Introduction ____________________________________________________________________

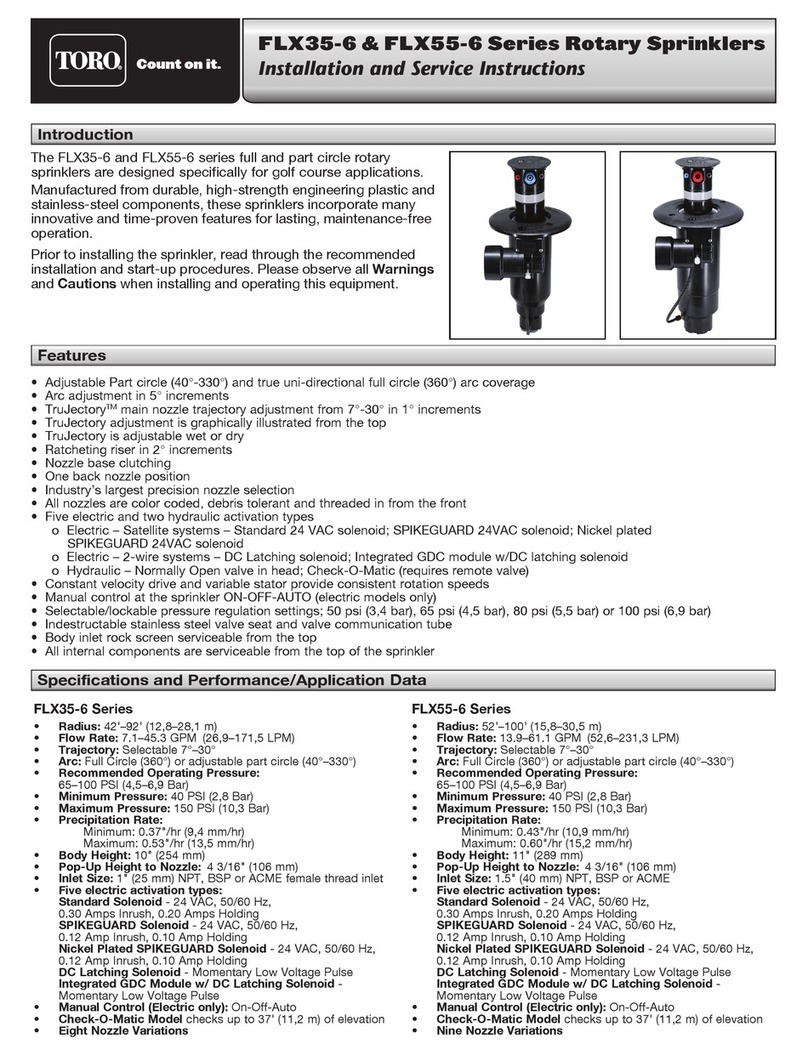

The DT35 and DT55 series full-circle/adjustable part-circle rotary sprinklers are

designed specifically for golf course applications.

Manufactured from durable, high-strength engineering plastic and stainless-steel

components, these sprinklers incorporate many innovative and time-proven

features for lasting, maintenance-free operation.

Prior to installing the sprinkler, read through the recommended installation and

start-up procedures. Please observe all WARNINGS and CAUTIONS when

installing and operating this equipment.

Features ________________________________________________________________________

