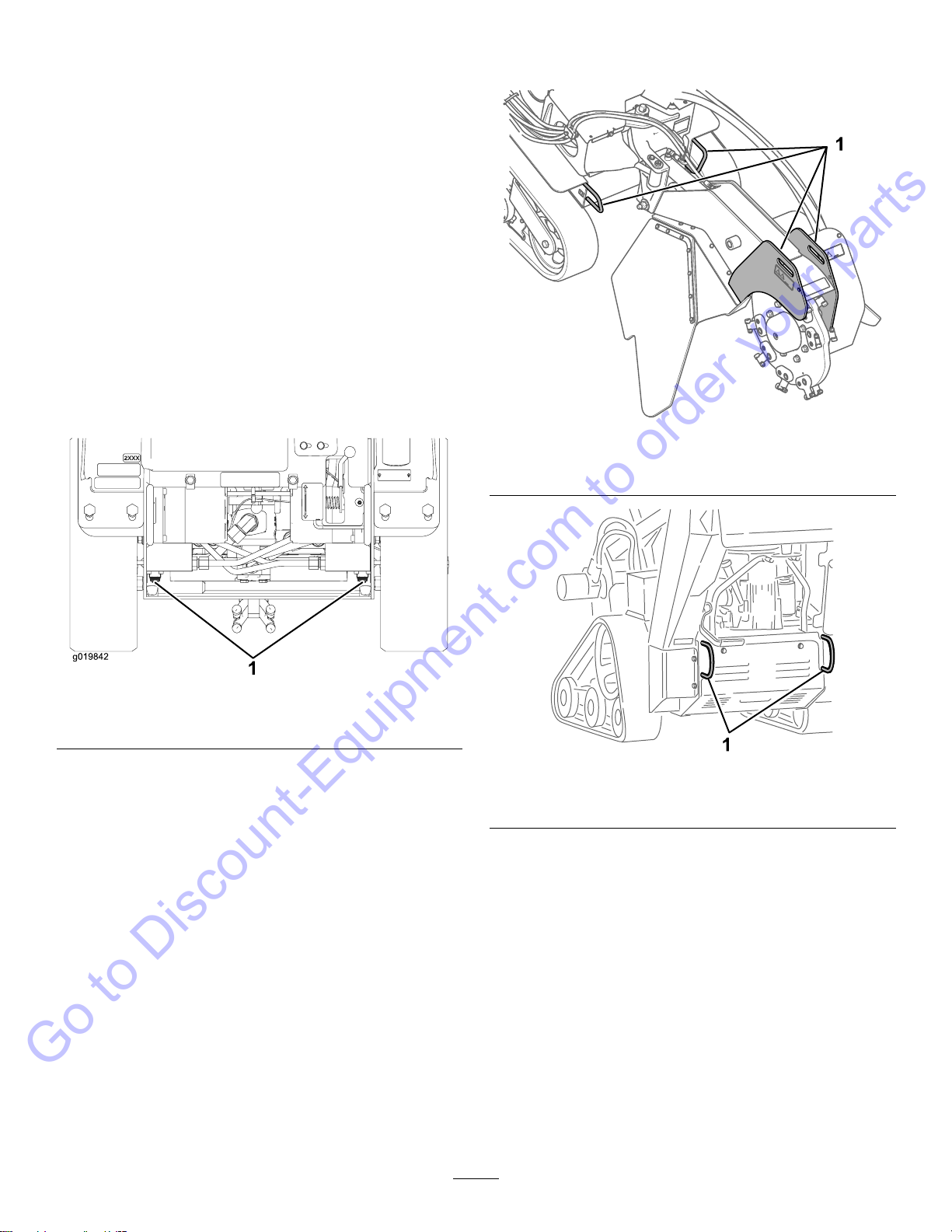

MovingaNon-Functioning

Machine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,oryouwill

damagethehydraulicsystem.

1.Engagetheparkingbrakeandlowerthegrinder.

2.Shutofftheengineandremovethekey.

3.Removethebottomshield.

4.Usingawrench,turnthetowvalvesonthe

hydraulicpumpstwicecounter-clockwise(Figure

21).

g019842

Figure21

1.Towvalves

5.Installthebottomshieldandtowthemachine

asrequired.

6.Afterrepairingthemachine,closethetowvalves

beforeoperatingit.

SecuringtheMachinefor

Transport

Important:Donotoperateordrivethemachine

onroadways.

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

grinder.

2.Shutofftheengineandremovethekey.

3.Securethemachinetoatrailerwithchainsor

strapsusingthetie-down/liftloopsatthefront

andrearofthemachine(Figure22andFigure

23).Refertoyourlocalordinancesfortrailerand

tie-downrequirements.

g319379

Figure22

1.Fronttie-down/liftloops

g319380

Figure23

1.Reartie-down/liftloops

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloops

asliftpoints(Figure22andFigure23).

17

Go to Discount-Equipment.com to order your parts

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyinthekeyswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromthekeyswitchanddisconnectthewiresfromthesparkplugsbefore

youdoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthe

sparkplugs.

