klers are recommended to be at close

range (instead of inspecting from the

floor level per NFPA 25). Inspection at

close range can better determine the

exact sprinkler condition and the long-

term integrity of the corrosion-resis-

tant coating, which can be affected by

the corrosive conditions present.

Responsibility lies with the owner for

the inspection, testing, and mainte-

nance of their fire protection system

and devices in compliance with this

document, as well as with the applica-

ble standards of the National Fire Pro-

tection Association (for example,

NFPA 25), in addition to the standards

of any authorities having jurisdiction.

Contact the installing contractor or

sprinkler manufacturer regarding any

questions.

Automatic sprinkler systems are rec-

ommended to be inspected, tested,

and maintained by a qualified Inspec-

tion Service in accordance with local

requirements and/or national codes.

Limited

Warranty

Products manufactured by Tyco Fire

Suppression & Building Products

(TFSBP) are warranted solely to the

original Buyer for ten (10) years

against defects in material and work-

manship when paid for and properly

installed and maintained under normal

use and service. This warranty will ex-

pire ten (10) years from date of ship-

ment by TFSBP. No warranty is given

for products or components manufac-

tured by companies not affiliated by

ownership with TFSBP or for products

and components which have been

subject to misuse, improper installa-

tion,corrosion, or which have not been

installed, maintained, modified or re-

paired in accordance with applicable

Standards of the National Fire Protec-

tion Association, and/or the standards

of any other Authorities Having Juris-

diction. Materials found by TFSBP to

be defective shall be either repaired or

replaced, at TFSBP’s sole option.

TFSBP neither assumes, nor author-

izes any person to assume for it, any

other obligation in connection with the

sale of products or parts of products.

TFSBP shall not be responsible for

sprinkler system design errors or inac-

curate or incomplete information sup-

plied by Buyer or Buyer’s repre-

sentatives.

In no event shall TFSBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect, special or consequential dam-

ages, including but not limited to labor

charges, regardless of whether

TFSBP was informed about the possi-

bility of such damages, and in no event

shall TFSBP’s liability exceed an

amount equal to the sales price.

Theforegoingwarrantyismadeinlieu

of any and all other warranties, ex-

press or implied, including warranties

of merchantability and fitness for a par-

ticular purpose.

This limited warranty sets forth the ex-

clusive remedy for claims based on

failure of or defect in products, materi-

als or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full ex-

tent permitted by law. The invalidity, in

whole or part, of any portion of this

warranty will not affect the remainder.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indi-

cate the full product name. Refer to the

Price List for a complete listing of Part

Numbers.

Sprinkler Assemblies with NPT

Thread Connections:

Specify: (Model/SIN), Standard Re-

sponse, (K-factor), (temperature rat-

ing), Issue D (Pendent or Upright)

Sprinkler with (type of finish or coat-

ing), P/N (from Table B).

Sprinkler Wrench:

Specify: W-Type 11 Sprinkler Wrench,

P/N 56-452-1-001.

© 2007-2009 TYCO FIRE SUPPRESSION & BUILDING PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

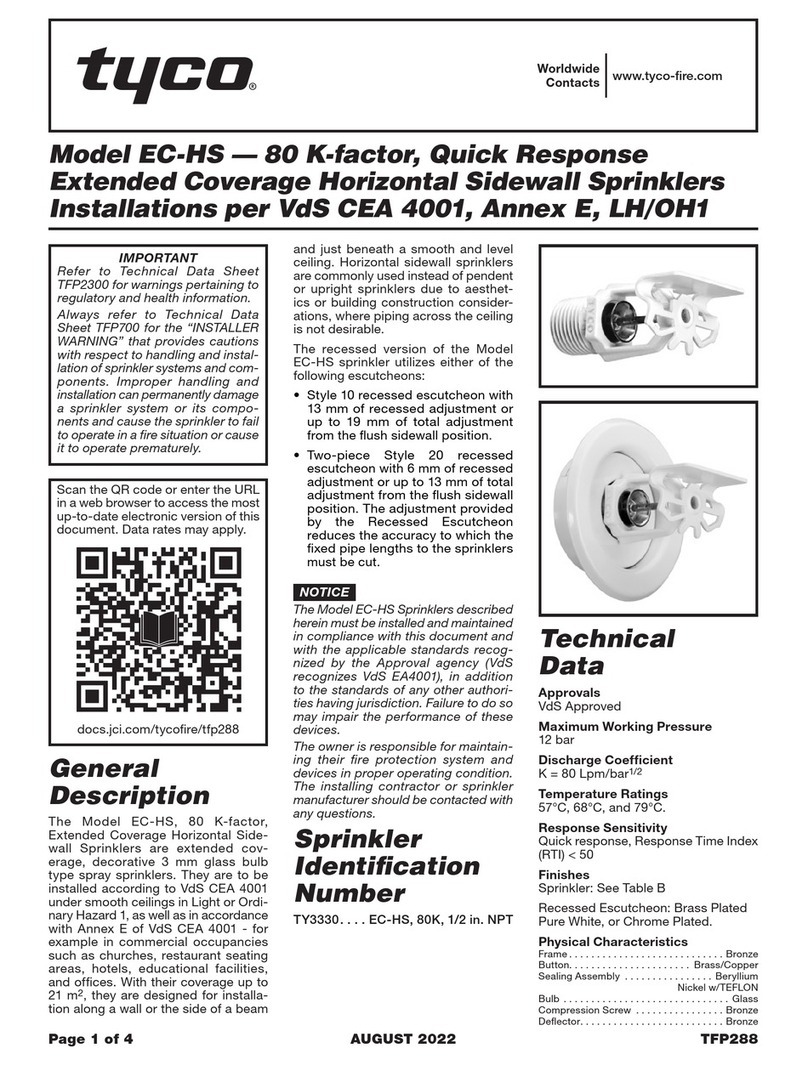

P/N 51 — XXX — X — XXX

500°F/260°C500

TEMPERATURE

RATING

400°F/204°C4001

SPRINKLER

TABLE B

PART NUMBER SELECTION

ISSUE D UPRIGHT AND PENDENT SPRINKLERS

650°F/343°C

(5.6K Only)

650

NATURAL BRASS

9

MODEL/SIN

CHROME PLATED

7LEAD COATED

(400°F & 500°F Only)

136 8.0K UPRIGHT (3/4"NPT)

140 8.0K PENDENT (3/4"NPT)

5.6K UPRIGHT (1/2"NPT)

5.6K PENDENT (1/2"NPT)

036

040 TY3296

TY3191

TY4292

TY4191

TFP690

Page4of4