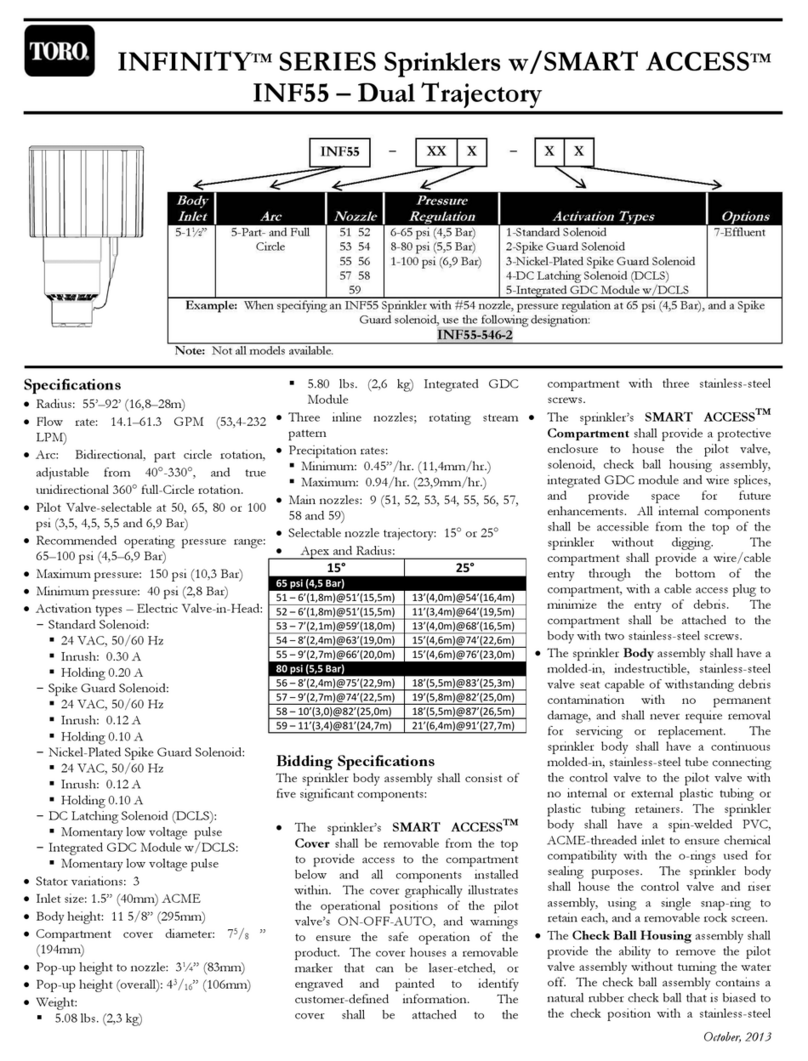

DT35 and DT55 Series Rotary Sprinklers

Installation & Service Instructions

DT35 Electric VIH DT55 Electric VIH

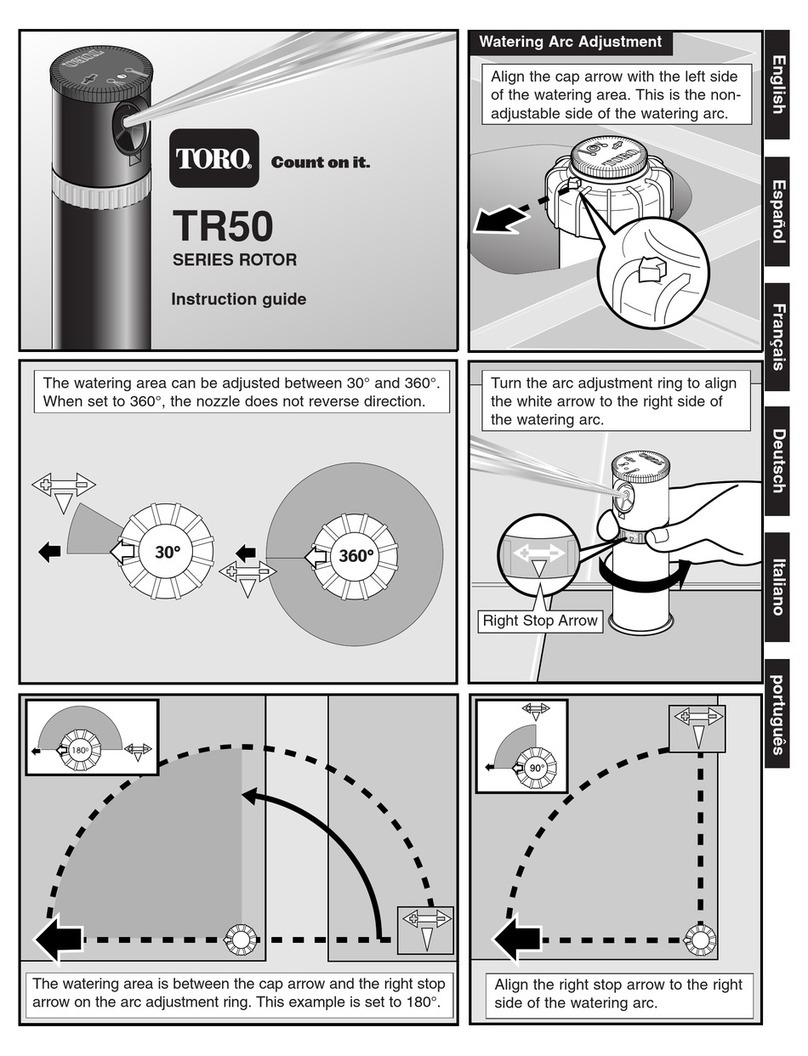

■Full-circle (360°) with uni-directional clockwise rotation and

adjustable part-circle (40°–330°) configuration

■Arc adjustment from riser band in 5° increments

■Trajectory main nozzle - Selectable 15° or 25°

■Full 4" (10.2 cm ) pop-up clears tall grasses

■Color-coded nozzles by radius and gallonage

■Cap serves as an effluent water indicator

■Variable stator ensures 3-minute rotation

■Selectable pressure regulation settings of 50 psi (3.4 bar),

65 psi, 80 psi or 100 psi to ensure consistently accurate

nozzle performance regardless of elevation (Electric only)

■Three valve activation types available: Electric Valve-In-Head,

Normally Open Hydraulic Valve-In-Head, and Check-O-Matic

DT35 Series

■Radius: 43'–88' (13,1 m–26,8 m) @ 25° trajectory

■Flow Rate: 15–50 GPM (56,8–189,3 LPM)

■Trajectory: Selectable 15° or 25°

■Arc: full circle (360°) or adjustable part circle (40°–330°)

■Recommended operating pressure: 65–100 psi (4,5–6,9 bar)

■Minimum pressure: 40 psi (2,8 bar)

■Maximum pressure: 150 psi (10,3 bar)

■Precipitation rate:

■Minimum: 0.46"/hr (1,17 cm/hr)

■Maximum: 0.63"/hr (1,60 cm/hr)

■Inlet Size: 1" (25 mm) NPT, BSP or ACME

■Electric Valve-in-head Solenoid:

■Inrush current: 0.30A @ 24 VAC, 50/60 Hz