MaintenanceSafety

•Parkthemachineonalevelsurface,disengage

thegrinderhydraulics,lowerthegrinder,engage

theparkingbrake,shutofftheengine,andremove

thekey.Waitforallmovementtostopandallow

themachinetocoolbeforeadjusting,servicing,

cleaning,orstoringit.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatterybeforemakinganyrepairs.

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Donottamperwiththesafetydevices.

•UseonlygenuineTororeplacementparts.

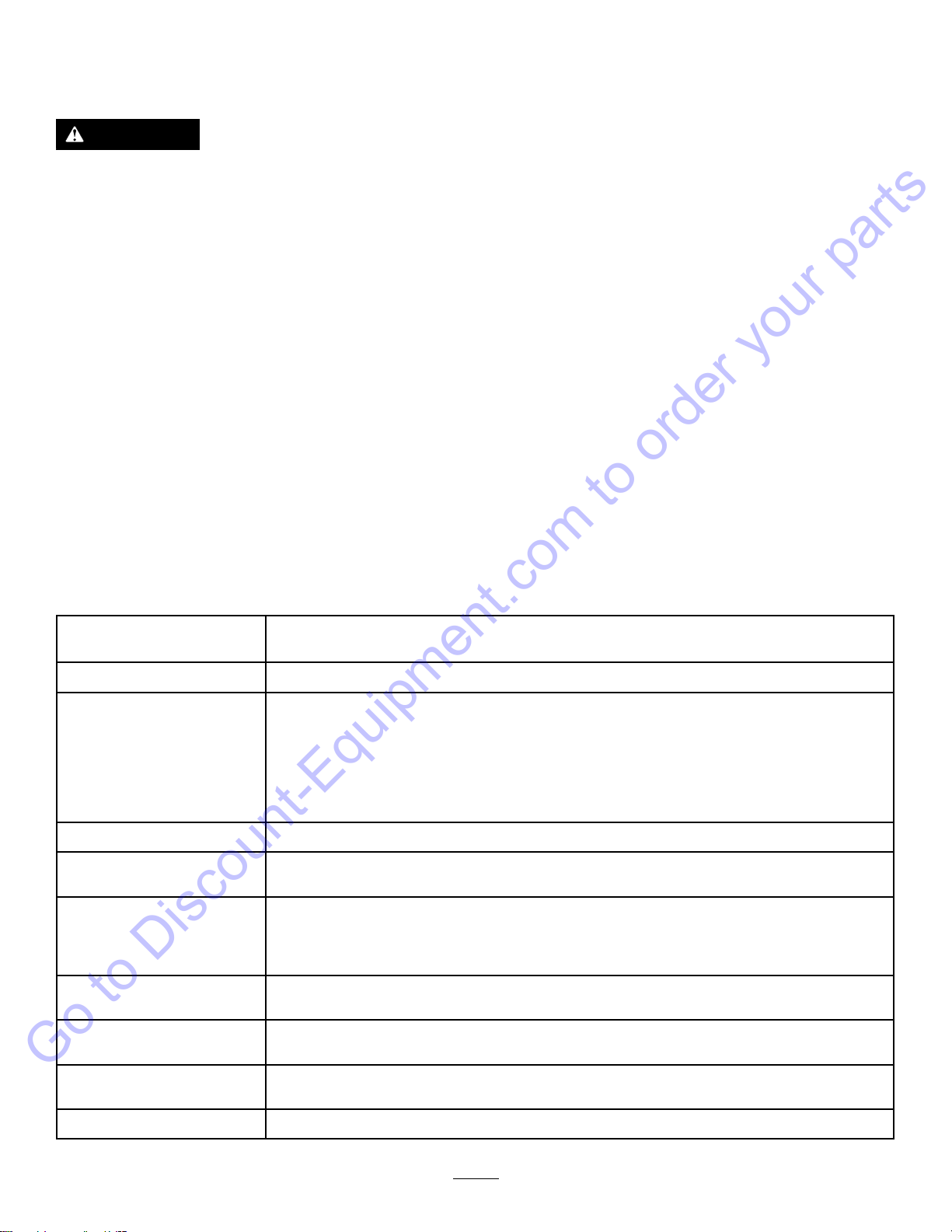

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst50hours•Checkandadjustthetracktension.

Beforeeachuseordaily

•Greasethemachine.(Greaseitimmediatelyaftereverywashing.)

•Checktheengine-oillevel.

•Checktheconditionofandcleanthetracks.

•Cleantheenginescreen.

•Checktheconditionoftheteeth;rotateorreplaceanythatarewornordamaged

andtorquethenutsforallteeth.

•Checkforloosefasteners.

Aftereachuse•Removedebrisfromthemachine.

Every25hours•Checkthebatteryelectrolytelevel.

•Checkthehydraulic-uidlevel.

Every100hours

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

Every150hours•Inspecttheprimarylter.

•Replacethelow-pressurefuellter(moreoftenindirtyordustyconditions).

Every200hours•Changetheengine-oillter.

•Replacethehydrauliclter.

Every250hours•Replacetheprimaryairlter(moreoftenindustyorsandyconditions).

•Checkandgreasetheroadwheels.

Every300hours•Checktheinnerairlter.

18

Go to Discount-Equipment.com to order your parts

This manual suits for next models

1

Table of contents

Other Toro Grinder manuals