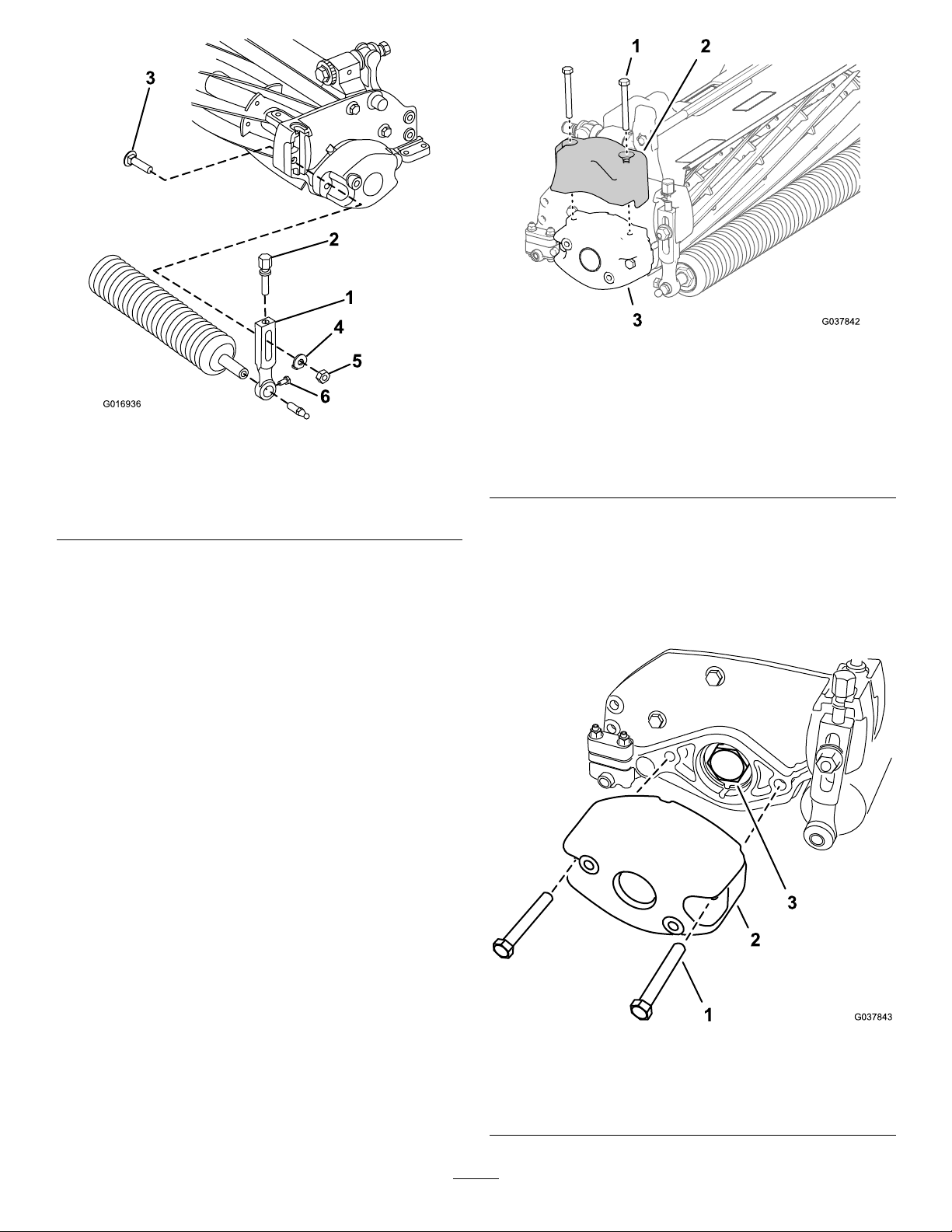

2.Foragroomerdriveboxinstalledattheleftside

ofthecuttingunit,assembletheshimwasher

overthethreadsoftheblackreeladapter(Figure

13).

Note:Noshimwasherisinstalledwithgroomer

driveboxinstalledatrightsideofthecuttingunit.

g232600

Figure13

1.Applythread-locking

compound

4.Shimwasher

2.Reeladapter(black)into

reelshaft

5.Hex-head

3.Cuttingunit

3.Applymedium-strengththread-locking

compound(suchasBlueLoctite®243)tothe

internalthreadsofthereelshaftthreads.

