Page 1 of 2 NOVEMBER 2022 TFP1950

Worldwide

Contacts

www.tyco-fire.com

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Scan the QR code or enter the URL

in a web browser to access the most

up-to-date electronic version of this

document. Data rates may apply.

docs.jci.com/tycore/tfp1950

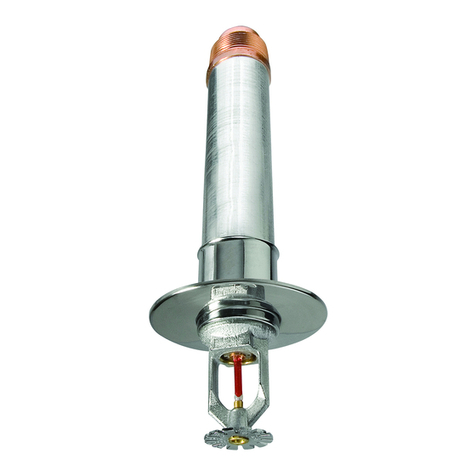

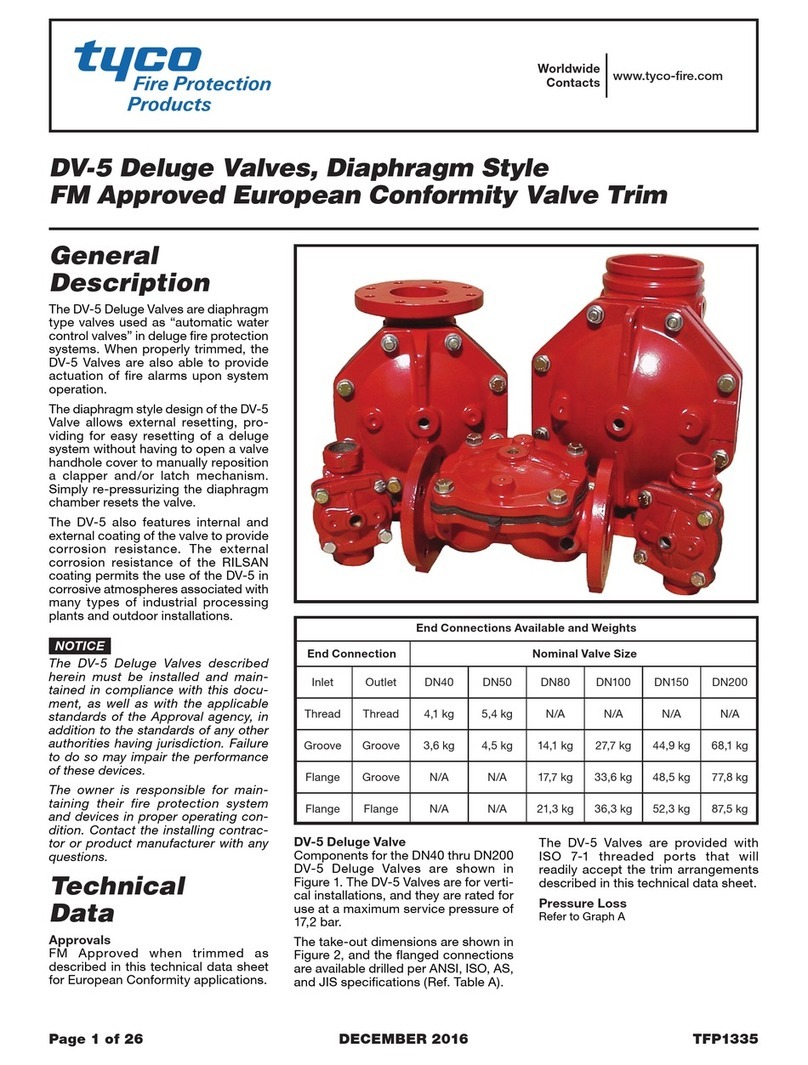

Model 3002B

CPVC Sprinkler Head Adapter Fitting

Holdback Wrench

General

Description

The TYCO Model 3002B CPVC Sprin-

kler Head Adapter (SHA) Fitting Hold-

back Wrench is designed to aid in

the service of CPVC fire sprinkler

piping systems. The wrench is used to

assist with the removal of a sprinkler

installed in nished ceilings by apply-

ing a holdback on the sprinkler head

adapter tting, while a sprinkler wrench

removes the sprinkler.