■Holding current: 0.20A @ 24 VAC, 50/60 Hz

■Check-O-Matic model checks up to 37' (11,27 m) of elevation

■Three valve activation types available: Electric Valve-In-Head,

Normally Open Hydraulic Valve-In-Head, and Check-O-Matic

■Three body thread types available: NPT, BSP and ACME

■Manual sprinkler operation control: On-Off-Auto (Electric only)

■All internal components serviceable from the top of the

sprinkler

■Large selection of color-coded nozzles available

■Durable plastic and stainless-steel construction

■Constant velocity drive

■Optional back nozzles available

■Color-coordinated nozzles

■Optional radius reduction screw

DT55 Series

■Radius: 52'–95' (15,8–28,9 m) @ 25° trajectory

■Flow rate: 15–62 GPM (56,8–234,7 LPM)

■Trajectory: Selectable 15° or 25°

■Arc: full circle (360°) or adjustable part circle (40°–330°)

■Recommended operating pressure: 65–100 psi (4,5–6,9 bar)

■Minimum pressure: 40 psi (2,8 bar)

■Maximum pressure: 150 psi (10,3 bar)

■Precipitation rate:

■Minimum: 0.50"/hr (1,27 cm/hr)

■Maximum: 0.72"/hr (1,83 cm/hr)

■Inlet Size: 1.5" (38 mm) NPT, BSP or ACME

■Electric Valve-in-head Solenoid:

■Inrush current: 0.30A @ 24 VAC, 50/60 Hz

■Holding current: 0.20A @ 24 VAC, 50/60 Hz

■Check-O-Matic model checks up to 37' (11,27 m) of elevation

Note: For preliminary use only.

Specifications and Performance/Application Data ________________________________________