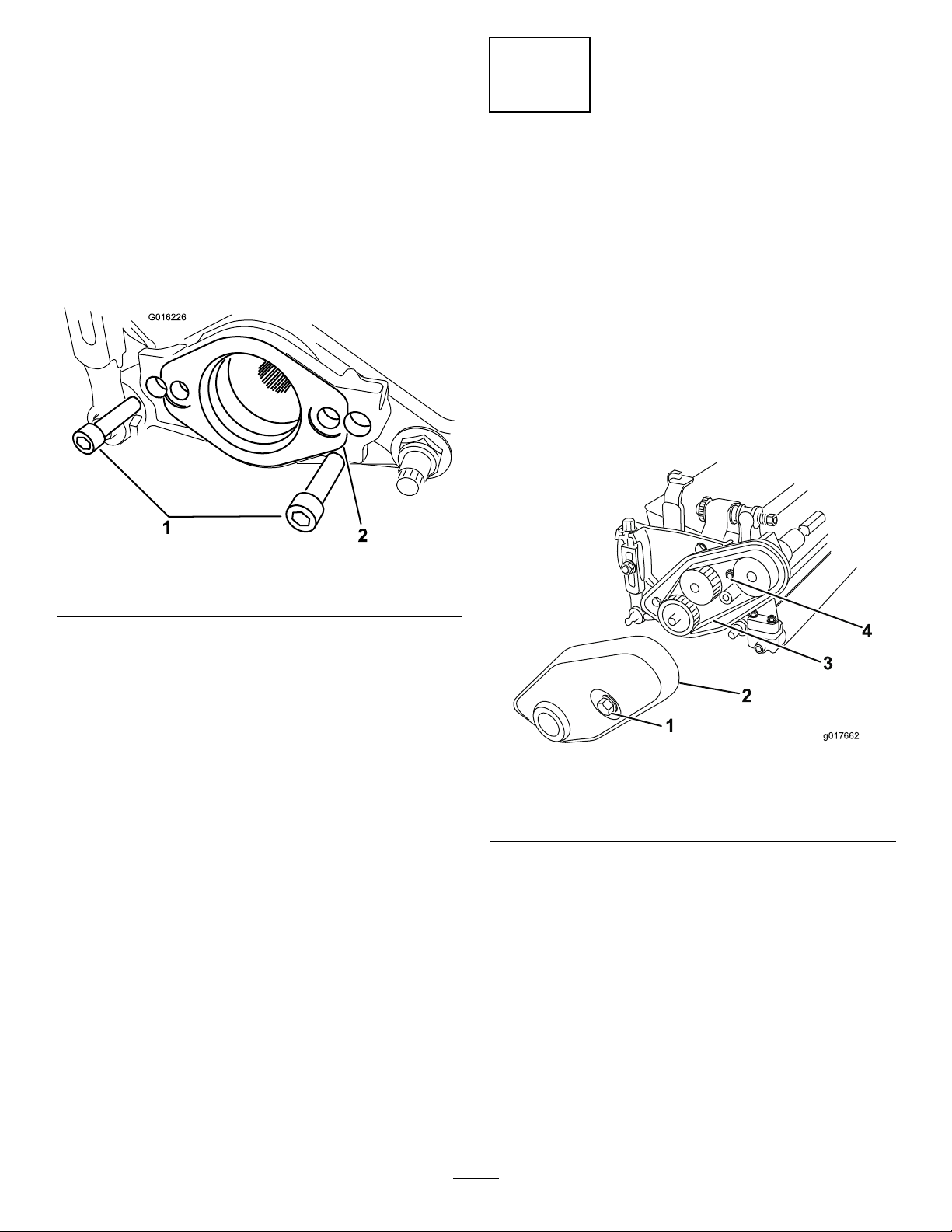

4.Attachthegroomerdriveboxtothereelshaft

(Figure10).

Important:Thesplinedinsertontheleft

sideofthecuttingunithasleft-handthreads.

Thesplinedinsertontherightsideofthe

cuttingunithasright-handthreads.

5.Usingablockofwoodorhavinganotherperson

restrainthereel,torquethehex-headdriveof

thedrive-boxshaftto135to150N∙m(100to

110ft-lb);refertoFigure14.

Important:Youmusttorquethetorquehex

driveofthedrive-boxshaftto135to150N∙m

(100to110ft-lb).