The wrench is specically designed to

work with TYCO CPVC sprinkler head

adapter ttings. Since CPVC pipe and

ttings are inherently exible, caution

must be taken to insure the pipe and

ttings are properly restrained when

removing a sprinkler.

CAUTION

The user of the TYCO Model 3002B

CPVC Sprinkler Head Adapter Fitting

Holdback Wrench must read all direc-

tions and user precautions presented

in this data sheet.

Failure to follow all printed instructions

for this product may cause injury to the

user or damage to the piping system

and structure being worked on.

As with use of all tools, proper training,

safety equipment and OSHA require-

ments must be sought, worn and

observed at all times.

Johnson Controls assumes no liability

for the use or misuse of this product.

NOTICE

The Model 3002B SHA Holdback

Wrench described herein must be uti-

lized and maintained in compliance

with this document, as well as with the

applicable standards of the NATIONAL

FIRE PROTECTION ASSOCIATION

(NFPA), in addition to the standards of

any other authorities having jurisdiction

(AHJ). Failure to do so may impair the

integrity of this device.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Technical

Data

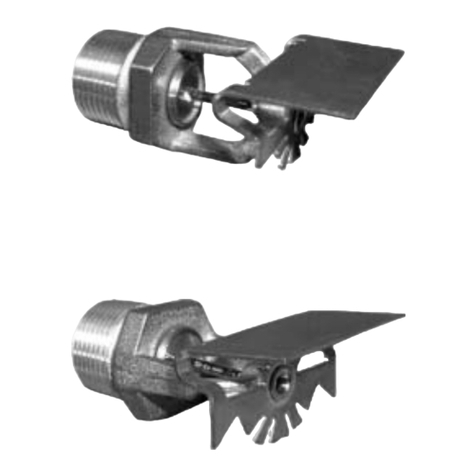

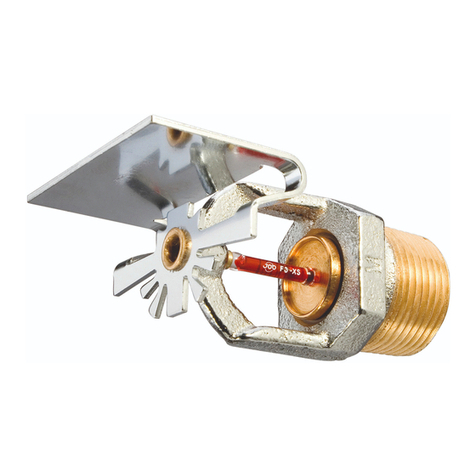

Construction - see Figure 1

• 3/8 in. drive socket extension

• Roller chain

• Cap

• Button head screw

Note: Two replacement chains are provided

with each wrench. Replacement chain kits

are separately available.

Care and

Maintenance

The TYCO Model 3002B CPVC SHA

Wrench must be maintained and ser-

viced in accordance with this section.

A worn or broken roller chain must be

replaced to prevent damage to CPVC

ttings and pipe or personal injury. To

replace a roller chain see Figure 1 for

reference and perform the following

steps:

Step 1. Loosen and remove the but-

ton head cap screw using a 1/4 in. hex

bit or allen wrench.

Step 2. Remove the end cap.

Step 3. Remove the roller chain from

the drive socket extension.

Step 4. Align and insert the link of

the replacement roller chain into the

recessed end of the drive socket exten-

sion, and ensure the link is fully seated.

Step 5. Align and fully seat the end

cap onto the end of the drive socket

extension.

Step 6. Install the button head cap

screw into the drive socket extension,

tightening using 1/4 in. hex bit or allen

wrench. Do not over-tighten to avoid

causing damage to threads.

Sprinkler Removal

NOTICE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

A sprinkler system must be de-pres-

surized and properly drained before

removing a sprinkler.

Other common hand tools, furnished

by the user, are needed in conjunc-

tion with the TYCO Model 3002B SHA

Fitting Holdback Wrench to facilitate

removal of a sprinkler from a CPVC re

sprinkler piping system.

The holdback wrench accepts a 3/8in.