Important:Youmustusea6-pointsocket

withheavywall.

Important:Donotuseanimpactwrenchfor

thisstep.

Important:Allowthethread-locking

compoundtocurefor15minutesbefore

continuingtheprocedure.

Note:Donotdamagethesealundertheouter

cover.

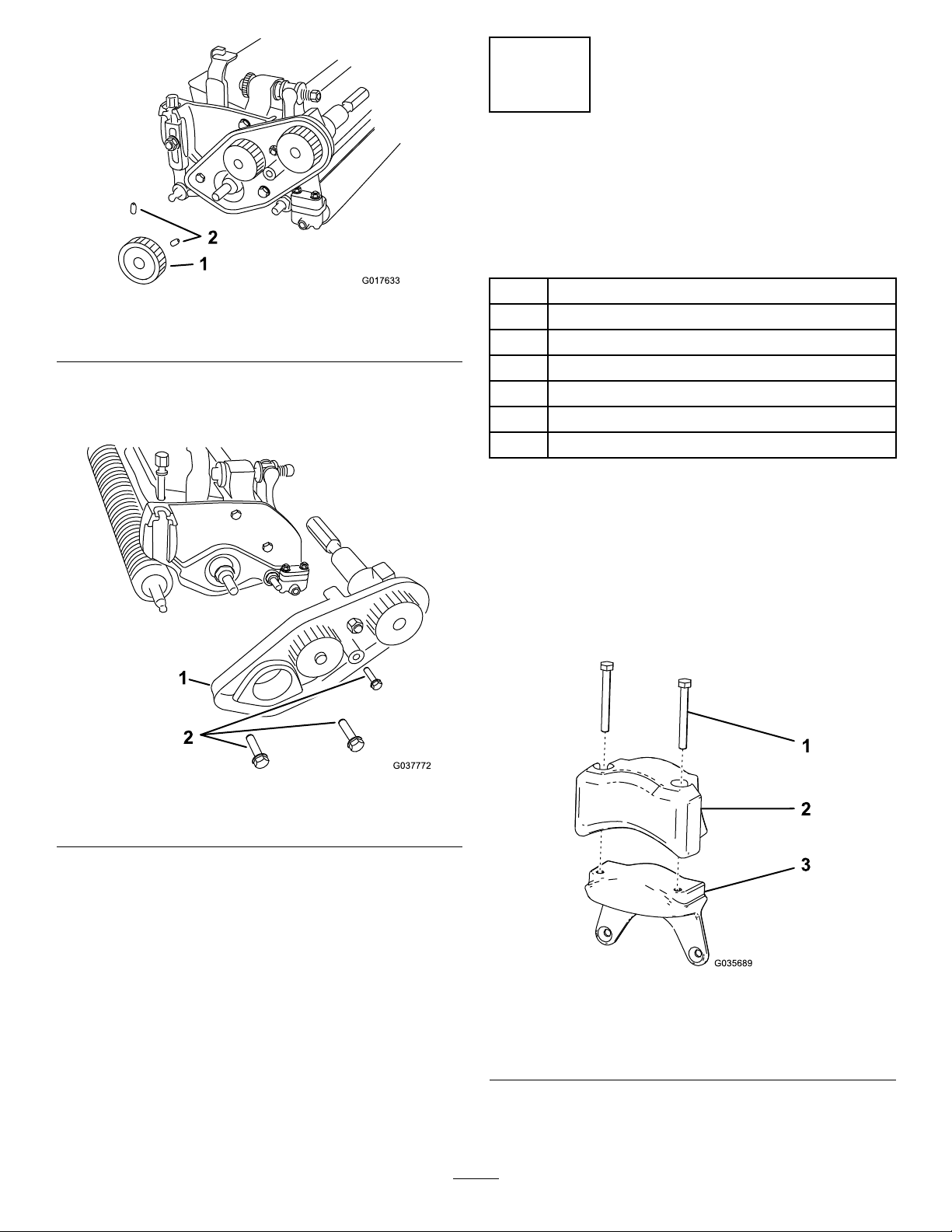

g244758

Figure14

1.O-ring3.Cotterpin

2.Hex-socketscrew(5/16x

1/2inch)

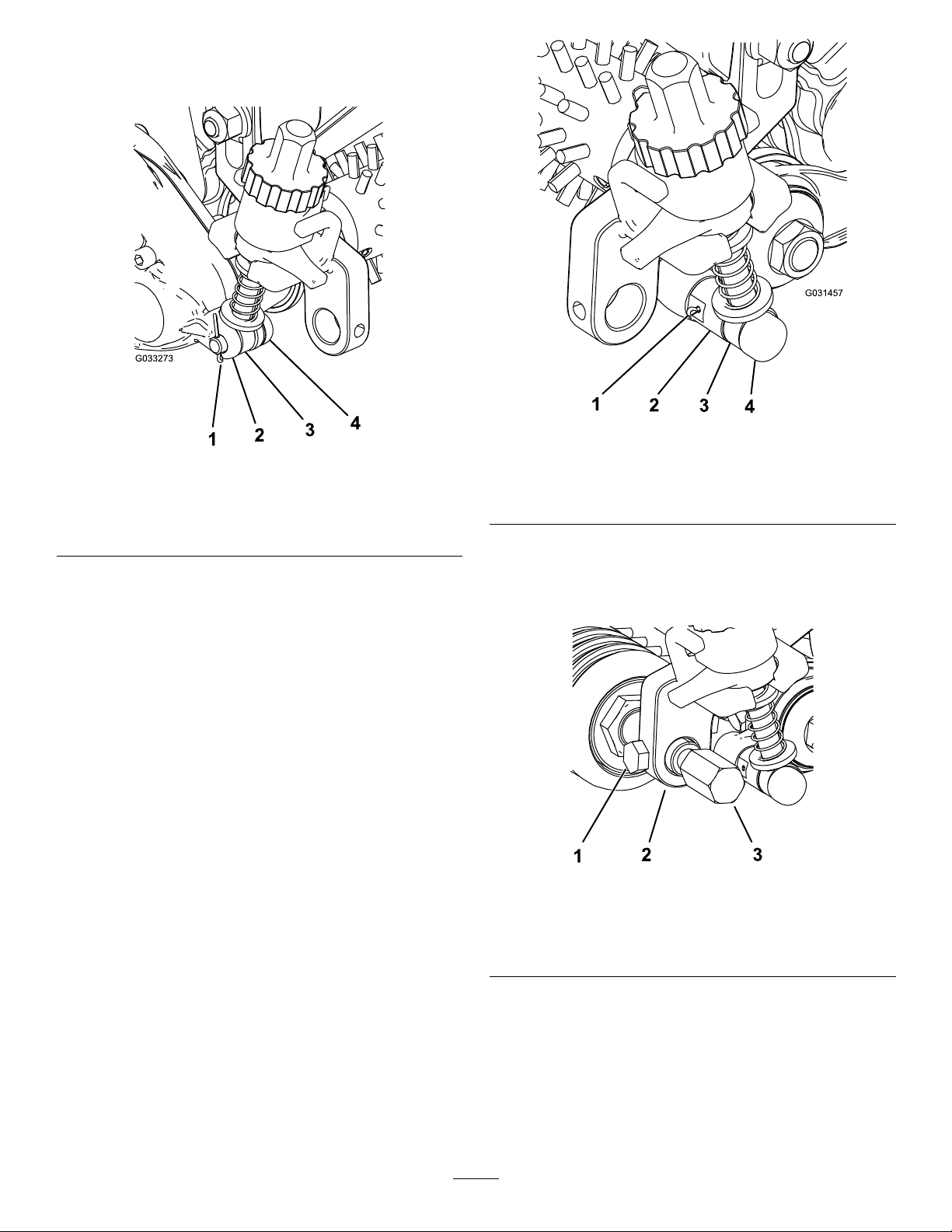

Note:Theclutch-knobassemblycomes

installedfromthefactoryforarightdrive

installation.

6.Ifyouareinstallingthegroomerattheleftside

ofthemachine,performthefollowing:

A.RemovetheO-ringfromtheclutchknob

(Figure15).

B.Removetheshearpinthatsecuresthe

clutchknobtotheactuatorshaft(Figure15).

C.Removetheclutch-knobassemblyandip

itover.

D.Assembletheclutchknobtotheactuator

shaftwiththeshearpin(Figure15).

E.InstalltheO-ringintothegrooveinthe

clutchknob.

g244757

Figure15

1.Shearpin3.O-ring

2.Clutch-knobassembly

7